1. Introduction

The controlled treatment of stormwater is critical in the reduction and removal of water pollutants and in ameliorating the risk of groundwater and downstream surface water pollution. Granular filters consisting of sand and gravel have now been used extensively for treatment of domestic wastewater for over a century. These filters are operated either in a single pass or recirculation mode. Geotextiles are used for separation, reinforcement, filtration, drainage and for acting as a barrier within urban drainage designs. Geotextiles orientated specifically for stormwater treatment are still being developed with some being used in drainage systems today. The use of geotextiles for filtration purposes dates back further than any of their other attributes [

1]. Geotextiles have been implemented as part of sand filter systems [

2]; as a baffle system for a combined sewer overflow [

3]; packed in a conduit for septic tank outflows; and, as part of a permeable paving system [

4]. There still is insufficient research solely on the effects of geotextiles within stormwater treatment and the effects of various contaminants found within stormwater. This research work is on-going and this study forms part of that work.

Geotextiles are permeable materials that can be woven, unwoven or knitted [

5]. Natural geotextiles are commonly used in developing countries since the raw material is often in abundance and cheaper than the synthetic equivalents. However, natural geotextiles often experience a lower resistance to degradation than their synthetic equivalents. Synthetic geotextiles are typically either formed from polypropylene or polyethylene terephthalate [

5]. Typically in construction, geotextiles are placed down gradient of the soil to be filtered. Water passes through the geotextile at a normal to the plane of flow, blocking any soil particles larger than the pore size from passing through. This allows for the use of geotextiles in roadside drainage as they provide some filtration to surface run-off. Another use is in permeable pavement systems where the filtered water is intended to be discharged into the ground and where the water proofed membrane is used in systems where a higher concentration of pollution (e.g., petrol and oils) in the water demands further treatment before discharge. The use of geotextiles in filtration systems all assume they are capable of sustaining a certain amount of structural load due to other layers present above the geotextile. It is assumed that this causes the geotextiles to compress thus decreasing the space between fibres, or pore space. The impact of this compression means that a geotextile will become prone to clogging as demonstrated in a recent study where the drainage and filtration properties of nonwoven geotextiles under confinement were explored and the pore size measured as the applied normal stress was increased [

6]. This means a greater retention time within the geotextiles occurs in practice particularly as the pores become clogged by soil particles that have been filtered [

7]. This supports the results which indicate that as the applied normal stress is increased, the geotextile’s permeability reduces.

The use of geotextiles in conjunction with soil filters have been used in drainage systems for leachate management from landfill sites [

8]. The geotextiles were initially installed to act as a barrier to avoid soil particles from reaching and clogging a geosynthetic drain. However, it was noticed that the geotextile itself was performing much of the filtration. Koerner and Koerner [

8] designed a number of experiments to test the change of permeability in the soil/geotextile filter system over time, and assessed potential remediation techniques to recover it. The permeability of the system, measured using a permeameter, was shown to reduce over the 20 month experimental period; however this could be recovered by back flushing the system to remove clogging by both soil particles and bacterial growth as biofilm. The research also showed that the geotextile filters appear to be less vulnerable to clogging when compared to soil filters alone (as applied in leaching field context), and concluded with several recommendations for usage of woven and nonwoven geotextiles alike [

8].

It may be noted that whilst geomembranes also form part of the category of geosynthetics, they are impermeable to water and therefore are used in projects where it essential for a hydraulic barrier. Investigations have been conducted to review the use of geotextiles to host biomass facilitating biological treatment, in order to reduce levels of total suspended solids (TSS), biochemical oxygen demand (BOD

5) and ammonia-nitrogen (NH

3). Yaman

et al. [

2] found that falling levels of permeability associated with clogging can be reduced by applying a dose and drain cycle feeding onto the system rather than a continuous feed operation, and recommended the use of two layers of geotextiles for improved filtration and permeability.

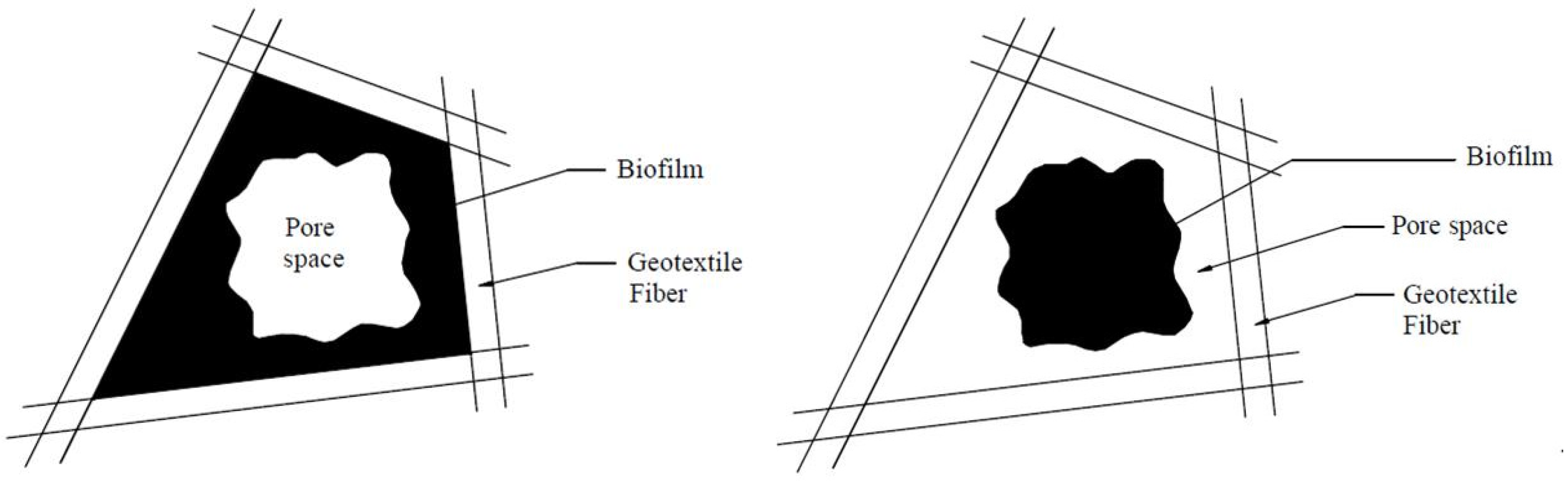

Figure 1 illustrates how the permeability of a geotextile stabilises by limitations on the growth of biofilm in and around the pore spaces. This is due to the outer layers limiting the oxygen required by the bacteria closer to the fibres, and thereby potentially achieving anaerobic conditions deeper within the biofilm zone [

2]. The biofilm forms within pores of the geotextile, rather than in the gravels and sands adjacent. This helps reduce the clogging in the overall system and maintains stable hydraulic loading rates when compared to standard sand filter systems. The drawback to having only aerobic treatment as part of the design is a reduction in treatment efficacies of nitrates requiring longer retention times from filtration. The stormwater itself has high dissolved oxygen levels (>5 mg/L) due to entrained oxygen gained as it flows through the surface drains and as it percolates through the pores of the filter media. This means that the bulk of stormwater treatment occurring is treated aerobically (removing dissolved organic matter and suspended particles) as it flows through the fixed biofilm zone around the geotextile layer. However, it must be noted that simultaneous anaerobic treatment takes place within pockets of the thickened biofilm where concentrations of attached flocs are greatest. As such, the suggestion that the biofilm has anaerobic zones within it indicates that a higher level of reduction can be achieved. Thus it is theorised that the suspended and dissolved organic matter in the stormwater is treated both aerobically and anaerobically by the fixed biofilm and any adjacent suspended flocs. This situation is desirable as it produces fewer by-products [

9].

Figure 1.

Two models for biomass accumulation in a fibrous geotextile structure(adapted after [

2]).

Figure 1.

Two models for biomass accumulation in a fibrous geotextile structure(adapted after [

2]).

The aim of this study was to assess the optimal design of geotextile filtration systems as a way to protect receiving waters from pollution discharges within urbanised environments. The main objectives of this research project were to further develop the use of geotextile membranes as a potential sustainable urban drainage system (SUDS) for urban stormwater treatment. This would in turn enhance the available water reuse strategies. Several key issues were addressed in this initial research work as follows:

- -

Does the introduction of a cost effective geotextile layer within the standard granular filter system enhance biochemical treatment performance? Is the number and location of the geotextile layer/s in relation to the granular filter layers important in determining the extent of treatment achieved?

- -

Does the addition of a further geotextile layer improve treatment efficiency whilst reducing the overall depth of the granular filter layers? Could this be a way of cost effectively reducing volumes of materials needed in granular stormwater filter systems?

- -

Was there a significant difference in the formation, growth and thickness of the biofilm that carries out the bulk of the treatment on the different geotextile membrane layers? Does any differences in biofilm formation match theory and expectations?

This study forms part of a much larger research effort some of which is described in Tota-Maharaj and Paul [

10]. Thus this work is an initial phase of research work that looks at the applicability of adding geotextile layering into the granular filter media layers, and its overall impact on stormwater treatment, volumetric loading throughput and associated biofilm formation.

2. Materials and Methods

Three cylindrical water butts were obtained to house the various layers of aggregate and geotextile that were used in the experiments. Each had a volumetric capacity of 200 L. The water butts were filled with layers of filter media including sand, pea gravel, gravel and as necessary geomembrane layer or layers according to the configurations shown in

Figure 2 and

Figure 3. Each water butt was equipped with a drainage tap at the base. These taps were checked for leaks prior to the beginning of the investigation and were sealed using a rubber sealant (

Figure 3).

A standard, cost effective, commercially available geotextile filter was selected that was made from a non-woven fabric having a 180 µm pore size. This specific geotextile was designed for applications in drainage, filtration and separation systems (Terram Geosynthetics, Essex, UK). The geotextile filter used in Filter Rigs No. 2 and No. 3 had a design permeability of 100 L/m

2.s and a thickness of 0.9 mm. The geotextiles were manufactured from UV (ultra-violet) stabilised, high tenacity, polypropylene fibres that were both mechanically and thermally bonded to provide high strength and excellent filterability characteristics. Significant factors affecting the flow velocity such as the porosity values for the filter media (

i.e., sand, pea gravel and gravel layers) embedded into the granular filters and relevant depths with corresponding saturation volumes are presented in detail in Tota-Maharaj and Paul [

10]. The aggregates and filter media used to make up the sand and gravel layers were commercially available (

Table 1). Specialist dry sand was used for the middle layers, whilst a coarse gravel and pea gravel were used in the lower and upper layers in each rig (

Figure 2 and

Figure 3).

Figure 2.

(a) Storage tank for stormwater undergoing aeration and prior to pumping to filters; (b–d) Granular Filter Rigs Nos. 1, 2 and 3 with varying layers of gravel, pea gravel, sand and geotextile membrane.

Figure 2.

(a) Storage tank for stormwater undergoing aeration and prior to pumping to filters; (b–d) Granular Filter Rigs Nos. 1, 2 and 3 with varying layers of gravel, pea gravel, sand and geotextile membrane.

Figure 3.

From Left to Right—Granular Filter Rigs Nos. 1, 2 and 3 with varying layers of gravel, pea gravel, sand and geotextile membrane.

Figure 3.

From Left to Right—Granular Filter Rigs Nos. 1, 2 and 3 with varying layers of gravel, pea gravel, sand and geotextile membrane.

Table 1.

Aggregates and filter media used in the granular filtration system.

Table 1.

Aggregates and filter media used in the granular filtration system.

| Filter Media | Product | Approx. Size (mm) |

|---|

| Sand | Leighton Buzzard BS16/30 | 0.5–1.00 |

| Pea Gravel | Amber Flint | 6 |

| Coarse Gravel | Pink Granite | 20 |

A water-proof commercially based rubber sealant was used as a temporary barrier between the geotextile and the water butt internal wall to prevent any possibilities of hydraulic short-circuiting. Additionally, biofilm growth was visually measured with periodic membrane autopsies, and carried out at one-third the distance from the rig’s wall to represent a typical location on the geotextile surface whereby most representative samples usually occurred. The experimental rigs were kept at a room temperature (20 °C) throughout the analysis. The particle size specifications for granular media used was D10 for sand, and D50 for gravel and pea gravel respectively. The D50 particle diameter for gravel and pea gravel represented 50% of the gravel particles (by weight).

Unlike conventional sand filters the order particle size distribution of the aggregates are essentially reversed [

11]. The depths for the different layers were set whereby the largest aggregate volume (sand) acts as an attenuating segment and slows the flow of the water through the rigs, thus increasing contact time within the geotextile layers. The upper coarse gravel layer role is to both dissipate energy from the water before reaching the geotextile layers and also to evenly distribute the water across the surface area [

12]. The large volumes of space between the larger aggregates and grains allows for the movement of air, encouraging the extraction of air during the dose/drain cycle and creating aerobic conditions leading to some natural degradation. The upper pea gravel layers also dissipate energy from the water and provide a housing and support for the geotextile membrane. The lower layers of pea and coarse gravel were employed to limit the travel of sand and into the taps and act as a tertiary stage filtration for the final effluent.

The configuration of Filter Rig No. 1 and Filter Rig No. 2 was almost identical volume wise apart from the addition of the single thin geotextile layer in the second rig. The difference, volume wise, between these two rigs and Filter Rig No. 3 was marked, with less filter media being used overall whilst an additional geotextile layer was added. This comparative experiment tested the effectiveness of volumetric flows used within the sub-base layer based on the cost of materials used for the same application. Thus it was carried out to see whether with an additional geotextile membranes layer with an associated 15% drop in volume of granular filter media used (and thus associated cost), allowed the system’s treatment performance to be improved or equally caused a deterioration since there would be less sub-base filler material such as sand and gravel to treat the same quality and quantity of stormwater. In terms of a full scale system, a considerable saving could be made in not only the volumes of materials needing to be transported and placed in situ, but also the amount of cut and fill actually required since potentially shallower profiles could be used. Shallower depths would also make recharging the system’s permeability by periodic back washing of the media and replacing or cleaning the geotextile membrane an easier operation to carry out.

The influent stormwater used was a mixture of river water from the River Pinn, London, and gully pot liquors. Gully pots are small settling chambers or sumps located along roadsides and covered with a protective cast iron grating, used to treat surface runoff entering the drainage system by removing its high organic pollutant load [

13]. The granular filter rigs operated in a batch-fed single pass mode under gravity,

i.e., the stormwater mixture flows through the filter only once from top to bottom. The stormwater mixture was distributed evenly over the upper surface of the filter using a system of a splash deck and a small perforated pipe network. The water then drained through the system, finally accumulating in the sub-base zone of the filter, and could be collected from the outlet pipe. This collected water could then be sampled for water quality analysis. This method was used due to its simplicity and low energy requirements, as opposed to a recirculating filter which would require extra energy to pump filtrate to the top to mix with incoming stormwater influent before cycling through the system again.

The efficacy of the three experimental granular filter rigs was compared by analysing various water quality parameters including suspended solid matter as TSS, chemical oxygen demand (COD), dissolved oxygen (DO), pH, temperature, conductivity, nitrate-nitrogen (NO

3-N) (mg/L), and phosphates (PO

43−) (mg/L). All water quality parameters were determined using the American Water and Wastewater Association’s Standard Methods [

14]. A Hanna H1991300 meter was used for temperature and pH measurement, with a precision of ±0.5 °C and for pH ± 0.1. Two additional Hanna meters H19033 and H19142 were used to measure conductivity and DO with a precision of µS/cm ± 1% full scale, and ±0.8 mg/L respectively. NO

3-N (mg/L) was measured using the cadmium reduction method with a Hach spectrophotometer (Hach Lange, Salford, UK) [

15,

16] and PO

43− (mg/L) was measured using the Amino Acid Method with the same spectrophotometer. The COD content was analysed using a Hach DRB 200 spectrophotometer using the dichromate/sulphuric acid digestion method [

15,

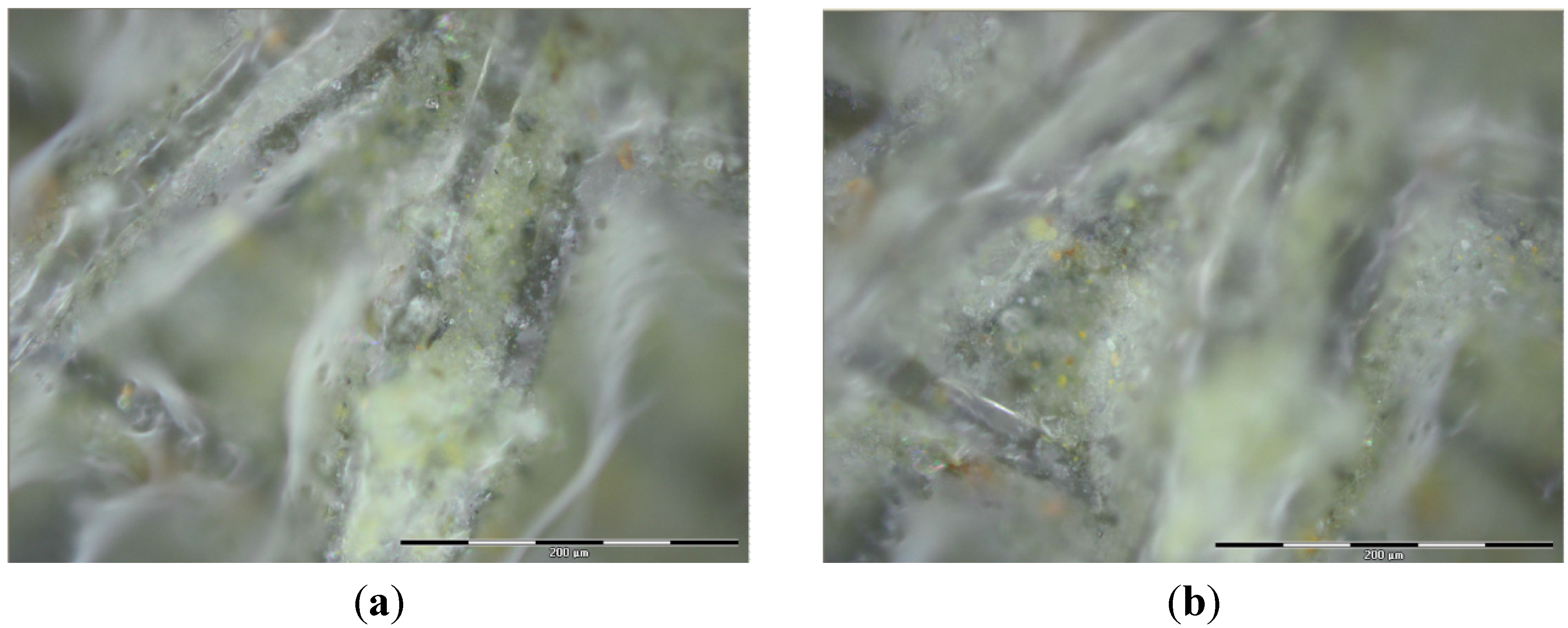

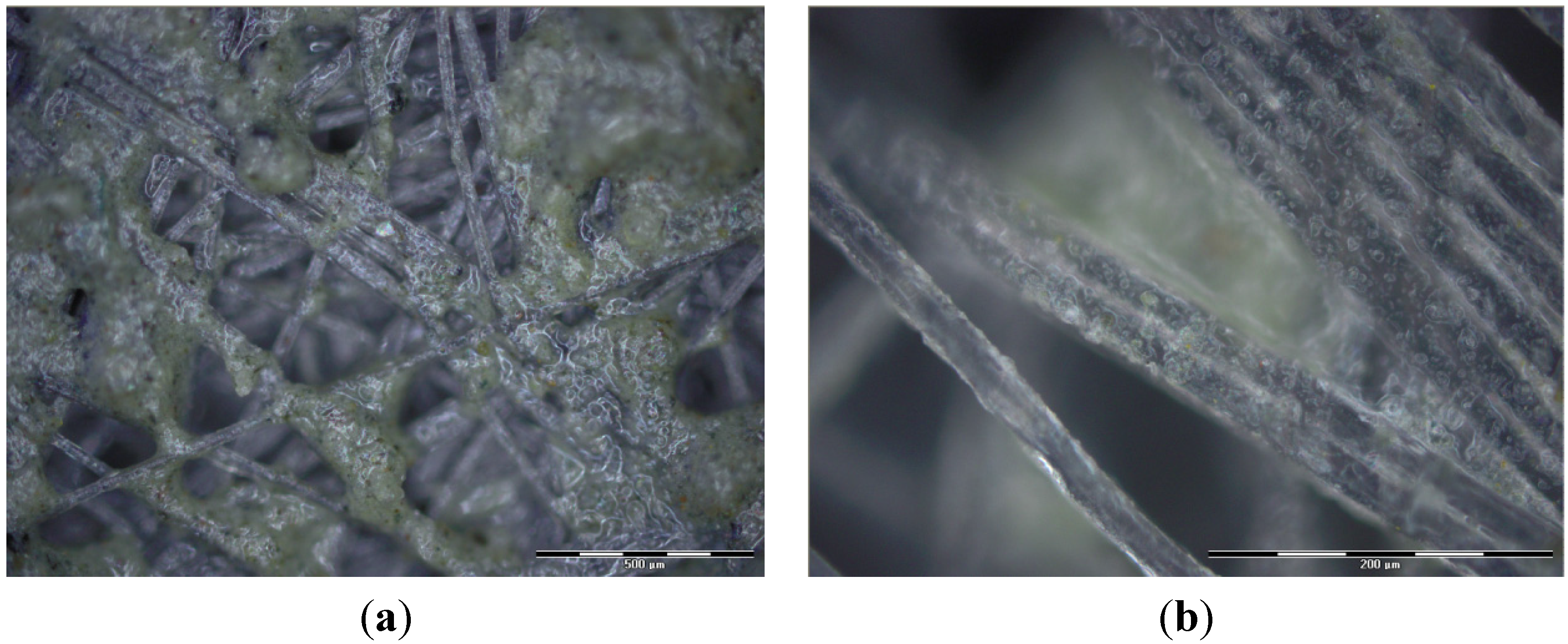

16]. In addition to the water quality tests, an optical microscope connected to a computer was used to take images of the various geotextile layers in Filter Rigs No.2 and No.3 using a standard membrane autopsy procedure. These images were then compared in order to identify any differences in the composition of the biofilm, and whether the biofilm had accumulated on the surface of the geotextile fibres or whether it was suspended largely in the pore spaces between the fibres. Further, the microscopic images were used to gauge, observationally, as to whether there was more or less biofilm growth for each autopsy sample, and whether this correlated with theory and expectation in terms of hydraulic throughput and treatment mechanisms occurring. Multivariate analysis of variance (MANOVA) which is an extension of the standard analysis of variance (ANOVA) procedure was used to statistical compare and correlate results since several dependent and independent variables were used in the experimental setup. The MANOVA statistical tests evaluated for differences in two or more vectors of means.

3. Results and Discussion

The water quality parameters for the inflow stormwater mixture (combined water from the River Pinn, London and gully pot liquors) are presented in

Table 2. It can be seen that the stormwater quality is in the typical range expected, and of generally low to moderate strength in terms of the COD, TSS and NO

3-N values.

Table 2.

Inflow stormwater composition and mixture (i) range (minimum–maximum); (ii) standard deviation; (iii) mean and (iv) standard error of the mean , sample number n = 80 and period of analysis (May 2012–October 2013).

Table 2.

Inflow stormwater composition and mixture (i) range (minimum–maximum); (ii) standard deviation; (iii) mean and (iv) standard error of the mean , sample number n = 80 and period of analysis (May 2012–October 2013).

| Stormwater Inflow Parameters | Range | Std. Deviation | Mean | Std. Error of Mean |

|---|

| Water Sample Temp (°C) | 12.0–21.0 | 1.15 | 15.71 | 0.64 |

| pH | 6.40–7.70 | 0.09 | 6.98 | 0.31 |

| Conductivity (μS/cm) | 567.0–1095.0 | 165.02 | 830.63 | 44.30 |

| Nitrate-Nitrogen (NO3-N, mg/L) | 0.17–4.03 | 0.81 | 2.16 | 0.32 |

| Phosphate ion (PO43−, mg/L) | 1.12–8.15 | 2.18 | 3.31 | 0.52 |

| Chemical Oxygen Demand (COD, mg/L) | 101.0–390.0 | 103.16 | 205.54 | 38.58 |

| Dissolved Oxygen (DO, mg/L) | 5.80–8.7 | 0.88 | 7.52 | 0.49 |

| Total Suspended Solids (mg/L) | 15.3–86.5 | 16.33 | 41.73 | 4.03 |

Table 3 shows the average concentrations of the measured water quality parameters at the outflow. Thus the effectiveness of the geotextile layer within the filters can be directly compared. The MANOVA statistical procedure that was used tested the means for COD, NO

3-N, PO

43−, and TSS outflow concentrations. The MANOVA procedure found that there were no significant differences found between the mean outflow concentrations between Filter Rig No. 2 and Filter Rig No. 3 (

p > 0.05). However, the MANOVA test did find that both rigs that contained one or more geotextile layers showed statistical differences in all the water parameter outflow concentrations when measured against the results obtained from Filter Rig No. 1 (

p < 0.05). This initial finding appears to confirm that inclusion of a cost effective geotextile layer within the standard granular filter system does enhance particulate removal and biochemical treatment performance, but that the addition of further layers do not improve upon the extent of treatment achieved, even though they achieve the same treatment level with a 15% reduction in overall granular filter layer thickness. Thus this initial work appears to indicate that significant savings could be made by including several geotextile layers at judicious points within the granular filter system. However this does not take into account any impact on the overall hydraulic performance which will be discussed in a later section.

Table 3.

Overall measured outflow—Mean (and Standard Deviation) of various effluent characteristics for each pilot granular filter rig, sample number n = 80 and period of analysis (May 2012–October 2013).

Table 3.

Overall measured outflow—Mean (and Standard Deviation) of various effluent characteristics for each pilot granular filter rig, sample number n = 80 and period of analysis (May 2012–October 2013).

| Water Quality Parameters | Granular Filters |

|---|

| 1 | 2 | 3 |

|---|

| Water Sample Temp (°C) | 20.94 ± (2.01) | 20.11 ± (2.02) | 20.03 ± 2.04 |

| pH | 6.98 ± (0.35) | 6.94 ± (0.23) | 7.01 ± 0.16 |

| Conductivity (μS/cm) | 783.49 ± (122.34) | 744.50 ± (132.21) | 725.18 ± (137.90) |

| Nitrate-Nitrogen (NO3-N, mg/L) | 1.21 ± (0.24) | 1.16 ± (0.88) | 1.07 ± (1.05) |

| Phosphate ion (PO43−, mg/L) | 2.18 ± (1.15) | 1.87 ± (0.34) | 1.74 ± (0.68) |

| Chemical Oxygen Demand (COD, mg/L) | 76.60 ± (37.31) | 69.81 ± (26.23) | 63.70 ± (31.44) |

| Dissolved Oxygen (DO, mg/L) | 7.25 ± (0.92) | 7.63 ± (0.87) | 7.42 ± (0.83) |

| Total Suspended Solids (TSS, mg/L) | 4.86 ± (3.27) | 3.37 ± (4.15) | 2.15 ± (2.31) |

3.1. Turbidity and Suspended Solids

The relationship between the effluent turbidity and suspended solids varied depending on the concentrations present within the gully pots themselves and the frequency of rainfall events.

Figure 4 shows the relationship between the effluent turbidity and suspended solids concentrations for Filter Rig No. 1 (no geotextile layer). A strong linear correlation existed for all three rigs with respect to outflow turbidity measurements and the suspended solids concentrations (

R2 = 0.88).

3.2. Hydraulic Characteristics and Water Quality

The method for testing the hydraulic flow rate through the three experimental rigs occurred periodically. An average flow rate of 600 L per hour with de-ionised water was poured onto each filter rig. The mean effluent flow rates were recorded, and are represented graphically in

Figure 5. It can be clearly seen that the flow rates are reduced significantly by the presence of the geotextile layer. The highest hydraulic conductivity occurs in Filter Rig No. 1 consisting simply of gravel, pea gravel and sand. Consequently, these results indicate that judicous use of geotextile layering whilst enhancing treatment performance, will, nevertheless, adversely impact on volume throughput, and the more the number of geotextile layers, the slower the percolation rate, since each layer has its own biofilm growth which increases geomembrane selectivity, thereby reducing localised flow rates even more. On a more positive note, over the entire five month experimental period, the overall hydraulic flow rates for each rig were not greatly impaired by clogging since at no time was back washing ever needed. Nevertheless, for a longer operational period or a heavier system loading, it is anticipated that backwashing would eventually be required on a periodic basis. Therefore in summary, it appears that even though two or more layers of geotextile may allow reductions in overall depths of granular filter media used, this is at the expense of volume throughput which can be significantly decreased. This could be a real problem if the surrounding soil type has a low permeability and the overall granular filter system has a subsequent reduced storage volume,

i.e., potential for micro flooding events to occur.

Figure 4.

Relationship between mean inflow concentrations for Turbidity (NTU) and Suspended Solids (mg/L) for Filter Rig No. 1.

Figure 4.

Relationship between mean inflow concentrations for Turbidity (NTU) and Suspended Solids (mg/L) for Filter Rig No. 1.

Figure 5.

Average effluent flow rates during the period of May–September 2013 (After 1 year of operation).

Figure 5.

Average effluent flow rates during the period of May–September 2013 (After 1 year of operation).

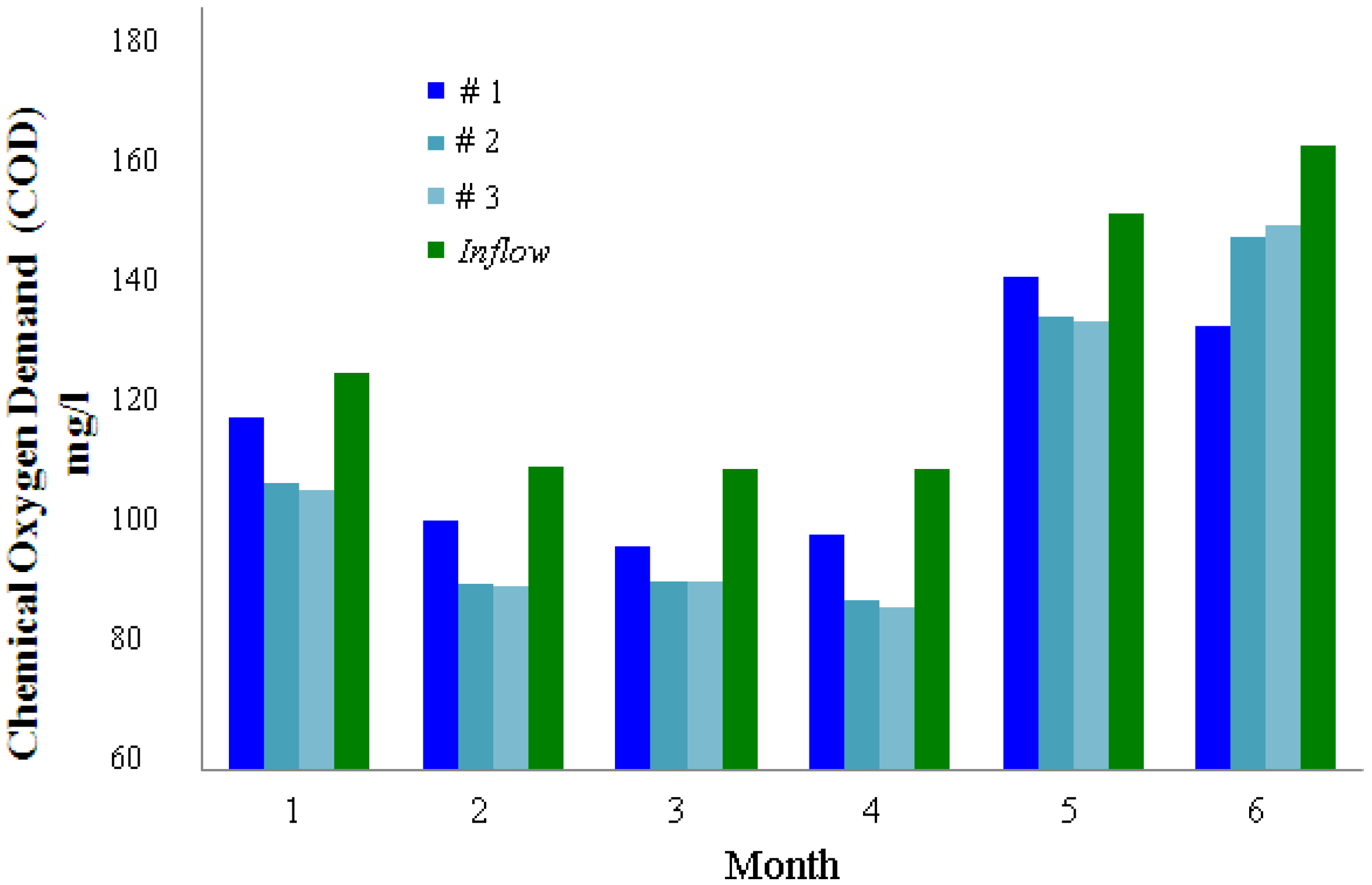

The amount of COD removed by each rig was an important measure. High levels of COD can have eco-toxic effects on aquatic organisms and consists of potentially harmful substances such as heavy metals, polycyclic aromatic hydrocarbons (PAHs), and organic matter. As a result of the high COD loading, the filters removed on average 30% to 50% of it. In terms of the organic matter (as COD) there were mean differences found between Filter Rig No. 1, Filter Rig No. 2 (upper geotextile membrane) and Filter Rig No. 3 (upper and lower geotextile membrane) as illustrated in

Figure 6. Overall Filter Rig No. 3 generally achieved the best removal as expected due to the biofilms formed on each of the upper and lower geotextiles layers which enhances geomembrane selectivity and subsequent treatment efficacy.

Figure 6.

Chemical oxygen demand (COD), mg/L influent and effluent concentrations from May to October 2013.

Figure 6.

Chemical oxygen demand (COD), mg/L influent and effluent concentrations from May to October 2013.

Nitrogen is an essential nutrient that is required for cell growth. Organic nitrogen and ammonia (NH

3) present in the inflow stormwater requires oxygen for oxidation to nitrite (NO

2) and nitrate (NO

3). NH

3 in the inflow can be converted to NO

2 by

nitrosomonas bacteria and further converted to NO

3 via

nitrobacter bacteria if the treatment system permits sufficient retention time. However, the process of endogenous respiration occurring to the microbial species that make up the biofilm can release further NH

3 which can lead to negative NO

3 removal rates as shown in

Figure 7. In this initial study, the extent of nitrogen in its nitrate form that was further converted to nitrogen gas (N

2) was not measured. This can occur if conditions are optimal for denitrifying bacteria to grow (

i.e., anaerobic and sufficient carbon sources exist). Accumulation of nitrates in still or slow moving bodies of water can lead to eutrophication which is the process whereby increased concentrations of nutrients can cause rapid growth of algal biomass. Hence further treatment for the removal of nitrogen based compounds may be required depending on the applicability of any water reuse scheme.