Wear-Resistant Coatings and Film Materials

A special issue of Lubricants (ISSN 2075-4442).

Deadline for manuscript submissions: 30 June 2024 | Viewed by 1393

Special Issue Editors

Interests: nanolubricants; structure of surface/interface

Special Issue Information

Dear Colleagues,

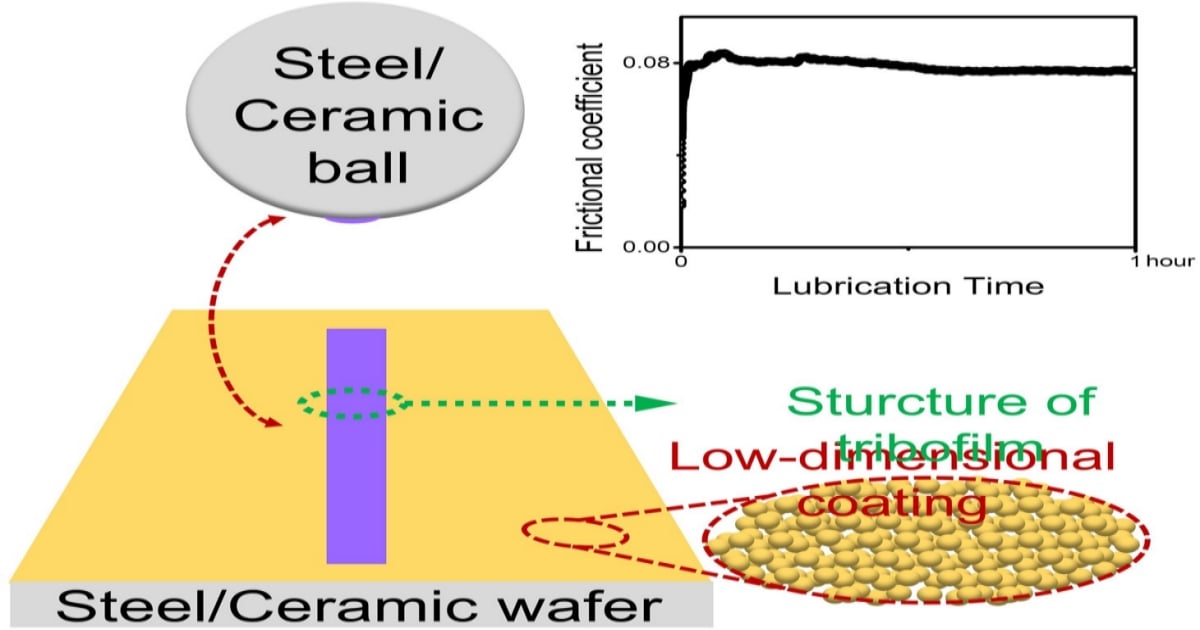

Wear-resistant coatings and film materials are essential in many industries, such as manufacturing and aerospace. These coatings and materials provide protection against wear and tear, extending the lifespan and durability of various products.

One of the key benefits of wear-resistant coatings, such as nanomaterials and polyurethane, is their ability to reduce friction. These coatings are commonly used in applications such as bearings. Another advantage of wear-resistant coatings is their ability to resist chemical and environmental degradation. This extends their lifespan and reduces the maintenance costs in harsh environments. Moreover, wear-resistant coatings can also enhance the aesthetic appeal of products with different colors or textures. This is particularly important in automotive and consumer electronics, where design plays a crucial role in customers’ perception. Despite the numerous benefits of wear-resistant coatings, there are also challenges and limitations.

The theme of this Special Issue aims to promote exchange and collaboration within the academic community to explore the latest research findings and future directions in this field. We invite you to submit your research. We look forward to your active participation and believe that your contribution will introduce breakthroughs to this field.

Dr. Xuan Yin

Dr. Jianxun Xu

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Lubricants is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- nanolubrication

- two-dimensional materials

- functional polymer

- quantum dot materials