Enzymatic Modification of Polyethersulfone Membranes

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals

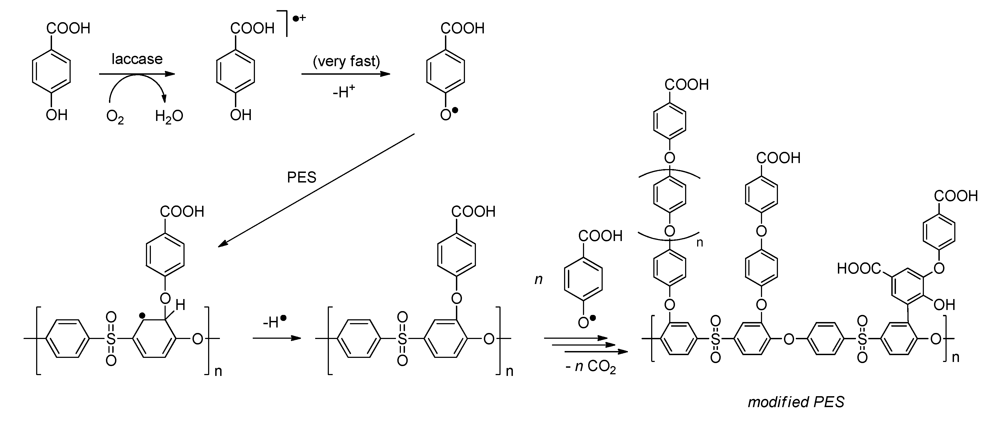

2.2. Membrane Modification and Surface Modification

2.2.1. Flat Sheet Membranes

2.2.2. Hollow Fiber Membranes

2.2.3. Modified PES Surfaces on Silicon Wafers

2.3. Bacterial Adhesion and Biofilm Formation

2.3.1. Listeria Monocytogenes Strains and Culture Conditions

2.3.2. Attachment and Biofilm Formation

2.3.2.1. Static Conditions

2.3.2.2. Dynamic Conditions

2.3.2.3. Statistics

2.4. Membrane and Surface Analysis

2.4.1. Grafting Yield

2.4.2. BSA Adsorption

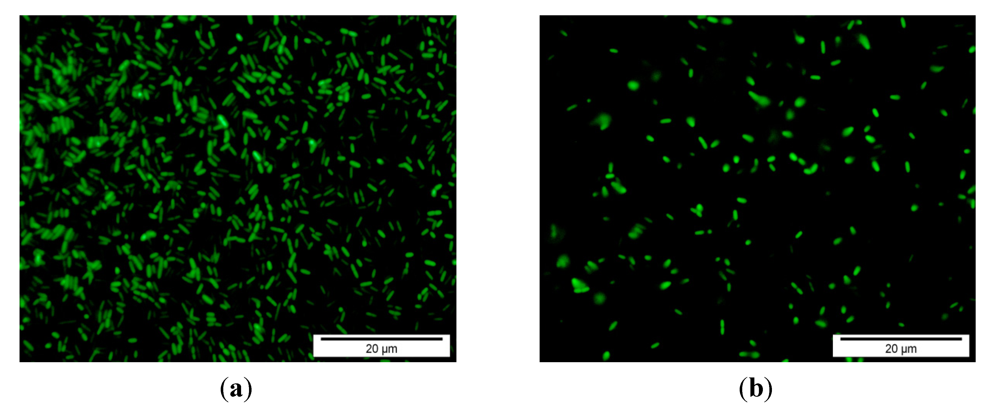

2.4.3. Fluorescence Microscopy for Bacterial Adhesion

3. Results and Discussion

3.1. Performance of Flat Sheet Membranes

3.2. Performance of Hollow Fiber Membranes

| Parameter | Unmodified | Unmodified | Modified | Modified |

|---|---|---|---|---|

| Length (cm) | 23.7 | 24 | 23.6 | 24 |

| Area (cm2) * | 5.88 | 5.96 | 5.86 | 5.96 |

| Flux (m3 m−2 h−1) | 0.3 ± 0.01 | 0.28 ± 0.01 | 0.32 ± 0.01 | 0.33 ± 0.01 |

| After modification (m3 m−2 h−1) | 0.072 ± 0.001 | 0.1 ± 0.001 | ||

| BSA flux (m3 m−2 h−1) | 0.04 ± 0.001 | 0.039 ± 0.001 | 0.043±0.001 | 0.046 ± 0.001 |

| BSA rejection (%) | 99 ± 0.8 | 99.1 ± 0.8 | 50.7 ± 0.9 | 50 ± 2.5 |

| Residual flux after BSA (m3 m−2 h−1) | 0.04 ± 0.001 | 0.04 ± 0.001 | 0.043 ±0.001 | 0.043 ± 0.001 |

3.3. Bacterial Adhesion

| Tested strain and conditions | Attachment | Growth |

|---|---|---|

| EDG-e strain | ||

| Static conditions | 57% ± 5.3 | 63% ± 2.4 |

| Dynamic conditions | 93% ± 0.2 | – |

| LR-991 strain | ||

| Static conditions | 59% ± 6.0 | 63% ± 2.0 |

| Dynamic conditions | 88% ± 1.7 | – |

3.4. Cost Analysis

| Material | Sigma/Fluka 2011 | Used amount/0.002 m2 membrane | Membrane cost per m2 (€/m2) |

|---|---|---|---|

| Sodium acetate | 43.1 €/1 kg | 0.11 g | 2.4 |

| Acetic acid | 13.5 €/1 L | 0.04 mL | 0.3 |

| Enzyme | 38.6 €/1 g | 6 mg | 115.4 |

| 4-hydroxybenzoic acid | 48 €/1 kg | 0.2 g | 4.8 |

| Total | 122 | ||

| On industrial scale the price will be 10 times lower, leading to a price per m2 | 12.2 | ||

4. Conclusions

Appendix

Acknowledgments

References

- Ulbricht, M. Advanced functional polymer membranes. Polymer 2006, 47, 2217–2262. [Google Scholar] [CrossRef]

- Rana, D.; Matsuura, T. Surface modifications for antifouling membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef]

- Nady, N.; Franssen, M.C.R.; Zuilhof, H.; Mohy Eldin, M.S.; Boom, R.; Schroën, K. Modification methods for poly(arylsulfone) membranes: A mini-review focusing on surface modification. Desalination 2011, 275, 1–9. [Google Scholar] [CrossRef]

- Nady, N.; Schroën, K.; Franssen, M.C.R.; van Langen, B.; Murali, S.; Boom, R.M.; Mohy Eldin, M.S.; Zuilhof, H. Mild and highly flexible enzyme-catalyzed modification of poly(ethersulfone) membranes. Appl. Mater. Interfaces 2011, 3, 801–810. [Google Scholar] [CrossRef]

- Nady, N.; Schroën, K.; Franssen, M.C.R.; Fokkink, R.; MohyEldin, M.S.; Zuilhof, H.; Boom, R.M. Enzyme-catalyzed modification of pes surfaces: Reduction in adsorption of bsa, dextrin and tannin. J. Colloid Interface Sci. 2012, 378, 191–200. [Google Scholar] [CrossRef]

- Nady, N.; Schroën, K.; Franssen, M.C.R.; Mohy Eldin, M.S.; Boom, R.M.; Zuilhof, H. Laccase-catalyzed modification of pes membranes with 4-hydroxybenzoic acid and gallic acid. J. Membr. Sci. 2012, 394–395, 69–79. [Google Scholar] [CrossRef]

- Baldrian, P. Fungal laccases—Occurrence and properties. FEMS Microbiol. Rev. 2006, 30, 215–242. [Google Scholar]

- Arends, I.W.C.E.; Li, Y.X.; Ausan, R.; Sheldon, R.A. Comparison of TEMPO and its derivatives as mediators in laccase catalyzed oxidation of alcohols. Tetrahedron 2006, 62, 6659–6665. [Google Scholar] [CrossRef]

- Schroën, C.G.P.H.; Cohen Stuart, M.A.; van der Voort Maarschalk, K.; van der Padt, A.; van’t Riet, K. Influence of preadsorbed block copolymers on protein adsorption: Surface properties, layer thickness, and surface coverage. Langmuir 1995, 11, 3068–3074. [Google Scholar] [CrossRef]

- Van der Veen, S.; Abee, T. Mixed species biofilms of Listeria monocytogenes and Lactobacillus plantarum show enhanced resistance to benzalkonium chloride and peracetic acid. Int. J. Food Microbiol. 2011, 144, 421–431. [Google Scholar] [CrossRef]

- Dong, B.; Jiang, H.; Manolache, S.; Wong, A.C.L.; Denes, F.S. Plasma-mediated grafting of poly(ethylene glycol) on polyamide and polyester surfaces and evaluation of antifouling ability of modified substrates. Langmuir 2007, 23, 7306–7313. [Google Scholar]

- Dong, B.; Manolache, S.; Somers, E.B.; Wong, A.C.L.; Denes, F.S. Generation of antifouling layers on stainless steel surfaces by plasma-enhanced crosslinking of polyethylene glycol. J. Appl. Polym. Sci. 2005, 97, 485–497. [Google Scholar] [CrossRef]

- Roosjen, A.; Norde, W.; van der Mei, H.C.; Busscher, H.J. The use of positively charged or low surface free energy coatings versus polymer brushes in controlling biofilm formation. Prog. Colloid Polym. Sci. 2006, 132, 138–144. [Google Scholar] [CrossRef]

- Van Dinther, A.M.C.; Schroën, C.G.P.H.; Boom, R.M. High-flux membrane separation using fluid skimming dominated convective fluid flow. J. Membr. Sci. 2011, 371, 20–27. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Nady, N.; Franssen, M.C.R.; Zuilhof, H.; Boom, R.M.; Schroën, K. Enzymatic Modification of Polyethersulfone Membranes. Water 2012, 4, 932-943. https://doi.org/10.3390/w4040932

Nady N, Franssen MCR, Zuilhof H, Boom RM, Schroën K. Enzymatic Modification of Polyethersulfone Membranes. Water. 2012; 4(4):932-943. https://doi.org/10.3390/w4040932

Chicago/Turabian StyleNady, Norhan, Maurice Charles René Franssen, Han Zuilhof, Remko Marcel Boom, and Karin Schroën. 2012. "Enzymatic Modification of Polyethersulfone Membranes" Water 4, no. 4: 932-943. https://doi.org/10.3390/w4040932