Implementation of Synchronous Micromotor in Developing Integrated Microfluidic Systems

Abstract

:1. Introduction

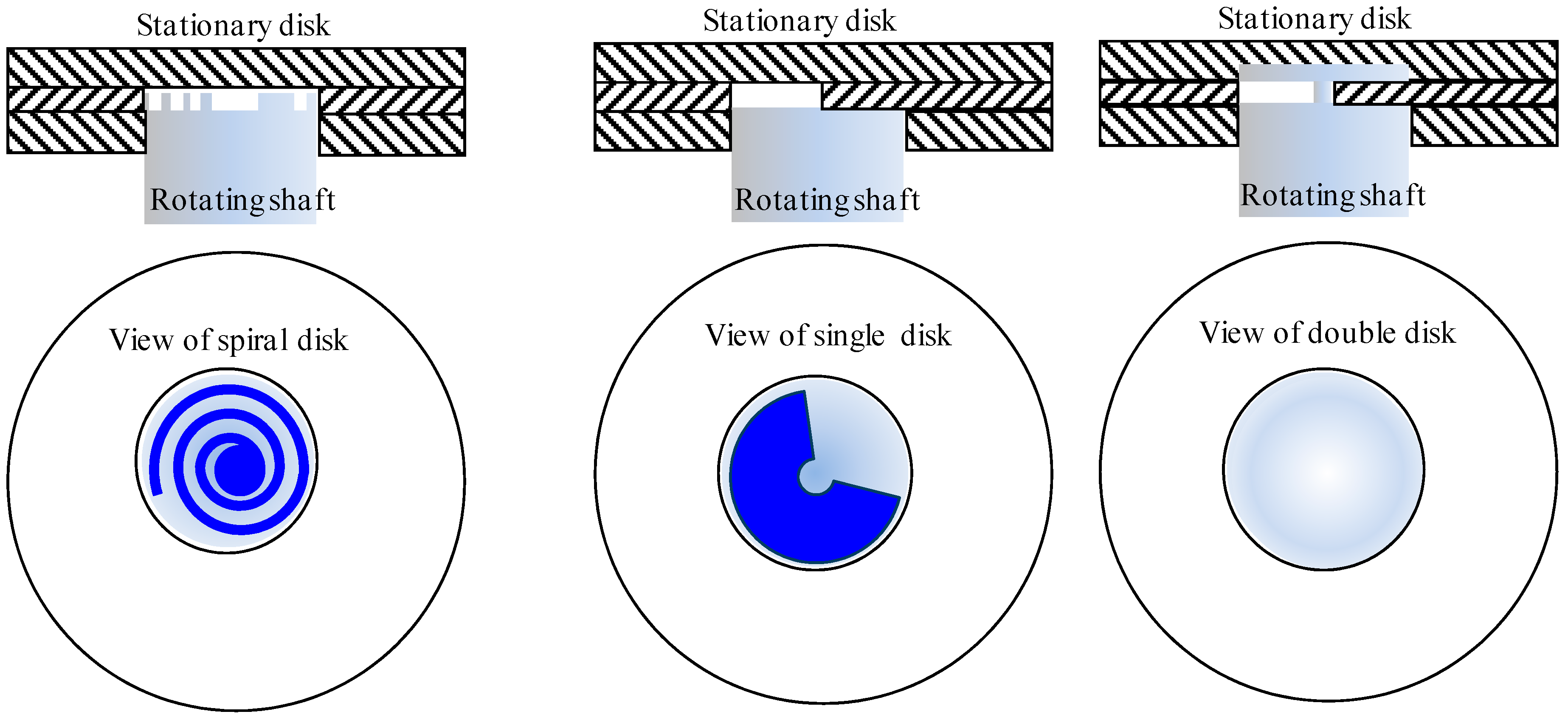

2. Externally Driven Microfluidic Systems

| Reference | Pump type | Rotor material | Fluid | w (rpm) | Drotor (mm) | Qmax (mL·min−1) |

|---|---|---|---|---|---|---|

| Blanchard et al., 2005 [9] | Single disk | stainless steel | Water | 5000 | 2.38 | 1.00 |

| Blanchard et al., 2005 [9] | Double disk | stainless steel | Water | 5000 | 2.38 | 2.10 |

| Blanchard et al., 2006 [10] | Single disk | PEEK plastic | Water | 5000 | 10.16 | 4.75 |

| Haik et al., 2007 [11] | Spiral channel | - | Water | 1200 | 25.4 | 46.66 |

| Al-Halhouli et al., 2008 [12] | Spiral channel | Aluminium | Glycerin | 4285 | 10 | 3.05 |

| Al-Halhouli et al., 2009 [8] | Spiral channel | SU-8 | Glycerin | 3065 | 6 | 1.17 |

| Lei and Li, 2004 [13] | Vortex pump | copper | Water | - | 4.5 | 2.45 |

| Waldschik and Büttgenbach [14] | Micro gear pump | SU-8 | Water | 150 | 7.5–10 | 0.15 |

| Present | Spiral channel | SU-8 | Water | 4500 | 4.5 | 1.02 |

3. Synchronous Micromotors Concept and Fabrication

4. Micromotor Operated Microfluidic Systems

4.1. Micro Gear Pump

is approximated by:

is approximated by:

4.2. Centrifugal Micropump

5. New Applications of Synchronous Micromotors in Microfluidic Systems

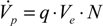

5.1. Spiral Channel Viscous Micropump

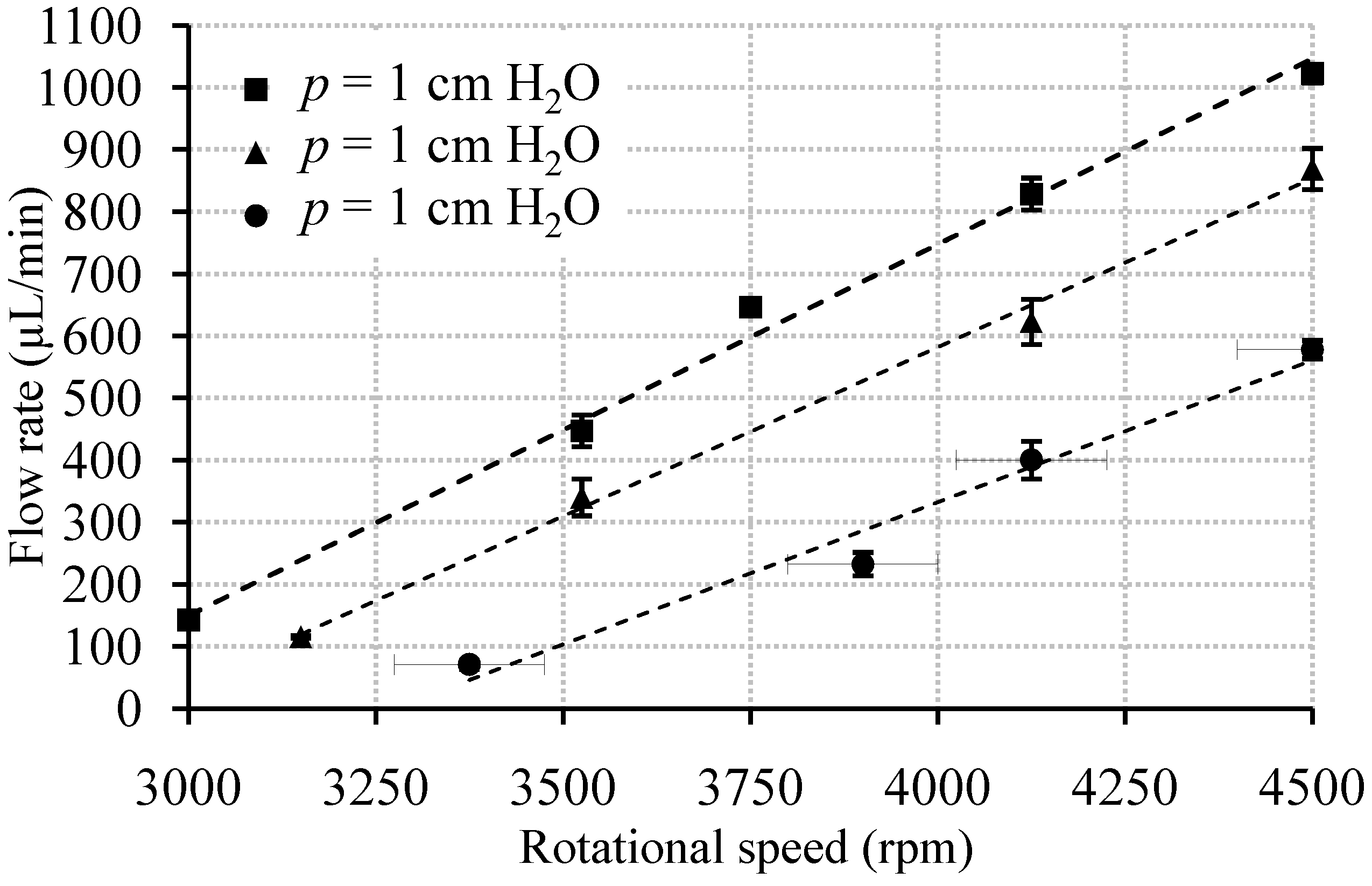

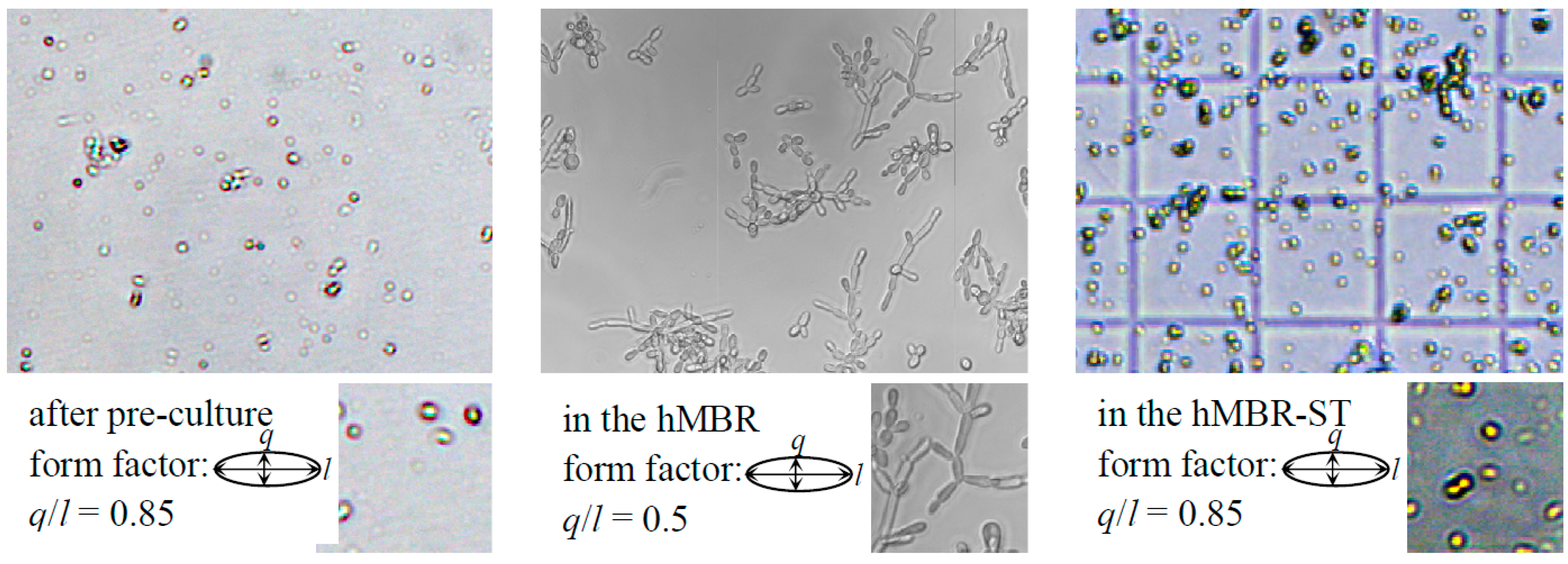

5.2. Microstirrer for Microbioreactor Application

6. Conclusions and Outlook for the Future

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Draft translation of the French standard NF E 01-010. Available online: http://www.thesame-innovation.com/Publi/Fichier/NF E 01-010_draft_translation.pdf (accessed on 10 July 2014).

- Büttgenbach, S.; Burisch, A.; Hesselbach, J. Design and Manufacturing of Active Microsystems; Springer: Berlin, Germany, 2011. [Google Scholar]

- Trimmer, W.S.N.; Gabriel, K.J. Design considerations for a practical electrostatic micro-motor. Sens. Actuators 1987, 11, 189–206. [Google Scholar] [CrossRef]

- Busch-Vishniac, I.J. The case for magnetically driven microactuators. Sens. Actuators A 1992, 33, 207–220. [Google Scholar] [CrossRef]

- Cugat, O.; Delamare, J.; Reyne, G. Magnetic micro-actuators and systems (MAGMAS). IEEE Trans. Magn. 2003, 39, 3607–3612. [Google Scholar] [CrossRef]

- Lorenz, H.; Despont, M.; Fahrni, N.; Brugger, J.; Vettiger, P.; Renaud, P. High-aspect-ratio, ultrathick, negative-tone near-UV photoresist and its application for MEMS. Sens. Actuators A 1998, 64, 33–39. [Google Scholar] [CrossRef]

- Hansen, S.; Gatzen, H.H. Development and Fabrication of Linear and Multi-Axis Microactuators. In Design and Manufacturing of Active Microsystems; Büttgenbach, S., Burisch, A., Hesselbach, J., Eds.; Springer: Berlin, Germany, 2011; pp. 225–244. [Google Scholar]

- Al-Halhouli, A.T. Recent advances in on-disk viscous micropumps. J. Microelectron. Electron. Packag. 2009, 6, 1–9. [Google Scholar]

- Blanchard, D.; Ligrani, P.; Gale, B. Single-disk and double-disk viscous micropumps. Sens. Actuators A 2005, 122, 149–158. [Google Scholar] [CrossRef]

- Blanchard, D.; Ligrani, P.; Gale, B. Miniature single-disk viscous pump (Single-DVP), performance characterization. J. Fluids Eng. 2005, 128, 602–610. [Google Scholar] [CrossRef]

- Haik, Y.; Kilani, M.I.; Hendrix, J.; Al Rifai, O.; Galambous, P. Flow field analysis in a spiral viscous micropump. Microfluid. Nanofluidics 2007, 3, 5527–5535. [Google Scholar]

- Al-Halhouli, A.T.; Demming, S.; Feldmann, M.; Büttgenbach, S.; Kilani, M.I.; Al-Salaymeh, A. Performance characterization of a miniature spiral-channel viscous pump. Sens. Actuators A 2008, 142, 256–262. [Google Scholar] [CrossRef]

- Lei, K.; Li, W. Vortex Micropump for Integrated Optically Transparent Microfluidic Chips. In Proceedings of the IEEE International Conference on Mechatronics and Machine Vision in Practice, Macau, China, 29 November–2 December 2004; pp. 219–225.

- Waldschik, A.; Büttgenbach, S. Micro gear pump with internal electromagnetic drive. Microsyst. Technol. 2010, 16, 1581–1587. [Google Scholar] [CrossRef]

- Blanchard, D.; Ligrani, P.; Gale, B.; Harvey, I. Micro-structure mechanical failure characterization using rotating Couette flow in a small gap. J. Micromech. Microeng. 2005, 15, 792–801. [Google Scholar] [CrossRef]

- Waldschik, A.; Feldmann, M.; Seidemann, V.; Büttgenbach, S. Development and Fabrication of Electromagnetic Microactuators. In Design and Manufacturing of Active Microsystems; Büttgenbach, S., Burisch, A., Hesselbach, J., Eds.; Springer: Berlin, Germany, 2011; pp. 207–224. [Google Scholar]

- Al-Halhouli, A.T.; Kilani, M.I.; Waldschik, A.; Phataralaoha, A.; Büttgenbach, S. Development and testing of a synchronous micropump based on electroplated coils and microfabricated polymer magnets. J. Micromech. Microeng. 2012, 22. [Google Scholar] [CrossRef]

- Waldschik, A.; Büttgenbach, S. Fabrication of internally driven micro centrifugal force pumps based on synchronous micro motors. Microsyst. Technol. 2010, 16, 1105–1110. [Google Scholar] [CrossRef]

- Lee, C.; Chen, Z. Valveless impedance micropump with integrated magnetic diaphragm. Biomed. Microdevices 2010, 12, 197–205. [Google Scholar] [CrossRef] [PubMed]

- Cha, K.J.; Kim, D.S. A portable pressure pump for microfluidic lab-on-a-chip systems using a porous polydimethylsiloxane (PDMS) sponge. Biomed. Microdevices 2011, 13, 877–883. [Google Scholar] [CrossRef] [PubMed]

- Rhie, W.; Higuchi, T. Design and fabrication of a screw-driven multi-channel peristaltic pump for portable microfluidic devices. J. Micromech. Microeng. 2010, 20. [Google Scholar] [CrossRef]

- Kilani, M.I.; Al-Salaymeh, A.; Al-Halhouli, A.T. Effect of channel aspect ratio on the flow performance of a spiral-channel viscous micropump. J. Fluids Eng. 2006, 128, 618–627. [Google Scholar] [CrossRef]

- Schäpper, D.; Alam, M.N.H.Z.; Scita, N.; Lantz, A.E.; Gernaey, K.V. Application of microbioreactors in fermentation process development: A review. Anal. Bioanal. Chem. 2009, 395, 679–695. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, A.K.; Atencia, J.; Beebe, D.J.; Jiang, H. Magnetically Driven Temperature-Controlled Microfluidic Actuators. In the Proceedings of 1st International Workshop on Networked Sensing Systems, Tokyo, Japan, 22–23 June 2004; pp. 51–55.

- Ryu, K.S.; Shaikh, K.; Goluch, E.; Fan, Z.; Liu, C. Micro magnetic stir-bar mixer integrated with parylene microfluidic channels. Lab Chip 2004, 4, 608–613. [Google Scholar] [CrossRef] [PubMed]

- Demming, S.; Llobera, A.; Wilke, R.; Büttgenbach, S. Single and multiple internal reflection poly(dimethylsiloxane) absorbance-based biosensors. Sens. Actuators B 2008, 139, 166–173. [Google Scholar] [CrossRef]

- Demming, S. Disposable Lab-on-Chip Systems for Biotechnological Screening. Ph.D. Thesis, Technische Universität Braunschweig, Braunschweig, Germany, 2010. [Google Scholar]

- Edlich, A. Entwicklung eines Mikroreaktors als Screening-Instrument für biologische Prozesse. Ph.D. Thesis, Technische Universität Braunschweig,, Braunschweig, Germany, 2010. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Al-Halhouli, A.; Demming, S.; Waldschik, A.; Büttgenbach, S. Implementation of Synchronous Micromotor in Developing Integrated Microfluidic Systems. Micromachines 2014, 5, 442-456. https://doi.org/10.3390/mi5030442

Al-Halhouli A, Demming S, Waldschik A, Büttgenbach S. Implementation of Synchronous Micromotor in Developing Integrated Microfluidic Systems. Micromachines. 2014; 5(3):442-456. https://doi.org/10.3390/mi5030442

Chicago/Turabian StyleAl-Halhouli, Ala'aldeen, Stefanie Demming, Andreas Waldschik, and Stephanus Büttgenbach. 2014. "Implementation of Synchronous Micromotor in Developing Integrated Microfluidic Systems" Micromachines 5, no. 3: 442-456. https://doi.org/10.3390/mi5030442

APA StyleAl-Halhouli, A., Demming, S., Waldschik, A., & Büttgenbach, S. (2014). Implementation of Synchronous Micromotor in Developing Integrated Microfluidic Systems. Micromachines, 5(3), 442-456. https://doi.org/10.3390/mi5030442