Metals 2023, 13(3), 457; https://doi.org/10.3390/met13030457 - 22 Feb 2023

Cited by 2 | Viewed by 1837

Abstract

The use of low frequency or DC (i.e., direct current) operation in the electroslag remelting process may lead to the electrolysis of some oxides in the slag pool, which will adversely affect the cleanliness of the electroslag ingot. In order to confirm this

[...] Read more.

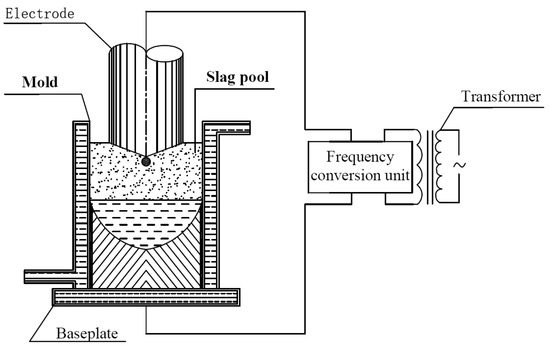

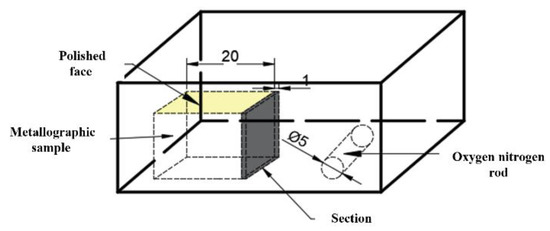

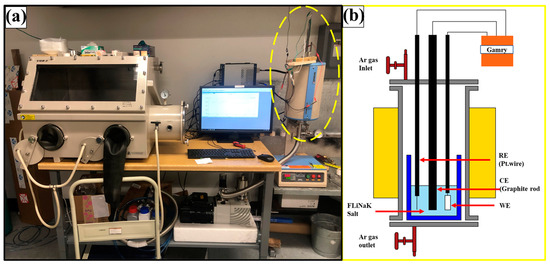

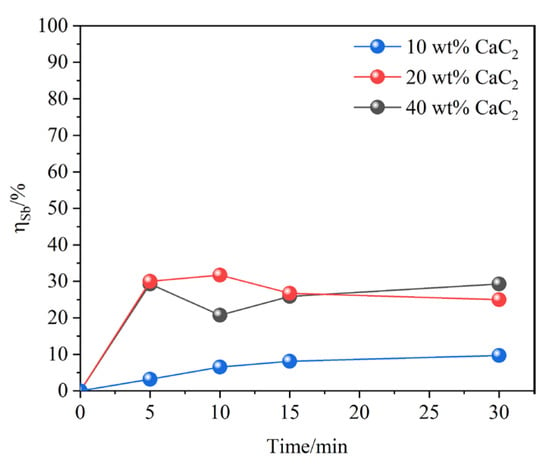

The use of low frequency or DC (i.e., direct current) operation in the electroslag remelting process may lead to the electrolysis of some oxides in the slag pool, which will adversely affect the cleanliness of the electroslag ingot. In order to confirm this view, the effect of different power supply modes on the oxygen content and inclusions in electroslag ingot has been studied by adopting the self-designed electroslag remelting furnace as experimental equipment. The pulse heating inert gas fusion-infra-red absorption method is used for analyzing oxygen content. The analysis of non-metallic inclusion is conducted using an automatic SEM (i.e., scanning electron microscope) made by the American ASPEX Company, where the inclusion type and the inclusion size are determined. Results show that the oxygen content in the electroslag ingot increase significantly compared with that in the consumable metal electrode, whether under the frequency of 50 Hz, low-frequency, or DC. When DCSP (i.e., the consumable electrode is connected to the cathode of the DC power supply), DCRP (i.e., the consumable electrode is connected to the anode of the DC power supply), 2 Hz, 10 Hz, and 50 Hz power supply modes are adopted, the oxygen content in electroslag ingot is 155.3 ppm, 100.4 ppm, 75.8 ppm, 66.3 ppm, and 43.2 ppm respectively. With the increase in oxygen content, the number of inclusions in electroslag ingots increases significantly, and the increased inclusions are mainly Al2O3 inclusions. Regardless of the power supply mode, the largest diameter of inclusion is less than 20 μm. The electrolysis of Al2O3 is the direct reason for the increase in oxygen in the electroslag ingot when CaF2-Al2O3 slag is used. With the decrease in frequency, the electrolysis trend increases, and the oxygen content and the number of inclusions also increase. However, most of the inclusions are regenerated with the decrease in metal pool temperature and solidification, so the size is fine.

Full article

(This article belongs to the Special Issue Advanced Tundish Metallurgy and Clean Steel Technology)

►

Show Figures