Potential of Piezoelectric MEMS Resonators for Grape Must Fermentation Monitoring †

Abstract

:1. Introduction

2. Experimental Details

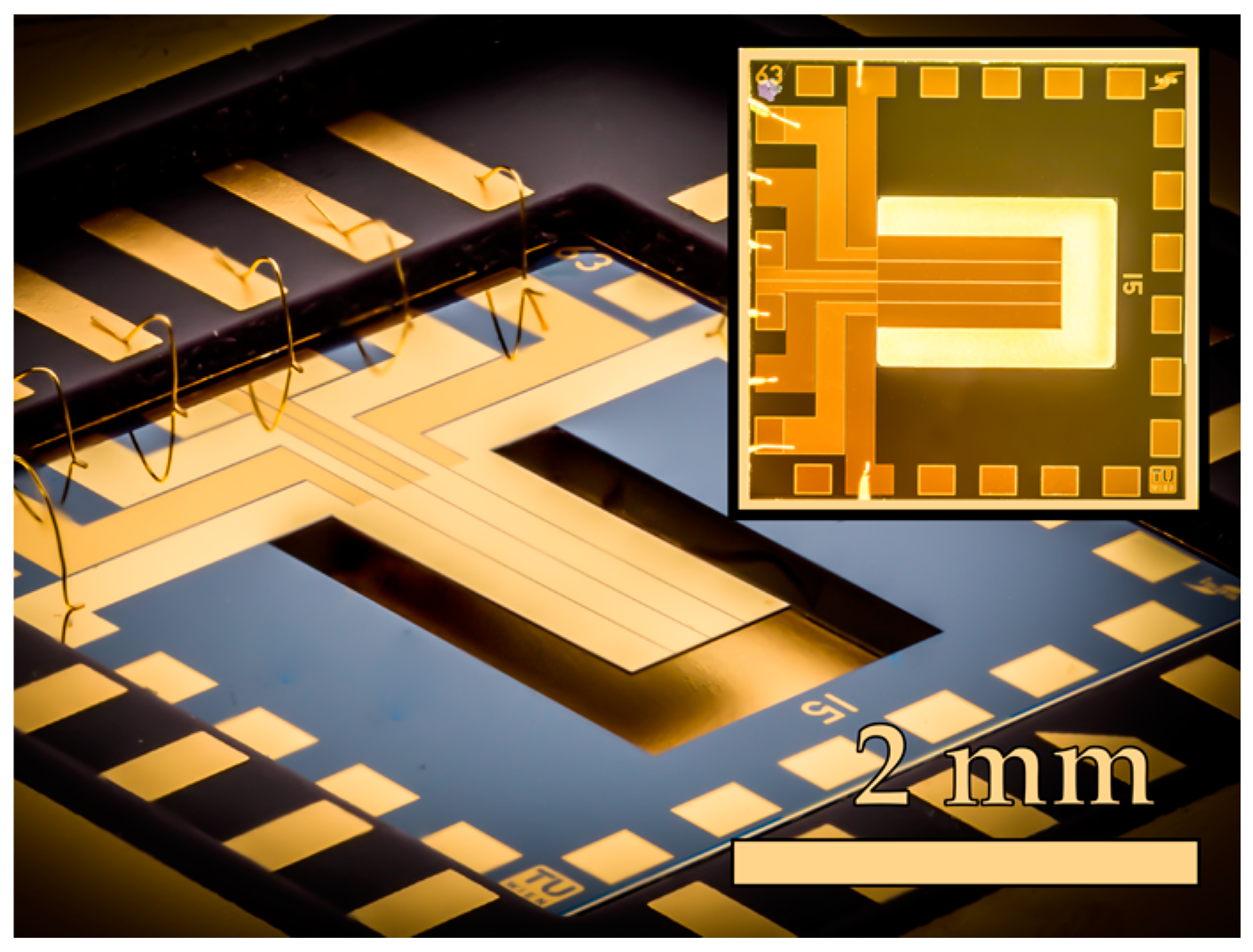

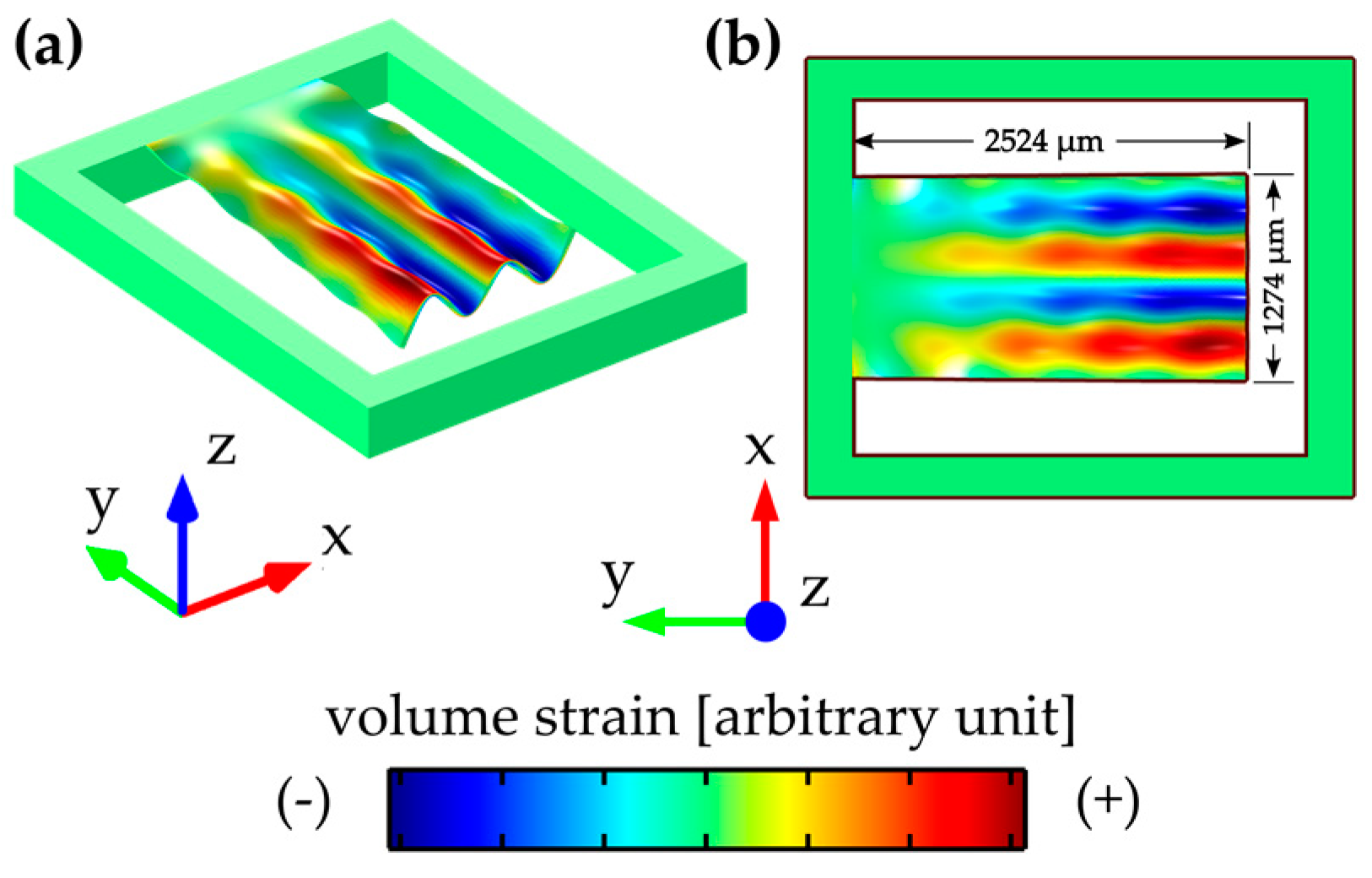

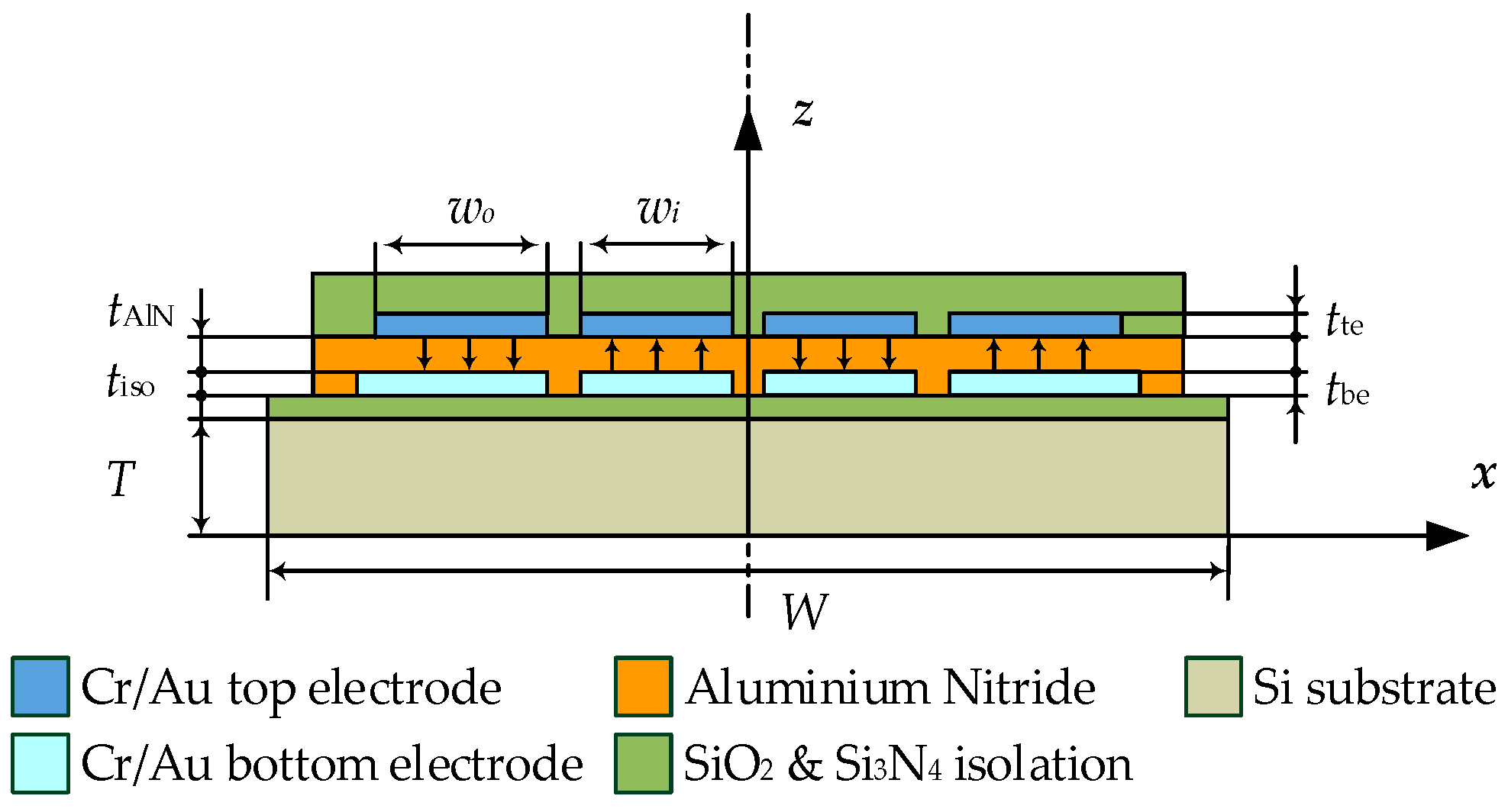

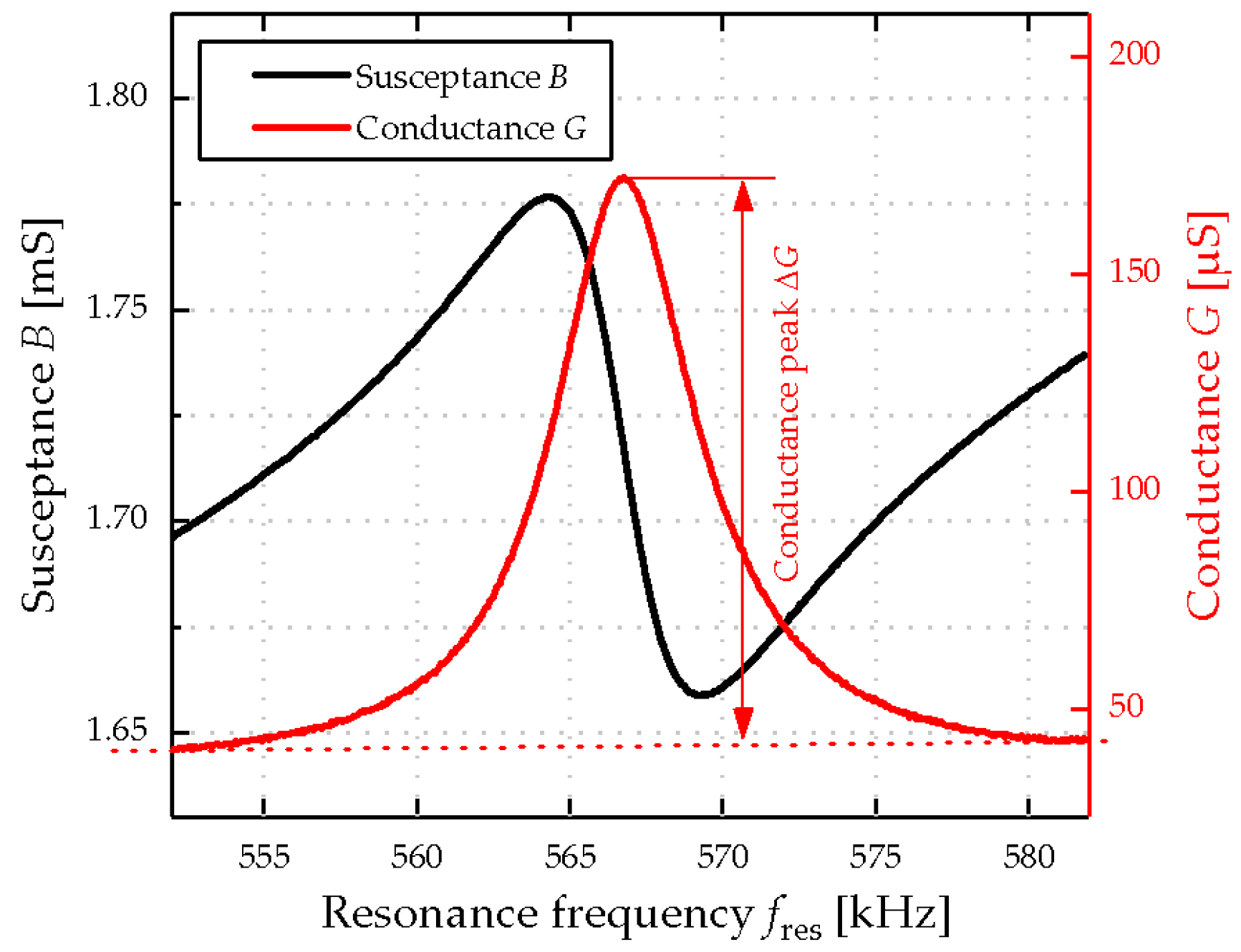

2.1. Sensor Specification

2.2. Artificial Model Solutions and Sensing Principle

2.3. Real Grape Must Fermentation

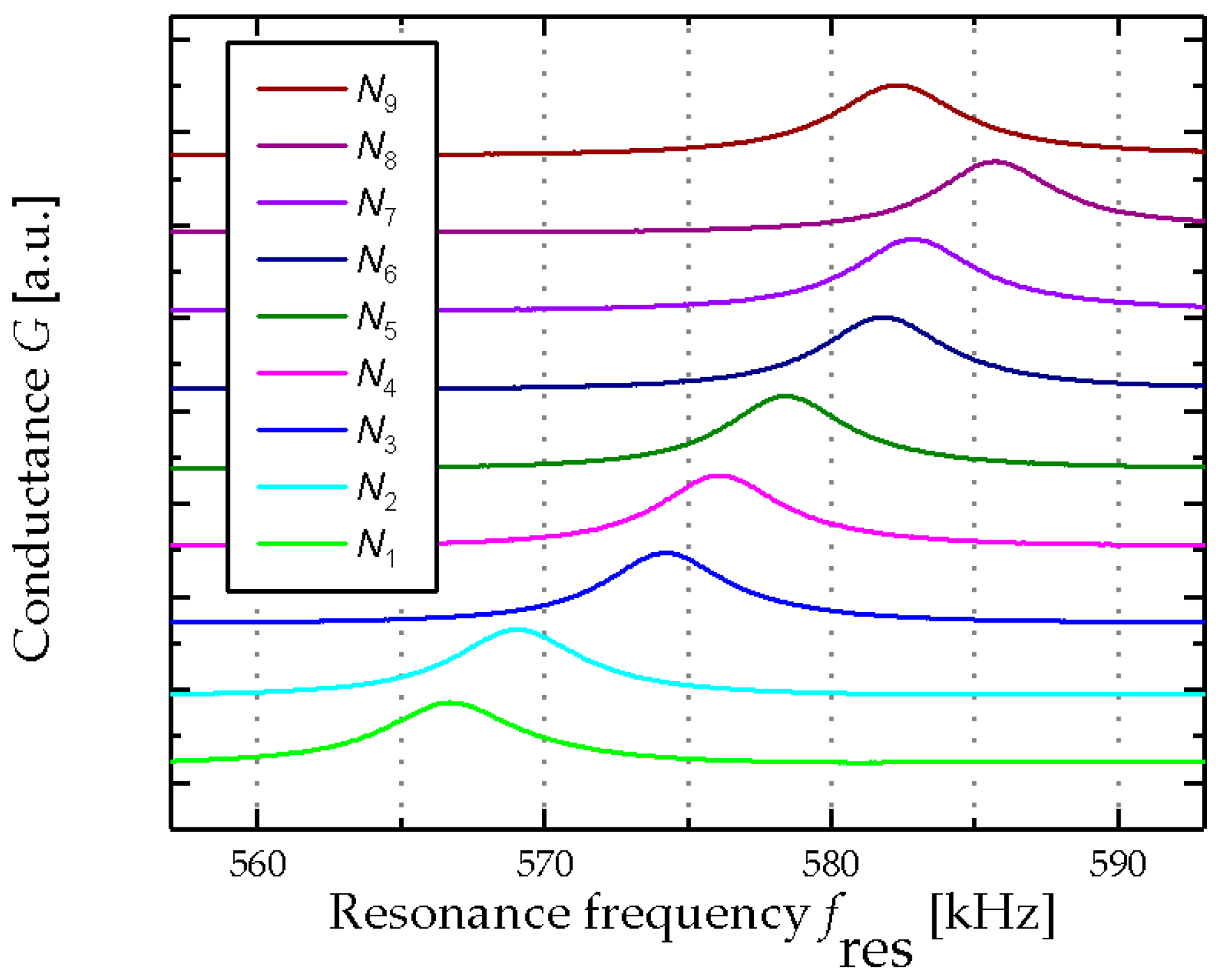

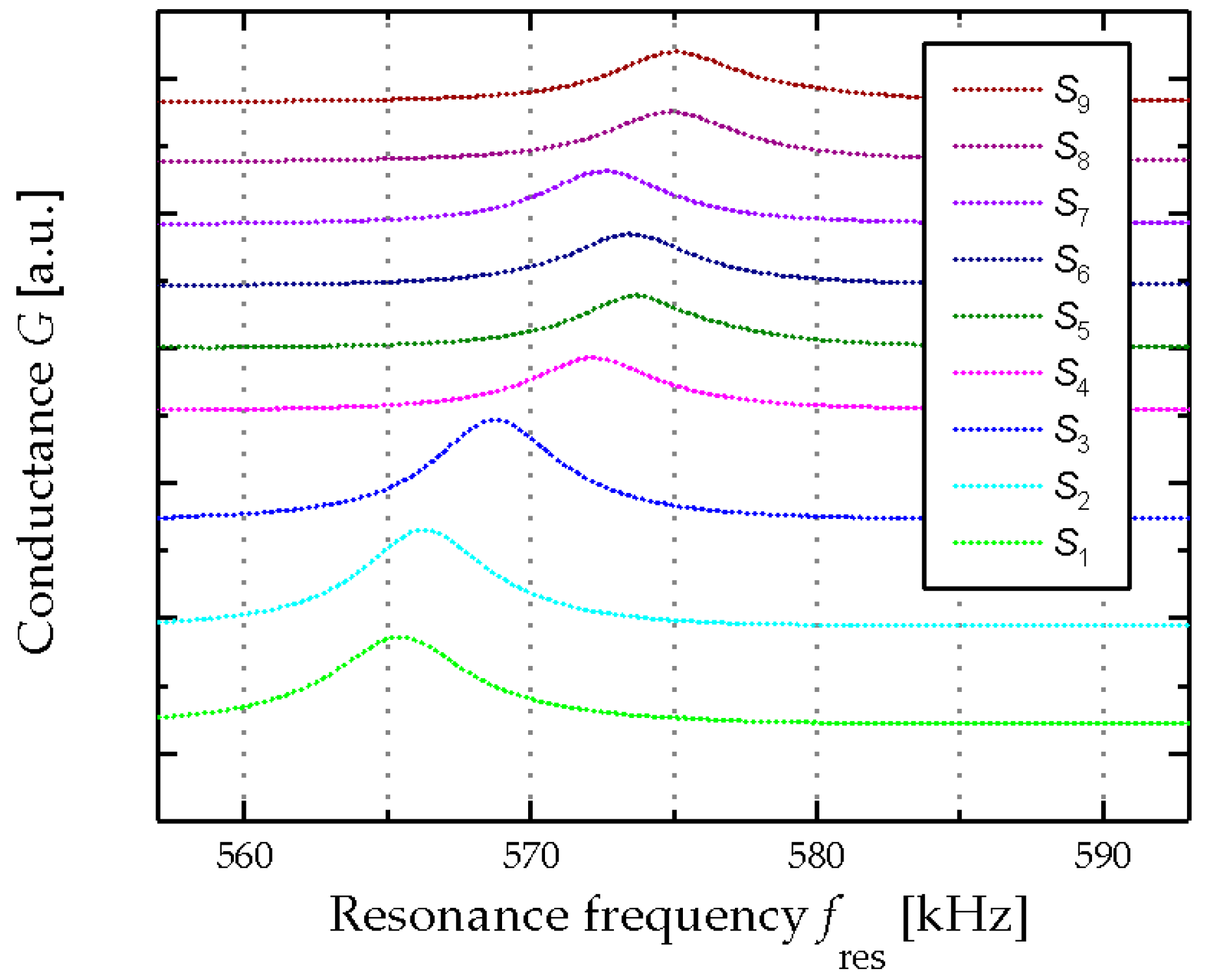

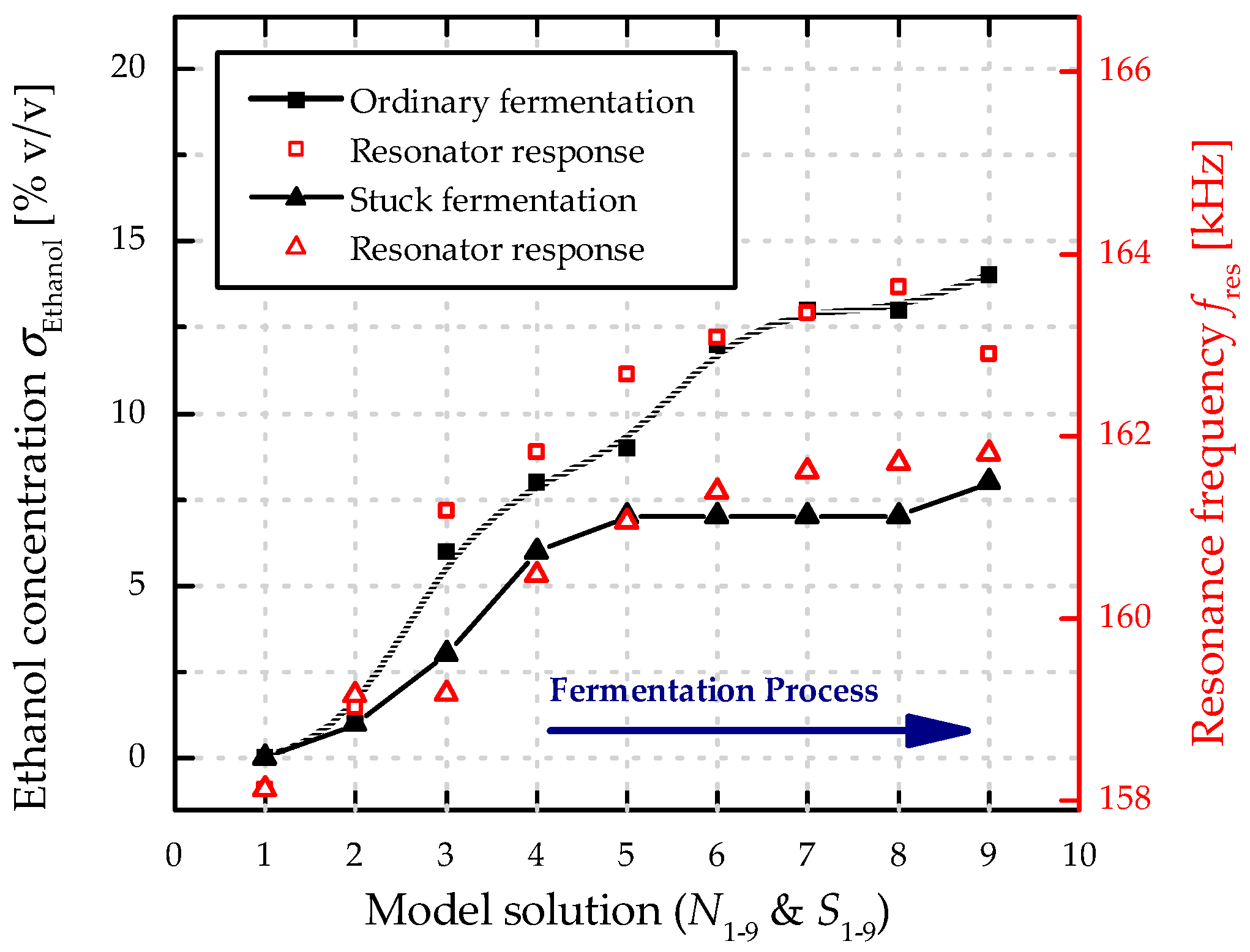

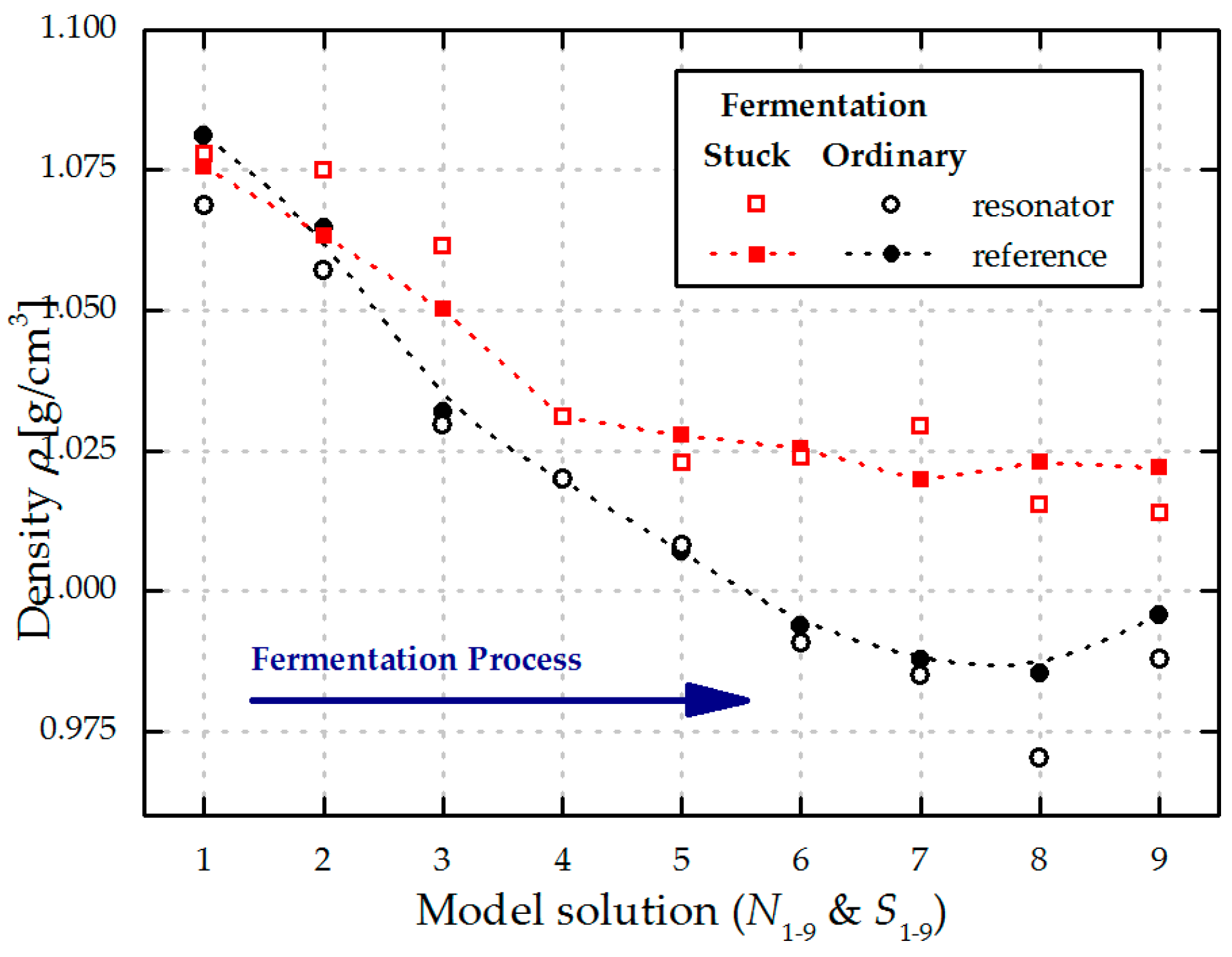

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fleet, G.H. Wine Microbiology and Biotechnology; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Larue, F.; Lafon-Lafourcade, S. Survival factors in wine fermentation. In Alcohol Toxicity in Yeasts and Bacteria; CRC Press: Boca Raton, FL, USA, 1989; pp. 193–215. [Google Scholar]

- Munoz, E.; Ingledew, W.M. Yeast hulls in wine fermentations—A review. J. Wine Res. 1990, 1, 197–209. [Google Scholar] [CrossRef]

- El Haloui, N.; Picque, D.; Corrieu, G. Alcoholic fermentation in winemaking: On-line measurement of density and carbon dioxide evolution. J. Food Eng. 1988, 8, 17–30. [Google Scholar] [CrossRef]

- Nerantzis, E.; Tataridis, P.; Sianoudis, I.; Ziani, X.; Tegou, E. Winemaking process engineering on line fermentation monitoring—Sensors and equipment. Sci. Technol. 2007, 5, 29–36. [Google Scholar]

- Koukolitschek, K. Verfahren und Vorrichtung zur Präzisen Bestimmung der Alkoholkonzentration in Flüssigkeiten. German Patent DE413,841,9C2, 2 September 1993. [Google Scholar]

- Pérez, M.A.; Muñiz, R.; De La Torre, C.; García, B.; Carleos, C.E.; Crespo, R.; Cárcel, L.M. Impedance spectrometry for monitoring alcoholic fermentation kinetics under wine-making industrial conditions. In Proceedings of the XIX IMEKO World Congress Fundamental and Applied Metrology, Lisbon, Portugal, 6–11 September 2009; pp. 2574–2578. [Google Scholar]

- Crespo, R.; Cárcel, L.; Pérez, M.; Nevares, I.; Del Álamo, M. Suitable at-line turbidity sensor for wine fermentation supervision. In Proceedings of the International Conference on Food Innovation 2010, Valencia, Spain, 25–29 October 2010; pp. 1–4. [Google Scholar]

- Lamberti, N.; Ardia, L.; Albanese, D.; Di Matteo, M. An ultrasound technique for monitoring the alcoholic wine fermentation. Ultrasonics 2009, 49, 94–97. [Google Scholar] [CrossRef] [PubMed]

- Resa, P.; Elvira, L.; De Espinosa, F.M.; González, R.; Barcenilla, J. On-line ultrasonic velocity monitoring of alcoholic fermentation kinetics. Bioprocess Biosyst. Eng. 2009, 32, 321–331. [Google Scholar] [CrossRef] [PubMed]

- Acevedo, J.M.; Gandoy, J.D.; Del Río Vázquez, A.; Freire, C.M.-P.; Soria, M.L. Plastic optical fiber sensor for real time density measurements in wine fermentation. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference (IMTC), Warsaw, Poland, 1–3 May 2007. [Google Scholar]

- Graña, C.Q.; Acevedo, J.M. Experiences in measuring density by fiber optic sensors in the grape juice fermentation process. In Proceedings of the XIX IMEKO World Congress Fundamental Applied Metrology, Lisbon, Portugal, 6–11 September 2009; pp. 2579–2582. [Google Scholar]

- Boisen, A.; Dohn, S.; Keller, S.S.; Schmid, S.; Tenje, M. Cantilever-like micromechanical sensors. Rep. Prog. Phys. 2011, 74, 036101. [Google Scholar] [CrossRef]

- Burg, T.P.; Manalis, S.R. Suspended microchannel resonators for biomolecular detection. Appl. Phys. Lett. 2003, 83, 2698–2700. [Google Scholar] [CrossRef]

- Cakmak, O.; Ermek, E.; Kilinc, N.; Bulut, S.; Baris, I.; Kavakli, I.H.; Yaralioglu, G.G.; Urey, H. A cartridge based sensor array platform for multiple coagulation measurements from plasma. Lab Chip 2015, 15, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Godin, M.; Bryan, A.K.; Burg, T.P.; Babcock, K.; Manalis, S.R. Measuring the mass, density, and size of particles and cells using a suspended microchannel resonator. Appl. Phys. Lett. 2007, 91, 123121. [Google Scholar] [CrossRef]

- Khan, M.F.; Schmid, S.; Larsen, P.E.; Davis, Z.J.; Yan, W.; Stenby, E.H.; Boisen, A. Online measurement of mass density and viscosity of pL fluid samples with suspended microchannel resonator. Sens. Actuators B Chem. 2013, 185, 456–461. [Google Scholar] [CrossRef]

- Bircher, B.A.; Duempelmann, L.; Renggli, K.; Lang, H.P.; Gerber, C.; Bruns, N.; Braun, T. Real-time viscosity and mass density sensors requiring microliter sample volume based on nanomechanical resonators. Anal. Chem. 2013, 85, 8676–8683. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Shen, W.; Payer, K.; Burg, T.P.; Manalis, S.R. Toward attogram mass measurements in solution with suspended nanochannel resonators. Nano Lett. 2010, 10, 2537–2542. [Google Scholar] [CrossRef] [PubMed]

- Cakmak, O.; Ermek, E.; Kilinc, N.; Yaralioglu, G.G.; Urey, H. Precision density and viscosity measurement using two cantilevers with different widths. Sens. Actuators A Phys. 2015, 232, 141–147. [Google Scholar] [CrossRef]

- Bircher, B.A.; Krenger, R.; Braun, T. Automated high-throughput viscosity and density sensor using nanomechanical resonators. Sens. Actuators B Chem. 2016, 223, 784–790. [Google Scholar] [CrossRef]

- Kucera, M.; Wistrela, E.; Pfusterschmied, G.; Ruiz-Díez, V.; Manzaneque, T.; Sánchez-Rojas, J.L.; Schalko, J.; Bittner, A.; Schmid, U. Characterization of a roof tile-shaped out-of-plane vibrational mode in aluminum-nitride-actuated self-sensing micro-resonators for liquid monitoring purposes. Appl. Phys. Lett. 2014, 104, 233501. [Google Scholar] [CrossRef]

- Kucera, M.; Wistrela, E.; Pfusterschmied, G.; Ruiz-Díez, V.; Sánchez-Rojas, J.L.; Schalko, J.; Bittner, A.; Schmid, U. Characterisation of multi roof tile-shaped out-of-plane vibrational modes in aluminium-nitride-actuated self-sensing micro-resonators in liquid media. Appl. Phys. Lett. 2015, 107, 053506. [Google Scholar] [CrossRef]

- Pfusterschmied, G.; Kucera, M.; Wistrela, E.; Steindl, W.; Ruiz-Díez, V.; Bittner, A.; Sánchez-Rojas, J.L.; Schmid, U. Piezoelectric response optimization of multi roof tile-shaped modes in MEMS resonators by variation of the support boundary conditions. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 969–972. [Google Scholar]

- Toledo, J.; Jiménez-Márquez, F.; Úbeda, J.; Ruiz-Díez, V.; Pfusterschmied, G.; Schmid, U.; Sánchez-Rojas, J.L. Piezoelectric MEMS resonators for monitoring grape must fermentation. J. Phys. Conf. Ser. 2016. [Google Scholar] [CrossRef]

- Toledo, J.; Manzaneque, T.; Ruiz-Díez, V.; Jiménez-Márquez, F.; Kucera, M.; Pfusterschmied, G.; Wistrela, E.; Schmid, U.; Sánchez-Rojas, J.L. Out-of-plane piezoelectric microresonator and oscillator circuit for monitoring engine oil contamination with diesel. In Proceedings of the Smart Sensors, Actuators, and MEMS VII, and Cyber Physical Systems, Barcelona, Spain, 4 May 2015. [Google Scholar]

- Toledo, J.; Manzaneque, T.; Ruiz-Díez, V.; Jiménez-Márquez, F.; Kucera, M.; Pfusterschmied, G.; Wistrela, E.; Schmid, U.; Sánchez-Rojas, J.L. Comparison of in-plane and out-of-plane piezoelectric microresonators for real-time monitoring of engine oil contamination with diesel. Microsyst. Technol. 2016, 22, 1–10. [Google Scholar] [CrossRef]

- Pfusterschmied, G.; Kucera, M.; Ruiz-Díez, V.; Bittner, A.; Sánchez-Rojas, J.L.; Schmid, U. Multi roof tile-shaped vibration modes in MEMS cantilever sensors for liquid monitoring purposes. In Proceedings of the 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015. [Google Scholar]

- Van Eysden, C.A.; Sader, J.E. Frequency response of cantilever beams immersed in compressible fluids with applications to the atomic force microscope. J. Appl. Phys. 2009, 106, 094904. [Google Scholar] [CrossRef]

- Jiménez-Márquez, F.; Vázquez, J.; Úbeda, J.; Sánchez-Rojas, J.L. High-resolution low-cost optoelectronic instrument for supervising grape must fermentation. Microsyst. Technol. 2014, 20, 769–782. [Google Scholar] [CrossRef]

- Manzaneque, T.; Hernando, J.; Rodriguez-Aragon, L.; Ababneh, A.; Seidel, H.; Schmid, U.; Sánchez-Rojas, J.L. Analysis of the quality factor of AlN-actuated micro-resonators in air and liquid. Microsyst. Technol. 2010, 16, 837–845. [Google Scholar] [CrossRef]

- Pfusterschmied, G.; Kucera, M.; Wistrela, E.; Manzaneque, T.; Ruiz-Díez, V.; Sánchez-Rojas, J.L.; Bittner, A.; Schmid, U. Temperature dependent performance of piezoelectric MEMS resonators for viscosity and density determination of liquids. J. Micromech. Microeng. 2015, 25, 105014. [Google Scholar] [CrossRef]

| fres | Q | Rm_air | Lm_air | Cm_air |

|---|---|---|---|---|

| [kHz] | [1] | [kΩ] | [mH] | [fF] |

| 1014.1 | 329.6 | 1.365 | 70.662 | 348.77 |

| Solution | Fructose | Glucose | Glycerol | Ethanol | ||||

|---|---|---|---|---|---|---|---|---|

| - | [g/L] | [g/L] | [g/L] | [% v/v] | ||||

| - | Nom. | Meas. | Nom. | Meas. | Nom. | Meas. | Nom. | Meas. |

| N1 | 110 | 109.90 | 100 | 99.90 | 0 | 0 | 0 | - |

| N2 | 90 | 89.90 | 80 | 80.00 | 0 | 0 | 1 | - |

| N3 | 70 | 69.95 | 30 | 30.03 | 5 | 4.99 | 6 | - |

| N4 | 60 | 59.97 | 20 | 19.99 | 5 | 5.00 | 8 | - |

| N5 | 40 | 39.90 | 10 | 9.95 | 6 | 5.99 | 9 | - |

| N6 | 20 | 19.90 | 2 | 2.00 | 7 | 6.97 | 12 | - |

| N7 | 8 | 8.02 | 2 | 2.00 | 7 | 6.99 | 13 | - |

| N8 | 5 | 5.00 | 2 | 2.00 | 7 | 6.99 | 13 | - |

| N9 | 2 | 2.00 | 1 | 0.99 | 9 | 8.99 | 14 | - |

| Solution | Fructose | Glucose | Glycerol | Ethanol | ||||

|---|---|---|---|---|---|---|---|---|

| - | [g/L] | [g/L] | [g/L] | [% v/v] | ||||

| - | Nom. | Meas. | Nom. | Meas. | Nom. | Meas. | Nom. | Meas. |

| S1 | 110 | 109.90 | 100 | 99.98 | 0 | 0 | 0 | - |

| S2 | 90 | 90.00 | 80 | 79.98 | 0 | 0 | 1 | - |

| S3 | 80 | 79.98 | 60 | 60.01 | 3 | 3.00 | 3 | - |

| S4 | 70 | 69.98 | 30 | 29.98 | 5 | 4.99 | 6 | - |

| S5 | 66 | 65.99 | 27 | 27.03 | 5 | 4.99 | 7 | - |

| S6 | 64 | 64.00 | 26 | 26.06 | 5 | 5.01 | 7 | - |

| S7 | 62 | 61.99 | 24 | 24.00 | 6 | 5.99 | 7 | - |

| S8 | 58 | 57.99 | 22 | 22.00 | 6 | 5.99 | 7 | - |

| S9 | 57 | 56.99 | 21 | 21.00 | 7 | 7.01 | 8 | - |

| Ordinary | Stuck/Sluggish | ||||||

|---|---|---|---|---|---|---|---|

| Sol. | Density ρ [g/cm3] | Sol. | Density ρ [g/cm3] | ||||

| - | Stabinger | Res. | Dev. | - | Stabinger | Res. | Dev. |

| N1 | 1.081 | 1.082 | −0.001 | S1 | 1.075 | 1.075 | - |

| N2 | 1.065 | 1.063 | 0.002 | S2 | 1.063 | 1.064 | −0.001 |

| N3 | 1.032 | 1.033 | −0.001 | S3 | 1.050 | 1.050 | - |

| N4 | 1.020 | 1.023 | −0.003 | S4 | 1.031 | 1.031 | - |

| N5 | 1.007 | 1.010 | −0.003 | S5 | 1.028 | 1.023 | 0.005 |

| N6 | 0.994 | 0.994 | - | S6 | 1.025 | 1.024 | 0.001 |

| N7 | 0.988 | 0.989 | −0.001 | S7 | 1.020 | 1.029 | −0.009 |

| N8 | 0.985 | 0.978 | 0.007 | S8 | 1.023 | 1.020 | 0.003 |

| N9 | 0.996 | 0.995 | 0.001 | S9 | 1.021 | 1.020 | 0.001 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfusterschmied, G.; Toledo, J.; Kucera, M.; Steindl, W.; Zemann, S.; Ruiz-Díez, V.; Schneider, M.; Bittner, A.; Sanchez-Rojas, J.L.; Schmid, U. Potential of Piezoelectric MEMS Resonators for Grape Must Fermentation Monitoring. Micromachines 2017, 8, 200. https://doi.org/10.3390/mi8070200

Pfusterschmied G, Toledo J, Kucera M, Steindl W, Zemann S, Ruiz-Díez V, Schneider M, Bittner A, Sanchez-Rojas JL, Schmid U. Potential of Piezoelectric MEMS Resonators for Grape Must Fermentation Monitoring. Micromachines. 2017; 8(7):200. https://doi.org/10.3390/mi8070200

Chicago/Turabian StylePfusterschmied, Georg, Javier Toledo, Martin Kucera, Wolfgang Steindl, Stefan Zemann, Víctor Ruiz-Díez, Michael Schneider, Achim Bittner, Jose Luis Sanchez-Rojas, and Ulrich Schmid. 2017. "Potential of Piezoelectric MEMS Resonators for Grape Must Fermentation Monitoring" Micromachines 8, no. 7: 200. https://doi.org/10.3390/mi8070200

APA StylePfusterschmied, G., Toledo, J., Kucera, M., Steindl, W., Zemann, S., Ruiz-Díez, V., Schneider, M., Bittner, A., Sanchez-Rojas, J. L., & Schmid, U. (2017). Potential of Piezoelectric MEMS Resonators for Grape Must Fermentation Monitoring. Micromachines, 8(7), 200. https://doi.org/10.3390/mi8070200