Effect of Welding Parameters on Microstructure and Mechanical Properties of Cast Fe-40Al Alloy

Abstract

:1. Introduction

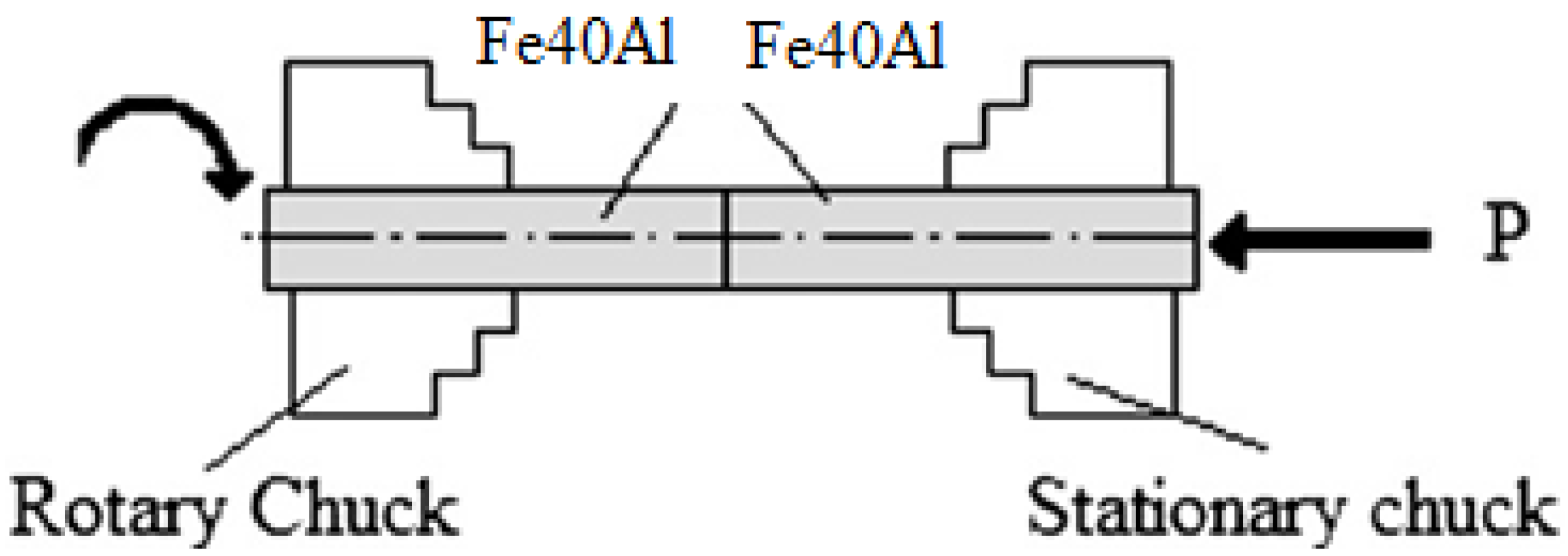

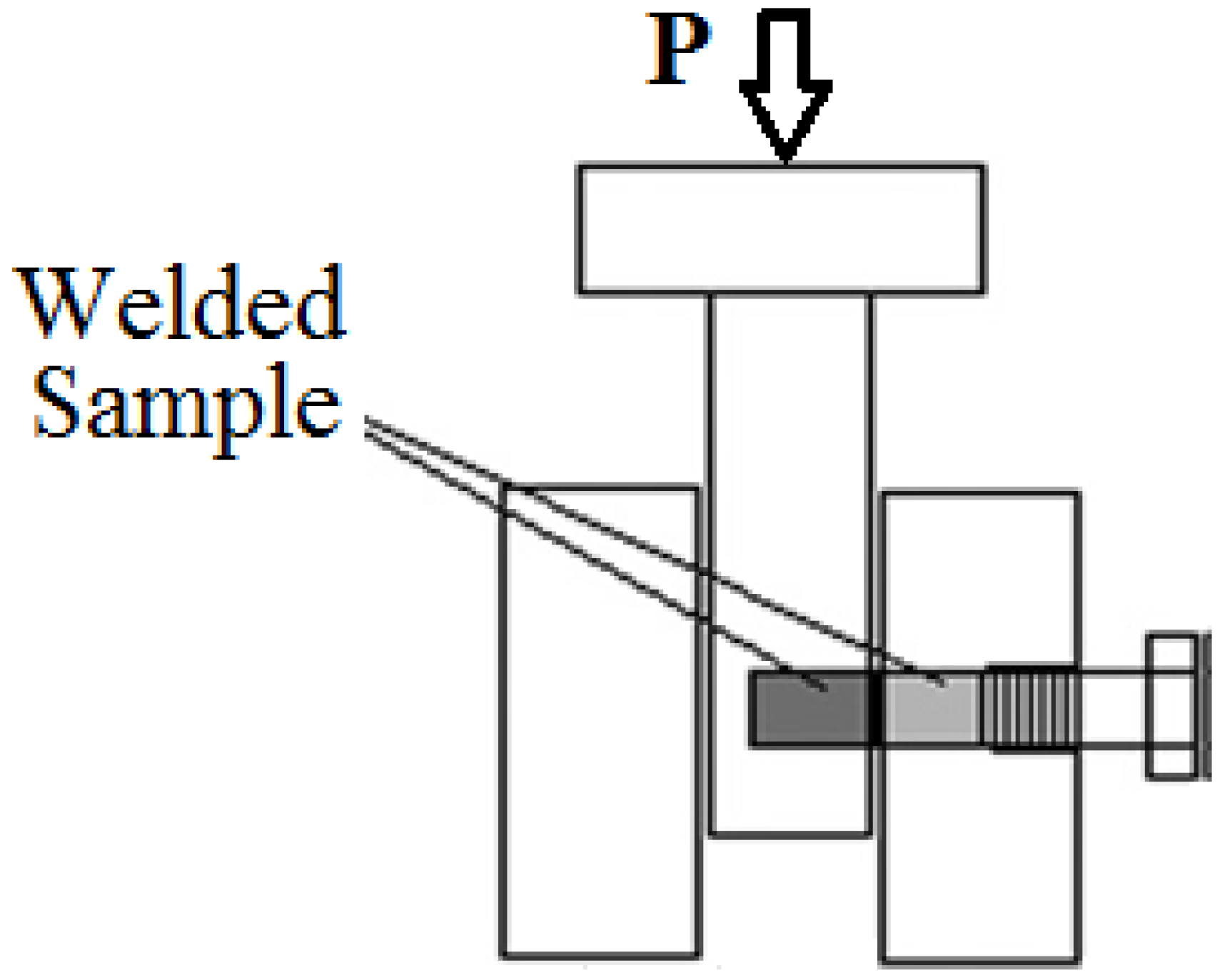

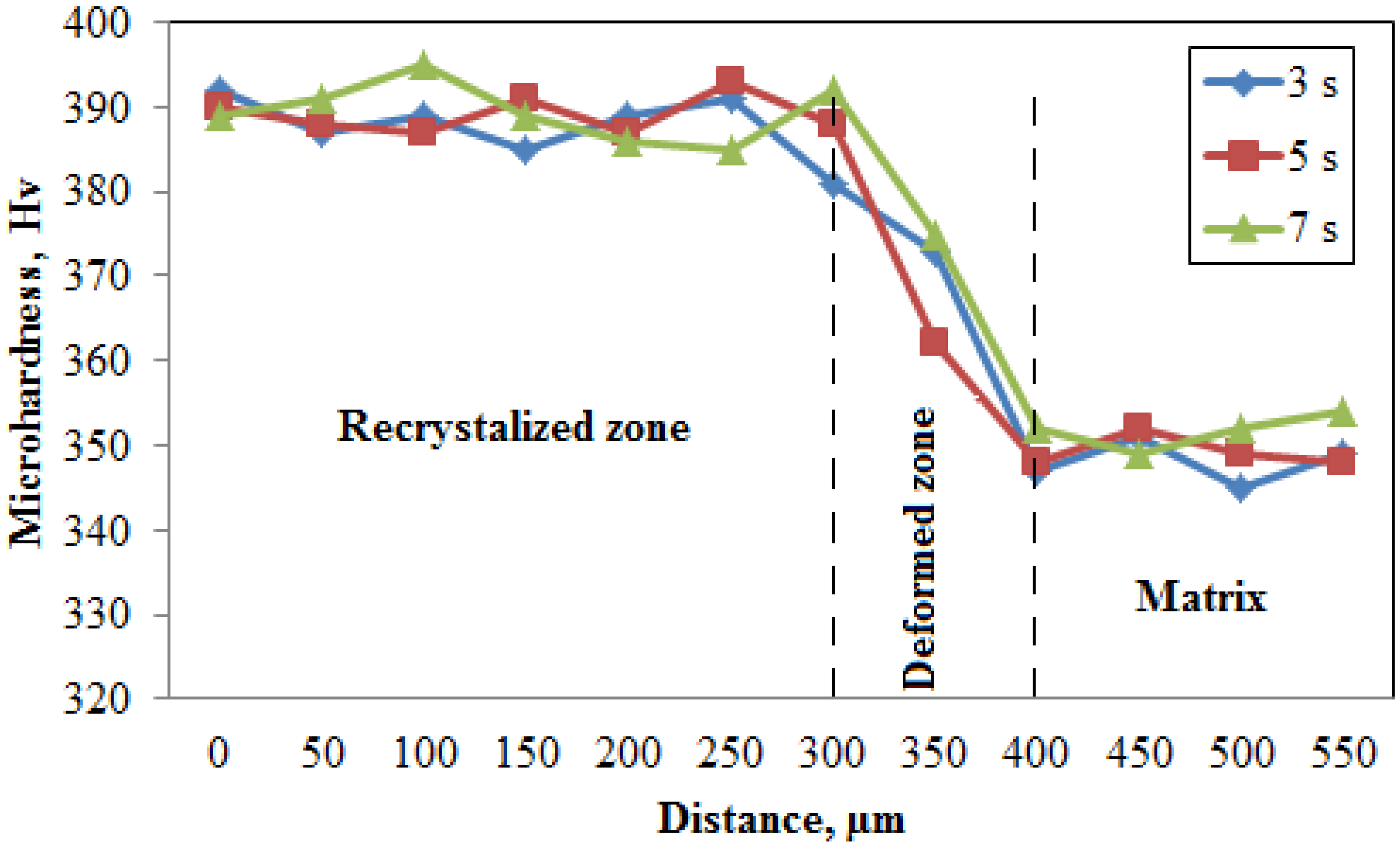

2. Experimental Studies

3. Results and Discussion

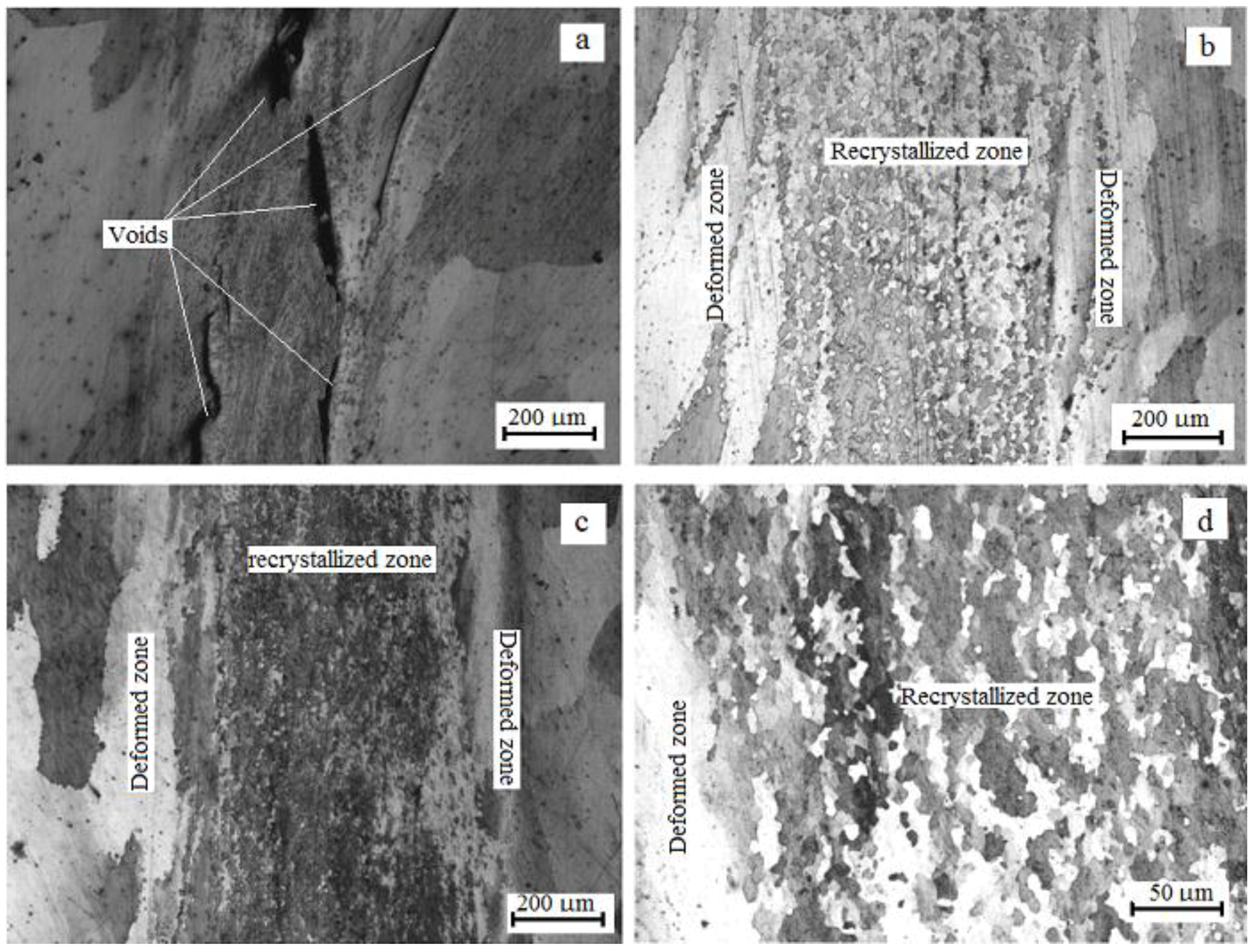

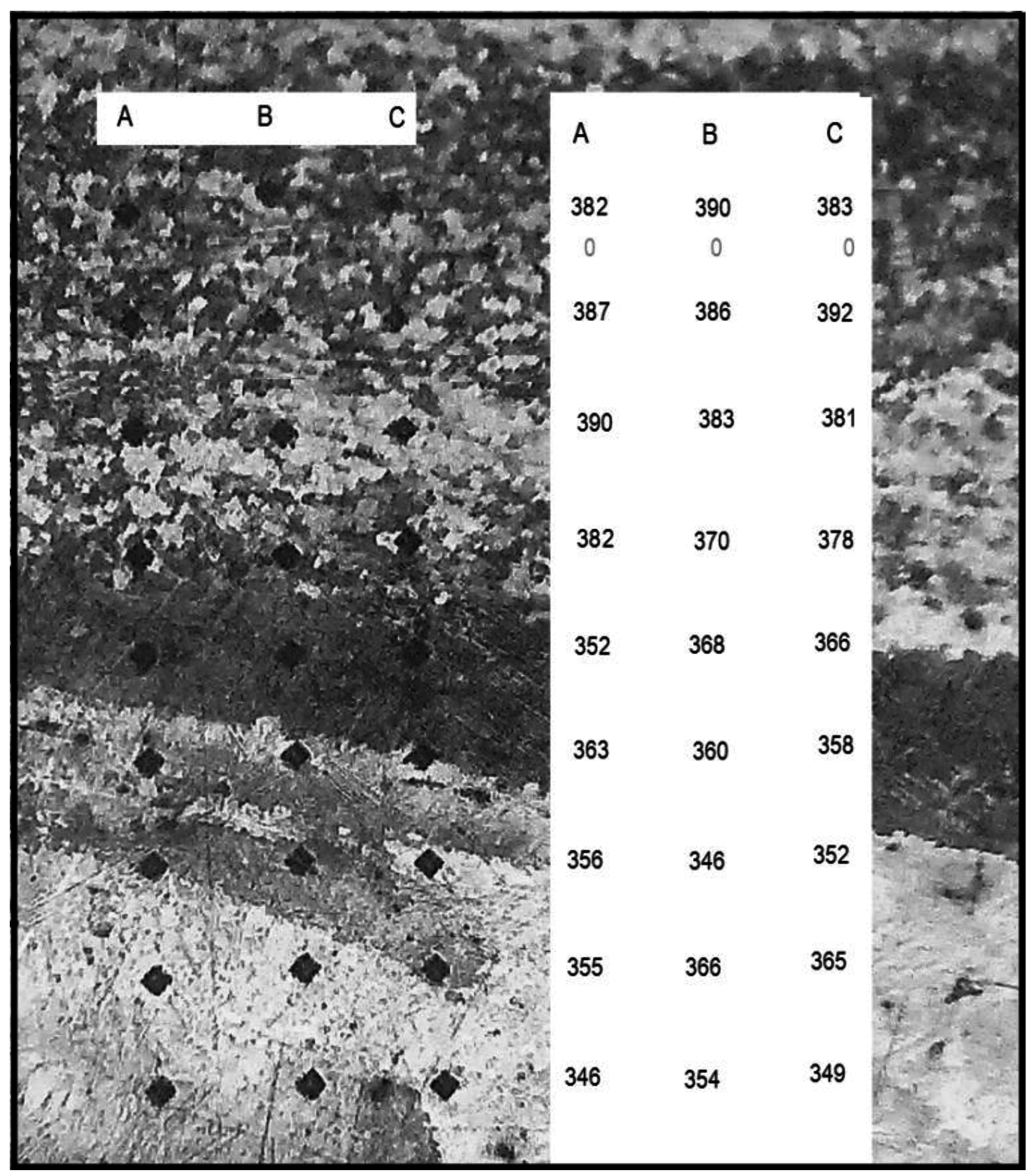

3.1. Microstructure

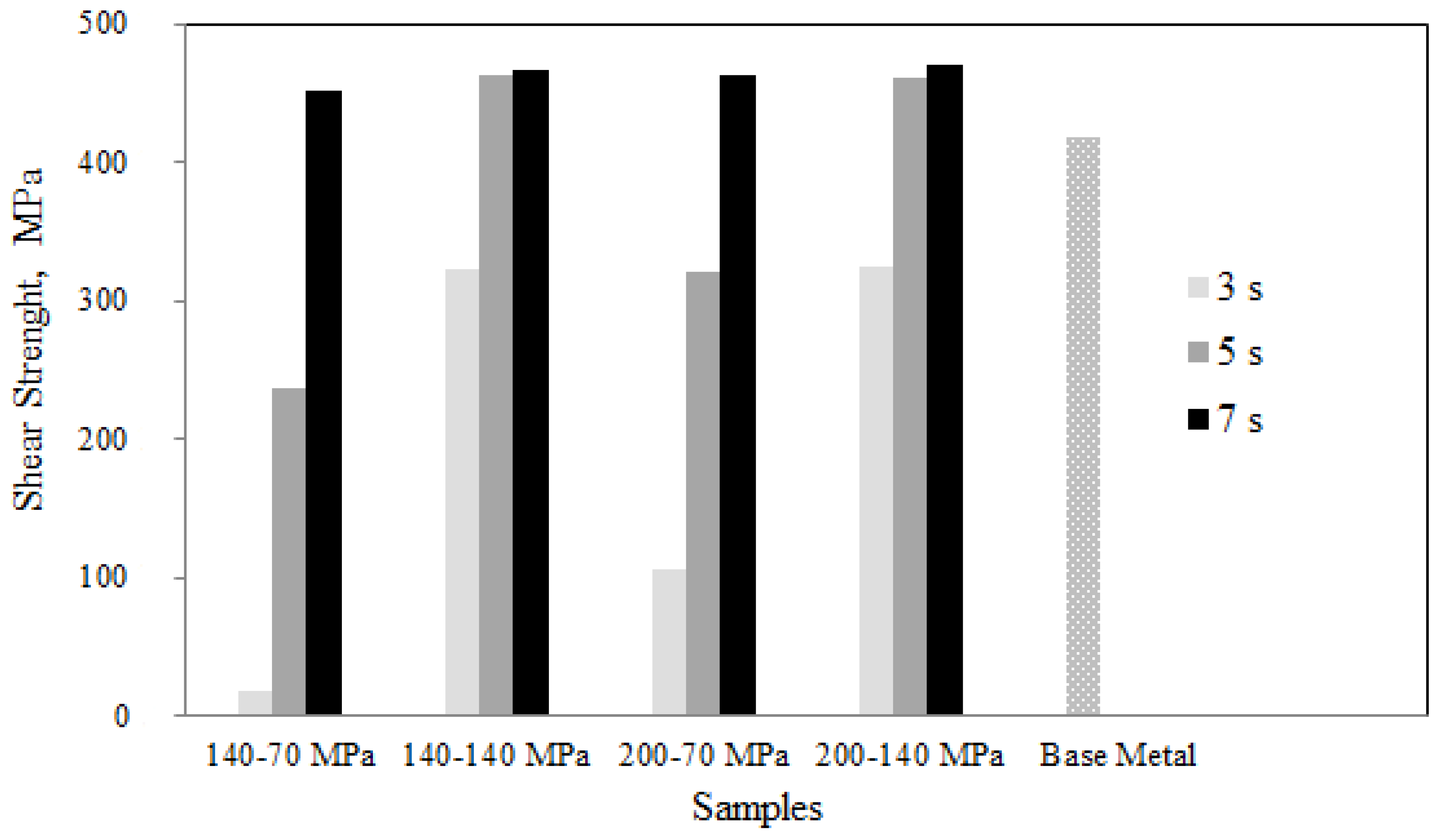

3.2. Mechanical Properties

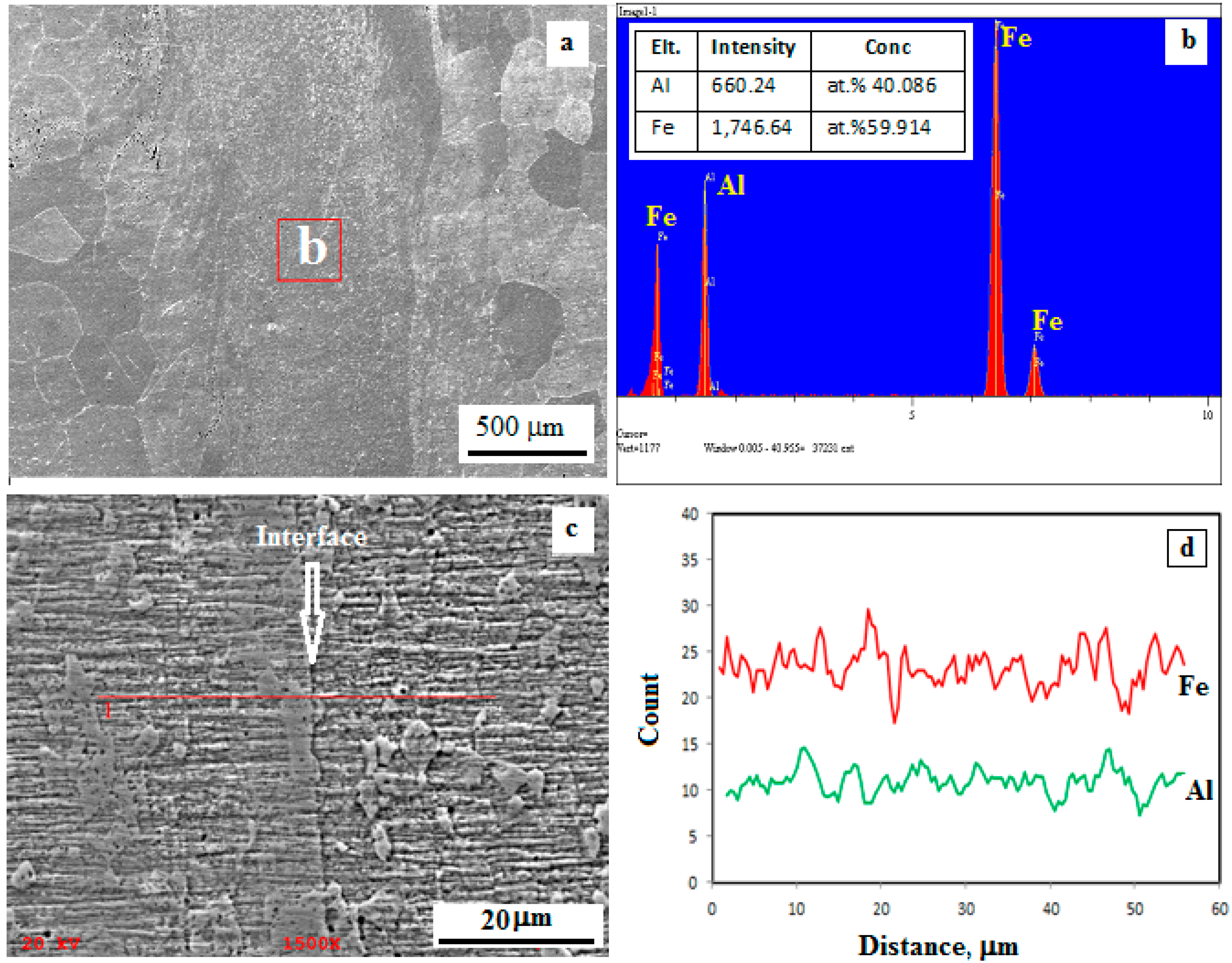

3.3. Fractographs

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Pank, D.R.; Nathal, M.V.; Koss, D.A. High Temperature Ordered Intermetallics Alloys III; Liu, C.T., Taub, A.I., Stoloff, N.S., Koch, C.C., Eds.; Materials Research Society: Pittsburgh, PA, USA, 1988; pp. 561–565. [Google Scholar]

- Liu, C.T.; Stringer, J.; Mundy, J.N.; Horton, L.L.; Angelini, P. Ordered intermetallic alloys: An assessment. Intermetallics 1997, 5, 579–596. [Google Scholar] [CrossRef]

- Stoloff, N.S.; Liu, C.T.; Deevi, S.C. Emerging applications of intermetallics. Intermetallics 2000, 8, 1313–1320. [Google Scholar] [CrossRef]

- Deevi, S.C.; Sikka, V.K.; Liu, C.T. Processing, properties, and applications of nickel and iron aluminides. Progress. Mater. Sci. 1997, 42, 177–179. [Google Scholar] [CrossRef]

- Deevi, S.C.; Swindeman, R.W. Yielding, hardening and creep behavior of iron aluminides. Mater. Sci. Eng. A 1998, 258, 203–210. [Google Scholar] [CrossRef]

- Stoloff, N.S. Iron aluminides: Present status and future prospects. Mater. Sci. Eng. A 1998, 258, 1–14. [Google Scholar] [CrossRef]

- McKamey, C.G.; DeVan, J.H.; Tortorelli, P.F.; Sikka, V.K. A review of recent developments in Fe3Al based alloys. J. Mater. Res. 1991, 6, 1779–1805. [Google Scholar] [CrossRef]

- Fasching, A.A.; Ash, D.I.; Edwards, G.R.; David, S.A. Hydrogen cracking behavior in an iron aluminide alloy weldment. Scr. Metall. 1995, 32, 389–396. [Google Scholar] [CrossRef]

- Lee, Y.L.; Shiue, R.K.; Wu, S.K. The microstructural evolution of infrared brazed Fe3Al by BNi-2 braze alloy. Intermetallics 2003, 11, 187–195. [Google Scholar] [CrossRef]

- Morris, D.G.; Chao, J.; Garcia Oca, C.; Morris-Munnoz, M.A. Obtaining good ductility in an FeAl intermetallic. Mater. Sci. Eng. A 2003, 339, 232–240. [Google Scholar] [CrossRef]

- Morris, D.G.; Morris-Munnoz, M.A. The infuence of microstructure on the ductility of iron aluminides. Intermetallics 1999, 7, 1121–1129. [Google Scholar] [CrossRef]

- Morris, D.G.; Gutierrez-Urrutia, I.; Morris-Munnoz, M.A. Evolution of microstructure of an iron aluminide during severe plastic deformation by heavy rolling. J. Mater. Sci. 2008, 43, 7438–7444. [Google Scholar] [CrossRef]

- Ozdemir, N. Investigation of the mechanical properties of friction-welded joints between AISI 304L and AISI 4340 steel as a function rotational speed. Mater. Lett. 2005, 59, 2504–2511. [Google Scholar] [CrossRef]

- Ateş, H.; Turker, M.; Kurt, A. Effect of friction pressure on the properties of friction welded MA956 iron-based superalloy. Mater. Des. 2007, 28, 948–953. [Google Scholar] [CrossRef]

- Tao, B.H.; Li, Q.; Zhang, Y.H.; Zhang, T.C.; Liu, Y. Effects of post-weld heat treatment on fracture toughness of linear friction welded joint for dissimilar titanium alloys. Mater. Sci. Eng. A 2015, 634, 141–146. [Google Scholar] [CrossRef]

- Rovere, C.A.D.; Ribeiro, C.R.; Silva, R.; Baroni, L.F.S.; Alcântara, N.G.; Kuri, S.E. Microstructural and mechanical characterization of radial friction welded supermartensitic stainless steel joints. Mater. Sci. Eng. A 2013, 586, 86–92. [Google Scholar] [CrossRef]

- Winiczenko, R.; Kaczorowski, M. Friction welding of ductile iron abd stainless steel. Mater. Process. Technol. 2013, 213, 453–462. [Google Scholar] [CrossRef]

- Kırık, I.; Ozdemir, N.; Çalıgülü, U. Effect of particle size and volume fraction of the reinforcement on the microstructure and mechanical properties of friction welded MMC to AA6061. Kov. Mater. 2013, 51, 221–227. [Google Scholar]

- Davis, C.J. Micro friction welding aluminum studs to mild steel plates. Metal Constr. 1977, 9, 196–197. [Google Scholar]

- Yılbaş, B.S.; Şahin, A.Z.; Kahraman, N.; Garni, Z.A.A. Friction welding of St-Al and Al-Cu materials. J. Mater. Process. Technol. 1995, 49, 431–443. [Google Scholar] [CrossRef]

- Tanaka, T.; Morishige, T.; Hirata, T. Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr. Mater. 2009, 61, 756–759. [Google Scholar] [CrossRef]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Pierpaolo, C.; Antonello, A.; Gaetano, S.P.; Valentino, P.; Antonino, S. Microstructural aspects in Al-Cu dissimilar joining by FSW. Int. J. Adv. Manuf. Technol. 2015, 79, 1109–1116. [Google Scholar]

- Sketchley, P.D.; Threadgill, P.L.; Wright, I.G. Rotary friction welding of an Fe3Al based ODS alloy. Mater. Sci. Eng. A 2002, 329–331, 756–762. [Google Scholar] [CrossRef]

- Inkson, B.J.; Threadgill, P.L. Friction welding of FeAl40 Grade 3 ODS alloy. Mater. Sci. Eng. A 1998, 258, 313–318. [Google Scholar] [CrossRef]

- Torun, O.; Çelikyürek, I.; Baksan, B. Friction welding of cast Fe-28Al alloy. Intermetallics 2011, 19, 1076–1079. [Google Scholar] [CrossRef]

- Çelikyürek, İ.; Torun, O.; Baksan, B. Microstructure and strength of friction-welded Fe–28Al and 316 L stainless steel. Mater. Sci. Eng. A 2011, 528, 8530–8536. [Google Scholar] [CrossRef]

- Karabulut, A.; Tasgetiren, S. Sürekli tahrikli sürtünme kaynak makinesi tasarım ve imalatı. Mak. Teknol. Elektron. Derg. 2004, 3, 38–46. [Google Scholar]

- Misra, M.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Dey, H.C.; Ashfaq, M.; Bhaduri, A.K.; Rao, K.P. Joining of titanium to 304L stainless steel by friction welding. J. Mater. Process. Technol. 2009, 209, 5862–5870. [Google Scholar] [CrossRef]

| Friction Speed (rmp) | Forging Pressure (MPa) | Friction Pressure (MPa) | Friction Time (s) | Burn-Off (mm) |

|---|---|---|---|---|

| 1000 | 140 | 70 | 3 | 1.5 |

| 1000 | 140 | 70 | 5 | 4.2 |

| 1000 | 140 | 70 | 7 | 9.2 |

| 1000 | 140 | 140 | 3 | 4.2 |

| 1000 | 140 | 140 | 5 | 10.9 |

| 1000 | 140 | 140 | 7 | 18.5 |

| 1000 | 200 | 70 | 3 | 4.2 |

| 1000 | 200 | 70 | 5 | 10.9 |

| 1000 | 200 | 70 | 7 | 18.5 |

| 1000 | 200 | 140 | 3 | 5.3 |

| 1000 | 200 | 140 | 5 | 11.7 |

| 1000 | 200 | 140 | 7 | 20.5 |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torun, O. Effect of Welding Parameters on Microstructure and Mechanical Properties of Cast Fe-40Al Alloy. Metals 2016, 6, 229. https://doi.org/10.3390/met6100229

Torun O. Effect of Welding Parameters on Microstructure and Mechanical Properties of Cast Fe-40Al Alloy. Metals. 2016; 6(10):229. https://doi.org/10.3390/met6100229

Chicago/Turabian StyleTorun, Osman. 2016. "Effect of Welding Parameters on Microstructure and Mechanical Properties of Cast Fe-40Al Alloy" Metals 6, no. 10: 229. https://doi.org/10.3390/met6100229