1. Introduction

Precision turning plays an important role in manufacturing industry. The products made by turning process include automotive components, aerospace parts, and precise industrial parts, etc. Turning accuracy is mainly influenced by the accuracy of the machine, the condition of the cutter, cutting parameters, and environmental conditions, such as external vibration, the environment temperature, etc. Since tool wear could cause more cutting resistance, machining vibration, machining temperature, and machining errors, it usually needs on-line monitoring of the status of tool wear and compensating of the tool wear via offsetting the tool position for the next machining process.

To receive a better performance from a machining process, Greg

et al. carried out a series of research activities [

1,

2] on improving the multi-gene genetic programming approach. They proposed a modified multi-gene genetic programming (M-MGGP) method using a stepwise regression approach in which the lower-performance genes were eliminated and the high-performing genes were combined. Validation was carried out by applying surface roughness to modeling when turning hardened American Iron and Steel Institute (AISI) H11 steel, and the results showed that M-MGGP has better performance than that of standard MGGP and other methods. They also proposed a new complexity-based multi-gene genetic programming approach in which the functional relationships between the energy consumption and the input process parameters of a milling process were obtained to find an optimum set of input settings; this will conserve a greater amount of energy from these operations. To improve the generalization ability of MGGP, Greg

et al. [

3] developed a new ensemble-based MGGP framework that used statistical and classification strategies. The method was applied on the reliable experimental database in which the outputs were surface roughness, tool life and power consumption. With the use of an embedded approach to molecular dynamics and MGGP, Greg

et al. [

4] proposed a method to investigate the thermal property of single-layer graphene sheet. In this study, the response of thermal conductivity of the graphene sheet with changes in system temperature and Stone-Thrower-Wales (STW) defect concentration was analyzed. In addition, they [

5] also used an explicit model formulated by a molecular dynamics-based computational intelligence approach and a paradigm of a computational intelligence (CI) cluster comprising genetic programming to study the nano-drilling process of boron nitride nanosheet panels.

Much research related to tool wear prediction and monitoring had been carried out in past years. Usui

et al. [

6] proposed a method of cutter wear prediction for certain cutting condition, and conducted verification cutting experiments. With the use of different sensor signals, Dimla

et al. [

7] proposed a monitoring method of cutter wear. Li

et al. [

8] proposed methods for cutter wear inspection and failure diagnosis, which could predict the influence of surface quality of the machined work piece caused by cutter wear. Choi

et al. [

9] developed an intelligent monitoring system which could provide on-line monitoring of the wear condition of the turning tool. Prickett

et al. studied [

10] the ways for monitoring the condition of end mills. With the use of the neural network method, Risbood

et al. [

11] proposed a way to predict the dimension errors caused by cutting force and radial cutting vibration. Panda

et al. [

12] used a back-propagation neural network (BPN) to predict the status of tool wear to avoid cutter breakage.

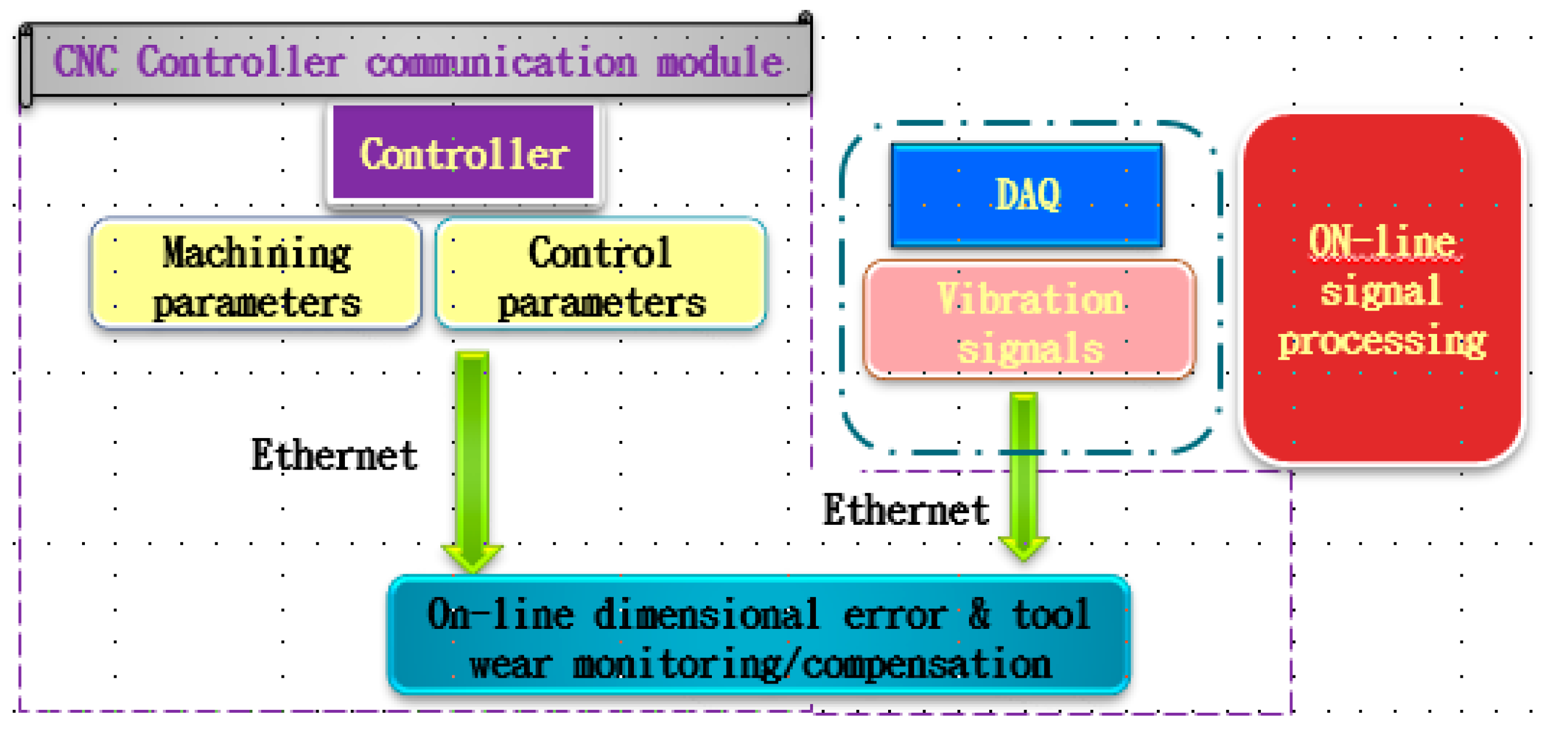

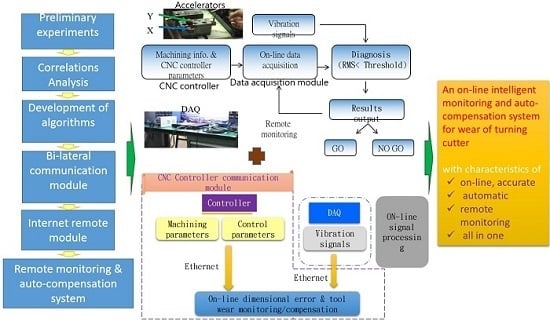

In order to meet the requirements of tight tolerance and high production yield rates for production, in-process tool wear monitoring and compensation and in-process quality inspection are usually developed and become a part of the manufacturing process. However, because those processes are off-machine or manual, they take more time and incur greater costs due to the additional measurement and inspection instruments and work hours. With the use of the on-line diagnosis method, information and communication technology (ICT), and the empirical statistics method, an on-line monitoring and auto-compensation system for the wear of the turning cutter was developed in this study. The system predicts the machining quality inspection and status of the cutter based on the analysis of on-line turning vibration and machining information while turning is operational. Subsequently, the predicted tool wear will be auto-compensated to the computer numerical control (CNC) controller for next turning work. The method was implemented on an automotive component production line, and both of the original off-machine quality inspection and the manually tool wear compensation were able to be eliminated and replaced by the proposed method.

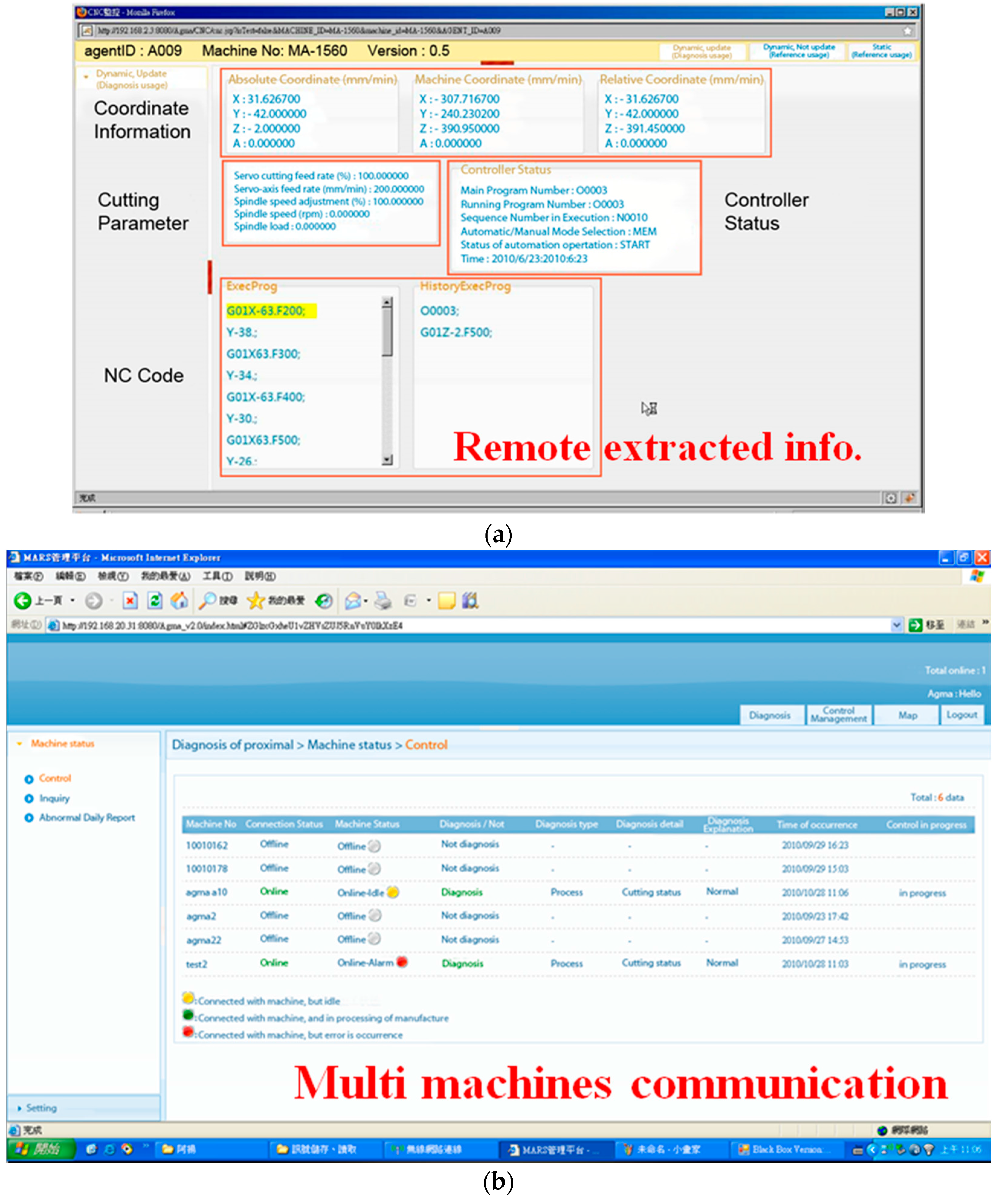

In the study, preliminary experiments were first conducted to collect the data so that the correlations between the variation of cutting vibration signals, cutter wear, and machining errors could be obtained. The diagnosis algorithms were then developed based on the correlations. Lots of experimental data were collected to analyze the characteristics of tool wear and determine the compensation value for tool wear. Based on the statistical analysis and the developed algorithms, a monitoring system with an auto-compensation function was built. Furthermore, adopting FANUC Open CNC API (application programming interface) Specification provided by FANUC Co., Oshino-mura, Japan, a bilateral communication module for a CNC controller was developed with the ability for on-line communication with the CNC controller in order to extract cutting information (such as instantly executing NC (numerical control) codes, coordinates, and the number of cuts, etc.) and send compensation commands to the CNC controller for the predicted tool wear. The module can also save all the monitoring results and information to a remote central computer for continuous engineering improvement in the future. An interface with functions of data acquisition, inspection, and error compensation was developed in C# language for easy operation. Finally, experiments on a CNC turning machine were conducted to verify the feasibility and effectiveness of the proposed system.

2. Preliminary Experiments

An automotive component (

Figure 1) (GlobalTek, Taoyuan, Taiwan) made of steel (SAE 1018) was chosen for the experiment. Two finish turning processes for the automotive component were used as an implementation object in this study: (1) T03—finishing for the inner diameter; (2) T04—finishing for the outer diameter. Different tungsten turning tools with Chemical vapor deposition (CVD) coatings of TiCN + Al

2O

3 + TiN were used in the two turning processes. The automotive components was produced on a mass production line. According to the manufacturing requirement, production needs to have a quality inspection of 100%, especially for the inner and outer diameters. Therefore, after the T04 and T03 processes finished, the work pieces were removed from the turning machine for outer/inner-diameter inspection with four air gauge instruments (GlobalTek, Taoyuan, Taiwan). The differences in inspected errors between two consecutive work pieces were regarded as the influence of tool wear, and were used as the tool wear compensation values which were manually inputted in the CNC controller (FANUC, Tokyo, Japan).

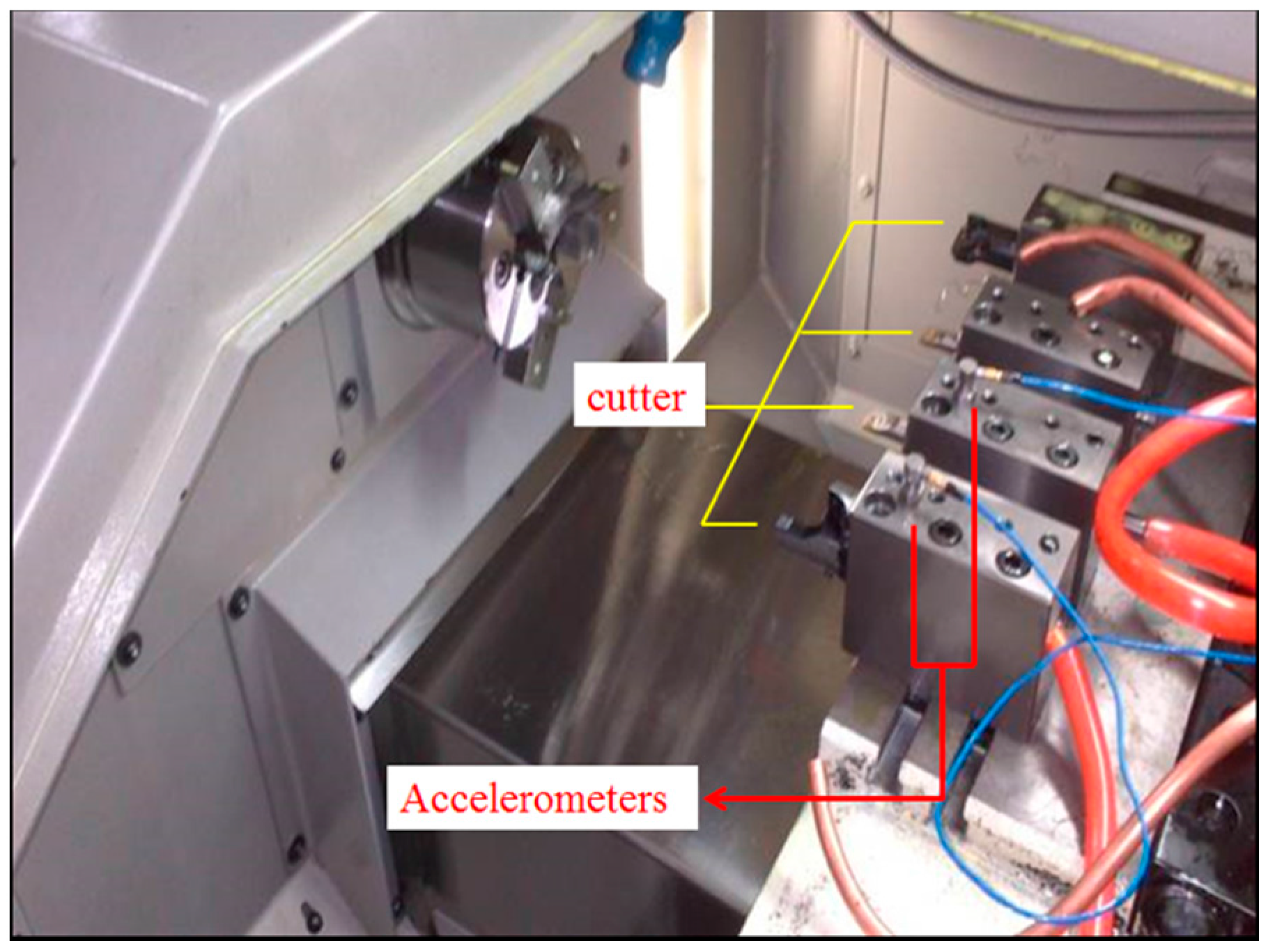

The preliminary experiments were designed to understand three phenomena: (1) the characteristics of the cutting vibration caused by machining force and tool wear; (2) the correlation between the depth of cut and cutting vibration; (3) the correlation between vibration signals and machining quality. The experimental results were used to design the algorithms for dimension inspection and tool wear compensation. The experimental analysis includes: (1) the correlation between dimension error and cutting vibration; (2) an investigation of the vibration pattern caused by tool wear. In order to carry out on-line collection the cutting vibration signals for analysis, two accelerometers (PCB Piezatronics Inc., Depew, NY, USA) were attached to the tool posts (

Figure 2), which are close to the work piece to collect the actual vibration signals.

2.1. Correlation between Dimension Error and Cutting Vibration

Tool wear could influence the depth of cut, and the variation of the depth of cut could cause changes to the cutting vibration. Variation in the depth of cut could also cause dimension errors in the component. Using cutting vibration as an index of tool wear, it is very important to ensure that the cutting vibration is sensitive enough to identify the occurrence of tool wear, and sensitive enough to differentiate the variation in the dimension errors.

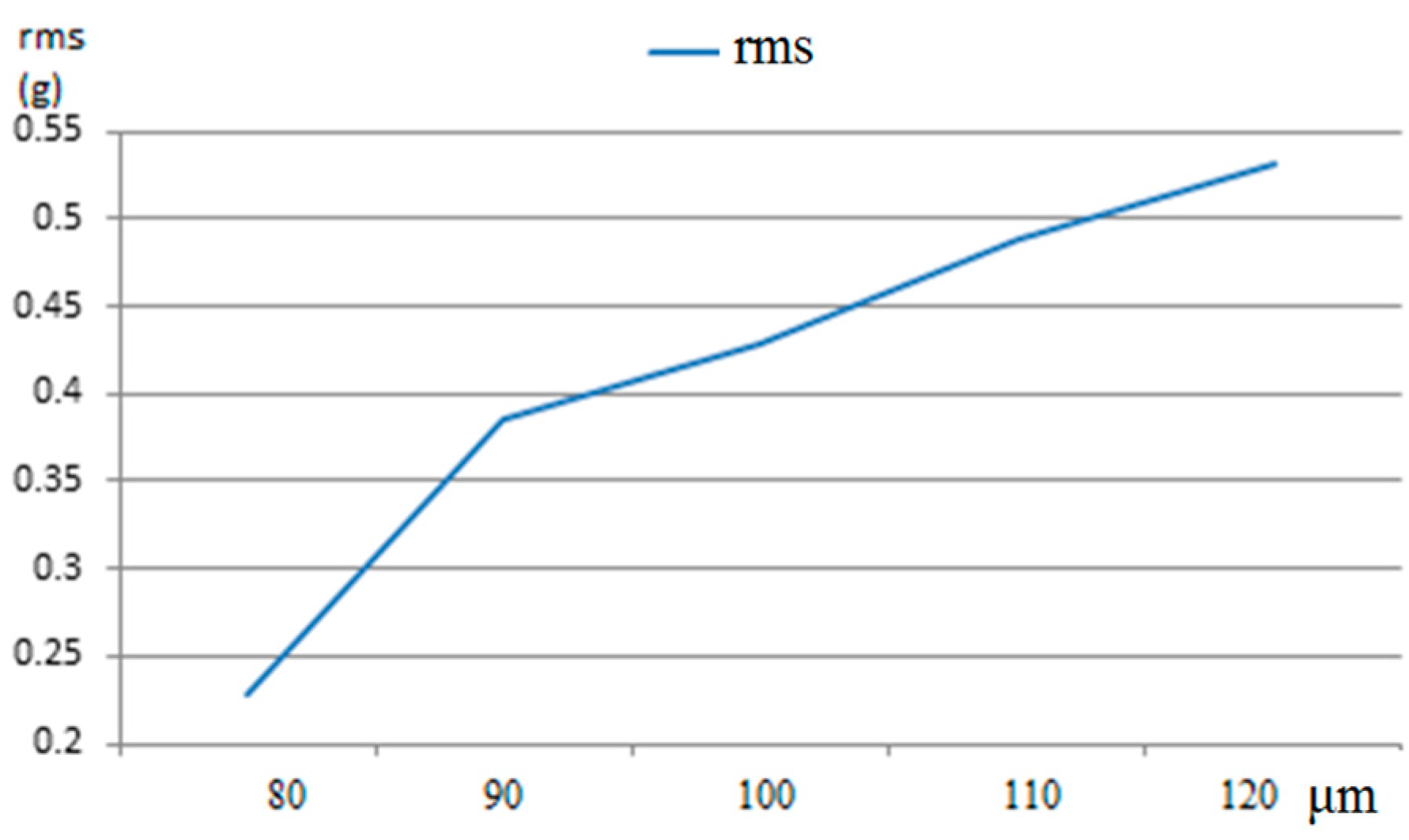

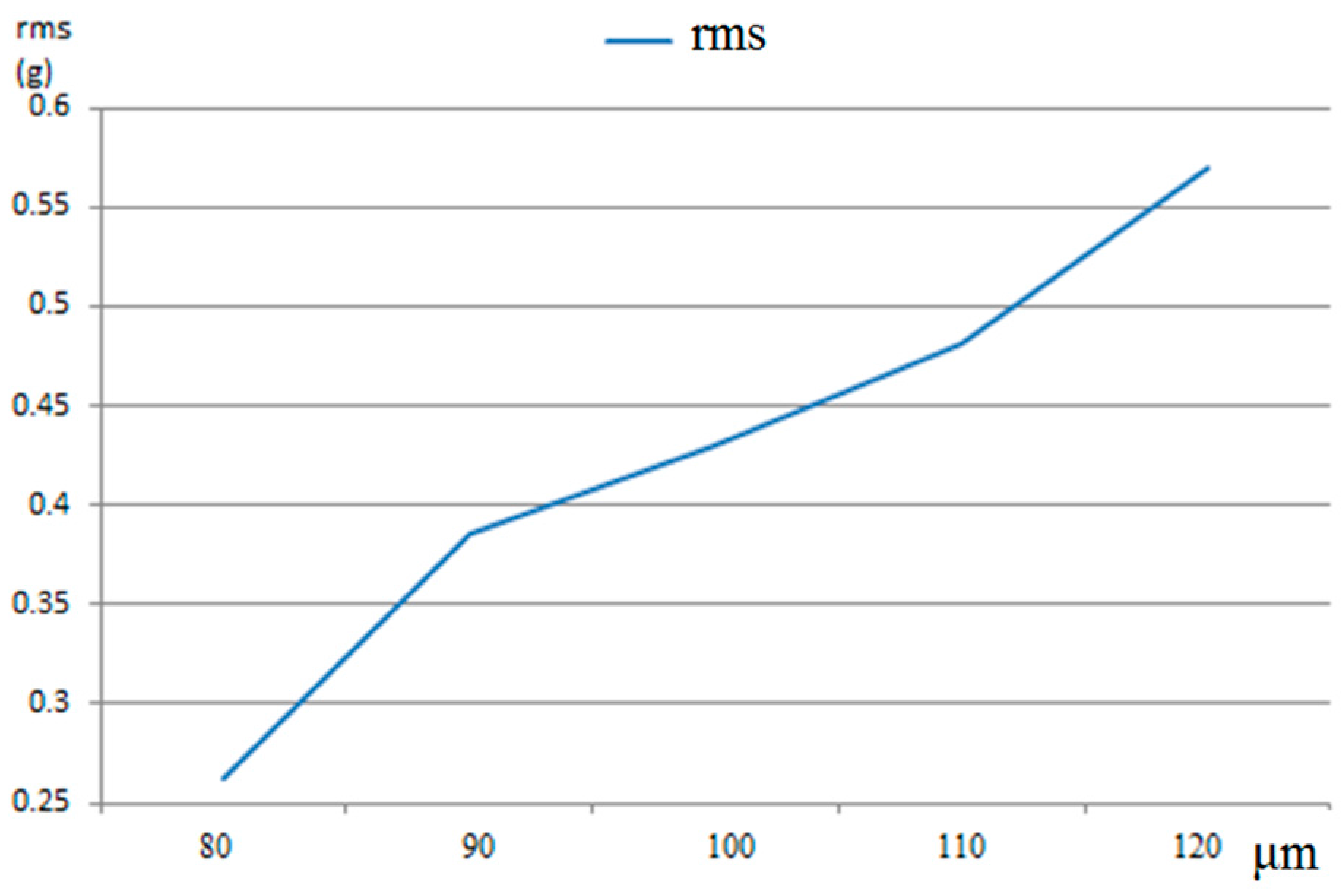

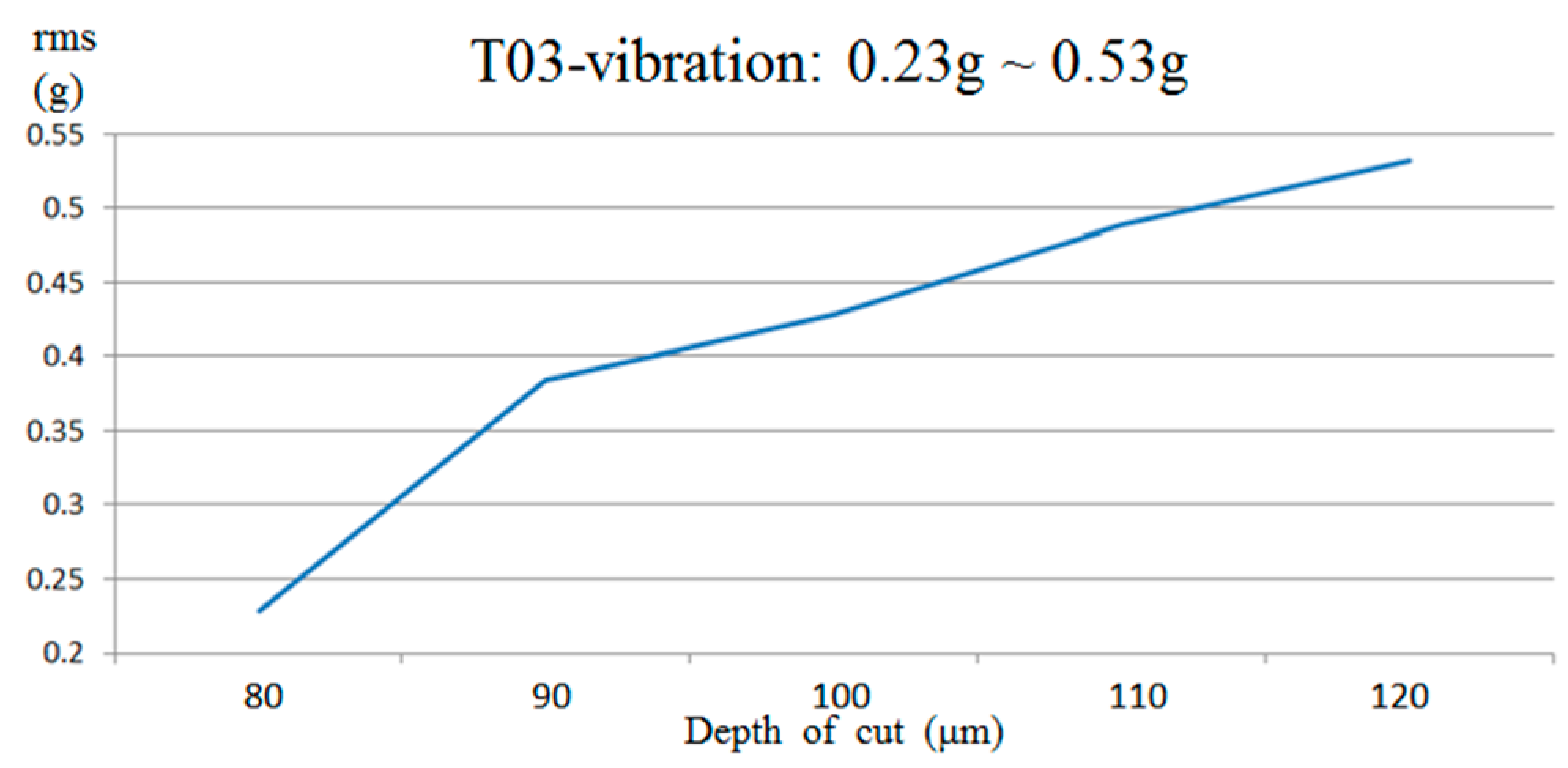

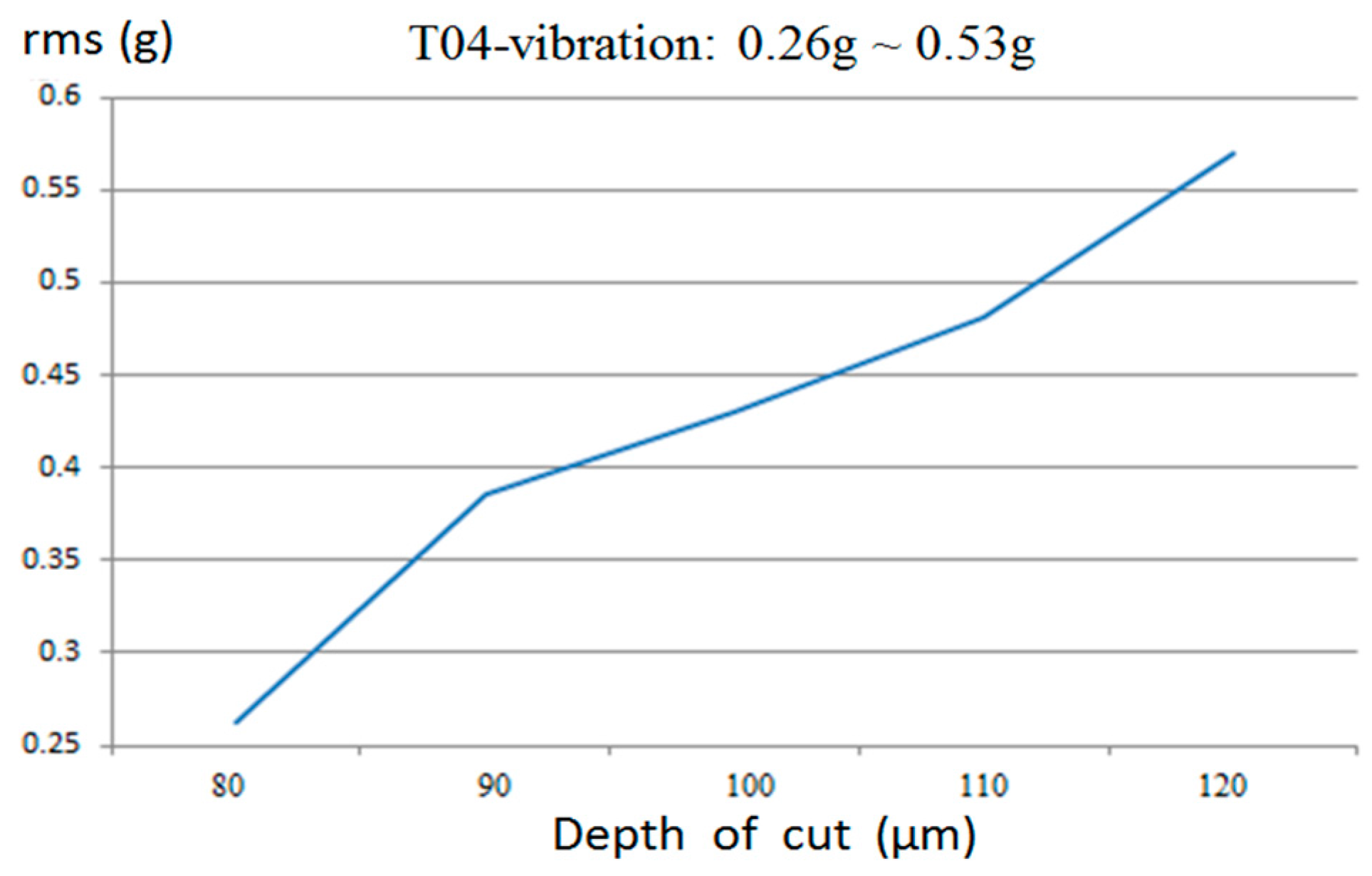

The experiment started with 0.08 mm for the depth of cut, and increased by 0.01 mm each time to 0.12 mm. The cutting vibration for each cut was measured by the accelerometers, and root-mean-square values of the vibration were calculated.

Figure 3 and

Figure 4, respectively, show the correlation of the depth of cut and cutting vibration for T03 and T04. It is noted that the cutting vibration is nearly linear in proportion to the depth of cut (0.05 g/0.01 mm), and the depth of cut can be estimated based on the measured vibration of a stable machining process. The same experiment was repeated 14 times, and the results were very repeatable.

2.2. Investigation of Tool Wear Patterns and Cutting Vibration Patterns

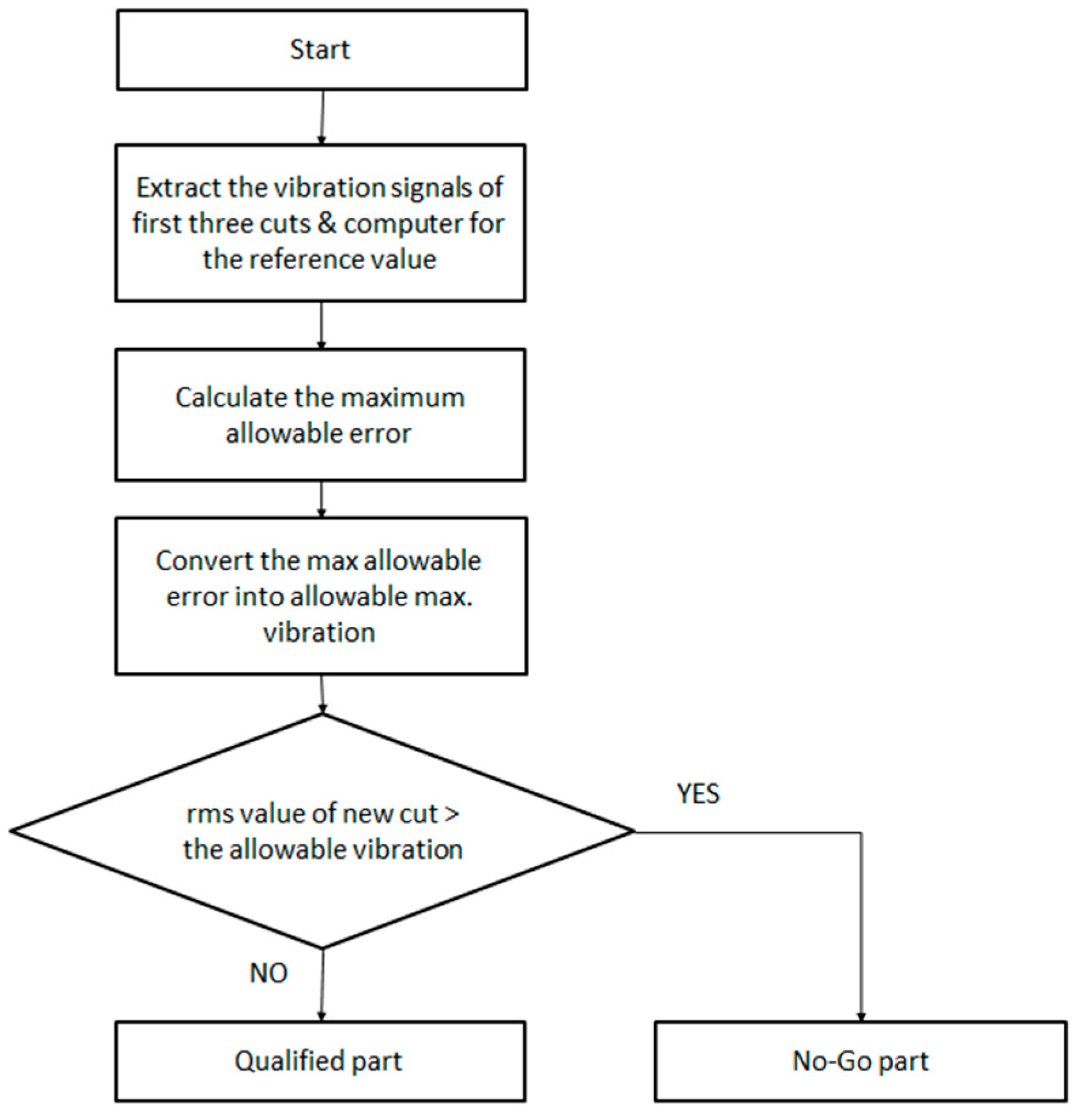

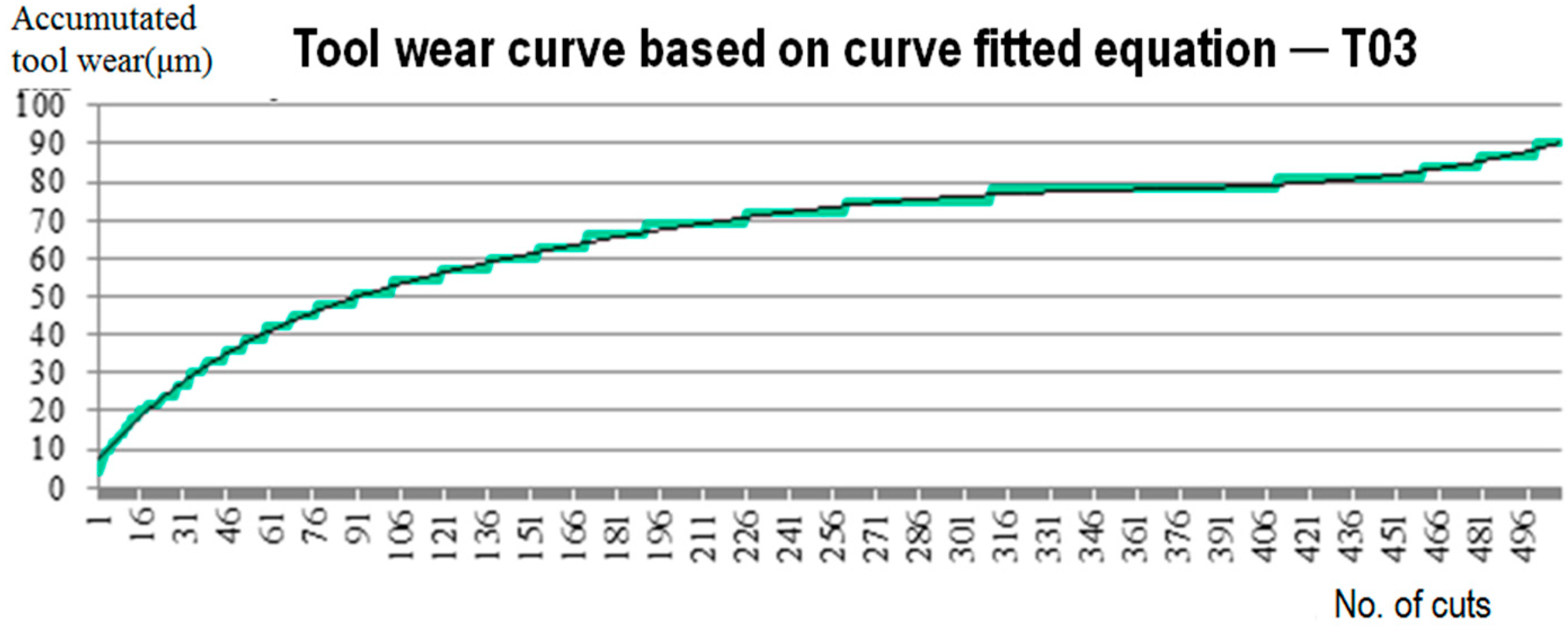

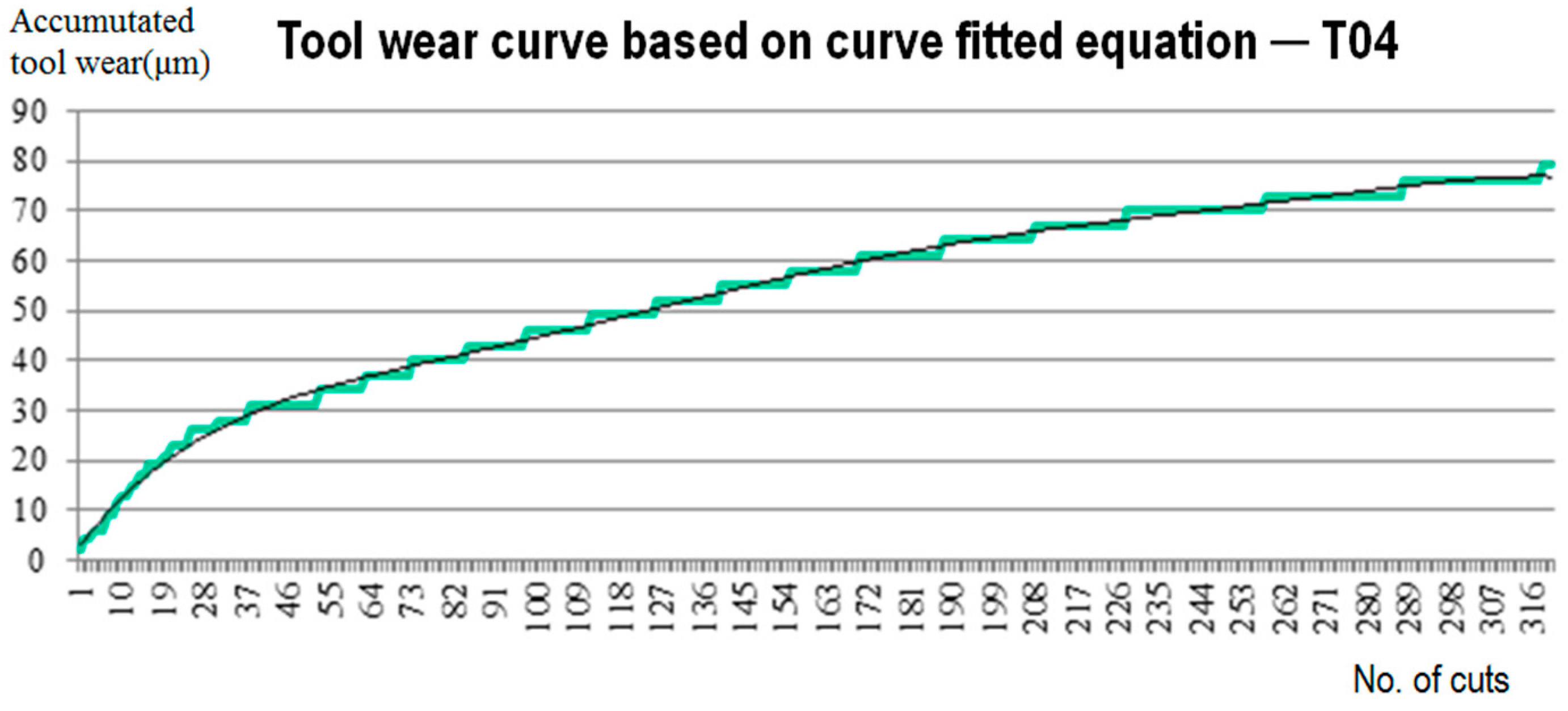

In a stable machining process, when the number of cuts increases, the tool wear of a cutter increases with a repeatable pattern. Through empirical analysis, the correlation of tool wear and the number of cuts can be obtained and used to build the pattern. Subsequently, the pattern can be used to check whether the tool wear increases normally or not. If the tool wear increases following the pattern, it could be estimated based on the statistical model built with collected experimental data.

In the preliminary experiments, the machining processes T03 and T04 were consecutively conducted, and the relationship between tool wear and its associated numbers of cuts was investigated. The tool wear was measured using a vision-based measurement system.

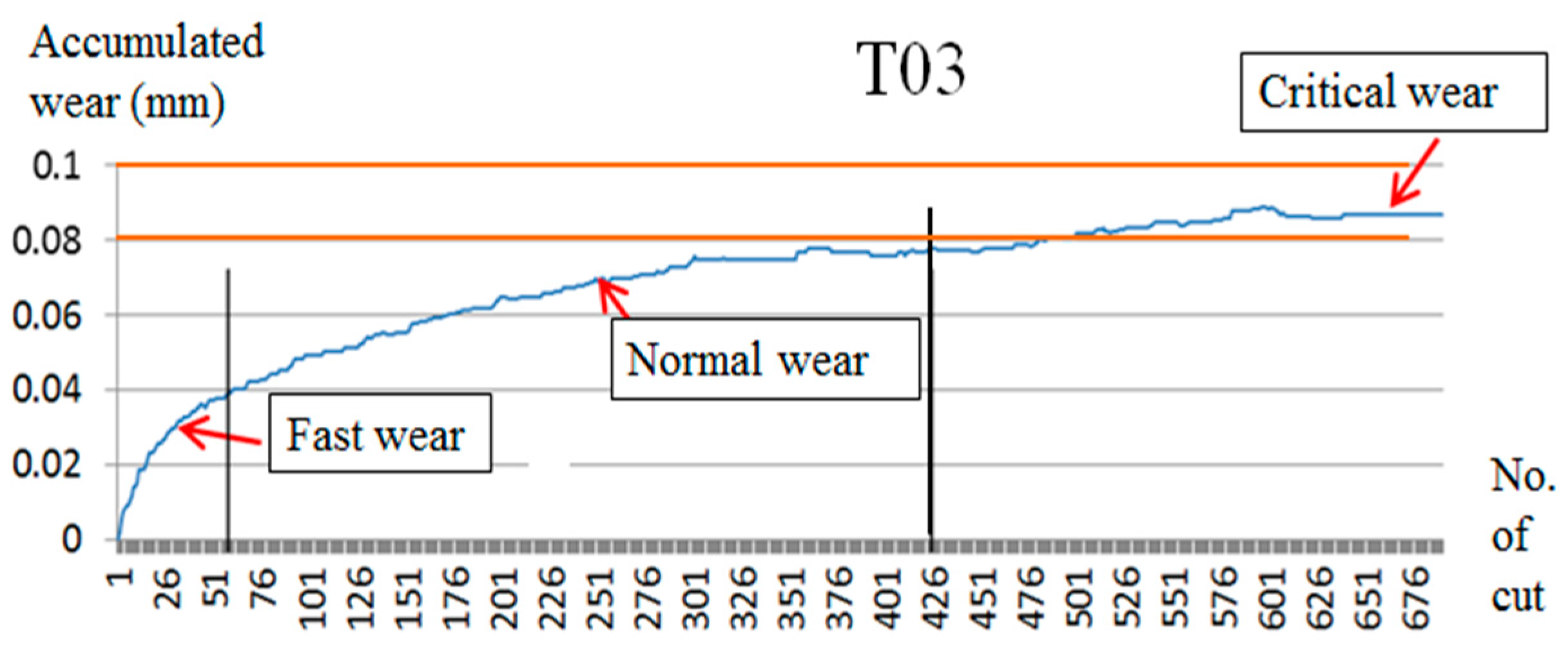

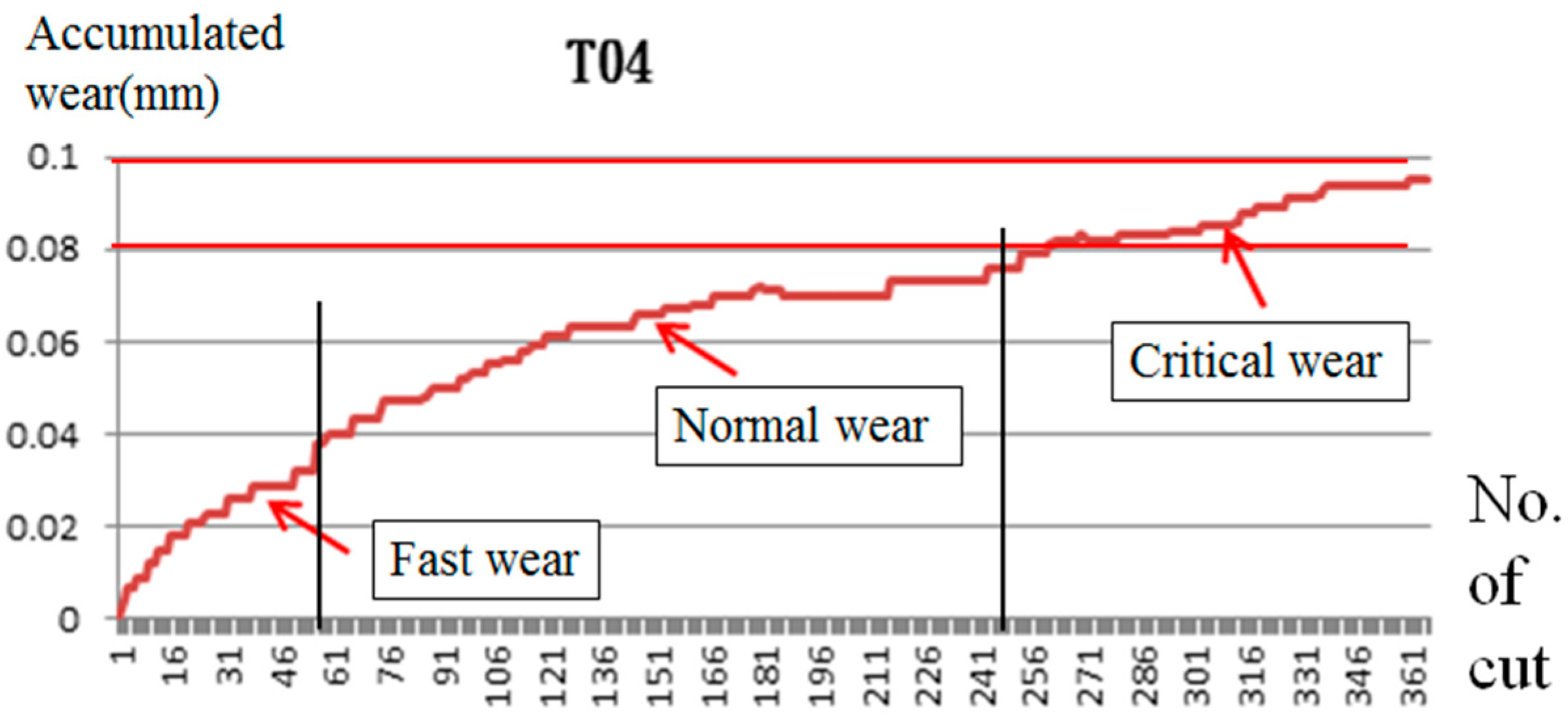

Figure 5 and

Figure 6, respectively, show the correlation of tool wear and the numbers of cuts of T03 and T04. It is noted that the tool wear of a cutter have three developing stages: faster wear, normal wear, and critical wear. The fast wear stage usually happens when a new cutter has begun to be used, because the new cutter is sharper and wear occurs more easily. At the normal wear stage, the tool wears slowly and stably. After the normal wear stage, tool wear will increase again at a faster rate. When a cutter is close to its tool life, tool wear will increase rapidly and it will soon to be worn out. This is regarded as critical wear. When critical wear occurs, the cutter wears out quickly and could damage the work piece. Therefore, critical wear could be a significantly signal to monitor for cutter replacement.

From the figures, it was found that the cutter had fast wear when it was new (for example, for the first 50 cuts for T03, and the first 60 cuts for T04), and then the wear increased slowly until the accumulated wear was close to the upper limit of the dimension tolerance of 0.1 mm. As we can see from

Figure 5, the tool wear of T03 increased slowly and stably when the accumulated wear was within the range of 40 μm to 77 μm. This period was regarded as the normal wear stage. The total number of cuts made within this range were 425 (from cut 51 to cut 476). The tool wear that happened at this stage was very small (<1 µm). After the 476th cut, the tool wear increased rapidly at about 90 μm for about 100 cuts. Since the required tolerances of the machining are ±10 μm for both the inner diameter and the outer diameter, it is easy to produce a No-Go (

i.e., dimension accuracy not qualified) part when the accumulated wear of the cutter approaches 0.1 mm. Therefore, the cutter should be replaced at this time. According to the results, the tool life for T03 and T04 could be respectively defined as 450 cuts and 250 cuts.

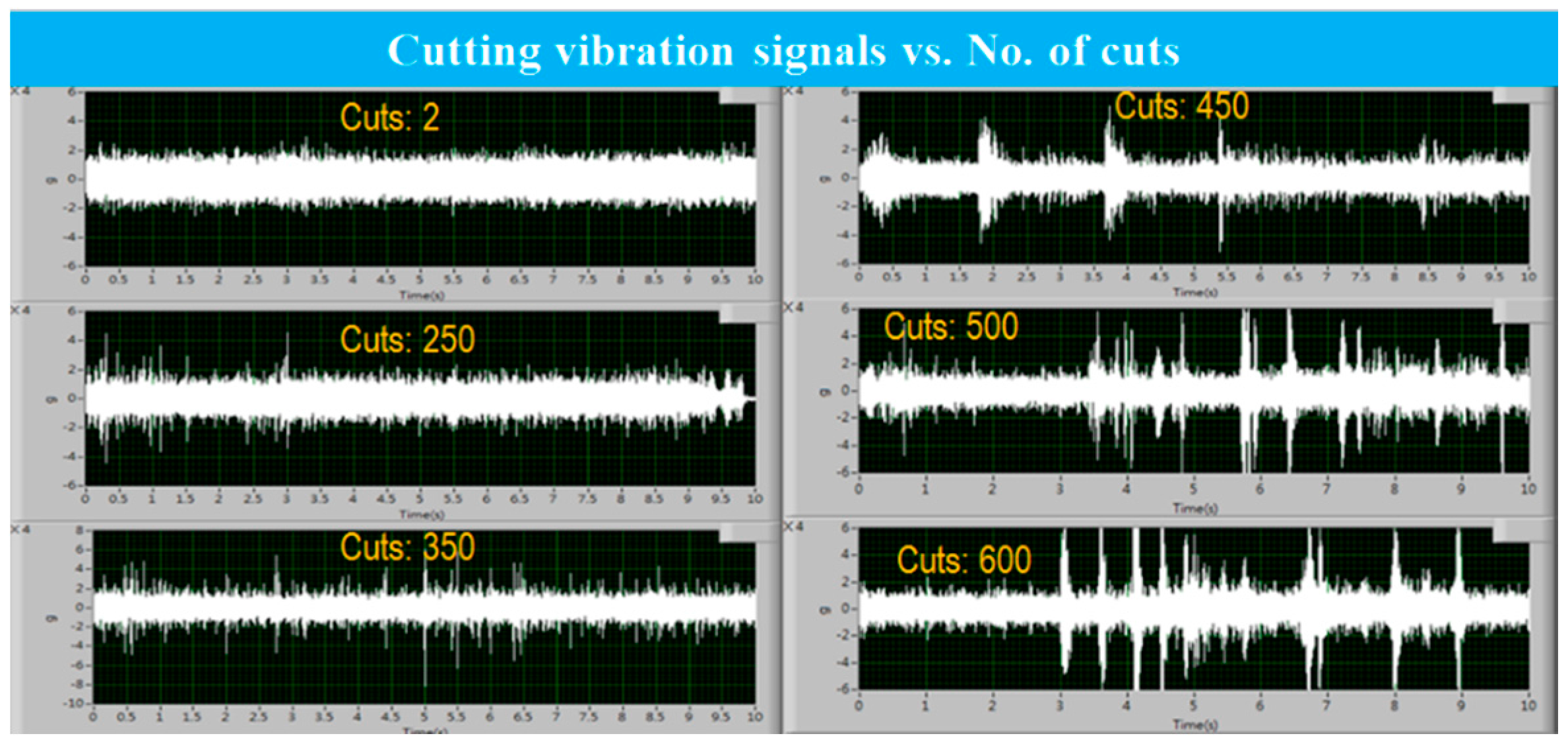

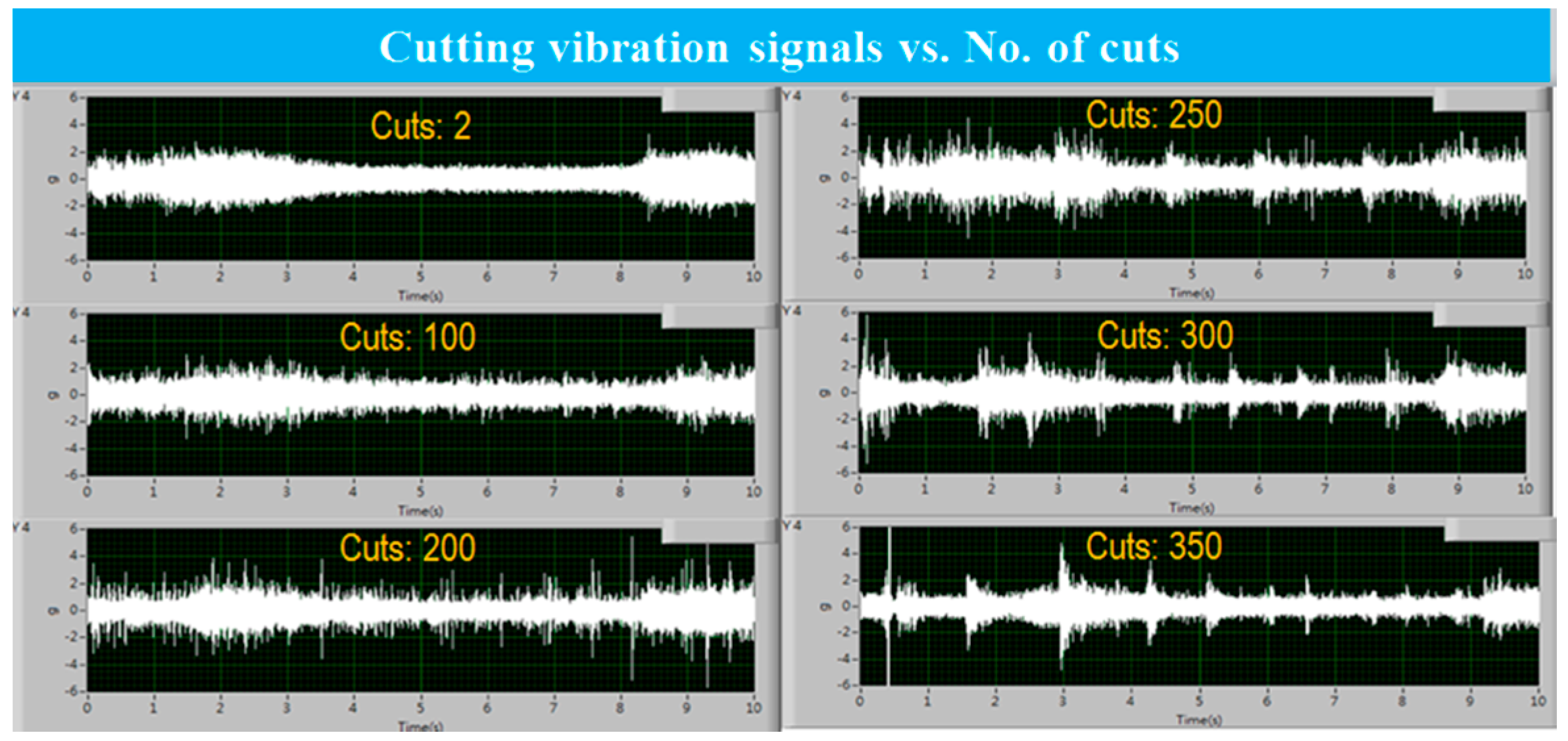

Different levels of tool wear will cause different cutting resistances, which will generate different cutting vibrations. In order to use cutting vibration as the index for tool wear monitoring, it is necessary to understand the characteristics of the change in the cutting vibration pattern caused by tool wear. Thus, while conducting the preliminary experiments for the relationship between tool wear and the number of cuts, the associated cutting vibration signals were also on-line measured by the accelerators.

Figure 7 and

Figure 8, respectively, show the cutting vibration at different cuts of T03 and T03. It is noted that when the cutter showed light wear, the cutting vibration (<2 g) was quite stable (for cut 2 and 250 for T03; cut 2 and 100 for T04). As the tool wear increased, few significant vibrations (4 g) occurred (cut 200 for T03; cut 350 for T04). When the tool wear became greater, significant vibration occurred more frequently (this happened at cut 450 and 500 for T03 and cut 300 and 350 for T04). When comparing

Figure 5 and

Figure 6, it can be concluded that the significant vibrations were mainly caused by the tool wear. When significant vibration occurred frequently, the tool wear had reached 80 µm and up. According to the results, it can be concluded that the variation of vibration and the frequency of occurrence could be the two indexes for monitoring the status of tool wear. For a stable turning process, the tool wear can be predicted based on the number of cuts. Meanwhile, by checking the cutting vibration pattern, it is able to know whether the cutter has abnormal wear conditions. If a cutter is at the normal wear stage but is experiencing large vibrations, it means the cutter has an abnormal wear status.

6. Experimental Verification

Two experiments, including on-machine machining error (diameter error) inspection and on-machine tool wear monitoring auto-compensation, were conducted to verify the feasibility and effectiveness of the proposed algorithms and the developed system. The automotive component part shown in

Figure 1 was the tested work piece, because the component was produced in a mass production line. The experiments were directly applied to the two finish turning processes for T03 and T04.

Table 1 shows the experiment conditions. The tolerance of the inner and outer diameters is ±6 µm. Two accelerometers were attached to the cutter post to on-line collect the cutting vibration signals for monitoring. Meanwhile, machining information, such as instantly executing NC codes, machining parameters,

etc., were also extracted with the bilateral communication module as a reference for monitoring.

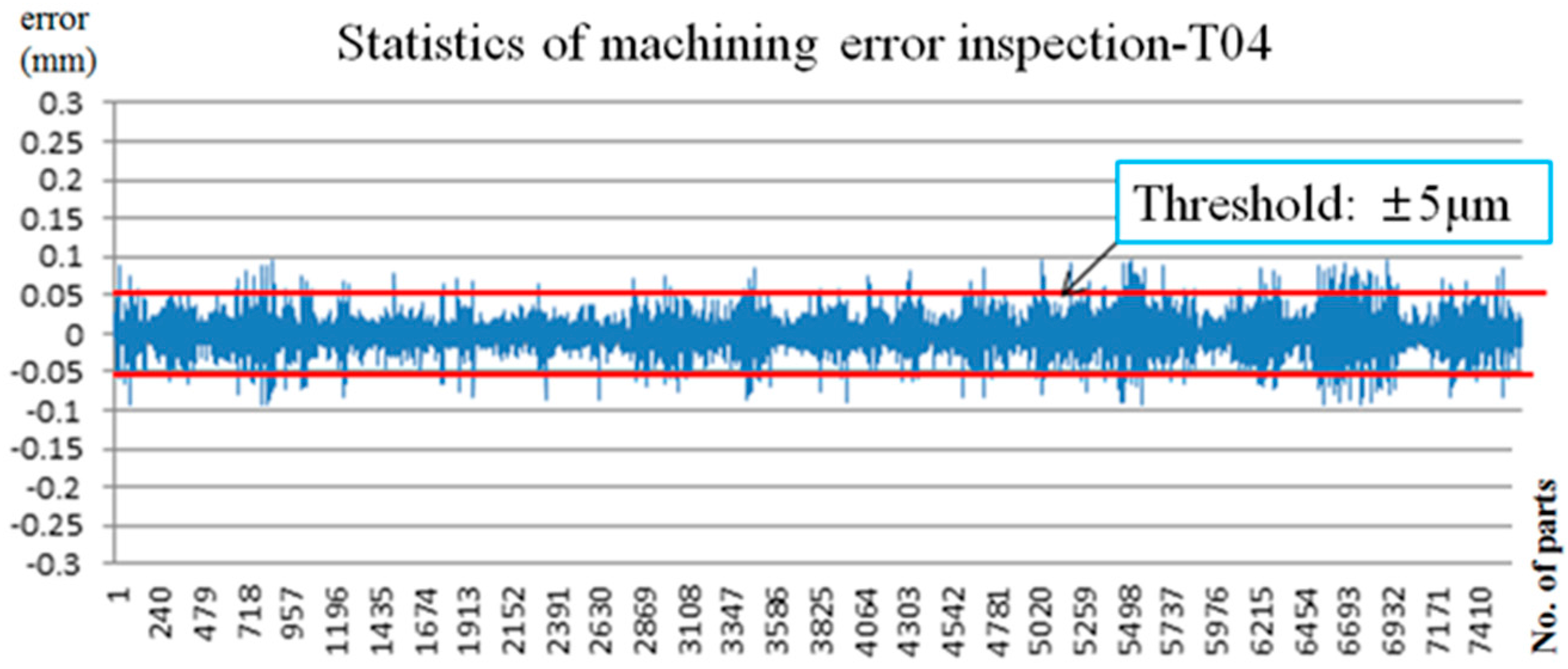

6.1. On-Machine Machining Error (Diameter Error) Inspection

In this experiment, the on-machine machining error auto-inspection function was applied to the production line of GlobalTek Co. (Taoyuan, Taiwan) to verify the effectiveness of the inspection function. A total of 7643 components were tested in this experiment. The inspection results made by the auto-inspection function were compared to that made using the air gauge instruments, which were originally used by the company. The threshold value of the inspection was set to ±5 µm. Of the produced components, 93% were qualified, and 7% of the produced components were inspected as No-Go parts. The results were very close to the results made using the air gauge instruments. It shows that the proposed function can be used to replace the original manual inspection process made with air gauge instruments. It saved work hours and manufacturing cost for the production.

Figure 18 shows the inspection results.

Figure 20 and

Figure 21 show the statistics of the inspection of T03 and T04, respectively.

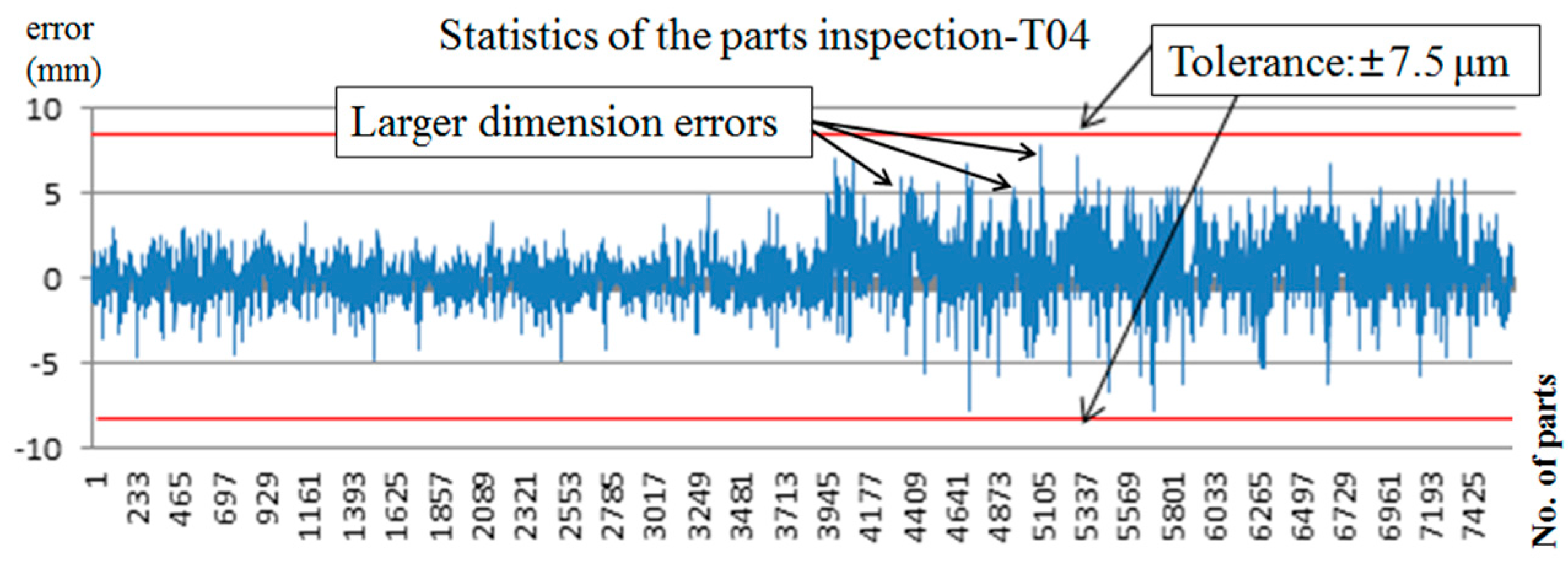

6.2. On-Machine Tool Wear Monitoring and Auto-Compensation

In this experiment, the two functions, on-machine auto-monitoring and auto-compensation of tool wear, were used in the production line of GlobalTek Co. to verify the effectiveness and feasibility of the two functions. Except for the tolerances (T03: ±6 μm; T04: ±7.5 μm), the same machining conditions as shown in

Table 1 were used. Another 7643 components were tested in this experiment. With use of the proposed system, the tool wear of each cut was predicted and auto-compensated to the CNC controller of the turning machine for the next component.

Figure 22 and

Figure 23 show the statistics of the dimension inspection results made with the air gauge instruments. It can be seen that all the machined components matched the requirement for dimension tolerance. It was also noted that most of the parts had dimension errors of about 2–3 μm. Because of the tool wear, some parts had larger dimension errors of about 4–5 μm, but they all still met the tolerance requirement. The results showed that the two functions (on-machine auto-monitoring and auto-compensation of tool wear) can provide appropriate prediction and compensation of tool wear for each cutting process.

According to the verification results, it showed that the proposed method is suitable for on-line monitoring/compensation for a mass production line. The proposed method is mainly based on the correlation between the variation of cutting vibration signals (detected by the vibration sensors), cutter wear, and machining errors. However, very light tool wear causes very little change in cutting vibration, which it may not be possible to clearly detect using a vibration sensor if the sensitivity of the sensor used is not fine enough. Therefore, the possible limitation of this method is the sensitivity of the selected vibration sensors. The better the sensors, the higher the cost. Thus, the vibration sensors should be selected based on the requirements of the machining process.