Development of an Abbe Error Free Micro Coordinate Measuring Machine

Abstract

:1. Introduction

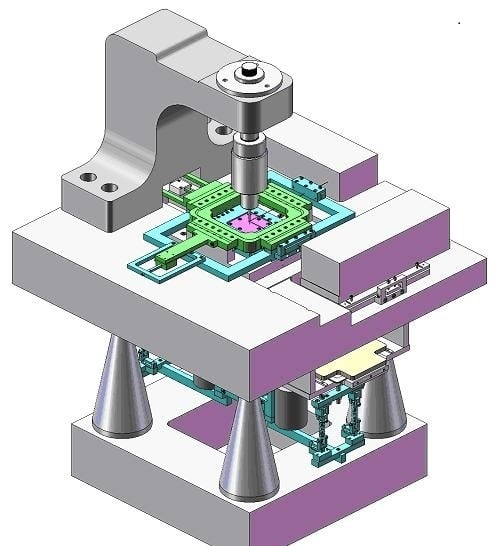

2. Basic Structure and Key Technologies

2.1. Basic Structure

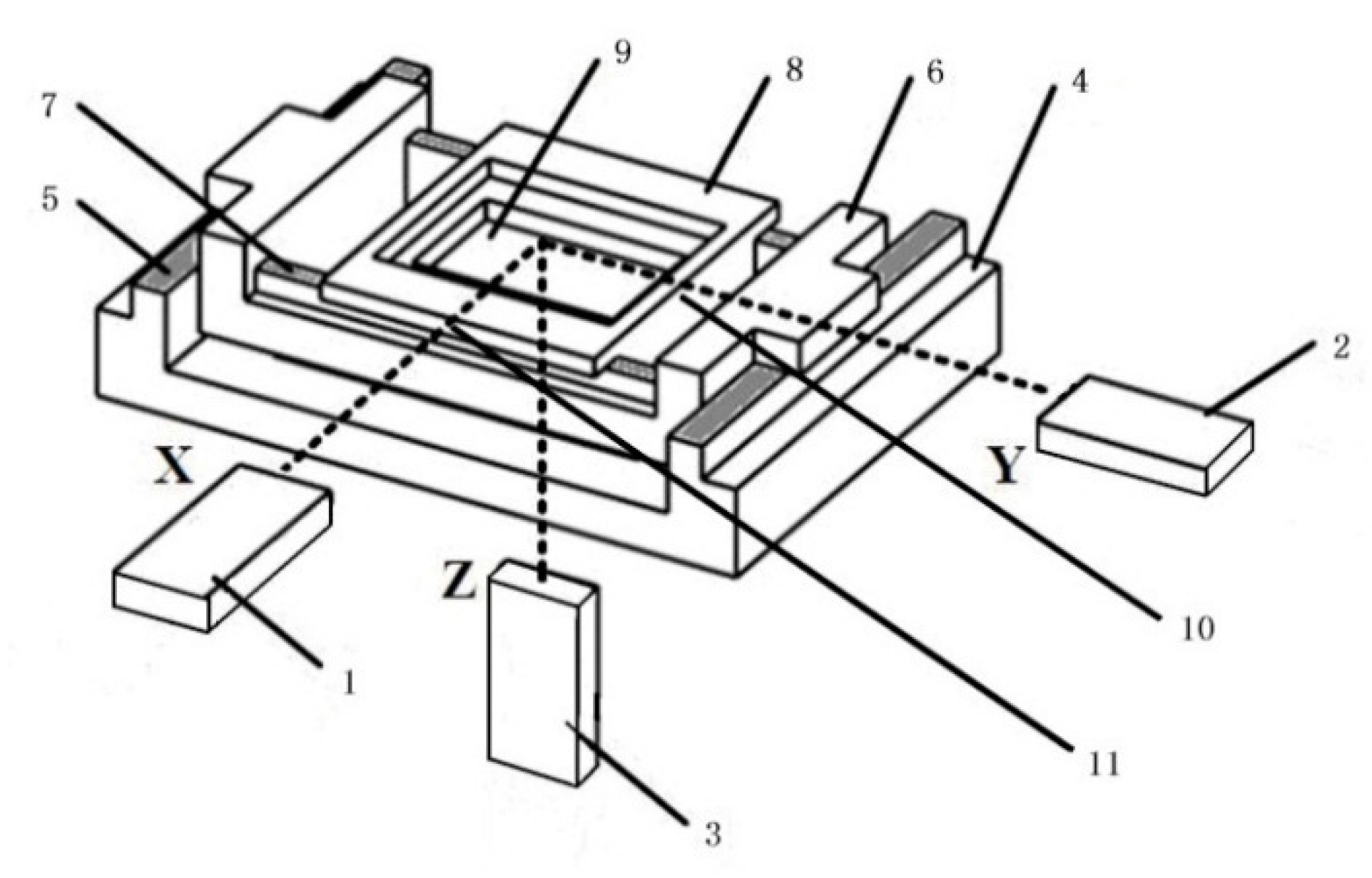

2.2. Special Structure of the 3D Stage

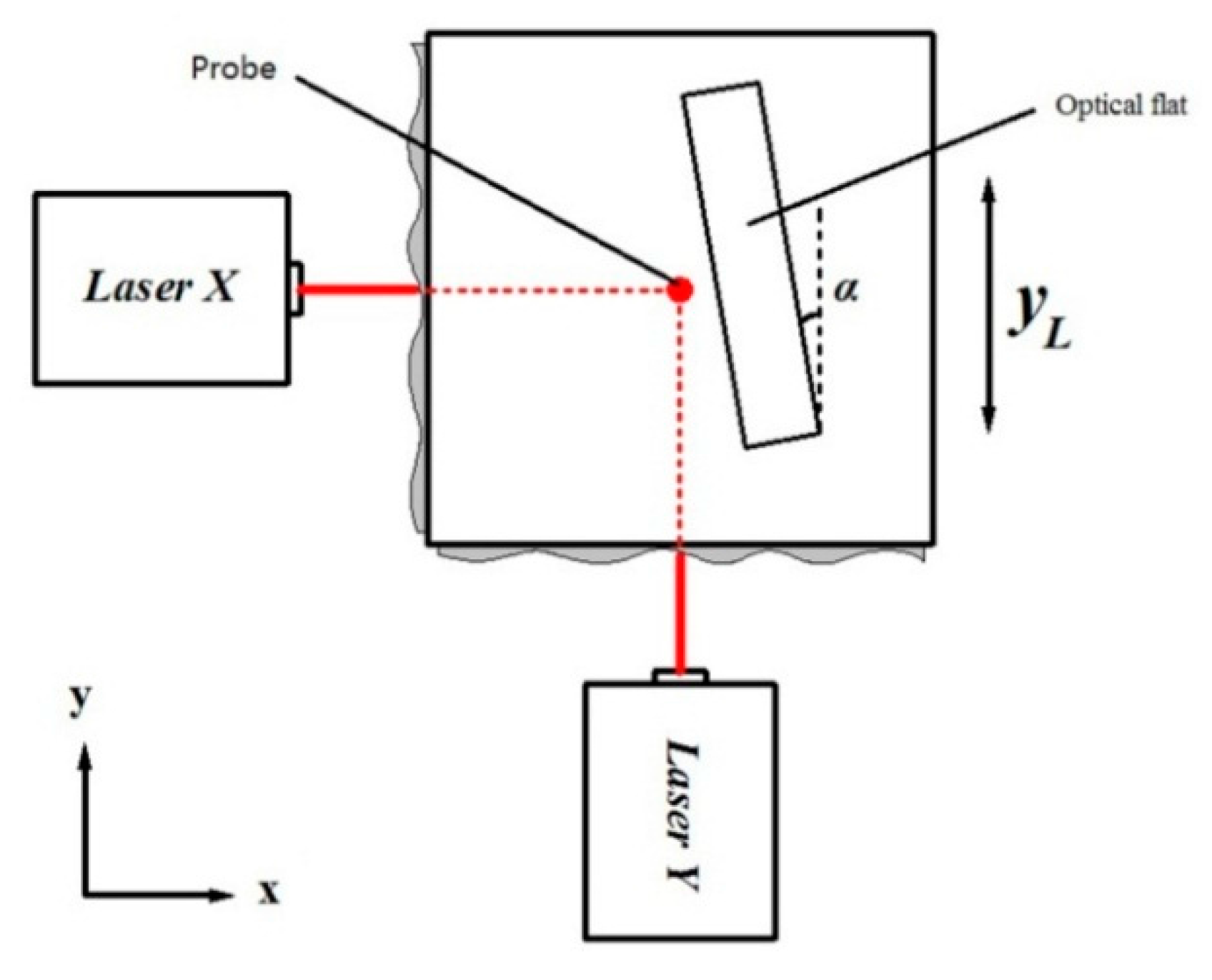

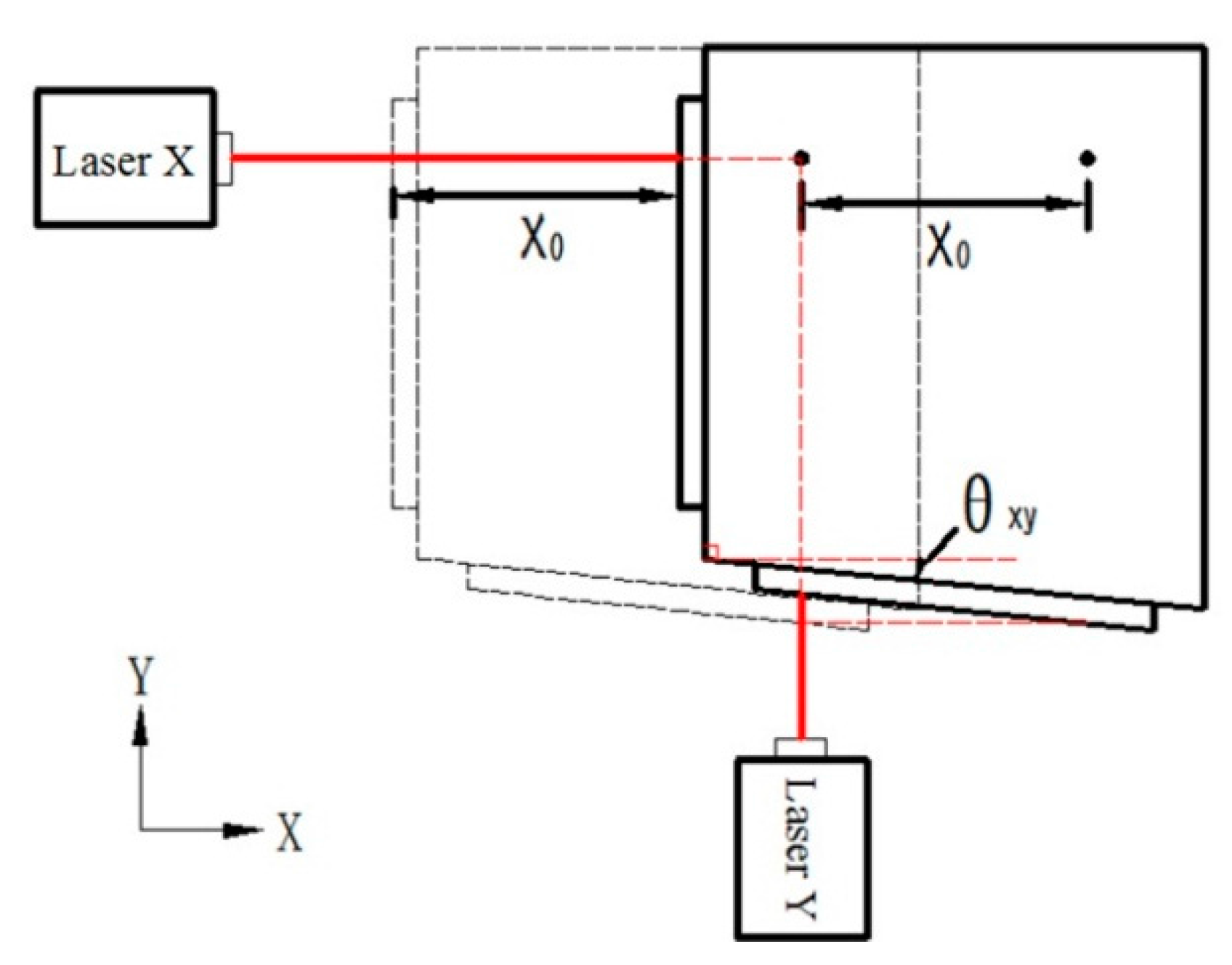

2.3. The Metrological System and Its Layout

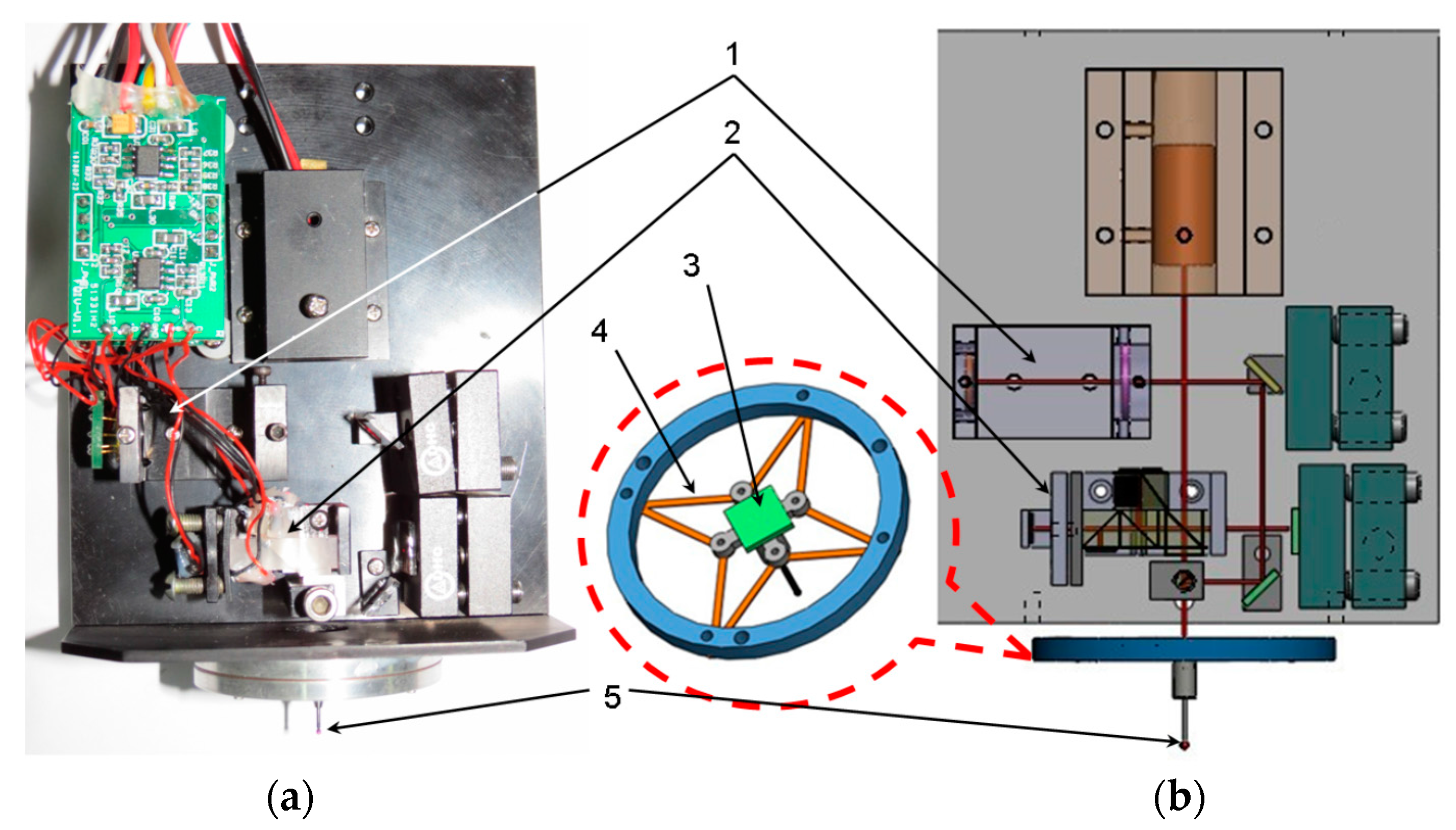

2.4. The 3D Measuring Probe

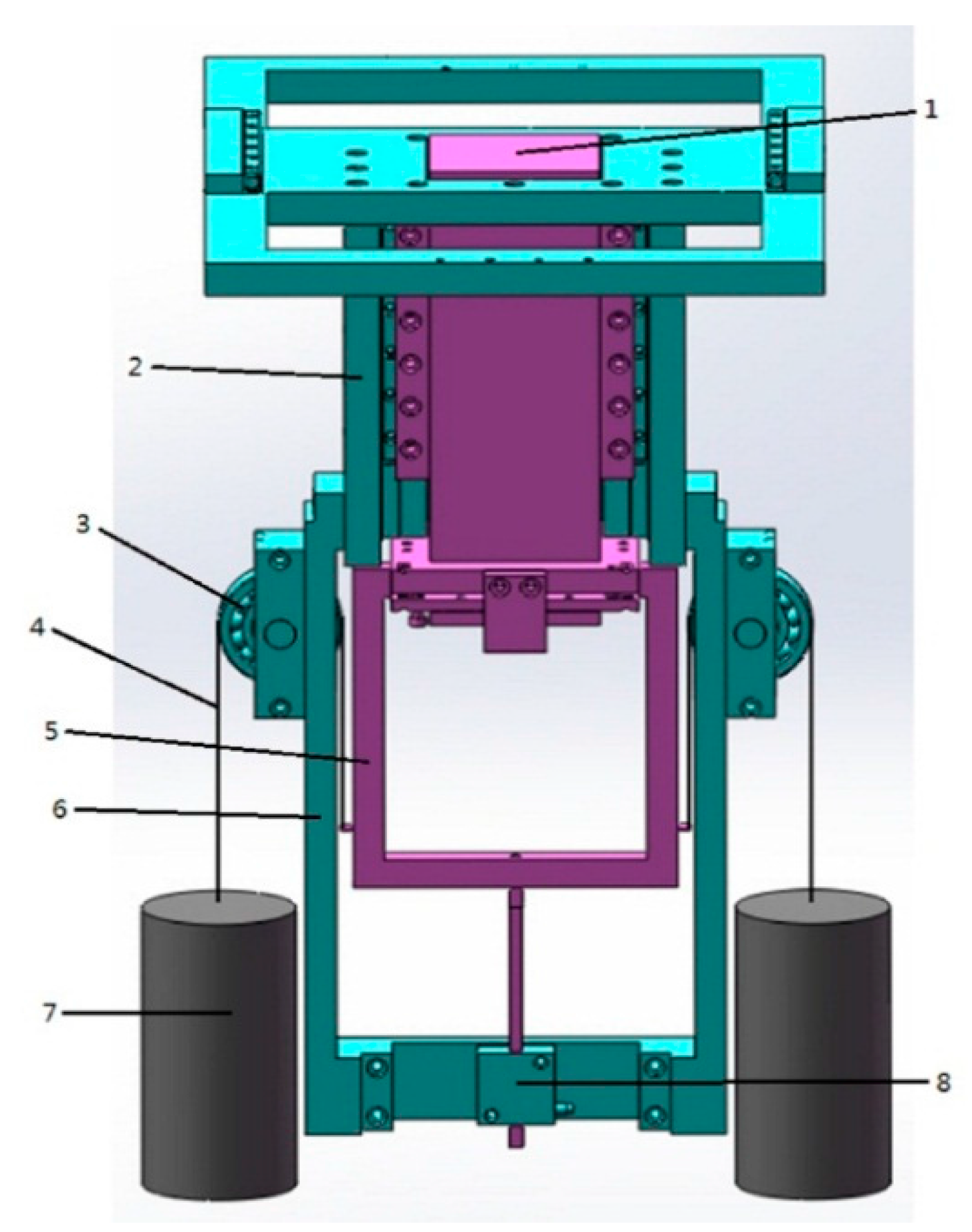

2.5. Deadweight Balance Structure

2.5.1. Z-Stage Deadweight Balance System

2.5.2. Lateral Deadweight Balance System

3. Analysis and Correction of Main Errors

3.1. Stability of Frequency Stabilized Nd:YAG Laser Feedback Interferometer

3.2. Error Calibration and Correction of Interferometers’ Reflection Mirrors

3.3. Separation and Correction of Non-Orthogonal Errors

4. Performance Tests

4.1. Step Height Measurement in Z Direction

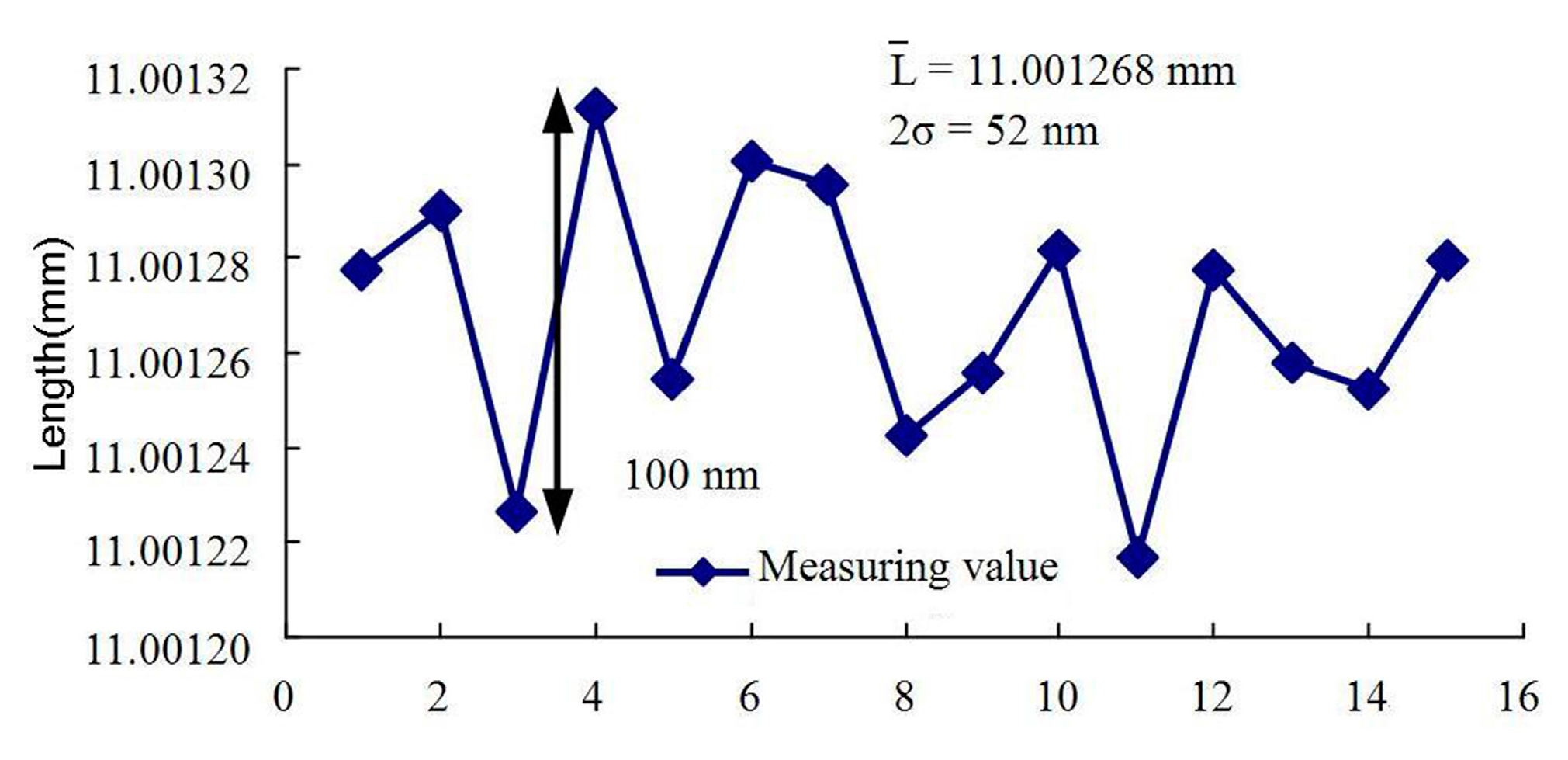

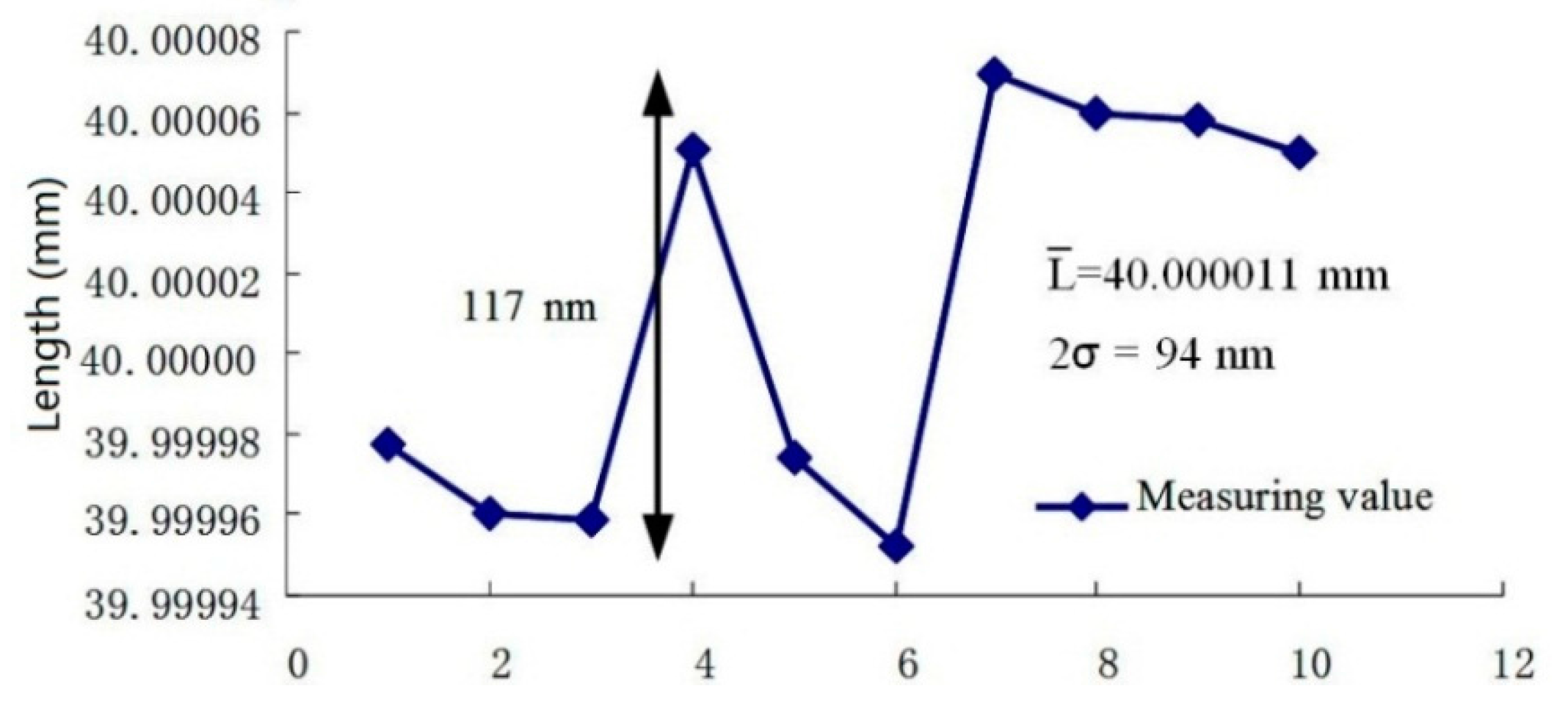

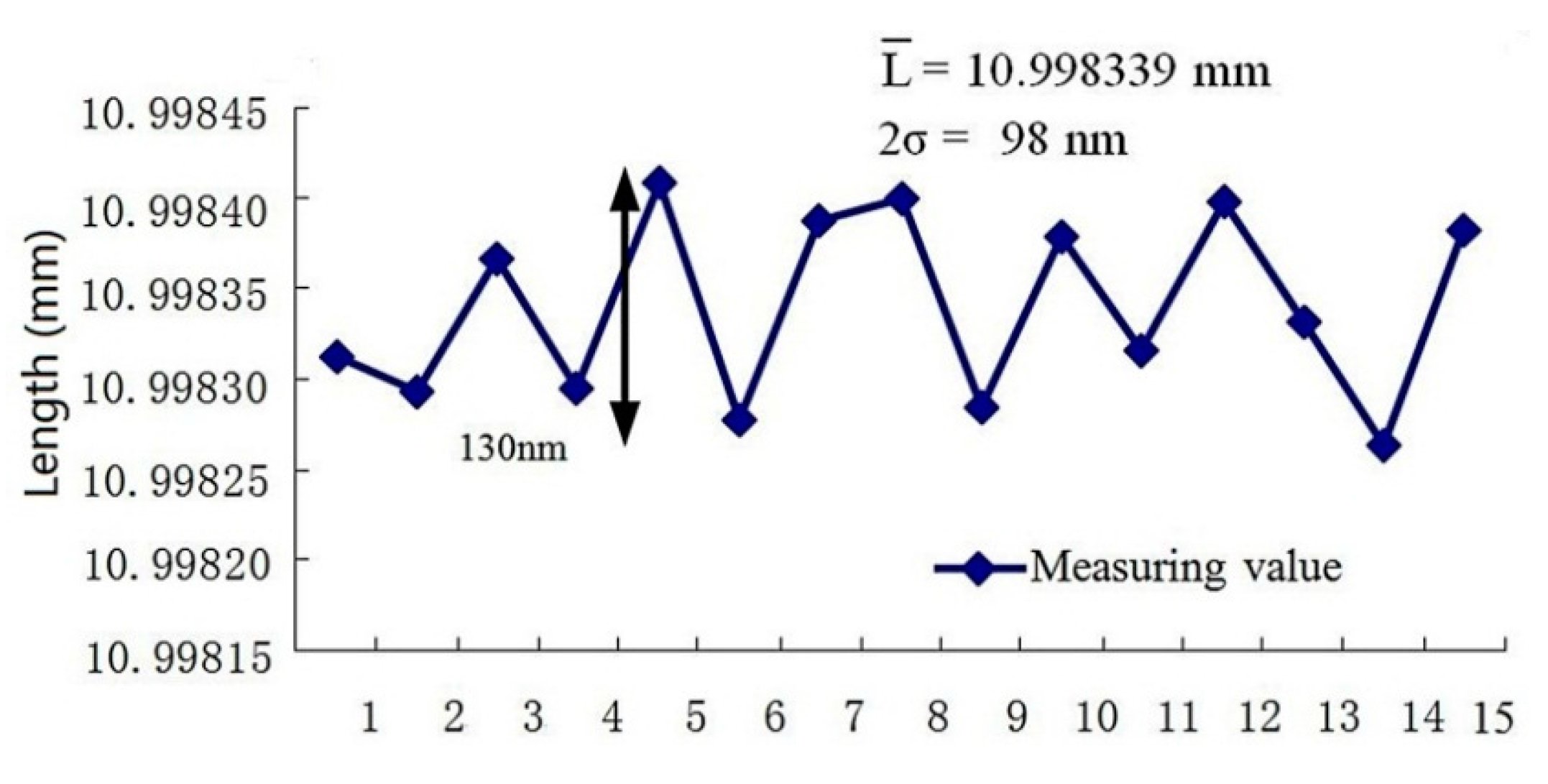

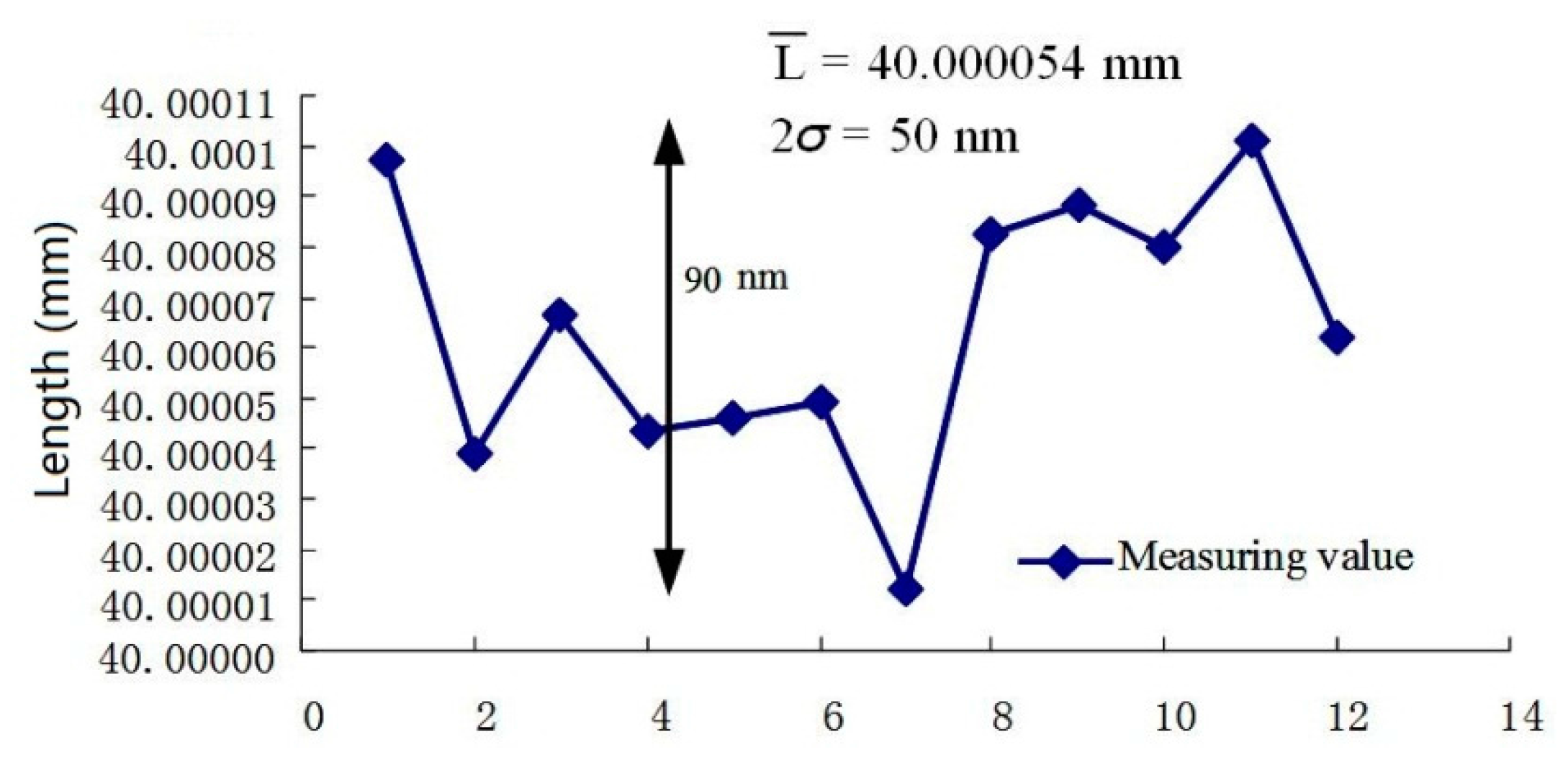

4.2. Length Measurement in Lateral Direction

4.3. Flatness Error Measurement

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Claverley, J.D.; Leach, R.K. A review of the existing performance verification infrastructure for micro-CMMs. Prec. Eng. 2015, 39, 1–15. [Google Scholar] [CrossRef]

- Kramar, J.A. Nanometre resolution metrology with the Molecular Measuring Machine. Meas. Sci. Tech. 2005, 16, 2121–2128. [Google Scholar] [CrossRef]

- Yang, P.; Takamura, T.; Takahashi, S.; Takamasu, K.; Sato, O.; Osawa, S.; Takatsuji, T. Development of high-precision micro-coordinate measuring machine: Multi-probe measurement system for measuring yaw and straightness motion error of XY linear stage. Prec. Eng. 2011, 35, 424–430. [Google Scholar] [CrossRef]

- Brand, U.; Kleine-Besten, T.; Schwenke, H. Development of a special CMM for dimensional metrology on microsystem components. In Proceedings of the Sixth International Symposium on Precision Mechanical Measurements, GuiYang, China, 8 August 2013; pp. 542–546.

- Lewis, A.; Oldfield, S.; Peggs, G.N. The NPL Small CMM-3-D measurement of small features. 5th LAMDAMAP. 2001, 34, 197–207. [Google Scholar]

- Manske, E.; Jäger, G.; Hausotte, T.; Füβl, R. Recent developments and challenges of nanopositioning and nanomeasuring technology. Meas. Sci. Tech. 2012, 23, 74001–74010. [Google Scholar] [CrossRef]

- Balzer, F.G.; Hausotte, T.; Dorozhovets, N.; Manske, E.; Jäger, G. Tactile 3D microprobe system with exchangeable styli. Meas. Sci. Tech. 2011, 22. [Google Scholar] [CrossRef]

- Schmidt, I.; Hausotte, T.; Gerhardt, U.; Manske, E.; Jäger, G. Investigations and calculations into decreasing the uncertainty of a nanopositioning and nanomeasuring machine (NPM-Machine). Meas. Sci. Tech. 2007, 18, 482–486. [Google Scholar] [CrossRef]

- Kornel, F.E.; David, B.; Martin, L.C.; Thom, J.H.; Thomas, R.K.; Marc, M.; Kamlakar, R.; Richard, D. Micromanufacturing; Springer: Dordrecht, The Netherlands, 2007; pp. 89–109. [Google Scholar]

- Spaan, H.A.M.; Widdershoven, I. Isara 400 Ultra-precision CMM. In Proceedings of the Optical Fabrication, Testing, and Metrology IV, Marseille, France, September 2011.

- Fan, K.C.; Fei, Y.T.; Yu, X.F.; Chen, Y.J.; Wang, W.L.; Chen, F.; Liu, Y.S. Development of a low-cost micro-CMM for 3D micro/nano measurements. Meas. Sci. Tech. 2006, 17, 524–532. [Google Scholar] [CrossRef]

- Tan, Y.D.; Zhang, S.L. Self-mixing interference effects of microchip Nd:YAG laser with a wave plate in the external cavity. Appl. Opt. 2007, 46, 6064–6048. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.D.; Zhang, S.L.; Zhang, S.; Zhang, Y.Q.; Liu, N. Response of microchip solid-state laser to external frequency-shifted feedback and its applications. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef]

- Li, R.J.; Fan, K.C.; Miao, J.W.; Huang, Q.X.; Tao, S.; Gong, E.M. An analogue contact probe using a compact 3D optical sensor for micro/nano coordinate measuring machines. Meas. Sci. Tech. 2014, 25, 1–9. [Google Scholar] [CrossRef]

| Point | Coordinates (xi, yi, zi) (mm) | Point | Coordinates (xi, yi, zi) (mm) |

|---|---|---|---|

| 1 | (18.004414, 34.999884, 34.741144) | 2 | (18.003694, 28.000295, 34.741274) |

| 3 | (18.002475, 22.000374, 34.741458) | 4 | (22.004273, 21.995507, 34.731724) |

| 5 | (22.005775, 27.999635, 34.731491) | 6 | (22.006136, 34.999752, 34.731304) |

| Flatness | 66 nm | ||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Q.; Wu, K.; Wang, C.; Li, R.; Fan, K.-C.; Fei, Y. Development of an Abbe Error Free Micro Coordinate Measuring Machine. Appl. Sci. 2016, 6, 97. https://doi.org/10.3390/app6040097

Huang Q, Wu K, Wang C, Li R, Fan K-C, Fei Y. Development of an Abbe Error Free Micro Coordinate Measuring Machine. Applied Sciences. 2016; 6(4):97. https://doi.org/10.3390/app6040097

Chicago/Turabian StyleHuang, Qiangxian, Kui Wu, Chenchen Wang, Ruijun Li, Kuang-Chao Fan, and Yetai Fei. 2016. "Development of an Abbe Error Free Micro Coordinate Measuring Machine" Applied Sciences 6, no. 4: 97. https://doi.org/10.3390/app6040097