Journal Description

Machines

Machines

is an international, peer-reviewed, open access journal on machinery and engineering published monthly online by MDPI. The IFToMM is affiliated with Machines and its members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, and other databases.

- Journal Rank: JCR - Q2 (Engineering, Mechanical) / CiteScore - Q1 (Control and Optimization)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 16.9 days after submission; acceptance to publication is undertaken in 2.4 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Journal Cluster of Mechanical Manufacturing and Automation Control: Aerospace, Automation, Drones, Journal of Manufacturing and Materials Processing, Machines, Robotics and Technologies.

Impact Factor:

2.5 (2024);

5-Year Impact Factor:

2.6 (2024)

Latest Articles

Adaptive PI Control Using Recursive Least Squares for Centrifugal Pump Pipeline Systems

Machines 2025, 13(11), 1064; https://doi.org/10.3390/machines13111064 - 18 Nov 2025

Abstract

Pipeline transportation of petroleum products remains one of the safest and most efficient methods of bulk energy delivery, yet overpressure events continue to pose serious operational and regulatory challenges. Traditional fixed-gain PI controllers, commonly used with centrifugal pump drives, cannot adapt to varying

[...] Read more.

Pipeline transportation of petroleum products remains one of the safest and most efficient methods of bulk energy delivery, yet overpressure events continue to pose serious operational and regulatory challenges. Traditional fixed-gain PI controllers, commonly used with centrifugal pump drives, cannot adapt to varying product densities or transient disturbances such as valve closures that generate water hammer. This paper proposes a self-tuning adaptive controller based on Recursive Least Squares (RLS) parameter estimation to improve safety and efficiency in pipeline pump operations. A nonlinear simulation model of a centrifugal pump driven by an induction motor is developed, incorporating pipeline friction losses via the Darcy–Weisbach relation and pressure transients induced by rapid valve closures. The RLS algorithm continuously estimates effective loop dynamics, enabling online adjustment of proportional and integral gains under changing fluid and operating conditions. Simulation results demonstrate that the proposed RLS-based adaptive controller maintains discharge pressure within ±2% of the target setpoint under density variations from 710 to 900 kg/m3 and during severe transient events. Compared to a fixed-gain PI controller, the adaptive strategy reduced pressure overshoot by approximately 31.9% and settling time by 6%. Model validation using SCADA field data yielded an

(This article belongs to the Section Turbomachinery)

►

Show Figures

Open AccessArticle

Federated Learning-Enabled Secure Multi-Modal Anomaly Detection for Wire Arc Additive Manufacturing

by

Mohammad Mahruf Mahdi, Md Abdul Goni Raju, Kyung-Chang Lee and Duck Bong Kim

Machines 2025, 13(11), 1063; https://doi.org/10.3390/machines13111063 - 18 Nov 2025

Abstract

This paper presents a federated learning (FL) architecture tailored for anomaly detection in wire arc additive manufacturing (WAAM) that preserves data privacy while enabling secure and distributed model training across heterogeneous process units. WAAM’s inherent process complexity, characterized by high-dimensional and asynchronous sensor

[...] Read more.

This paper presents a federated learning (FL) architecture tailored for anomaly detection in wire arc additive manufacturing (WAAM) that preserves data privacy while enabling secure and distributed model training across heterogeneous process units. WAAM’s inherent process complexity, characterized by high-dimensional and asynchronous sensor streams, including current, voltage, travel speed, and visual bead profiles, necessitates a decentralized learning paradigm capable of handling non-identical client distributions without raw data pooling. To this end, the proposed framework integrates reversible data hiding in the encrypted domain (RDHE) for the secure embedding of sensor-derived features into weld images, enabling confidential parameter transmission and tamper-evident federation. Each client node employs a domain-specific long short-term memory (LSTM)-based classifier trained on locally curated time-series or vision-derived features, with model updates embedded and transmitted securely to a central aggregator. Three FL strategies, FedAvg, FedProx, and FedPer, are systematically evaluated against four robust aggregation techniques, including KRUM, Multi KRUM, and Trimmed Mean, across 100 communication rounds using eight non-independent and identically distributed (non-IID) WAAM clients. Experimental results reveal that FedPer coupled with Trimmed Mean delivers the optimal configuration, achieving maximum F1-score (0.912), area under the curve (AUC) (0.939), and client-wise generalization stability under both geometric and temporal noise. The proposed approach demonstrates near-lossless RDHE encoding (PSNR > 90 dB) and robust convergence across adversarial conditions. By embedding encrypted intelligence within weld imagery and tailoring FL to WAAM-specific signal variability, this study introduces a scalable, secure, and generalizable framework for process monitoring. These findings establish a baseline for federated anomaly detection in metal additive manufacturing, with implications for deploying privacy-preserving intelligence across smart manufacturing (SM) networks. The federated pipeline is backbone-agnostic. We instantiate LSTM clients because the sequences are short (five steps) and edge compute is limited in WAAM. The same pipeline can host Transformer/TCN encoders for longer horizons without changing the FL or security flow.

Full article

(This article belongs to the Special Issue In Situ Monitoring of Manufacturing Processes)

►▼

Show Figures

Figure 1

Open AccessArticle

Research on Denoising Methods for Infrasound Leakage Signals Using Improved Wavelet Threshold Algorithm

by

Zunmin Liu, Jingchun Tang, Baogang Li, Yuhuan Li and Fazhan Yang

Machines 2025, 13(11), 1062; https://doi.org/10.3390/machines13111062 - 18 Nov 2025

Abstract

Infrasound leakage signals, with low propagation energy loss, are ideal for long-distance and small leakage detection but suffer severe background noise interference. Existing wavelet denoising methods using traditional soft/hard threshold functions face critical limitations: soft thresholds introduce constant deviation, while hard thresholds cause

[...] Read more.

Infrasound leakage signals, with low propagation energy loss, are ideal for long-distance and small leakage detection but suffer severe background noise interference. Existing wavelet denoising methods using traditional soft/hard threshold functions face critical limitations: soft thresholds introduce constant deviation, while hard thresholds cause discontinuities, both leading to suboptimal noise reduction for infrasound signals—this gap hinders accurate leakage detection. To address this, we propose a wavelet denoising method with an improved threshold function, analyze its process via the Mallat algorithm, and prove its continuity and convergence. Comparative experiments on infrasound leakage data show that, at the optimal decomposition level, our method reduces RMSE by 41.19% and increases SNR by 5.1326 dB compared to the soft threshold method; versus the hard threshold method, RMSE decreases by 34.65% and SNR increases by 4.2148 dB. It also separates background noise more thoroughly in time–frequency domains, demonstrating strong feasibility for pipeline infrasound leakage detection.

Full article

(This article belongs to the Section Machines Testing and Maintenance)

►▼

Show Figures

Figure 1

Open AccessArticle

Predicting Real-Time Carbon Emissions for Power Grids Using Graph Convolutional Networks

by

Qian Zhao, Jianhua Chen, Qianwei Jia, Cong Sun, Xi Chen and Hongtian Chen

Machines 2025, 13(11), 1061; https://doi.org/10.3390/machines13111061 - 18 Nov 2025

Abstract

►▼

Show Figures

Accurate prediction of carbon emissions is crucial for both providing effective carbon reduction guidance to the power grid sector and driving society-wide carbon emission reduction. Existing methods based on power flow calculation theory heavily rely on real-time grid parameters and cannot accurately predict

[...] Read more.

Accurate prediction of carbon emissions is crucial for both providing effective carbon reduction guidance to the power grid sector and driving society-wide carbon emission reduction. Existing methods based on power flow calculation theory heavily rely on real-time grid parameters and cannot accurately predict grid carbon emissions. To address the challenge, this paper proposes a novel spatiotemporal prediction model by integrating graph convolutional networks (GCNs) and temporal convolutional networks (TCNs). The GCN layer enhances node representation by aggregating neighborhood information, while the TCN layer captures long-term temporal dependencies through expanded causal convolutions. Experiments conducted on the IEEE 14-bus system demonstrate that the model achieves high accuracy and real-time processing capabilities, confirming its robustness and practical value for dynamic carbon emission predictions.

Full article

Figure 1

Open AccessArticle

Towards Robust Physical Adversarial Attacks on UAV Object Detection: A Multi-Dimensional Feature Optimization Approach

by

Hailong Xi, Le Ru, Jiwei Tian, Wenfei Wang, Rui Zhu, Shiliang Li, Zhenghao Zhang, Longhao Liu and Xiaohui Luan

Machines 2025, 13(11), 1060; https://doi.org/10.3390/machines13111060 - 17 Nov 2025

Abstract

Deep neural network (DNN)-based object detection has been extensively implemented in Unmanned Aerial Vehicles (UAVs). However, these architectures reveal significant vulnerabilities when faced with adversarial attacks, particularly the physically realizable adversarial patches, which are highly practicable. Existing methods for generating adversarial patches are

[...] Read more.

Deep neural network (DNN)-based object detection has been extensively implemented in Unmanned Aerial Vehicles (UAVs). However, these architectures reveal significant vulnerabilities when faced with adversarial attacks, particularly the physically realizable adversarial patches, which are highly practicable. Existing methods for generating adversarial patches are easily affected by factors such as motion blur and color distortion, leading to a decline in the attack success rate (ASR). To address these limitations, a low-frequency robust adversarial patch (LFRAP) generation framework that integrates three dimensions of color, texture, and frequency domain is proposed. Firstly, a dynamic extraction mechanism for the environmental color pool based on clustering is proposed. This mechanism not only improves the degree of environmental integration but also reduces printing losses. Secondly, mathematical modeling of the effects of Unmanned Aerial Vehicle (UAV) high-speed motion is incorporated into the patch training process. The specialized texture derived from this modeling alleviates patch blurring and the subsequent decrease in attack efficiency caused by the high-speed movement of UAVs. Finally, a frequency domain separation strategy is introduced in the generation process to optimize the frequency space distribution, thereby reducing information loss during image recapture by UAV vision systems. The experimental results show that this framework increased the environment integration rate of the generated patches by 18.9%, and the attack success rate under the condition of motion blur increased by 19.2%, which significantly outperformed conventional methods.

Full article

(This article belongs to the Special Issue Intelligent Control Techniques for Unmanned Aerial Vehicles)

►▼

Show Figures

Figure 1

Open AccessArticle

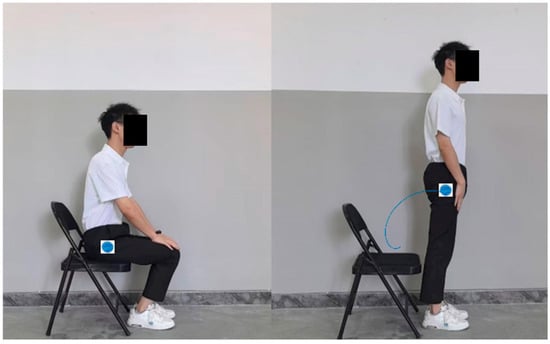

Mechanism Design of Lower-Limb Rehabilitation Robot Based on Chord Angle Descriptor Method

by

Liuxian Zhu, Wei Wei, Li Li and Shan Gong

Machines 2025, 13(11), 1059; https://doi.org/10.3390/machines13111059 - 17 Nov 2025

Abstract

The rapid aging of the global population and the escalating prevalence of conditions such as stroke and spinal cord injuries are driving an urgent demand for effective lower-limb rehabilitation. This necessitates the development of robotic devices capable of providing intensive, repetitive, and consistent

[...] Read more.

The rapid aging of the global population and the escalating prevalence of conditions such as stroke and spinal cord injuries are driving an urgent demand for effective lower-limb rehabilitation. This necessitates the development of robotic devices capable of providing intensive, repetitive, and consistent movement therapy, with superior stability and safety being paramount. This paper presents a comprehensive design and modeling framework for a novel lower-limb rehabilitation robot, addressing the critical gap between computational complexity and model fidelity in gear-linkage mechanisms. A single-degree-of-freedom gear-five-bar mechanism synthesized via a Chord Angle Descriptor method is proposed that enables efficient, normalized-trajectory generation for standing motions. Subsequently, a hybrid dynamic modeling framework is developed, which explicitly incorporates time-varying gear mesh stiffness—a factor typically oversimplified in traditional models. By decomposing stiffness via a Finite Element Method-based potential energy analysis, characterizing it with a Fourier series, and integrating it into a Lagrangian model, our approach accurately captures complex dynamics with minimal degrees of freedom. Computational validation confirms exceptional stability, with a maximum gear angular amplitude below 0.003145 radians for a 250 kg user. This study provides both a robust theoretical foundation and a practical design paradigm for high-performance rehabilitation robots.

Full article

(This article belongs to the Special Issue Advanced Human–Machine Interaction and Assistive Robotics for Rehabilitation)

►▼

Show Figures

Figure 1

Open AccessArticle

Adaptive Remaining Useful Life Estimation of Rolling Bearings Using an Incremental Unscented Kalman Filter with Nonlinear Degradation Tracking

by

Xiangdian Shang, Junxing Li, Taishan Lou, Zhihua Wang, Xiaoxu Pang and Zhiwen Zhang

Machines 2025, 13(11), 1058; https://doi.org/10.3390/machines13111058 - 16 Nov 2025

Abstract

In consideration of the characteristics of two-stage (stable and degraded), nonlinearity and non-stationary randomness in the full life-cycle evolution process of the rolling bearing health indicator (HI), a novel remaining useful life (RUL) prediction method for rolling bearings is proposed based on long

[...] Read more.

In consideration of the characteristics of two-stage (stable and degraded), nonlinearity and non-stationary randomness in the full life-cycle evolution process of the rolling bearing health indicator (HI), a novel remaining useful life (RUL) prediction method for rolling bearings is proposed based on long short-term memory network–Mahalanobis distance (LSTM-MD) and an incremental unscented Kalman filter (IUKF). First, an LSTM-MD hybrid algorithm is developed to precisely identify the critical change point (CP) between stable operation and incipient degradation in bearing HI trajectories, effectively mitigating the susceptibility of conventional threshold-based methods to HI fluctuations. Second, during the degradation stage, a degradation analysis model based on the nonlinear Wiener process is constructed. Simultaneously, an IUKF-based RUL prediction method for bearings is proposed, which overcomes the implicit assumption of the traditional UKF method that one-step prediction can replace state prediction, particularly in scenarios with significant HI fluctuations, thereby significantly reducing prediction errors. Finally, the proposed method is validated through comparisons with traditional methods using both the XJTU-SY public dataset and a self-built bearing test dataset. The results demonstrate that compared to traditional methods, the accuracy of initial degradation change point identification is improved by 32.6%, and the root mean square error (MSE) of RUL prediction is decreased by 41.8%.

Full article

(This article belongs to the Special Issue Data-Driven RUL Prediction: Innovations in Generalization, Uncertainty, and Efficiency for Industrial PHM)

►▼

Show Figures

Figure 1

Open AccessArticle

Optimization Analysis of the Dynamic Performance of Permanent Magnet Levitation Vehicles Based on Magnetic Wheelset

by

Pengfei Zhan, Hongping Luo, Chuanjin Liao, Linjie Wang and Bin Yang

Machines 2025, 13(11), 1057; https://doi.org/10.3390/machines13111057 - 15 Nov 2025

Abstract

The permanent magnet levitation (PML) transportation system utilizes Halbach arrays to achieve zero-power levitation. However, the system’s lateral negative stiffness characteristic leads to a significant increase in lateral force during operation, exacerbating lateral vibration and compromising system stability. Taking the Xingguo Line PML

[...] Read more.

The permanent magnet levitation (PML) transportation system utilizes Halbach arrays to achieve zero-power levitation. However, the system’s lateral negative stiffness characteristic leads to a significant increase in lateral force during operation, exacerbating lateral vibration and compromising system stability. Taking the Xingguo Line PML system as the research object, this study systematically analyzes the nonlinear characteristics of the levitation force and lateral force in a single-point levitation system through theoretical modeling, finite element simulation, and experimental validation. The concept of a ‘Magnetic Wheelset’ coupling the left and right levitation points of the bogie is proposed. The influence of five mounting forms—Aligned, X-type, Different center distance, Double V-type, and Single V-type—on the levitation performance of the Magnetic Wheelset is investigated. The coefficient of variation (CV) method is employed to evaluate force stability, and an optimal case is subsequently screened out using a dual-objective constraint approach that incorporates mean levitation force and lateral force thresholds. Results indicate that the X-type mounting at 25° is the optimal case. At 40 km/h, compared to the baseline Aligned configuration, the root mean square (RMS) values of the bogie’s vertical and lateral vibration accelerations are reduced by 14.7% and 23.8%, respectively. The vehicle’s vertical and lateral ride comfort indices decrease by 0.33 and 0.27, respectively, and the track beam’s vertical and lateral vibration accelerations are reduced by 19.4% and 13.3%. The methodology presented in this study provides a valuable reference for vibration suppression in PML systems.

Full article

(This article belongs to the Section Vehicle Engineering)

►▼

Show Figures

Figure 1

Open AccessArticle

Vibration Characteristics and Fatigue Performance of Bogie Frame with Inner Axle Box for High-Speed Trains

by

Tao Guo, Bingzhi Chen, Yuedong Wang, Guojie Cai, Maorui Hou and Qi Dong

Machines 2025, 13(11), 1056; https://doi.org/10.3390/machines13111056 - 14 Nov 2025

Abstract

With the continuous increase in high-speed train operation speeds, lightweight bogie design has become a key means to enhance dynamic performance, which also increases the risk of structural fatigue. High-frequency wheel–rail excitations are transmitted to the bogie frame and couple with its higher-order

[...] Read more.

With the continuous increase in high-speed train operation speeds, lightweight bogie design has become a key means to enhance dynamic performance, which also increases the risk of structural fatigue. High-frequency wheel–rail excitations are transmitted to the bogie frame and couple with its higher-order modes at around 200 Hz, inducing local high-frequency resonance. This coupling markedly increases the stress amplitude within the affected frequency range and accelerates vibration-induced fatigue damage. This study investigates the vibration fatigue characteristics of a bogie frame with an inner axle box under high-speed operation and wheel polygon wear conditions. Using a high-speed wheel–rail interaction test rig, dynamic stresses and the vibration acceleration of the bogie frame are measured under different speeds and polygon orders. Based on modal analysis and vibration fatigue methods, a high-frequency vibration fatigue assessment method for the bogie is developed. Wheel polygon significantly amplifies mid-to-high-frequency vibration energy, and for the bogie frame with an inner axle box, pronounced modal coupling is observed at around 200 Hz. In particular, under the 11th-order polygon condition, the equivalent stress at critical locations such as the traction motor seat weld seam exceeds the fatigue limit, while the effect of the 20th-order polygon is relatively mitigated. The proposed vibration fatigue assessment method provides a theoretical basis for the safe design and operational maintenance of high-speed trains with bogie frames with inner axle boxes.

Full article

(This article belongs to the Special Issue Research and Application of Rail Vehicle Technology)

►▼

Show Figures

Figure 1

Open AccessArticle

Time-Domain and Neural Network-Based Diagnosis of Bearing Faults in Induction Motors Under Variable Loads

by

Hwi Gyo Lee, Seon Min Yoo, Wang Ke Hao and In Soo Lee

Machines 2025, 13(11), 1055; https://doi.org/10.3390/machines13111055 - 14 Nov 2025

Abstract

Bearing faults are the most common type of failure in induction motors, given their long operating times and mechanical loads. Because induction motors in industrial environments operate under various load conditions, effective methods for diagnosing bearing faults across these conditions have become increasingly

[...] Read more.

Bearing faults are the most common type of failure in induction motors, given their long operating times and mechanical loads. Because induction motors in industrial environments operate under various load conditions, effective methods for diagnosing bearing faults across these conditions have become increasingly important. Here, different load conditions were implemented with a powder clutch and a tension controller, and vibration data were acquired under both normal and faulty bearing conditions. To ensure diagnostic accuracy while improving time efficiency, a model bank-based fault diagnosis classifier is proposed, which utilizes independent classifiers trained for each load condition. For comparison, a single model-based classifier trained on all load conditions is also implemented. Both approaches are validated with three classifiers: support vector machine (SVM), multilayer neural network (MNN), and random forest (RF), with three input types: raw time-series signals, six statistical features, and three t-test–selected statistical features. Experimental results reveal that the model bank-based fault diagnosis classifier utilizing three statistical features selected by t-test maintained 98–100% accuracy while reducing operating time compared with Method 1 by 60.0, 71.2, and 60.0% for SVM, MNN, and RF, respectively. These results confirm that the proposed Method 2 utilizing time-domain analysis provides reliable and time-efficient performance for bearing fault diagnosis under variable load conditions.

Full article

(This article belongs to the Special Issue Data-Driven Fault Diagnosis for Machines and Systems, 2nd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Effects of Inflow Deflection Angle on the Stall Formation Mechanism and Flow Field Structure in a Vertical Axial-Flow Pump

by

Fan Meng, Qixiang Hu, Jinhe Liu, Yanjun Li, Guangjian Zhang and Jiaxing Lu

Machines 2025, 13(11), 1054; https://doi.org/10.3390/machines13111054 - 14 Nov 2025

Abstract

The influence of inflow angle on the stall characteristics of a vertical axial flow pump is investigated numerically by solving the unsteady Reynolds-averaged Navier–Stokes equations. The study predicts both performance parameters and internal flow structures under varying inflow conditions. It is found that

[...] Read more.

The influence of inflow angle on the stall characteristics of a vertical axial flow pump is investigated numerically by solving the unsteady Reynolds-averaged Navier–Stokes equations. The study predicts both performance parameters and internal flow structures under varying inflow conditions. It is found that as the deflection angle decreases, both the critical and deep stall points shift toward higher flow rates. For the −30° scheme, the design efficiency and design head decrease by 16.27% and increase by 19.59%, respectively, compared to the 0° scheme. As stall develops, an axisymmetric blockage region forms at the impeller inlet, which reduces axial velocity and increases the impeller’s angle of attack. Under design conditions, a smaller deflection angle exacerbates boundary layer separation near the blade leading edge, thereby weakening the local work capacity and intensifying turbulent dissipation. Furthermore, although a reduced deflection angle promotes an earlier onset of stall, it also leads to a decrease in the instability intensity of the stall flow field. These results reveal a critical trade-off: while a smaller deflection angle promotes an earlier stall onset, it effectively mitigates the intensity of stall instability, providing crucial guidance for optimizing the hydraulic design and operational stability of vertical axial flow pumps.

Full article

(This article belongs to the Section Machine Design and Theory)

►▼

Show Figures

Figure 1

Open AccessArticle

Development of a Simulation Computational Model for Hole Detection and Generation of Robot Tool Movement for Fitting Mold Preparation Nozzles

by

Martin Pollák and Karol Goryl

Machines 2025, 13(11), 1053; https://doi.org/10.3390/machines13111053 - 14 Nov 2025

Abstract

This article focuses on the design, development and optimization of a mechanical system with the aim of increasing the efficiency of the production process. The article describes the issues involved in the production of molds used for EPS (Expanded Polystyrene) and EPP (Expanded

[...] Read more.

This article focuses on the design, development and optimization of a mechanical system with the aim of increasing the efficiency of the production process. The article describes the issues involved in the production of molds used for EPS (Expanded Polystyrene) and EPP (Expanded Polypropylene) materials, specifically the assembly of mold nozzles. Currently, the assembly of nozzles is performed manually, and the proposed solution aims to automate this process using software and robotics. The solution involves scanning the mounting holes and then modifying the mold model in Siemens NX, based on which a trajectory is generated in the virtual environment of RoboDK software. Communication between Siemens NX and RoboDK software is implemented via a Python algorithm using NXOpen and RoboDK API (Application Programming Interface) libraries. The proposed tool has flexible settings and is not dependent on a robotic arm or tool. The result is a prototype software tool for offline programming of automated assembly, which is adapted to different hole layouts, allowing its use in small-batch production in the future. The proposed tool has flexible settings and is not dependent on a specific robotic arm or tool. The solution was validated through comprehensive simulation testing in the RoboDK environment, demonstrating significant potential for time reduction and process optimization.

Full article

(This article belongs to the Special Issue Advances in Computer-Aided Technology, 3rd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Study on Dynamic Characteristics and Key Gear Parameter Selection of the Cutting Gear Transmission System of Bauxite Mining Machine Under Overload Conditions

by

Qiulai Huang, Weipeng Xu, Ziyao Ma, Ning Jiang, Yu Bu, Kuidong Gao and Xiaodi Zhang

Machines 2025, 13(11), 1052; https://doi.org/10.3390/machines13111052 - 14 Nov 2025

Abstract

In certain mining areas, bauxite ore exhibits high and uneven hardness, causing frequent overloads in the cutting heads of bauxite mining equipment and challenging the dynamic performance and reliability of its gear transmission system. To investigate the influence of macro-geometric parameters, a dynamic

[...] Read more.

In certain mining areas, bauxite ore exhibits high and uneven hardness, causing frequent overloads in the cutting heads of bauxite mining equipment and challenging the dynamic performance and reliability of its gear transmission system. To investigate the influence of macro-geometric parameters, a dynamic model was built using MASTA software (version 13.0.1). This study systematically analyzed the effects of pressure angle, face width, and bottom clearance coefficient on gear meshing characteristics, service life, and vibration noise under various loads. A preferred set of parameters was determined and validated through vibration and noise tests. The results show that increasing the pressure angle and face width improves gear meshing and fatigue life, while the bottom clearance coefficient has an optimal value of 0.4. Increasing the bottom clearance coefficient exacerbates vibration and noise, with other parameters causing fluctuations under different conditions. The optimal parameters of 23° pressure angle, 75 mm face width, and 0.4 bottom clearance coefficient effectively reduce vibration and noise, providing a theoretical and practical basis for improving the cutting transmission system.

Full article

(This article belongs to the Section Machine Design and Theory)

►▼

Show Figures

Figure 1

Open AccessArticle

Towards Sustainable Manufacturing: Particle Emissions in Milling Post-Processing of 3D-Printed Titanium Alloy

by

Fahad M. Alqahtani, Mustafa Saleh, Abdelaty E. Abdelgawad, Ibrahim A. Almuhaidib and Faisal Alessa

Machines 2025, 13(11), 1051; https://doi.org/10.3390/machines13111051 - 13 Nov 2025

Abstract

Electron beam melting (EBM) is an additive manufacturing method that enables the manufacturing of metallic parts. EBM-printed parts require post-processing to meet the surface quality and dimensional accuracy requirements. Machining is one approach that is beneficial for achieving these requirements. However, during machining,

[...] Read more.

Electron beam melting (EBM) is an additive manufacturing method that enables the manufacturing of metallic parts. EBM-printed parts require post-processing to meet the surface quality and dimensional accuracy requirements. Machining is one approach that is beneficial for achieving these requirements. However, during machining, particles are emitted and can affect the environment and the operator’s health. This study aims to investigate the concentration of particles emitted during the milling of 3D-printed Ti6Al4V alloy produced by EBM. First, the influence of machining speed and cutting fluids, namely flood and minimum quantity lubricant (MQL), on particle emissions was statistically investigated. Then, the standby time required for the operator to safely open the machine door and interact with the machine within the machining area was studied. In this regard, two scenarios were proposed. In the first scenario, the machine door is open immediately after machining, and the operator waits until the particle concentration is acceptable. In the second, the machine door will be opened only when the particle concentration is acceptable. Statistical findings revealed that cutting fluids have a significant impact on particle emissions, exhibiting distinct patterns for both fine and coarse particles. Irrespective of the scenario, MQL results in higher particle concentration peaks and larger particle sizes, and the operator needs a longer standby time before interacting with the machine. For instance, the standby time in MQL is 328% more than that of the flood system. This study provides insight into sustainable manufacturing by taking into account social factors such as worker health and safety.

Full article

(This article belongs to the Section Industrial Systems)

►▼

Show Figures

Figure 1

Open AccessArticle

To Boldly Go: Redefining Mobility with Thrust-Augmented Rocker-Bogie CanBots for Simulated Planetary Exploration

by

Carrington Chun and Muhammad Hassan Tanveer

Machines 2025, 13(11), 1050; https://doi.org/10.3390/machines13111050 - 13 Nov 2025

Abstract

This research presents the first known example of a Thrust-Augmented Rocker Bogie (TARB). As a robust and passive mechanisms, the rocker bogie suspension system has seen widespread application in ground-based robotic planetary exploration rovers. However, with the first demonstration of a multirotor on

[...] Read more.

This research presents the first known example of a Thrust-Augmented Rocker Bogie (TARB). As a robust and passive mechanisms, the rocker bogie suspension system has seen widespread application in ground-based robotic planetary exploration rovers. However, with the first demonstration of a multirotor on Mars, there is clearly a need to expand the locomotion capacity for planetary rovers. The TARB builds on the existing flight heritage of the rocker rogie but also innovatively combines the system with a multirotor configuration. The combined homogeneous mobility solution can successfully demonstrate multimodal mobility including in terrestrial, aerial, and hybrid forms of locomotion. The prototype TARB developed for this research was constructed in the form of a CanBot. CanBots provide a means to test space-oriented rover technologies with earth-based analogues. Three prototype multimodal CanBots are described in this work, with each showing improvements in mobility and overall design robustness. Laboratory validation of the final TARB-equipped CanBot showed that it could utilize the rocker-bogie system to engage complicated terrestrial terrains while also maintaining the capacity to fly as an aerial vehicle. The laboratory testing also indicated that the CanBot could climb significantly steeper slopes when employing the TARB in a hybrid mode, successfully climbing slopes of 60 degrees, demonstrating static stability on inclines of up to 90 degrees, and successfully navigating along fully inverted surfaces.

Full article

(This article belongs to the Section Robotics, Mechatronics and Intelligent Machines)

►▼

Show Figures

Figure 1

Open AccessArticle

Experimental Evaluation of Milling Post-Processing on the Surface Quality of MEX-Printed Carbon Fiber-Reinforced PLA Composites

by

Abdullah Yahia AlFaify

Machines 2025, 13(11), 1049; https://doi.org/10.3390/machines13111049 - 13 Nov 2025

Abstract

This study explores the machinability of Material Extrusion (MEX) printed parts made from carbon fiber-reinforced polylactic acid (PLA). MEX-printed parts typically exhibit high surface roughness, necessitating post-processing to enhance their quality. In this work, milling was used as a post-processing method to improve

[...] Read more.

This study explores the machinability of Material Extrusion (MEX) printed parts made from carbon fiber-reinforced polylactic acid (PLA). MEX-printed parts typically exhibit high surface roughness, necessitating post-processing to enhance their quality. In this work, milling was used as a post-processing method to improve the surface finish. Response surface methodology (RSM) experimental design was employed to investigate the effects of cutting velocity, feed rate, and depth of cut on the surface quality of the machined surfaces. Results showed that the as-built MEX-printed sample exhibited a high average surface roughness (Sa) of ~7.982 µm, indicating the need for post-processing. Post-processing milling considerably enhances the Sa by reducing it to ~1.621 µm under the optimal condition. Statistical findings showed that all considered factors have significant influence on the Sa, with feed rate as the most influential one, contributing to 47.63% of the total variation. The Sa values varied from 1.834 µm to 4.146 µm due to changes in the considered factors. Increasing feed rate leads to the emergence of cavities and ridges along the deposited filaments associated with brittle removal mechanism, resulting in higher surface roughness.

Full article

(This article belongs to the Special Issue Recent Advances in Surface Integrity with Machining and Milling)

►▼

Show Figures

Figure 1

Open AccessArticle

A Health-Aware Fuzzy Logic Controller Optimized by NSGA-II for Real-Time Energy Management of Fuel Cell Electric Commercial Vehicles

by

Juan Du, Xuening Zhang, Shanglin Wang and Xiaodong Liu

Machines 2025, 13(11), 1048; https://doi.org/10.3390/machines13111048 - 13 Nov 2025

Abstract

This study introduces a health-aware fuzzy logic (FL) energy management strategy (EMS) for fuel cell electric commercial vehicles (FCECVs) that aimed to improve energy efficiency and extending fuel cell system (FCS) lifespan. The FL-based EMS was developed using vehicle power demand and battery

[...] Read more.

This study introduces a health-aware fuzzy logic (FL) energy management strategy (EMS) for fuel cell electric commercial vehicles (FCECVs) that aimed to improve energy efficiency and extending fuel cell system (FCS) lifespan. The FL-based EMS was developed using vehicle power demand and battery state of charge (SOC) as inputs, with the FCS power change rate as the output, aiming to mitigate degradation induced by abrupt load transitions. A multi-objective optimization framework was established to optimize the fuzzy logic controller (FLC) parameters, achieving a balanced trade-off between fuel economy and FCS longevity. The non-dominated sorting genetic algorithm-II (NSGA-II) was utilized for optimization across various driving cycles, with average Pareto-optimal solutions employed for real-time application. Performance evaluation under standard and stochastic driving cycles benchmarked the proposed strategy against dynamic programming (DP), charge-depletion charge-sustaining (CD-CS), conventional FL strategies, and a non-optimized baseline. Results demonstrated an approximately

(This article belongs to the Special Issue Energy Storage and Conversion of Electric Vehicles)

►▼

Show Figures

Figure 1

Open AccessArticle

The Influence of Suspension Elastokinematics on Vehicle Handling and Stability

by

Albert Basiul, Vidas Žuraulis, Robertas Pečeliūnas and Saugirdas Pukalskas

Machines 2025, 13(11), 1047; https://doi.org/10.3390/machines13111047 - 12 Nov 2025

Abstract

This study investigates the influence of suspension elastokinematics on vehicle handling and stability through a combined research of experimental testing and numerical simulation. Laboratory tests were conducted on the front suspension of a Mercedes-Benz S320 using a quarter-car test rig equipped with specialized

[...] Read more.

This study investigates the influence of suspension elastokinematics on vehicle handling and stability through a combined research of experimental testing and numerical simulation. Laboratory tests were conducted on the front suspension of a Mercedes-Benz S320 using a quarter-car test rig equipped with specialized sensors to measure wheel displacements, steering angles, camber, and accelerations. Complementary dynamic tests were carried out under real driving conditions, including braking in a turn and “fishhook” maneuvers, to capture suspension behavior under critical operating scenarios. Based on the experimental data, an MSC Adams/Car multibody simulation model was used, incorporating varying stiffness values of suspension elastomeric elements that replicated progressive aging and degradation effects. The simulation results were compared with experimental data to validate the model’s predictive capability. Key findings indicate that reductions in elastomer stiffness significantly affect wheel kinematics, vehicle yaw response, and lateral acceleration, particularly during high-intensity maneuvers. The results underline the critical importance of accounting for elastomeric component degradation in suspension modeling to ensure vehicle safety and performance over the operational lifespan. The developed methodology demonstrates the effectiveness of integrating experimental measurements with advanced simulation tools to assess elastokinematic effects on vehicle dynamics.

Full article

(This article belongs to the Special Issue Advances in Vehicle Suspension System Optimization and Control)

►▼

Show Figures

Figure 1

Open AccessArticle

Slot Number Optimization for Motorcycle Traction Motor Considering Driving Duty Cycle

by

Yang Gu, Hui Yi, Huimin Ouyang, Lei Mei, Qiang Sun and Zichong Zhu

Machines 2025, 13(11), 1046; https://doi.org/10.3390/machines13111046 - 12 Nov 2025

Abstract

Due to their compact dimensions, high torque density, high efficiency, and superior flux-weakening capabilities, permanent magnet synchronous machines with tooth-coil winding (TC-PMSMs) are highly suitable for low-power electric transportation applications. This study incorporates the actual duty cycle of an electric motorcycle in the

[...] Read more.

Due to their compact dimensions, high torque density, high efficiency, and superior flux-weakening capabilities, permanent magnet synchronous machines with tooth-coil winding (TC-PMSMs) are highly suitable for low-power electric transportation applications. This study incorporates the actual duty cycle of an electric motorcycle in the optimization of the slot number for the drive machine. The proposed methodology addresses the shortcomings of conventional design strategies, which typically consider only a limited set of operating points, leading to suboptimal round-trip efficiency under real driving conditions. Firstly, the influence of slot number on torque output, electromagnetic losses, and flux-weakening performance is examined for 10-pole TC-PMSMs using finite element analysis. Subsequently, the optimal slot number is identified by integrating the real duty cycle of the drive motor into the evaluation. To verify the accuracy and effectiveness of the analytical results and design approach, prototypes of stator assemblies with varying slot numbers were fabricated and experimentally tested.

Full article

(This article belongs to the Section Electrical Machines and Drives)

►▼

Show Figures

Figure 1

Open AccessArticle

Ball Mill Load Classification Method Based on Multi-Scale Feature Collaborative Perception

by

Saisai He, Zhihong Jiang, Wei Huang, Lirong Yang and Xiaoyan Luo

Machines 2025, 13(11), 1045; https://doi.org/10.3390/machines13111045 - 12 Nov 2025

Abstract

Against the backdrop of intelligent manufacturing, the ball mill, as a key energy-consuming piece of equipment, requires an accurate perception of its load state, which is crucial for optimizing production efficiency and ensuring operational safety. However, its vibration signals exhibit typical nonlinear and

[...] Read more.

Against the backdrop of intelligent manufacturing, the ball mill, as a key energy-consuming piece of equipment, requires an accurate perception of its load state, which is crucial for optimizing production efficiency and ensuring operational safety. However, its vibration signals exhibit typical nonlinear and non-stationary characteristics, intertwined with complex noise, posing significant challenges to high-precision identification. A core contradiction exists in existing diagnostic methods: convolution network-based methods excel at capturing local features but overlook global trends, while Transformer-type models, although capable of capturing long-range dependencies, tend to “average out” critical local transient information during modeling. To address this dilemma, this paper proposes a new paradigm for multi-scale feature collaborative perception. This paradigm is implemented through an innovative deep learning architecture—the Residual Block-Swin Transformer Network (RB-SwinT). This architecture subtly achieves hierarchical and in-depth integration of the powerful global context modeling capability of Swin Transformer and the excellent local detail refinement capability of the residual module (ResBlock), enabling synchronous and efficient representation of both the macro trends and micro mutations of signals. On the experimental dataset covering nine types of fine operating conditions, the overall recognition accuracy of the proposed method reaches as high as 96.20%, which is significantly superior to a variety of mainstream models. To further verify the model’s generalization ability, this study was tested on the CWRU public bearing fault dataset, achieving a recognition accuracy of 99.36%, which outperforms various comparative methods such as SAVMD-CNN. This study not only provides a reliable new technical approach for ball mill load identification but also demonstrates its practical application value in indicating critical operating conditions and optimizing production operations through an in-depth analysis of the physical connotations of each load level. More importantly, its “global-local” collaborative modeling concept opens up a promising technical path for processing a broader range of complex industrial time-series data.

Full article

(This article belongs to the Section Advanced Manufacturing)

►▼

Show Figures

Figure 1

Journal Menu

► ▼ Journal Menu-

- Machines Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Instructions for Authors

- Special Issues

- Topics

- Sections & Collections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Society Collaborations

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Actuators, Algorithms, BDCC, Future Internet, JMMP, Machines, Robotics, Systems

Smart Product Design and Manufacturing on Industrial Internet

Topic Editors: Pingyu Jiang, Jihong Liu, Ying Liu, Jihong YanDeadline: 31 December 2025

Topic in

Actuators, Automation, Electronics, Machines, Robotics, Eng, Technologies

New Trends in Robotics: Automation and Autonomous Systems

Topic Editors: Maki Habib, Fusaomi NagataDeadline: 31 January 2026

Topic in

Coatings, JMMP, Lubricants, Machines, Materials

Advanced Manufacturing and Surface Technology, 2nd Edition

Topic Editors: Dingding Xiang, Kaiming Wang, Xudong SuiDeadline: 20 March 2026

Topic in

Applied Sciences, Electricity, Electronics, Energies, Machines, Smart Cities, Vehicles, Batteries

Design and Control of Electrical Machines for Electric Vehicles

Topic Editors: Jinhua Du, Xuan WuDeadline: 31 March 2026

Conferences

Special Issues

Special Issue in

Machines

Recent Progress of Thin Wall Machining, 2nd Edition

Guest Editor: Yuwen SunDeadline: 30 November 2025

Special Issue in

Machines

Nonlinear Dynamics in Mechanical Systems, Automation and Control

Guest Editor: Louay S. YousufDeadline: 30 November 2025

Special Issue in

Machines

Trajectory Planning for Autonomous Vehicles: State of the Art

Guest Editor: Yiwen HuangDeadline: 30 November 2025

Special Issue in

Machines

Advances in Dynamics and Vibration Control in Mechanical Engineering

Guest Editor: Ahmed GuerineDeadline: 30 November 2025

Topical Collections

Topical Collection in

Machines

Machines, Mechanisms and Robots: Theory and Applications

Collection Editor: Raffaele Di Gregorio