1. Introduction

High-pressure torsion (HPT) is a promising top-down technique to produce bulk nanostructured materials. In contrast to other methods of severe plastic deformation, even very high strains can be obtained easily [

1]. Besides HPT deformation of bulk materials, the compaction and deformation of powders has introduced new possibilities to this technique. The oxide film on metal powder particles, for example, results in a higher amount of impurities as compared to bulk material which leads to a smaller saturation grain size and higher hardness during deformation [

2]. Also composites of any kind can be obtained easily by mixing the elemental powders of the components [

3].

An important issue for severe plastic deformation of composites is the structural homogeneity of the starting material. Although the initial microstructure does not affect the saturation state, which is obtained after a sufficient amount of strain, it has a strong impact on the homogeneity of deformation and the amount of strain which is necessary to obtain this state of saturation [

4]. In addition, the structural homogeneity of the starting material is also important for the formation of supersaturated solid solutions. This phenomenon has been reported for many systems, even for systems with a high positive enthalpy of mixing, which are generally considered to be immiscible [

5]. Various possible explanations for the supersaturation by plastic deformation have been discussed [

6]. Since homogeneous mixtures of small particles provide short diffusion paths, a large amount of heterogeneous interfaces as well as more parts with very small tips, such a starting material is expected to facilitate intermixing and result in faster formation of supersaturated solutions.

Inhomogeneity can occur in metallurgically prepared starting materials, for example when phase separation occurs on a length scale that approaches the HPT sample size. However, inhomogeneity is also an issue when powder mixtures are used as starting materials. Segregation is especially likely to occur when the various components of the powder mixture differ strongly in size and density, and can be only avoided using laborious techniques of mixing [

7]. On the contrary, if one component is added not as a second powder but as a coating on the powder particles of the other component, segregation cannot take place and the two components are separated in an invariable distance depending only on the size of the particle and the thickness of the coating. Coated powders have been used in [

2] to deform nickel with a significant amount of oxides homogeneously distributed throughout the sample. However, no HPT deformation of coated powders consisting of two metals has been reported so far, to the authors’ knowledge.

Such coated powders are investigated in the present study using the Fe-Cu system. According to the phase diagram, the system can be considered as immiscible, since only negligible intermixing of Fe and Cu occurs at room temperature [

8]. However, supersaturated solid solutions have been observed and investigated in many studies using both mechanical alloying (see [

9] and references therein) and severe plastic deformation. Investigations on HPT-deformed Fe-Cu alloys have been reported using various starting materials. Teplov et al. [

10,

11] found single-phase solid solutions of up to 20 at. % Cu on the iron-rich side and up to 20 at. % Fe on the copper-rich side of the phase diagram for both master alloys and powder mixtures as starting materials. Bachmaier et al. [

12] developed a two-step HPT process to reduce the saturation grain size and obtain solid solutions in a more efficient way. Up to 15 at. % from both sides of the phase diagram were found to result in single-phase solid solutions [

12]. For both alloys from the melt and powder mixtures, a continuous refinement of the Fe particles in Cu-rich alloys via fragmentation and dissolution was reported [

13,

14]. Also, a composite of iron fibers in a copper matrix has been deformed via HPT and the dissolution of the iron fibers was observed [

15,

16,

17]. In these studies, an inhomogeneous deformation of the composite due to Fe-rich and Fe-depleted regions in the samples was reported [

15,

17].

In the present study, copper-coated iron powders as starting materials for HPT deformation were produced via immersion deposition. Immersion deposition is a cheap and versatile technique for coating, since no expensive equipment and no vacuum is required. The immersion deposition of Cu on Fe has been known for more than a century [

18]. However, the deposition on powders is more complex since some processing steps (e.g., fast drying) cannot be directly transferred from the plating of macroscopic parts to powders. The coating of Fe powder with Cu via immersion deposition from an electrolyte with citrate complexation was investigated by Turoňová et al. [

19]. Citrate complexes slow down the deposition rate [

19]. This is not only of interest to reduce the reaction if it is unintended, but also to elongate the deposition process and enable more homogeneous coatings.

The aim of the present study is to investigate the effect of the coated powder on the microstructure and hardness evolution during HPT deformation, as compared to a powder mixture. Special attention is attributed to the homogeneity of the starting material, the deformation behavior as well as the formation of supersaturated solutions.

2. Materials and Methods

In this study, three different configurations of Fe-Cu alloys were deformed via high pressure torsion: a copper-coated iron powder, an undeformed powder mixture of iron and copper powders, and a powder mixture after previous HPT deformation.

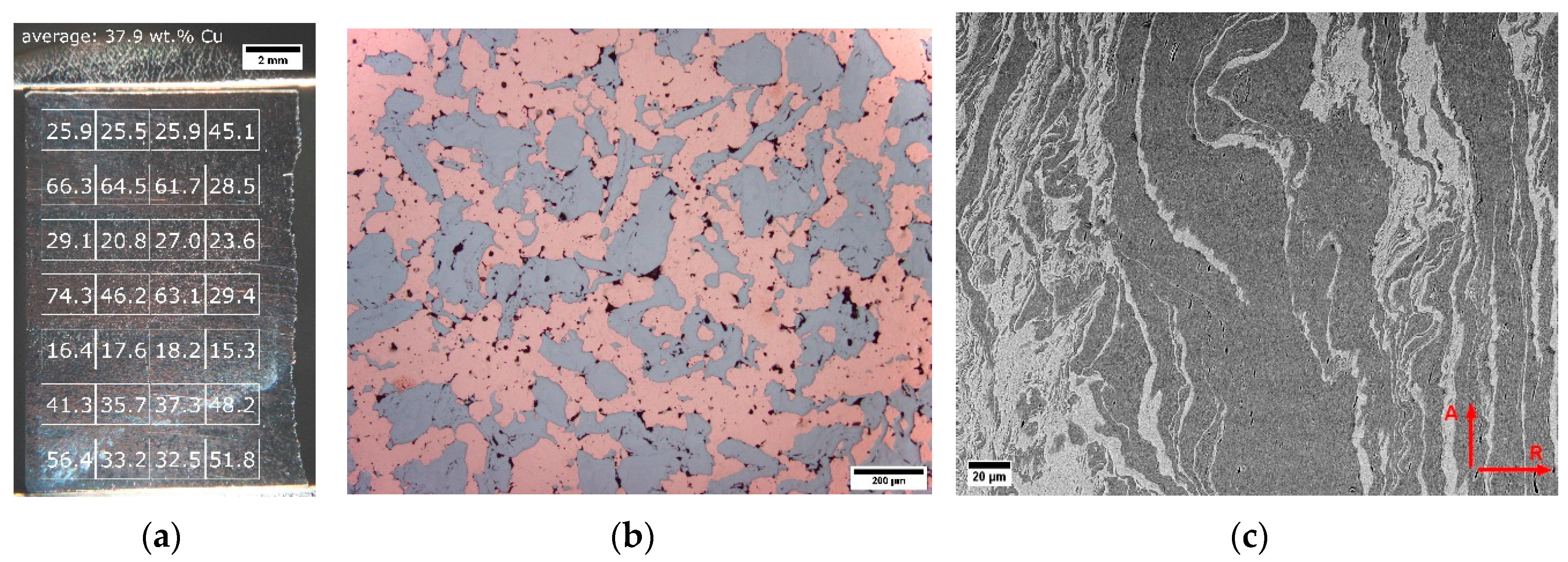

The coated powder was produced via immersion deposition. The electrolyte consisted of 0.8 mol·dm−3 cupric sulfate pentahydrate and 0.4 mol·dm−3 tri-sodium citrate dehydrate. Then 12 g of iron powder (−200 mesh, 99+% purity) were immersed in 0.15 cm³ of electrolyte for 30 s. During this deposition process the bath was agitated using a magnetic stirrer at 500 rpm. Subsequently, the powder was removed from the electrolyte using a magnetic rod. It was rinsed with de-ionized water and isopropyl and then dried in a filter paper (grade MN 615). This procedure was repeated various times to obtain larger amounts of coated powders. Using only small amounts of powders at once enabled the fast removal of the powder from the electrolyte as well as homogeneous coating. The coated powder was compacted by RHP-Technology (Seibersdorf, Austria) using inductive hot pressing at 650 °C and 30 MPa for 15 min. Subsequently, disks of 8 mm diameter and about 0.8 mm height were cut out of the compacted composite and used for HPT deformation.

For comparison, a powder mixture was prepared consisting of 16 g (33 wt. %) copper powder (−70 + 400 mesh, 99.9% purity) and 32 g (67 wt. %) iron powder (−100 + 200 mesh, 99.9% purity). It was compacted and cut in the same way as described above for the coated powder.

Besides, a mixture of iron and copper powder, which had been pre-deformed in a larger HPT device, was also used for comparison. A mixture of Fe70Cu30 was prepared from copper (−170 + 400 mesh, 99.9% purity) and iron (−100 + 200 mesh, 99.9% purity) powders. The powder mixture was compacted and a disk of 50 mm diameter and 9.5 mm thickness was deformed via HPT (10 rotations). Disks with 8 mm diameter and about 0.8 mm thickness were cut in such a way from the larger HPT disk, that the axial direction for the following deformation experiments was approximately the radial direction of the previous deformation. A detailed description of this two-step HPT process can be found in [

12].

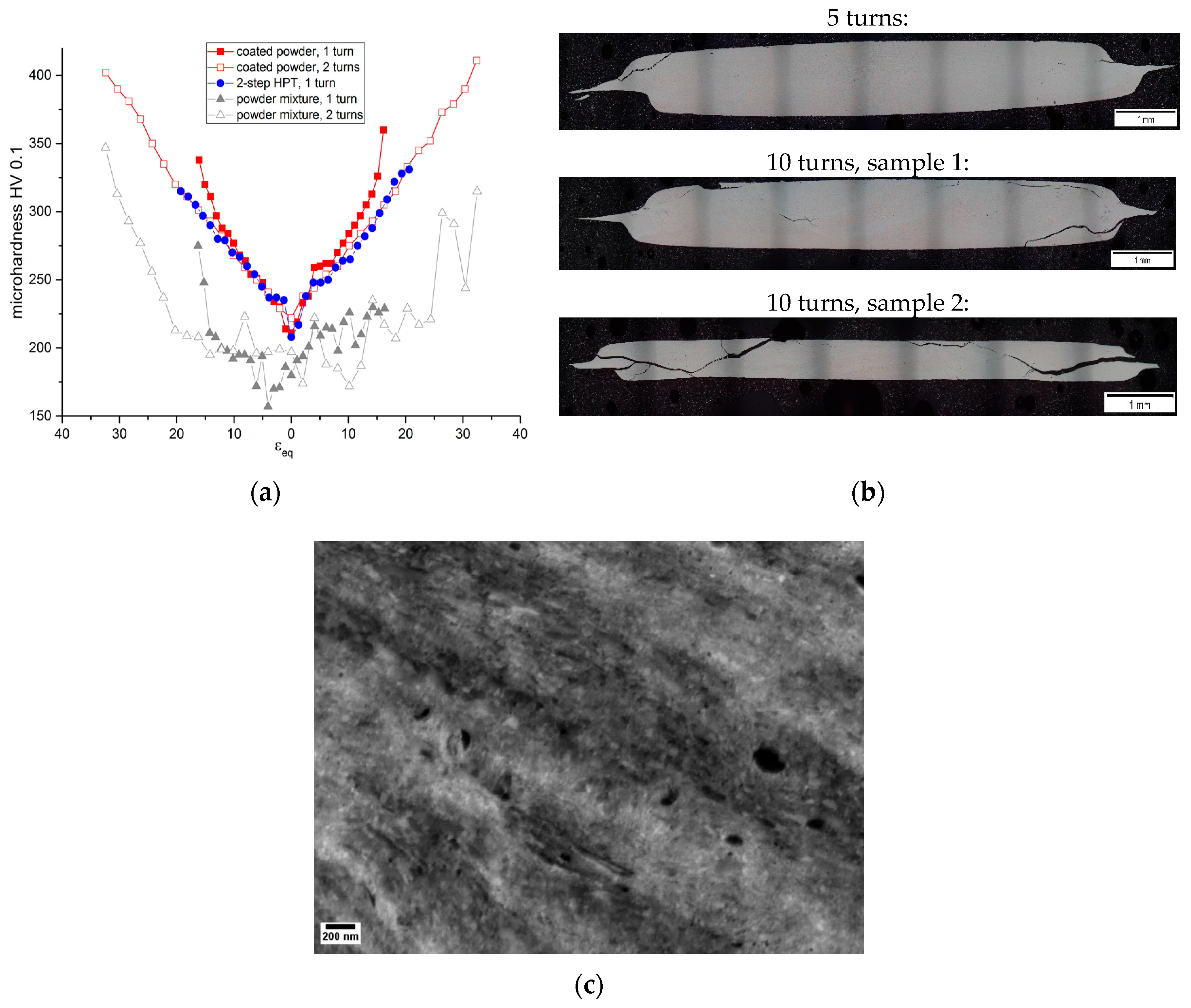

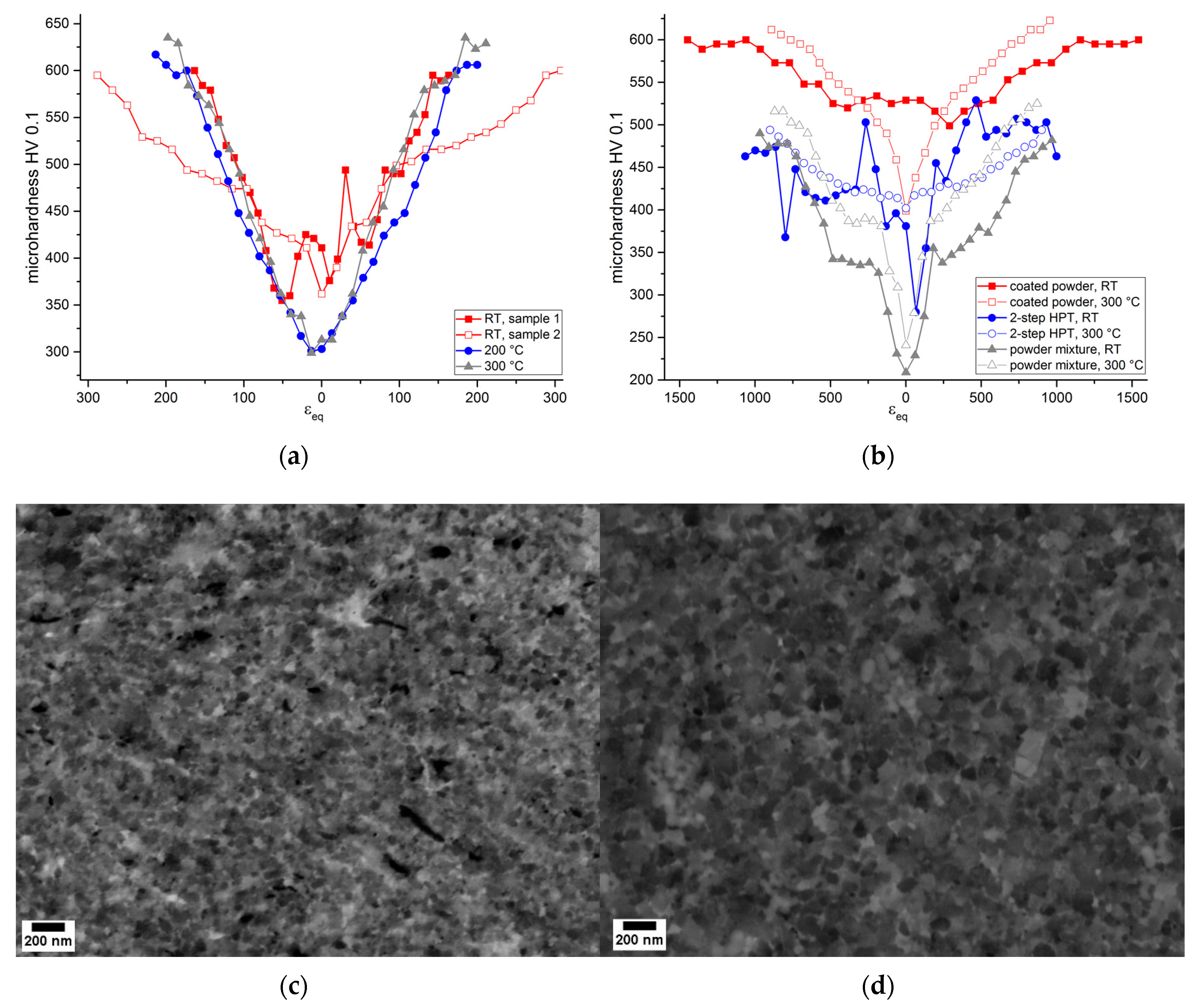

All samples were deformed via HPT at a pressure of 7.3 GPa with a sample size of 8 mm diameter and about 0.8 mm height. For deformation at elevated temperatures, the anvils and the sample were heated inductively. Room temperature experiments were performed at 0.2 rpm, whereas at elevated temperatures 0.6 rpm was used to reduce deformation time.

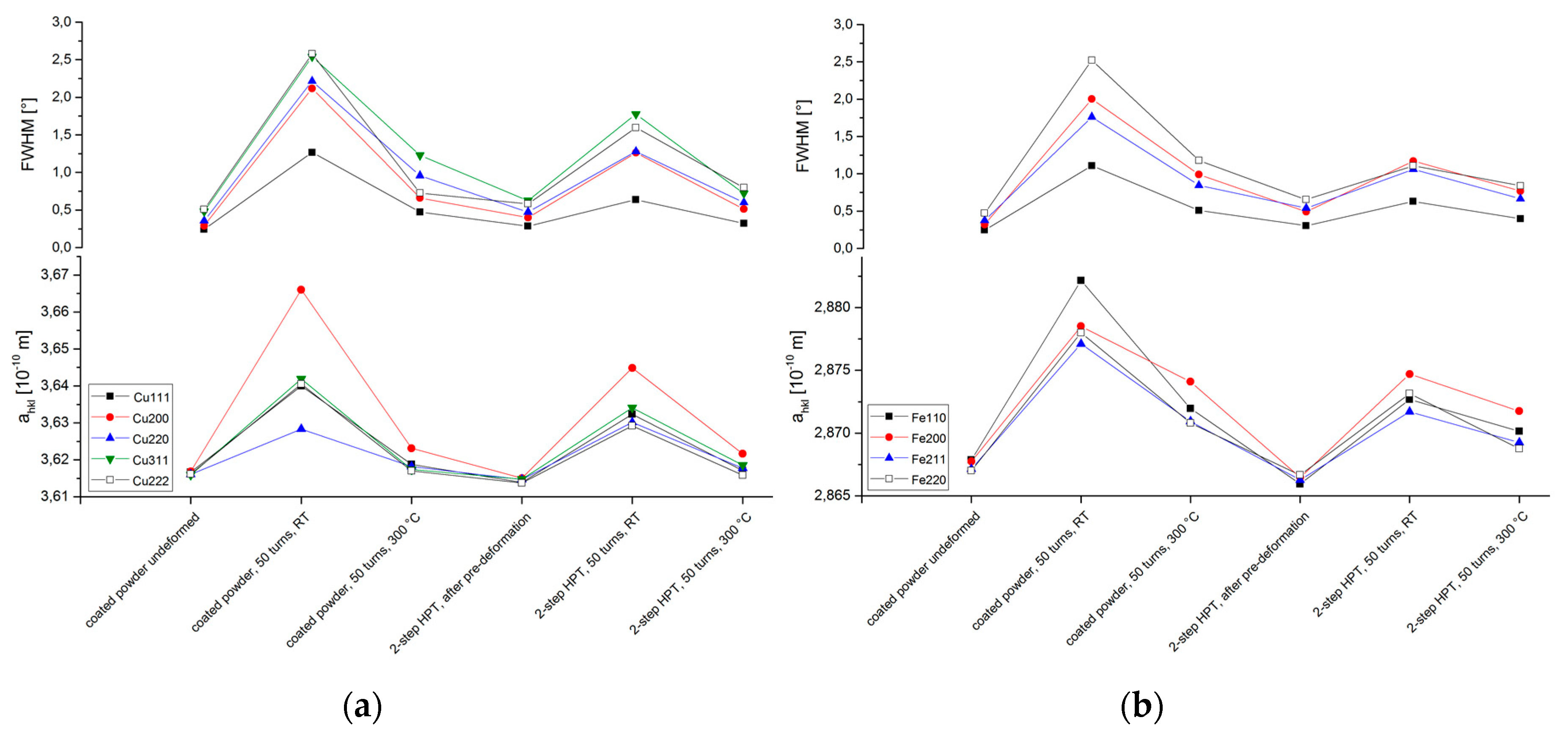

The structure of the undeformed and deformed state was investigated using light microscopy as well as scanning electron microscopy (SEM LEO 1525 from Zeiss, Oberkochen, Germany) with a back-scattered electron detector and an electron backscatter diffraction (EBSD) system from EDAX, Mahwah, NJ, USA. Grain size distributions of undeformed materials were obtained directly from EBSD measurements, whereas the grain size after deformation was estimated from manual analysis of SEM images obtained with the back scattered electron detector using ImageJ software. The given grain sizes are the shorter axis of fitted ellipses. The composition of the samples was also investigated with this device using an energy-dispersive x-ray spectroscopy (EDX) system from Oxford Instruments, Abingdon, UK. Vickers microhardness was measured using a Micromet 5104 (from BUEHLER, Chicago, IL, USA) with a load of 100 g (HV 0.1). All microstructural investigations and hardness measurements were carried out on a central cross-section of the HPT disc in tangential direction at different radii.

X-ray diffraction (XRD) experiments were performed with a SmartLab diffractometer (Rigaku Europe SE, Ettlingen, Germany) in parallel beam geometry using Cu-Kα radiation and a secondary monochromator in Leoben. Half of an HPT specimen with the axial direction parallel to the diffraction vector was used for these measurements. For analysis of peak position and peak width, the XRD pattern were fitted with pseudo-Voigt profiles and a parabolic background using Fityk software [

20].

Acknowledgments

Funding for this work has been provided by the Austrian Science fund (FWF): J3468-N20 and the European Research Council under ERC Grand Agreement No. 340185 USMS.

Author Contributions

T.M., A.B., and R.P. conceived and designed the experiments. T.M. performed the experiments and wrote the manuscript. E.N. and M.K. mixed and compacted the powders. A.B. prepared the pre-deformed HPT material. All authors contributed to the finalization of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pippan, R.; Wetscher, F.; Hafok, M.; Vorhauer, A.; Sabirov, I. The Limits of Refinement by Severe Plastic Deformation. Adv. Eng. Mater. 2006, 8, 1046–1056. [Google Scholar] [CrossRef]

- Bachmaier, A.; Hohenwarter, A.; Pippan, R. New Procedure to Generate Stable Nanocrystallites by Severe Plastic Deformation. Scr. Mater. 2009, 61, 1016–1019. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. Generation of metallic nanocomposites by severe plastic deformation. Int. Mater. Rev. 2013, 58, 41–62. [Google Scholar] [CrossRef]

- Pippan, R.; Bachmaier, A.; Hohenwarter, A.; Renk, O. Nanocomposites and super saturated solid solutions generated by SPD: The effect of initial structure and strain path. In Nanometals-Status and Perspective, Proceedings of the 33rd Risø International Symposium on Materials Science, Roskilde, Denmark, 3–7 September 2012; Faester, S., Ed.; Department of Wind Energy, Technical University of Denmark: Roskilde, Denmark, 2012; pp. 107–113. [Google Scholar]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Raabe, D.; Choi, P.-P.; Li, Y.; Kostka, A.; Sauvage, X.; Lecouturier, F.; Hini, K.; Kirchheim, R.; Pippan, R.; Embury, D. Metallic Composites Processed via Extreme Deformation: Toward the Limits of Strength in Bulk Materials. MRS Bull. 2010, 35, 982–991. [Google Scholar] [CrossRef]

- Thümmler, F.; Oberacker, R. Introduction to Powder Metallurgy; The Institute of Materials Series on Powder Metallurgy: London, England, 1993; p. 113. [Google Scholar]

- Predel, B. Cu-Fe (Copper-Iron). In Landolt-Börnstein–Group IV: Physical Chemistry (Cr-Cs–Cu-Zr); Madelung, O., Ed.; Springer: Berlin, Germany, 1994; Volume 5D. [Google Scholar] [CrossRef]

- Jiang, J.Z.; Gente, C.; Bormann, R. Mechanical Alloying in the Fe-Cu System. Mater. Sci. Eng. 1998, A242, 268–277. [Google Scholar] [CrossRef]

- Teplov, V.A.; Pilugin, V.P.; Gaviko, V.S.; Chernyshov, E.G. Non-equilibrium Solid Solution and Nanocrystal Structure of Fe-Cu Alloy after Plastic Deformation under Pressure. Phil. Mag. B 1993, 68, 877–881. [Google Scholar] [CrossRef]

- Teplov, V.A.; Pilugin, V.P.; Gaviko, V.S.; Chernyshov, E.G. Nanocrystalline Structure of Non-equilibrium Fe-Cu Alloys Obtained by Severe Plastic Deformation under Pressure. Nanostr. Mater. 1995, 6, 437–440. [Google Scholar] [CrossRef]

- Bachmaier, A.; Kerber, M.; Setman, D.; Pippan, R. The Formation of Supersaturated Solid Solutions in Fe-Cu Alloys Deformed by High-Pressure Torsion. Acta Mater. 2012, 60, 860–871. [Google Scholar] [CrossRef] [PubMed]

- Lukyanov, A.; Churakova, A.; Filatov, A.; Levion, E.; Valiev, R.; Gunderov, D.; Antipov, E. Microstructure Refinement in Cu-Fe Alloys Using High Pressure Torsion. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012102. [Google Scholar] [CrossRef]

- Krämer, L.; Wurster, S.; Pippan, R. Deformation Behavior of Cu-Composites Processed by HPT. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012026. [Google Scholar] [CrossRef]

- Sauvage, X.; Wetscher, F.; Pareige, P. Mechanical Alloying of Cu and Fe Induced by Severe Plastic Deformation of a Cu-Fe composite. Acta Mater. 2005, 53, 2127–2135. [Google Scholar] [CrossRef]

- Sauvage, X.; Pippan, R. Nanoscaled Structure of a Cu-Fe Composite Processed by High-Pressure Torsion. Mater. Sci. Eng. A 2005, 410–411, 345–347. [Google Scholar] [CrossRef]

- Quelennec, X.; Menand, A.; le Breton, J.M.; Pippan, R.; Sauvage, X. Homogeneous Cu-Fe Supersaturated Solid Solutions Prepared by Severe Plastic Deformation. Phil. Mag. 2010, 90, 1179–1195. [Google Scholar] [CrossRef]

- Clark, W.G. Improved Method of Coating Thin Iron or Steel Sheets, Wire or Tubing, or Small Iron Articles such as Nails or Screws, with Copper or its Alloys. Patent GB 13445, 1909. [Google Scholar]

- Turoňová, A.; Gálová, M.; Gernátová, M. Study of Electroless Copper Deposition on Fe Powder. Particul. Sci. Technol. 2008, 26, 126–135. [Google Scholar] [CrossRef]

- Wojdyr, M. Fityk: A general-purpose peak fitting program. J. Appl. Cryst. 2010, 43, 1126–1128. [Google Scholar] [CrossRef]

- TOPAS V4: General profile and structure analysis software for powder diffraction data. User’s manual; Bruker AXS: Karlsruhe, Germany, 2008; Available online: http://algol.fis.uc.pt/jap/TOPAS%204-2%20Users%20Manual.pdf (accessed on 20 September 2016).

- Ungár, T.; Tichy, G.; Gubicza, J.; Hellmig, R.J. Correlation between subgrains and coherently scattering domains. Powder Diffr. 2005, 20, 366–375. [Google Scholar] [Green Version]

- Suzuki, S.; Ishikawa, Y.; Isshiki, M.; Waseda, Y. Native oxide layers formed on the surface of ultra high-purity iron and copper investigated by angle resolved XPS. Mater. Trans. JIM 1997, 38, 1004–1009. [Google Scholar] [CrossRef]

- Andrievski, R.A. Review of thermal stability of nanomaterials. J. Mater. Sci. 2014, 49, 1449–1460. [Google Scholar] [CrossRef]

- Rane, G.K.; Welzel, U.; Meka, S.R.; Mittemeijer, E.J. Non-monotonic lattice parameter variation with crystallite size in nanocrystalline solids. Acta Mater. 2013, 61, 4524–4533. [Google Scholar] [CrossRef]

- Klement, W. Solid solutions in copper-iron alloys quenched rapidly from the melt. Trans. Met. Soc. AIME 1965, 233, 1080–1082. [Google Scholar]

- Gaffet, E.; Harmelin, M.; Faudot, F. Far-from equilibrium phase transition induced by mechanical alloysing in the Cu-Fe system. J. Alloy. Comd. 1993, 194, 23–30. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).