Optical and Surface Characterization of Radio Frequency Plasma Polymerized 1-Isopropyl-4-Methyl-1,4-Cyclohexadiene Thin Films

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

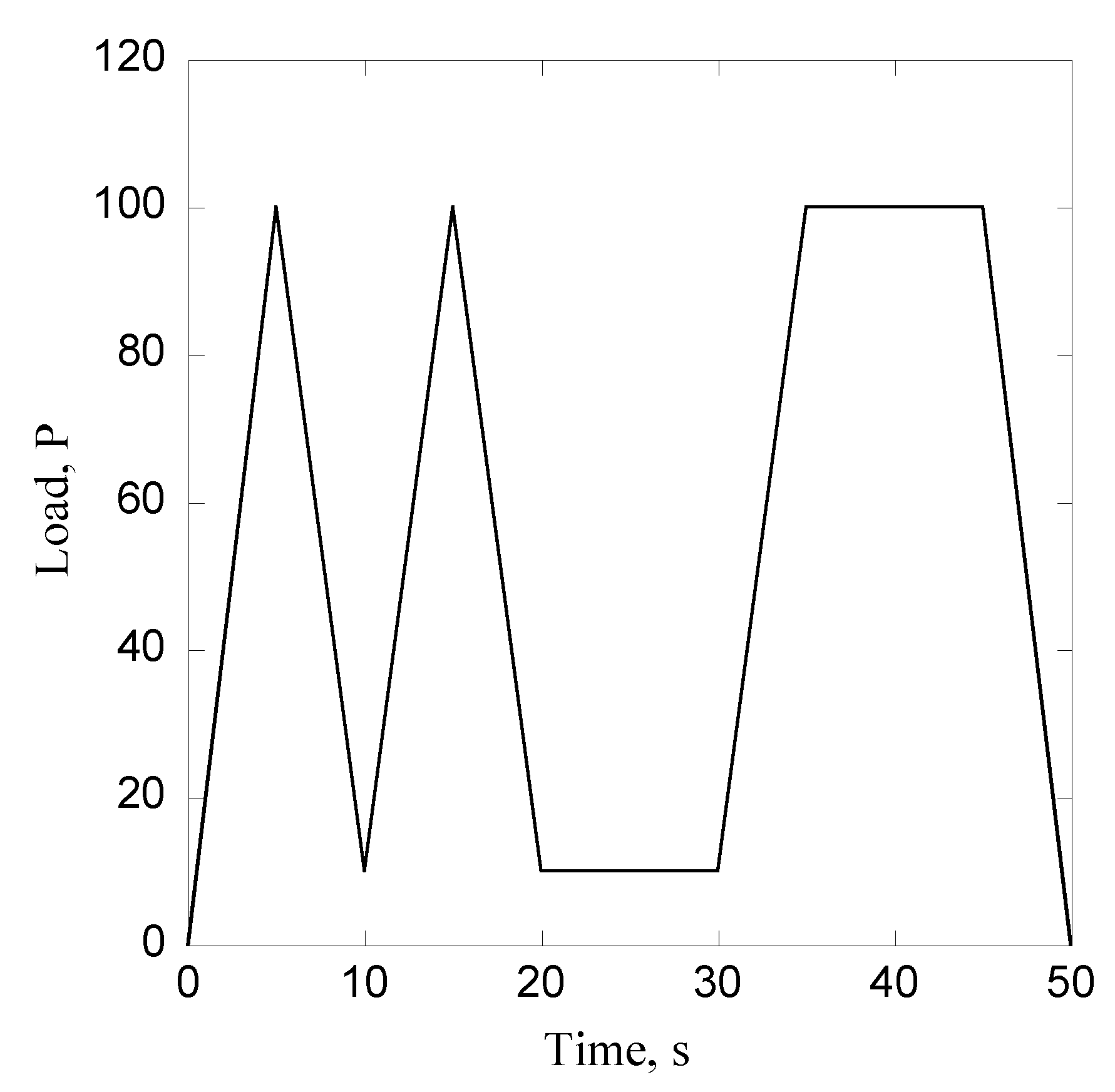

3.1. Effect of Time on Film Thickness

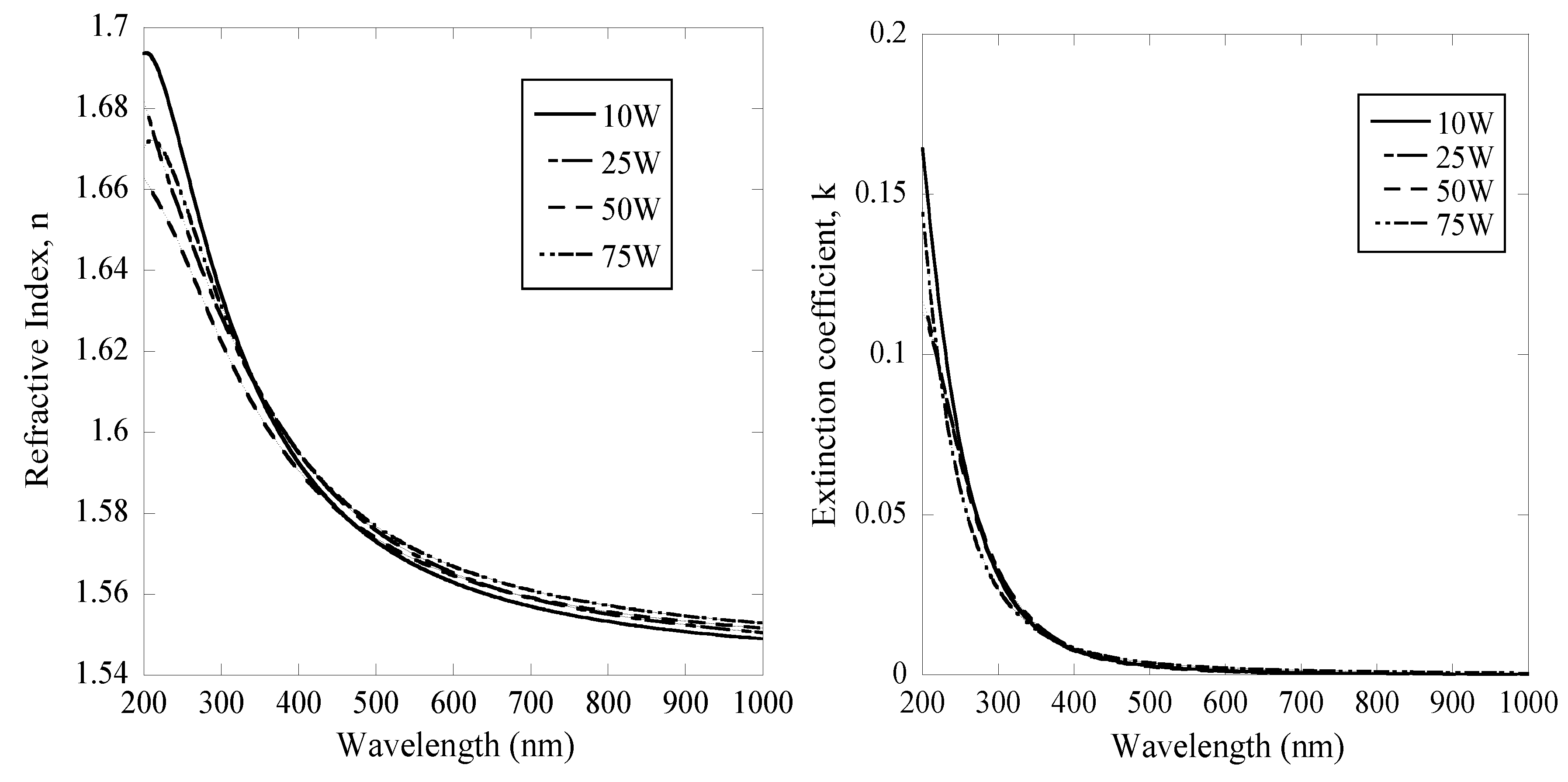

3.2. RF Power Dependence of Optical Constants

| RF Power (W) | vD |

|---|---|

| 10 | 35.37 |

| 25 | 35.18 |

| 50 | 37.80 |

| 75 | 40.35 |

3.3. Thickness Dependence of Optical Constants

3.4. Determination of the Energy Gap

| RF power (W) | Eg (eV) |

|---|---|

| 10 | 3.14 |

| 25 | 3.08 |

| 50 | 3.07 |

| 75 | 3.01 |

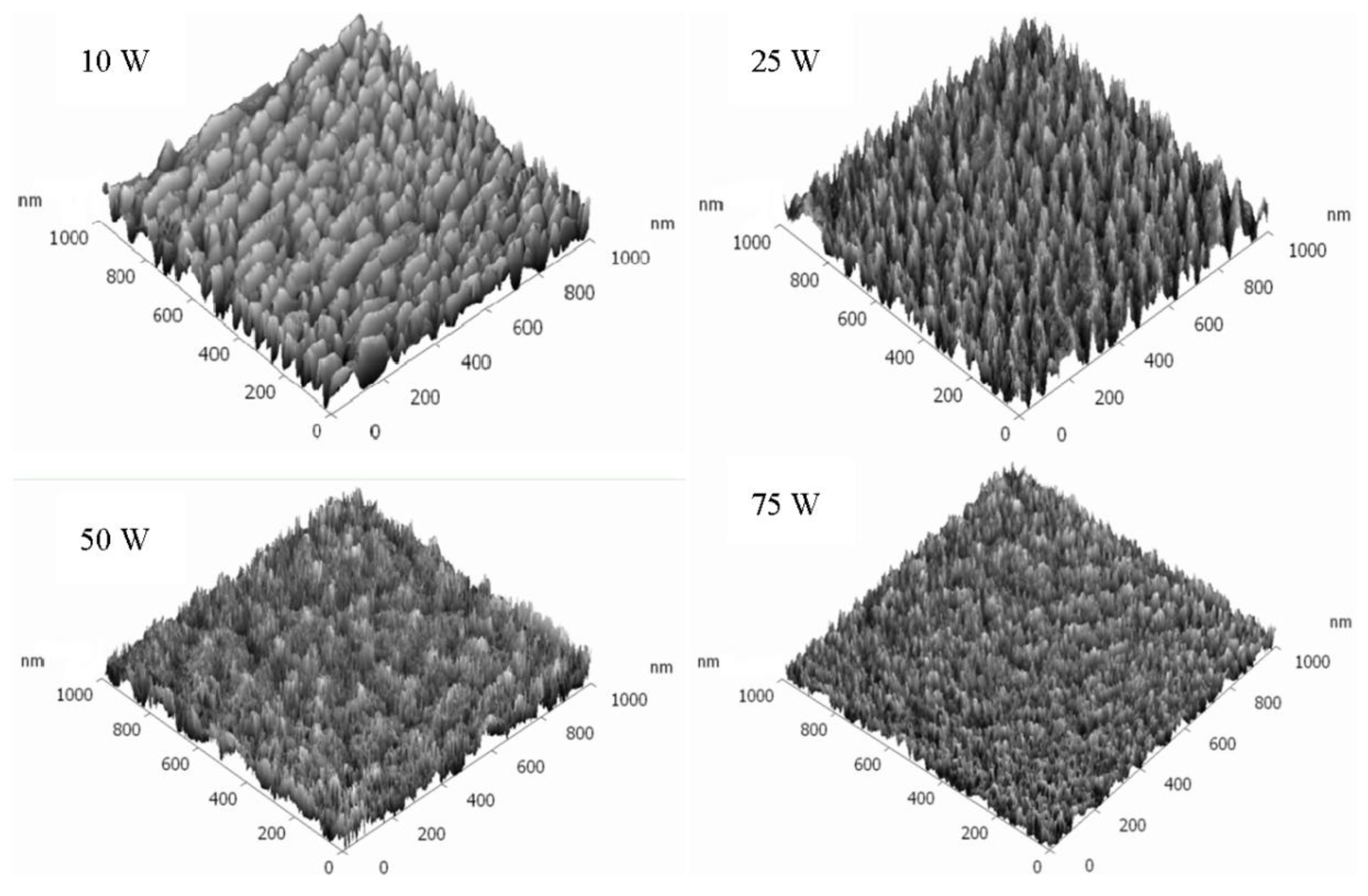

3.5. Surface Morphology

| Roughness parameters | 10 W | 25 W | 50 W | 75 W |

|---|---|---|---|---|

| Maximum peak height Rmax (nm) | 4.48 | 2.38 | 2.16 | 2.15 |

| Average roughness Ra (nm) | 0.30 | 0.28 | 0.25 | 0.21 |

| Root mean square Rq (nm) | 0.39 | 0.34 | 0.32 | 0.30 |

| Surface skewness Rsk | 0.32 | 0.22 | 0.14 | 0.08 |

| Coefficient of kurtosis Rkur | 0.06 | 0.54 | 0.63 | 0.77 |

| Entropy | 6.12 | 4.5 | 3.9 | 3.56 |

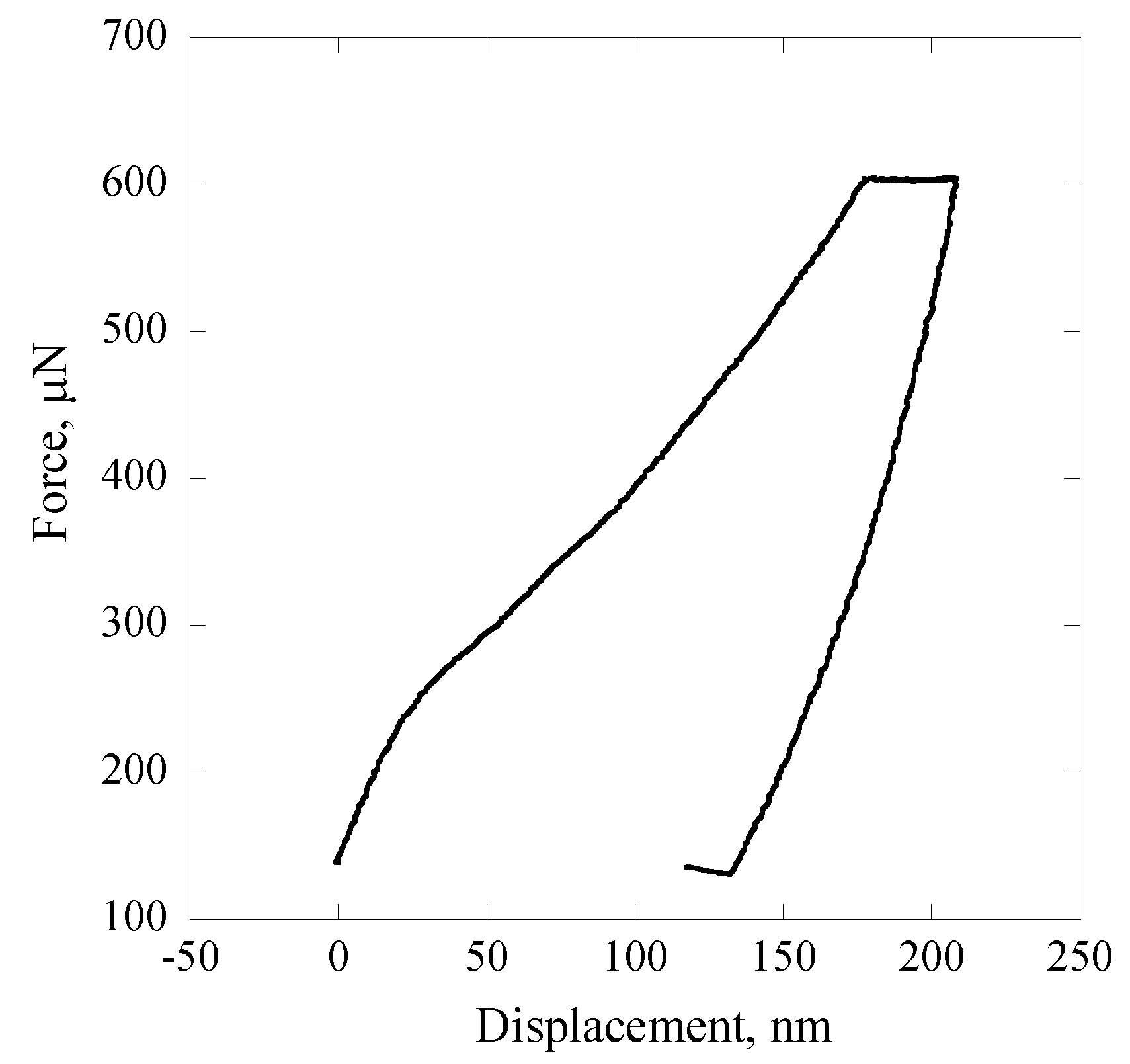

3.6. Nanoindentation

| RF power (W) | Contact depth, hc (nm) | Hardness, H ± SE (GPa) | Final depth, hf (nm) | Elastic modulus, E (GPa) |

|---|---|---|---|---|

| 10 | 221.5 | 0.40 ± 0.01 | 137.90 | 4.22 |

| 25 | 218.3 | 0.46 ± 0.02 | 102.53 | 4.61 |

| 50 | 211.7 | 0.51 ± 0.02 | 83.60 | 4.90 |

| 75 | 207.2 | 0.58 ± 0.03 | 69.76 | 5.96 |

3.7. Adhesion Study

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Jung, K.; Choi, W.-K.; Chae, K.H.; Song, J.-H.; Yoon, S.-J.; Lee, M.-H.; Choi, J.-W. Highly conductive and damp heat stable transparent ZnO based thin films for flexible electronics. J. Alloys Compd. 2013, 554, 240–245. [Google Scholar] [CrossRef]

- Dubal, D.P.; Holze, R. All-solid-state flexible thin film supercapacitor based on Mn3O4 stacked nanosheets with gel electrolyte. Energy 2013, 51, 407–412. [Google Scholar] [CrossRef]

- Qian, X.; Wang, T.; Yan, D. Transparent organic thin-film transistors based on high quality polycrystalline rubrene film as active layers. Org. Electron. 2013, 14, 1052–1056. [Google Scholar] [CrossRef]

- Ferguson, A.J.; Blackburn, J.L.; Kopidakis, N. Fullerenes and carbon nanotubes as acceptor materials in organic photovoltaics. Mater. Lett. 2013, 90, 115–125. [Google Scholar] [CrossRef]

- Kelly, F.M.; Meunier, L.; Cochrane, C.; Koncar, V. Polyaniline: Application as solid state electrochromic in a flexible textile display. Displays 2013, 34, 1–7. [Google Scholar] [CrossRef]

- He, H.; Xu, X.-B.; Zhang, D.-F. An aligned macro-porous carbon nanotube/waterborne polyurethane sensor for the detection of flowing organic vapors. Sens. Actuators B: Chem. 2013, 176, 940–944. [Google Scholar] [CrossRef]

- Curto, V.F.; Fay, C.; Coyle, S.; Byrne, R.; O’Toole, C.; Barry, C.; Hughes, S.; Moyna, N.; Diamond, D. Real-time sweat pH monitoring based on a wearable chemical barcode micro-fluidic platform incorporating ionic liquids. Sens. Actuators B: Chem. 2012, 171–172, 1327–1334. [Google Scholar] [CrossRef] [Green Version]

- Krebs, F.C. Alternative PV: Large scale organic photovoltaics. Refocus 2005, 6, 38–39. [Google Scholar] [CrossRef]

- Su, Y.-W.; Lan, S.-C.; Wei, K.-H. Organic photovoltaics—Review article. Mater. Today 2012, 15, 554–562. [Google Scholar] [CrossRef]

- Ahmad, J.; Bazaka, K.; Anderson, L.J.; White, R.D.; Jacob, M.V. Materials and methods for encapsulation of OPV: A review. Renew. Sustain. Energy Rev. 2013, 27, 104–117. [Google Scholar] [CrossRef]

- Lee, H.-J.; Kim, H.-P.; Kim, H.-M.; Youn, J.-H.; Nam, D.-H.; Lee, Y.-G.; Leeb, J.-G.; Yusoffa, A.R.M.; Jang, J. Solution processed encapsulation for organic photovoltaics. Sol. Energy Mater. Sol. Cells 2013, 111, 97–101. [Google Scholar] [CrossRef]

- Kim, N.; Graham, S. Development of highly flexible and ultra-low permeation rate thin-film barrier structure for organic electronics. Thin Solid Films 2013, 547, 57–62. [Google Scholar] [CrossRef]

- Cuddihy, E.; Coulbert, C.; Gupta, A.; Liang, R. Electricity from Photovoltaic Solar Cells: Flat-Plate Solar Array Project Final Report. Volume VII: Module Encapsulation; Jet Propulsion Laboratory: 1986. Available online: http://resolver.caltech.edu/JPLpub86-31-volumeVII (accessed on 17 April 2014).

- Kim, N. Fabrication and Characterization of Thin-Film Encapsulation for Organic Electronics. Ph.D. Thesis, Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA, USA, 2009. [Google Scholar]

- Spanggaard, H.; Krebs, F.C. A brief history of the development of organic and polymeric photovoltaics. Sol. Energy Mater. Sol. Cells 2004, 83, 125–146. [Google Scholar] [CrossRef]

- Shaheen, S.E.; Ginley, D.S.; Jabbour, G.E. Organic-Based Photovoltaics: Toward Low-Cost Power Generation. MRS Bull. 2005, 30, 10–19. [Google Scholar] [CrossRef]

- Forrest, S.R. The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 2004, 428, 911–918. [Google Scholar] [CrossRef]

- Vasilev, K.; Griesser, S.S.; Griesser, H.J. Antibacterial Surfaces and Coatings Produced by Plasma Techniques. Plasma Process. Polym. 2011, 8, 1010–1023. [Google Scholar] [CrossRef]

- Ostrikov, K.; Neyts, E.C.; Meyyappan, M. Plasma nanoscience: From nano-solids in plasmas to nano-plasmas in solids. Adv. Phys. 2013, 62, 113–224. [Google Scholar] [CrossRef]

- Michelmore, A.; Charles, C.; Boswell, R.W.; Short, R.D.; Whittle, J.D. Defining Plasma Polymerization: New Insight Into What We Should Be Measuring. ACS Appl. Mater. Interfaces 2013, 5, 5387–5391. [Google Scholar] [CrossRef]

- Rahman, M.J.; Bhuiyan, A.H. Structural and optical properties of plasma polymerized o-methoxyaniline thin films. Thin Solid Films 2013, 534, 132–136. [Google Scholar] [CrossRef]

- Jacob, M.V.; Easton, C.D.; Woods, G.S.; Berndt, C.C. Fabrication of a novel organic polymer thin film. Thin Solid Films 2008, 516, 3884–3887. [Google Scholar] [CrossRef]

- Jacob, M.V.; Olsen, N.S.; Anderson, L.; Bazaka, K.; Shanks, R.A. Plasma polymerised thin films for flexible electronic applications. Thin Solid Films 2013, 546, 167–170. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V. Nanotribological and nanomechanical properties of plasma-polymerized polyterpenol thin films. J. Mater. Res. 2011, 26, 2952–2961. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V.; Bowden, B.F. Optical and chemical properties of polyterpenol thin films deposited via plasma-enhanced chemical vapor deposition. J. Mater. Res. 2011, 26, 1018–1025. [Google Scholar] [CrossRef]

- Xu, Q.F.; Wang, J.N.; Sanderson, K.D. Organic−Inorganic Composite Nanocoatings with Superhydrophobicity, Good Transparency, and Thermal Stability. ACS Nano 2010, 4, 2201–2209. [Google Scholar] [CrossRef]

- Berggren, M.; Richter-Dahlfors, A. Organic bioelectronics. Adv. Mater. 2007, 19, 3201–3213. [Google Scholar] [CrossRef]

- Li, Y.X.; Yan, L.; Shrestha, R.P.; Yang, D.; Ounaies, Z.; Irene, E.A. A study of the optical and electronic properties of poly (vinylidene fluoride–trifluoroethylene) copolymer thin films. Thin Solid Films 2006, 513, 283–288. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V. Synthesis of radio frequency plasma polymerized non-synthetic Terpinen-4-ol thin films. Mater. Lett. 2009, 63, 1594–1597. [Google Scholar] [CrossRef]

- Kim, M.C.; Cho, S.H.; Han, J.G.; Hong, B.Y.; Kim, Y.J.; Yang, S.H.; Boo, J.-H. High-rate deposition of plasma polymerized thin films using PECVD method and characterization of their optical properties. Surf. Coat. Technol. 2003, 169–170, 595–599. [Google Scholar] [CrossRef]

- Anderson, L.J.; Jacob, M.V. Effect of RF power on the optical and morphological properties of RF plasma polymerised linalyl acetate thin films. Appl. Surf. Sci. 2010, 256, 3293–3298. [Google Scholar] [CrossRef]

- Pilla, P.; Iadicicco, A.; Contessa, L.; Campopiano, S.; Cutolo, A.; Giordano, M.; Guerra, G.; Cusano, A. Optical chemo-sensor based on long period gratings coated with δ form syndiotactic polystyrene. IEEE Photonics Technol. Lett. 2005, 17, 1713–1715. [Google Scholar] [CrossRef]

- Liu, J.-G.; Ueda, M. High refractive index polymers: Fundamental research and practical applications. J. Mater. Chem. 2009, 19, 8907–8919. [Google Scholar] [CrossRef]

- Enlow, J.O.; Jiang, H.; Grant, J.T.; Eyink, K.; Su, W.; Bunning, T.J. Plasma polymerized ferrocene films. Polymer 2008, 49, 4042–4045. [Google Scholar] [CrossRef]

- Okubo, T.; Kohmoto, S.; Yamamoto, M. Optical polymer having a high refractive index and high abbe number prepared by radical polymerization using 2,5-BiS(2-Thia-3-Butenyl)-1,4-Dithiane. J. Macromol. Sci. Part A 1998, 35, 1819–1834. [Google Scholar] [CrossRef]

- Dislich, H. Plastics as optical materials. Angew. Chem. Int. Ed. Engl. 1979, 18, 49–59. [Google Scholar] [CrossRef]

- Gaynor, J.F.; Desu, S.B. Optical properties of polymeric thin films grown by chemical vapor deposition. J. Mater. Res. 1996, 11, 236–242. [Google Scholar] [CrossRef]

- You, Z.Z.; Hua, G.J. Refractive index, optical bandgap and oscillator parameters of organic films deposited by vacuum evaporation technique. Vacuum 2009, 83, 984–988. [Google Scholar] [CrossRef]

- Fritz, S.E.; Kelley, T.W.; Frisbie, C.D. Effect of dielectric roughness on performance of pentacene TFTs and restoration of performance with a polymeric smoothing layer. J. Phys. Chem. B 2005, 109, 10574–10577. [Google Scholar] [CrossRef]

- Hu, X.; Zhao, X.; Uddin, A.; Lee, C.B. Preparation, characterization and electronic and optical properties of plasma-polymerized nitriles. Thin Solid Films 2005, 477, 81–87. [Google Scholar] [CrossRef]

- Tien, C.-L.; Lyu, Y.-R.; Jyu, S.-S. Surface flatness of optical thin films evaluated by gray level co-occurrence matrix and entropy. Appl. Surf. Sci. 2008, 254, 4762–4767. [Google Scholar] [CrossRef]

- Johnston, E.E.; Ratner, B.D. Surface characterization of plasma deposited organic thin films. J. Electron Spectrosc. Relat. Phenom. 1996, 81, 303–317. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Shi, F.F. Recent advances in polymer thin films prepared by plasma polymerization Synthesis, structural characterization, properties and applications. Surf. Coat. Technol. 1996, 82, 1–15. [Google Scholar] [CrossRef]

- Bull, S.J. Nanoindentation of coatings. J. Phys. D 2005, 38, R393. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Constantinescu, A. The influence of indenter bluntness on the apparent contact stiffness of thin coatings. Thin Solid Films 2009, 517, 4835–4844. [Google Scholar] [CrossRef]

- Zhao, M.; Xiang, Y.; Xu, J.; Ogasawara, N.; Chiba, N.; Chen, X. Determining mechanical properties of thin films from the loading curve of nanoindentation testing. Thin Solid Films 2008, 516, 7571–7580. [Google Scholar] [CrossRef]

- Tarefder, R.; Faisal, H. Effects of dwell time and loading rate on the nanoindentation behavior of asphaltic materials. J. Nanomech. Micromech. 2013, 3, 17–23. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ahmad, J.; Bazaka, K.; Jacob, M.V. Optical and Surface Characterization of Radio Frequency Plasma Polymerized 1-Isopropyl-4-Methyl-1,4-Cyclohexadiene Thin Films. Electronics 2014, 3, 266-281. https://doi.org/10.3390/electronics3020266

Ahmad J, Bazaka K, Jacob MV. Optical and Surface Characterization of Radio Frequency Plasma Polymerized 1-Isopropyl-4-Methyl-1,4-Cyclohexadiene Thin Films. Electronics. 2014; 3(2):266-281. https://doi.org/10.3390/electronics3020266

Chicago/Turabian StyleAhmad, Jakaria, Kateryna Bazaka, and Mohan V. Jacob. 2014. "Optical and Surface Characterization of Radio Frequency Plasma Polymerized 1-Isopropyl-4-Methyl-1,4-Cyclohexadiene Thin Films" Electronics 3, no. 2: 266-281. https://doi.org/10.3390/electronics3020266