Full-Scale Implementation of a Vertical Membrane Bioreactor for Simultaneous Removal of Organic Matter and Nutrients from Municipal Wastewater

Abstract

:1. Introduction

2. Materials and Methods

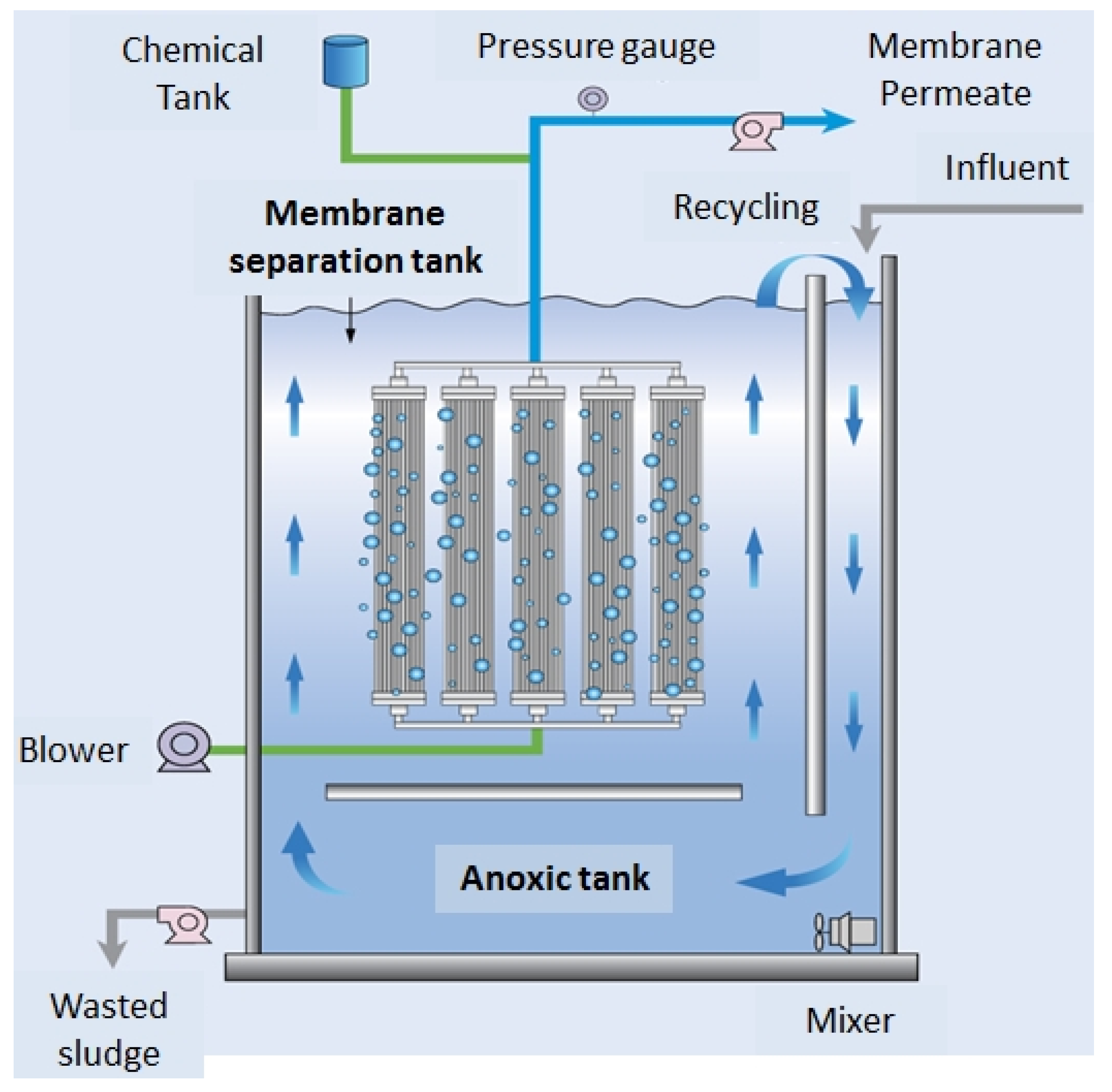

2.1. Operating Conditions of Field-Scale VMBRs

| Location in South Korea | Capacity (m3/d) | Commission (year) | Membrane Area (m2) | Water Temperature (°C) | HRT (h) | SRT (d) | MLSS Concentration (mg/L) |

|---|---|---|---|---|---|---|---|

| Dangjin-si (A) | 3,500 | 2009 | 6,720 | 17.9 ± 4.5 | 8.3 | 41 | 9,100 |

| Dangjin-si (B) | 1,500 | 2009 | 2,560 | 18.1 ± 4.2 | 7.9 | 45 | 9,600 |

| Gumi-si | 8,000 | 2011 | 15,360 | 19.1 ± 3.4 | 8.4 | 40 | 8,500 |

| Jecheon-si | 1,100 | 2012 | 1,920 | 17.1 ± 5.2 | 9.2 | 37 | 8,900 |

| Kwangju-si | 16,000 | 2013 | 32,400 | 19.3 ± 3.9 | 8.5 | 38 | 8,500 |

| Item | Dangjin-si (A) | Dangjin-si (B) | Gumi-si | Jecheon-si | Kwangju-si |

|---|---|---|---|---|---|

| pH | 7.5 | 7.4 | 7.2 | 7.1 | 7.1 |

| BOD5 (mg/L) | 91.6 | 151.5 | 128.3 | 165.4 | 177.0 |

| CODMn (mg/L) | 90.4 | 97.1 | 96.0 | 53.2 | 89.6 |

| SS (mg/L) | 73.6 | 144.0 | 168.8 | 161.0 | 179.8 |

| TN (mg/L) | 35.3 | 38.5 | 36.3 | 32.0 | 36.6 |

| TP (mg/L) | 4.3 | 4.9 | 3.3 | 2.8 | 3.6 |

| E. coli (cfu/100 mL) | 88,660 | 86,443 | 109,747 | 44,101 | 247,795 |

2.2. Chemical Cleaning of the Membranes

2.3. Characterization of Wastewater and Membrane Permeate

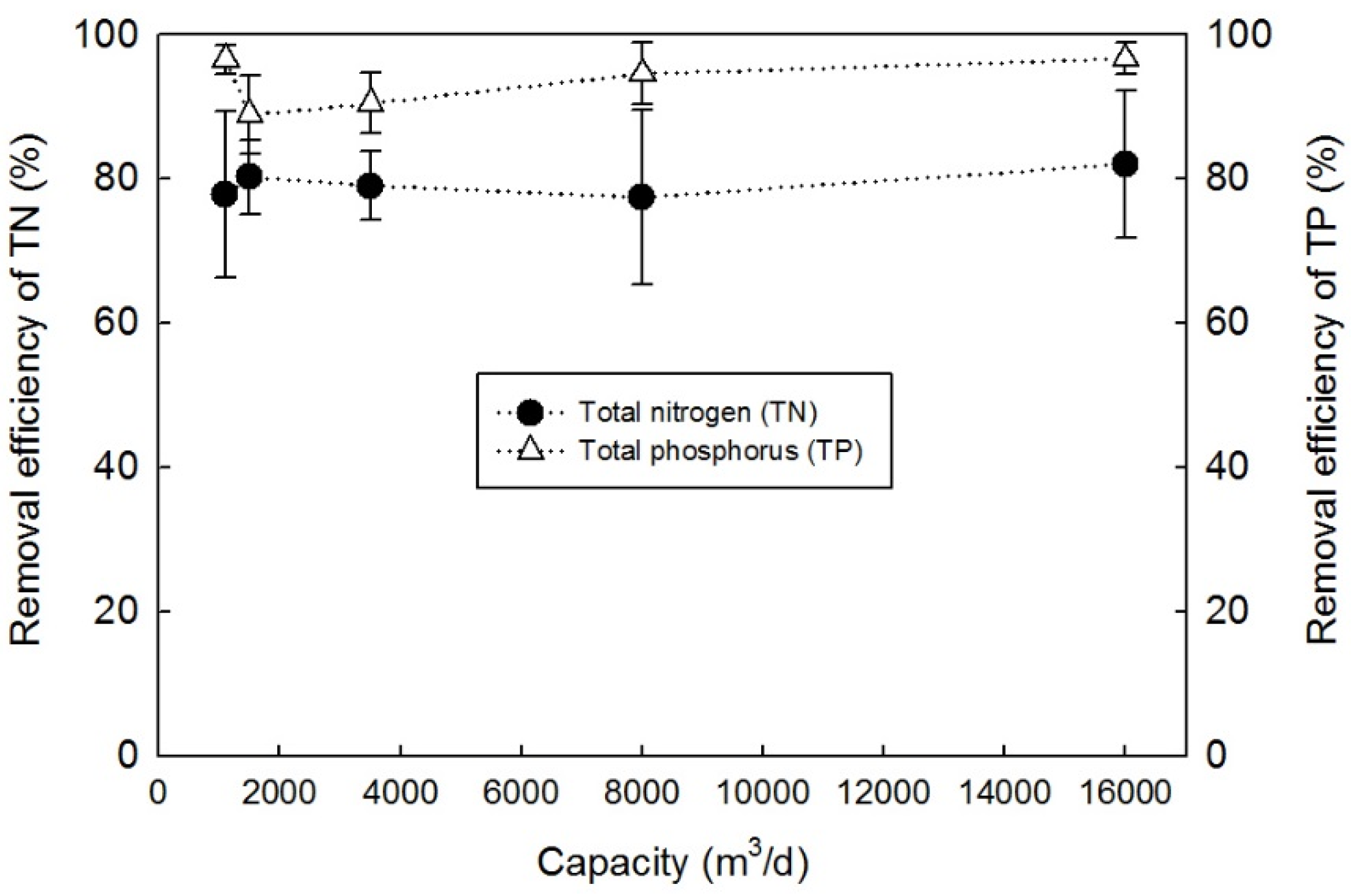

3. Results and Discussion

3.1. Performance and Fouling Characteristics of the Full-Scale DMBRTM Systems

| MBR Type | Capacity (m3/d) | Operating Conditions | Influent Characteristics (mg/L) | TN Removal (%) | TP Removal (%) | Influent COD/TN Ratio | Reference |

|---|---|---|---|---|---|---|---|

| MLE | 1,375 | HRT = 33 h SRT = n.a. | BOD = 114 TN = 29 TP = 3.4 | 78 | 50 | 3.9 a | [11] |

| MLE | 2,400 | HRT = 16.6 h SRT = 40 d | COD = 447 NH4-N = 26 TP = 7.3 | 99 | 91 | 17.2 b | [16] |

| MLE | 6,520 | HRT = 3.5–5 h SRT = 14–21 d | COD = 220 TN = 26 TP = 3.9 | 70 | 92 | 8.5 | [17] |

| Verical MLE | 1,100–16,000 | HRT = 7.9–9.2 h SRT = 37–45 d | COD = 53–97 TN = 32–39 TP = 2.8–4.9 | 78–82 | 89–97 c | 1.7–2.6 | This study |

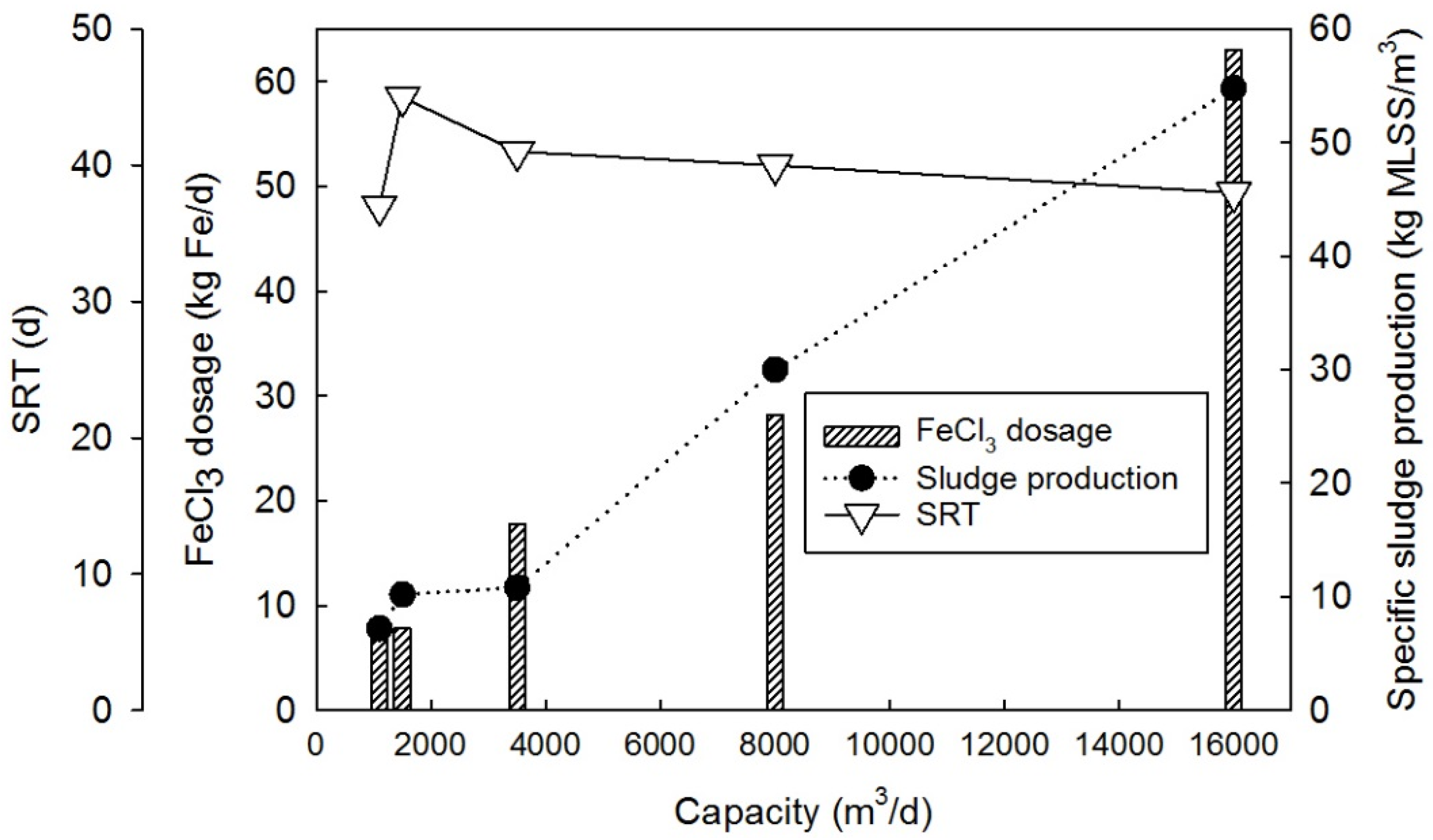

3.2. Chemical Dosage and Excess Sludge Production

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mesfioui, R.; Love, N.G.; Bronk, D.A.; Mulholland, M.R.; Hatcher, P.G. Reactivity and chemical characterization of effluent organic nitrogen from wastewater treatment plants determined by fourier transform ion cyclotron resonance mass spectrometry. Water Res. 2012, 46, 622–634. [Google Scholar] [CrossRef] [PubMed]

- Grady, C.P.L., Jr.; Daigger, G.T.; Love, N.G.; Filipe, C.D.M. Biological Wastewater Treatment; IWA Publishing–CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Huang, X.; Xiao, K.; Shen, Y.X. Recent advances in membrane bioreactor technology for wastewater treatment in china. Front. Environ. Sci. Eng. China 2010, 4, 245–271. [Google Scholar] [CrossRef]

- Santos, A.; Judd, S. The commercial status of membrane bioreactors for municipal wastewater. Sep. Sci. Technol. 2010, 45, 850–857. [Google Scholar] [CrossRef]

- Le-Clech, P. Membrane bioreactors and their uses in wastewater treatments. Appl. Microbiol. Biotechnol. 2010, 88, 1253–1260. [Google Scholar] [CrossRef] [PubMed]

- Van Nieuwenhuijzen, A.F.; Evenblij, H.; Uijterlinde, C.A.; Schulting, F.L. Review on the state of science on membrane bioreactors for municipal wastewater treatment. Water Sci. Technol. 2008, 57, 979–986. [Google Scholar] [CrossRef] [PubMed]

- Tai, C.S.; Snider-Nevin, J.; Dragasevich, J.; Kempson, J. Five years operation of a decentralized membrane bioreactor package plant treating domestic wastewater. Water. Pract. Technol. 2014, 9, 206–214. [Google Scholar] [CrossRef]

- Arevalo, J.; Ruiz, L.M.; Parada-Albarracin, J.A.; Gonzalez-Perez, D.M.; Perez, J.; Moreno, B.; Gomez, M.A. Wastewater reuse after treatment by MBR. Microfiltration or ultrafiltration? Desalination 2012, 299, 22–27. [Google Scholar] [CrossRef]

- Meng, F.G.; Chae, S.R.; Drews, A.; Kraume, M.; Shin, H.S.; Yang, F.L. Recent advances in membrane bioreactors (mbrs): Membrane fouling and membrane material. Water Res. 2009, 43, 1489–1512. [Google Scholar] [CrossRef] [PubMed]

- Chae, S.-R.; Ahn, Y.; Hwang, Y.; Jang, D.; Meng, F.; Shi, J.; Lee, S.-H.; Shin, H.-S. Advanced Wastewater Treatment Using Mbrs: Nutrient Removal and Disinfection; Iwa Publishing: London, UK, 2014; pp. 137–163. [Google Scholar]

- Itokawa, H.; Tsuji, K.; Yamashita, K.; Hashimoto, T. Design and operating experiences of full-scale municipal membrane bioreactors in japan. Water Sci. Technol. 2014, 69, 1088–1093. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.G.; Chae, S.R.; Shin, H.S.; Yang, F.L.; Zhou, Z.B. Recent advances in membrane bioreactors: Configuration development, pollutant elimination, and sludge reduction. Environ. Eng. Sci. 2012, 29, 139–160. [Google Scholar] [CrossRef]

- Chae, S.R.; Kang, S.T.; Watanabe, Y.; Shin, H.S. Development of an innovative vertical submerged membrane bioreactor (VSMBR) for simultaneous removal of organic matter and nutrients. Water Res. 2006, 40, 2161–2167. [Google Scholar] [CrossRef] [PubMed]

- Chae, S.R.; Shin, H.S. Characteristics of simultaneous organic and nutrient removal in a pilot-scale vertical submerged membrane bioreactor (VSMBR) treating municipal wastewater at various temperatures. Process Biochem. 2007, 42, 193–198. [Google Scholar] [CrossRef]

- Chae, S.R.; Shin, H.S. Effect of condensate of food waste (CFW) on nutrient removal and behaviours of intercellular materials in a vertical submerged membrane bioreactor (VSMBR). Bioresour. Technol. 2007, 98, 373–379. [Google Scholar] [CrossRef] [PubMed]

- Silva, A.F.; Carvalho, G.; Oehmen, A.; Lousada-Ferreira, M.; van Nieuwenhuijzen, A.; Reis, M.A.M.; Crespo, M.T.B. Microbial population analysis of nutrient removal-related organisms in membrane bioreactors. Appl. Microbiol. Biotechnol. 2012, 93, 2171–2180. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.Y.; de Weyer, H.; Diels, L.; Thoeye, C.; Liang, J.B.; Huang, L.N. Biodiversity and population dynamics of microorganisms in a full-scale membrane bioreactor for municipal wastewater treatment. Water Res. 2011, 45, 1129–1138. [Google Scholar] [CrossRef] [PubMed]

- Krzeminski, P.; van der Graaf, J.; van Lier, J.B. Specific energy consumption of membrane bioreactor (mbr) for sewage treatment. Water Sci. Technol. 2012, 65, 380–392. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.Q.; Yang, S.S.; Xiang, W.S.; Wang, X.J.; Ren, N.Q. Minimization of excess sludge production by in-situ activated sludge treatment processes—A comprehensive review. Biotechnol. Adv. 2013, 31, 1386–1396. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.W.; Yu, H.G.; Ma, J.X.; Zheng, X.; Wu, Z.C. Recent advances in membrane bio-technologies for sludge reduction and treatment. Biotechnol. Adv. 2013, 31, 1187–1199. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chae, S.-R.; Chung, J.-H.; Heo, Y.-R.; Kang, S.-T.; Lee, S.-M.; Shin, H.-S. Full-Scale Implementation of a Vertical Membrane Bioreactor for Simultaneous Removal of Organic Matter and Nutrients from Municipal Wastewater. Water 2015, 7, 1164-1172. https://doi.org/10.3390/w7031164

Chae S-R, Chung J-H, Heo Y-R, Kang S-T, Lee S-M, Shin H-S. Full-Scale Implementation of a Vertical Membrane Bioreactor for Simultaneous Removal of Organic Matter and Nutrients from Municipal Wastewater. Water. 2015; 7(3):1164-1172. https://doi.org/10.3390/w7031164

Chicago/Turabian StyleChae, So-Ryong, Jin-Ho Chung, Yong-Rok Heo, Seok-Tae Kang, Sang-Min Lee, and Hang-Sik Shin. 2015. "Full-Scale Implementation of a Vertical Membrane Bioreactor for Simultaneous Removal of Organic Matter and Nutrients from Municipal Wastewater" Water 7, no. 3: 1164-1172. https://doi.org/10.3390/w7031164