Inkjet Printing of High Aspect Ratio Superparamagnetic SU-8 Microstructures with Preferential Magnetic Directions

Abstract

:1. Introduction

2. Experimental Section

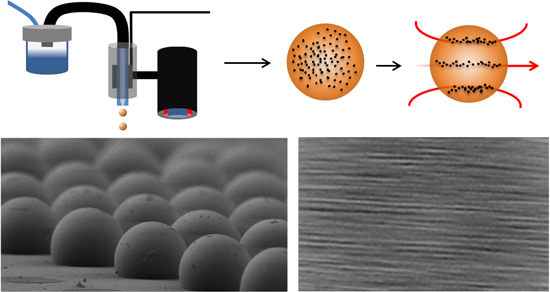

2.1. Confinement Pedestals

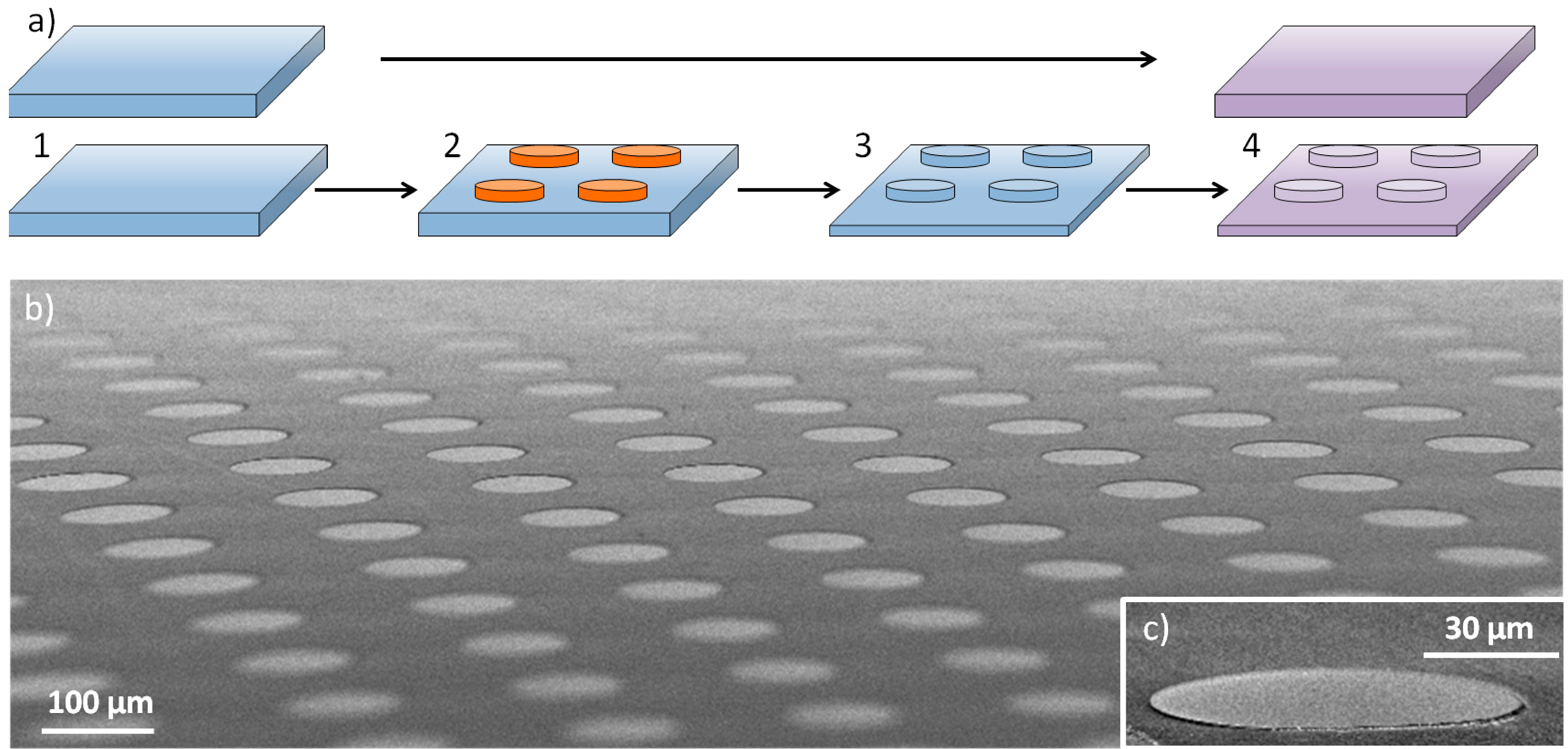

2.2. Experimental Setup

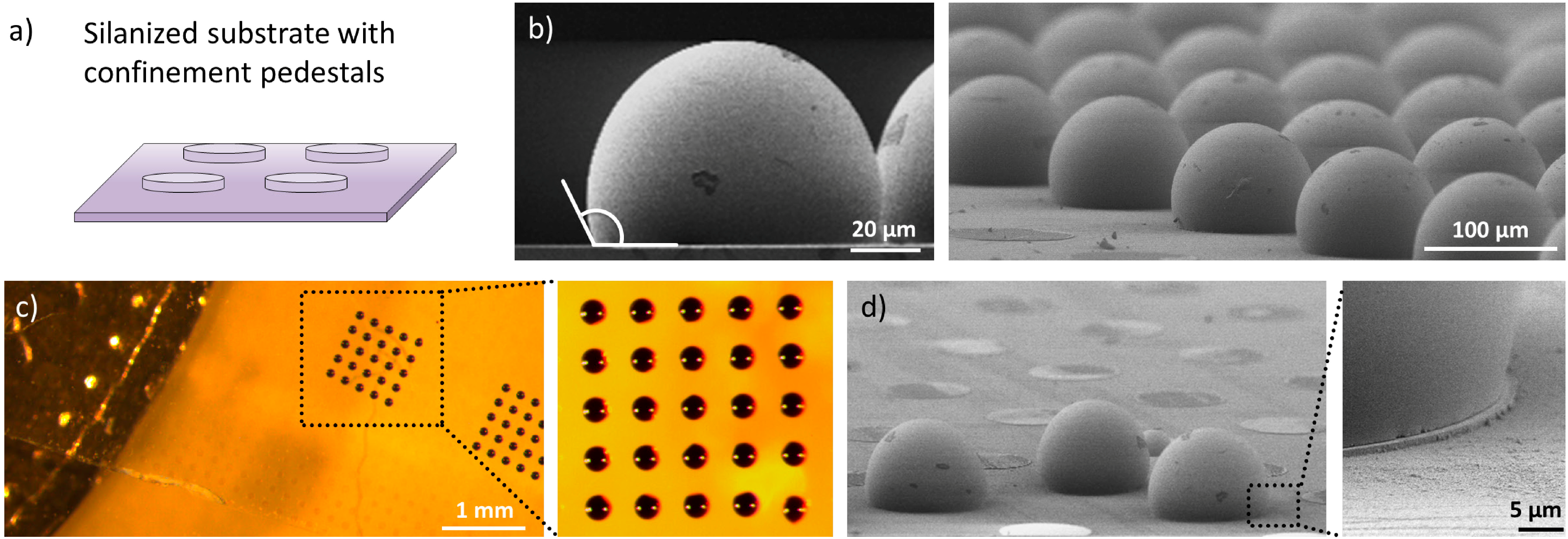

2.3. Fabrication Process

3. Results and Discussions

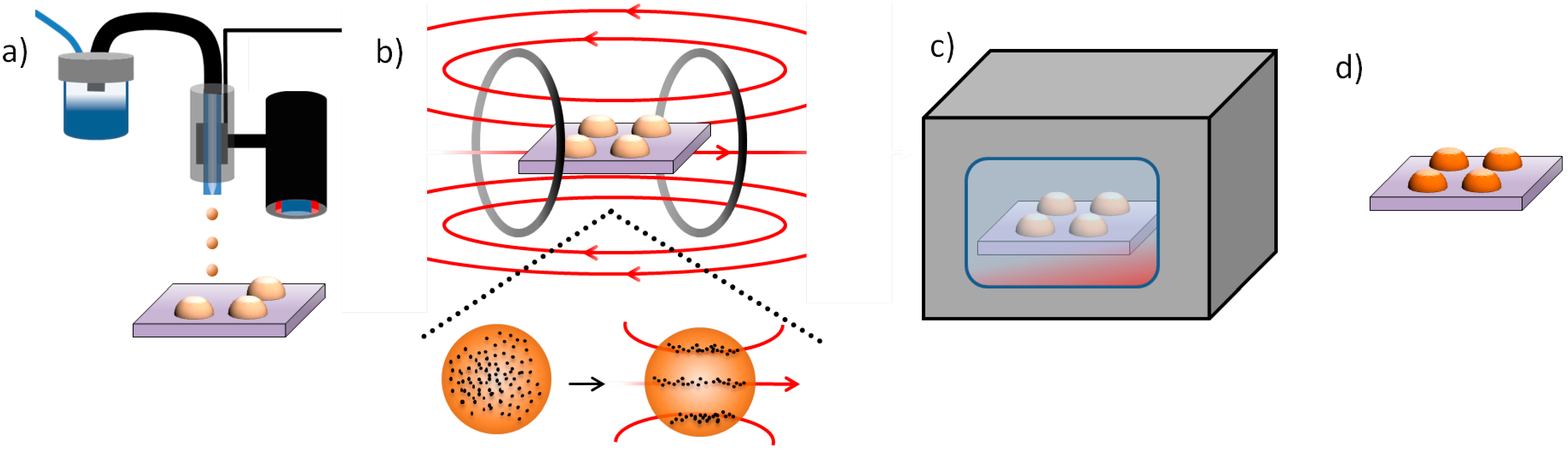

3.1. Inkjet Printed Structures on Flat Substrates

3.2. High Aspect Ratio Structures on Confinement Pedestals

3.3. Induced Preferential Magnetic Directions

3.4. Further Discussions and Improvements

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lorenz, H.; Despont, M.; Fahrni, N.; LaBianca, N.; Renaud, P.; Vettiger, P. SU-8: A low-cost negative resist for MEMS. J. Micromech. Microeng. 1997, 7, 121–124. [Google Scholar] [CrossRef]

- Genolet, G.; Brugger, J.; Despont, M.; Drechsler, U.; Vettiger, P.; de Rooij, N.F.; Anselmetti, D. Soft, entirely photoplastic probes for scanning force microscopy. Rev. Sci. Instrum. 1999, 70, 2398–2401. [Google Scholar] [CrossRef]

- Voigt, A.; Ostrzinski, U.; Pfeiffer, K.; Kim, J.Y.; Fakhfouri, V.; Brugger, J.; Gruetzner, G. New inks for the direct drop-on-demand fabrication of polymer lenses. Microelectron. Eng. 2011, 88, 2174–2179. [Google Scholar] [CrossRef]

- Jacot-Descombes, L.; Martin-Olmos, C.; Gullo, M.R.; Cadarso, V.J.; Mermoud, G.; Villanueva, L.G.; Mastrangeli, M.; Martinoli, A.; Brugger, J. Fluid-mediated parallel self-assembly of polymeric micro-capsules for liquid encapsulation and release. Soft Matter 2013, 9, 9931–9938. [Google Scholar] [CrossRef]

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.K.; Schueller, O.J.A.; Whitesides, G.M. Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 2000, 21, 27–40. [Google Scholar] [CrossRef]

- Nagstrup, J.; Keller, S.; Almdal, K.; Boisen, A. 3D microstructuring of biodegradable polymers. Microelectron. Eng. 2011, 88, 2342–2344. [Google Scholar] [CrossRef]

- Lorenz, H.; Despont, M.; Fahrni, N.; Brugger, J.; Vettiger, P.; Renaud, P. High-aspect-ratio, ultrathick, negative-tone near-UV photoresist and its applications for MEMS RID C-5357-2009 RID A-6994-2011. Sens. Actuators Phys. 1998, 64, 33–39. [Google Scholar] [CrossRef]

- Suter, M.; Zhang, L.; Siringil, E.C.; Peters, C.; Luehmann, T.; Ergeneman, O.; Peyer, K.E.; Nelson, B.J.; Hierold, C. Superparamagnetic microrobots: fabrication by two-photon polymerization and biocompatibility. Biomed. Microdevices 2013, 15, 997–1003. [Google Scholar] [CrossRef]

- Cadarso, V.J.; Pfeiffer, K.; Ostrzinski, U.; Bureau, J.B.; Racine, G.A.; Voigt, A.; Gruetzner, G.; Brugger, J. Direct writing laser of high aspect ratio epoxy microstructures. J. Micromech. Microeng. 2011, 21, 017003. [Google Scholar] [CrossRef]

- Fakhfouri, V.; Cantale, N.; Mermoud, G.; Kim, J.Y.; Boiko, D.; Charbon, E.; Martinoli, A.; Brugger, J. Inkjet printing of SU-8 for polymer-based MEMS a case study for microlenses. In Proceedings of IEEE 21st International Conference on Micro Electro Mechanical Systems, Tucson, AZ, USA, 13–17 January 2008; pp. 407–410.

- Cadarso, V.J.; Smolik, G.; Auzelyte, V.; Jacot-Descombes, L.; Brugger, J. Heterogeneous material micro-transfer by ink-jet print assisted mould filling. Microelectron. Eng. 2012, 98, 619–622. [Google Scholar] [CrossRef]

- Nelson, B.J.; Kaliakatsos, I.K.; Abbott, J.J. Microrobots for Minimally Invasive Medicine. Annu. Rev. Biomed. Eng. 2010, 12, 55–85. [Google Scholar] [CrossRef]

- Kim, J.; Chung, S.E.; Choi, S.-E.; Lee, H.; Kim, J.; Kwon, S. Programming magnetic anisotropy in polymeric microactuators. Nat Mater 2011, 10, 747–752. [Google Scholar] [CrossRef]

- Suter, M.; Graf, S.; Ergeneman, O.; Schmid, S.; Camenzind, A.; Nelson, B.J.; Hierold, C. Superparamagnetic photosensitive polymer nanocomposite for microactuators. In Proceedings of Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 869–872.

- Ergeneman, O.; Suter, M.; Chatzipirpiridis, G.; Zurcher, J.; Graf, S.; Pane, S.; Hierold, C.; Nelson, B.J. Characterization and actuation of a magnetic photosensitive polymer cantilever. In Proceedings of International Symposium on Optomechatronic Technologies, Istanbul, Turkey, 21–23 September 2009; pp. 266–270.

- Suter, M.; Ergeneman, O.; Zürcher, J.; Moitzi, C.; Pané, S.; Rudin, T.; Pratsinis, S.E.; Nelson, B.J.; Hierold, C. A photopatternable superparamagnetic nanocomposite: Material characterization and fabrication of microstructures. Sens. Actuators B Chem. 2011, 156, 433–443. [Google Scholar] [CrossRef]

- Suter, M.; Ergeneman, O.; Zürcher, J.; Schmid, S.; Camenzind, A.; Nelson, B.J.; Hierold, C. Superparamagnetic photocurable nanocomposite for the fabrication of microcantilevers. J. Micromech. Microeng. 2011, 21, 025023. [Google Scholar] [CrossRef]

- Peters, C.; Ergeneman, O.; García, P.D.W.; Müller, M.; Pané, S.; Nelson, B.J.; Hierold, C. Superparamagnetic twist-type actuators with shape-independent magnetic properties and surface functionalization for advanced biomedical applications. Adv. Funct. Mater. 2014. [Google Scholar] [CrossRef]

- Peters, C.; Ergeneman, O.; Sotiriou, G.A.; Pratsinis, S.E.; Nelson, B.J.; Hierold, C. Pushing the limits of photo-curable SU-8-based superparamagnetic polymer composites. In Proceedings of 2013 Transducers Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems, Barcelona, Spain, 16–20 June 2013; pp. 2676–2679.

- Chen, C.-T.; Chiu, C.-L.; Hsu, C.-Y.; Tseng, Z.-F.; Chuang, C.-T. Inkjet-Printed Polymeric Microstructures in n-Sided Regular Polygonal Cavities. J. Microelectromech. Syst. 2011, 20, 1001–1009. [Google Scholar] [CrossRef]

- Lu, J.-P.; Huang, W.-K.; Chen, F.-C. Self-positioning microlens arrays prepared using ink-jet printing. Opt. Eng. 2009, 48, 073606. [Google Scholar] [CrossRef]

- Chen, C.-T.; Tseng, Z.-F.; Chiu, C.-L.; Hsu, C.-Y.; Chuang, C.-T. Self-aligned hemispherical formation of microlenses from colloidal droplets on heterogeneous surfaces. J. Micromech. Microeng. 2009, 19, 025002. [Google Scholar] [CrossRef]

- Jacot-Descombes, L.; Gullo, M.R.; Cadarso, V.J.; Brugger, J. Fabrication of epoxy spherical microstructures by controlled drop-on-demand inkjet printing. J. Micromech. Microeng. 2012, 22, 074012. [Google Scholar] [CrossRef]

- Ondarcuhu, T.; Piednoir, A. Pinning of a contact line on nanometric steps during the dewetting of a terraced substrate. Nano Lett. 2005, 5, 1744–1750. [Google Scholar] [CrossRef]

- Chang, B.; Shah, A.; Routa, I.; Lipsanen, H.; Zhou, Q. Low-height sharp edged patterns for capillary self-alignment assisted hybrid microassembly. J. Micro-Bio Robot. 2014, 9, 1–10. [Google Scholar] [CrossRef]

- Jacot-Descombes, L.; Gullo, M.R.; Mastrangeli, M.; Cadarso, V.J.; Brugger, J. Inkjet printed SU-8 hemispherical microcapsules and silicon chip embedding. Micro Nano Lett. 2013, 8, 633–636. [Google Scholar] [CrossRef]

- Ergeneman, O.; Peters, C.; Gullo, M.R.; Jacot-Descombes, L.; Gervasoni, S.; Özkale, B.; Fatio, P.; Cadarso, V.J.; Mastrangeli, M.; Pané, S.; Brugger, J.; Hierold, C.; Nelson, B. Inkjet printed superparamagnetic polymer composite hemispheres with programmed magnetic anisotropy. Nanoscale 2014. [Google Scholar] [CrossRef]

- Ong, B.H.; Yuan, X.; Tao, S.; Tjin, S.C. Photothermally enabled lithography for refractive-index modulation in SU-8 photoresist. Opt. Lett. 2006, 31, 1367–1369. [Google Scholar] [CrossRef]

- Chen, C.-T.; Tu, K.-Z. Inkjet printing of individual polymer micro parts self-shaped with hemispherical caps. Sens. Actuators Phys. 2011, 188, 367–373. [Google Scholar] [CrossRef]

- Gao, M. Synthesis and Characterization of superparamagnetic Fe3O4@SiO2 core-shell composite nanoparticles. World J. Condens. Matter Phys. 2011, 1, 49–54. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Jacot-Descombes, L.; Gullo, M.R.; Cadarso, V.J.; Mastrangeli, M.; Ergeneman, O.; Peters, C.; Fatio, P.; Freidy, M.A.; Hierold, C.; Nelson, B.J.; et al. Inkjet Printing of High Aspect Ratio Superparamagnetic SU-8 Microstructures with Preferential Magnetic Directions. Micromachines 2014, 5, 583-593. https://doi.org/10.3390/mi5030583

Jacot-Descombes L, Gullo MR, Cadarso VJ, Mastrangeli M, Ergeneman O, Peters C, Fatio P, Freidy MA, Hierold C, Nelson BJ, et al. Inkjet Printing of High Aspect Ratio Superparamagnetic SU-8 Microstructures with Preferential Magnetic Directions. Micromachines. 2014; 5(3):583-593. https://doi.org/10.3390/mi5030583

Chicago/Turabian StyleJacot-Descombes, Loïc, Maurizio R. Gullo, Victor J. Cadarso, Massimo Mastrangeli, Olgaç Ergeneman, Christian Peters, Philipe Fatio, Mouhamad A. Freidy, Christofer Hierold, Bradley J. Nelson, and et al. 2014. "Inkjet Printing of High Aspect Ratio Superparamagnetic SU-8 Microstructures with Preferential Magnetic Directions" Micromachines 5, no. 3: 583-593. https://doi.org/10.3390/mi5030583