Stencil Lithography for Scalable Micro- and Nanomanufacturing

Abstract

:1. Introduction

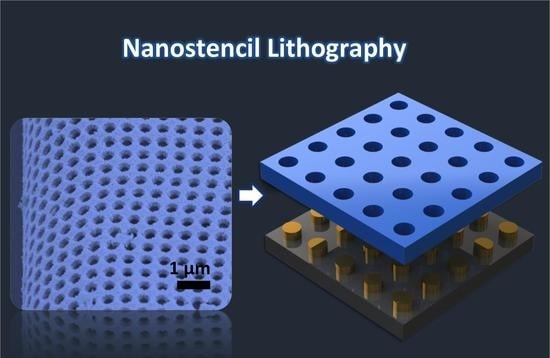

2. Rigid Stencil Mask

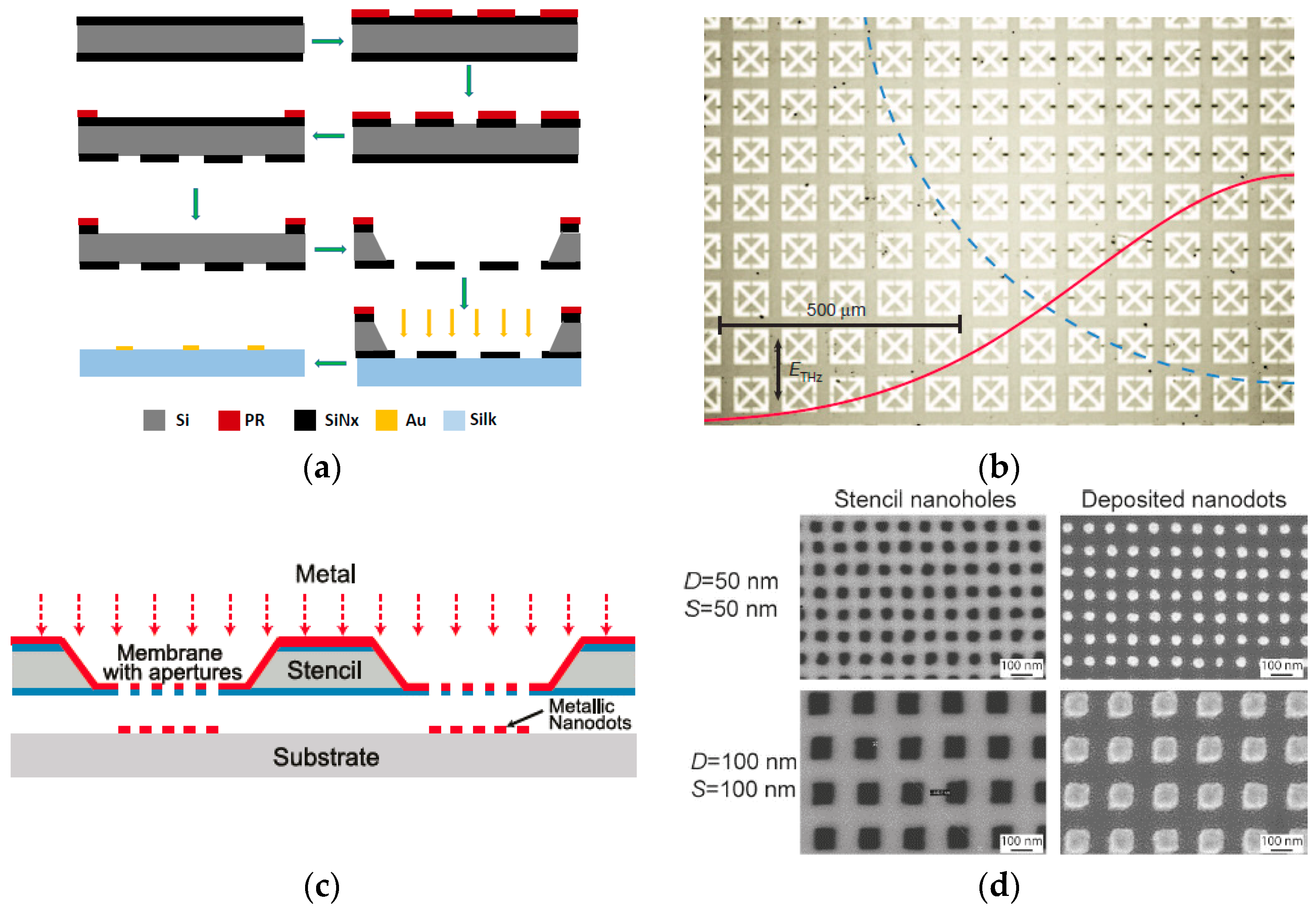

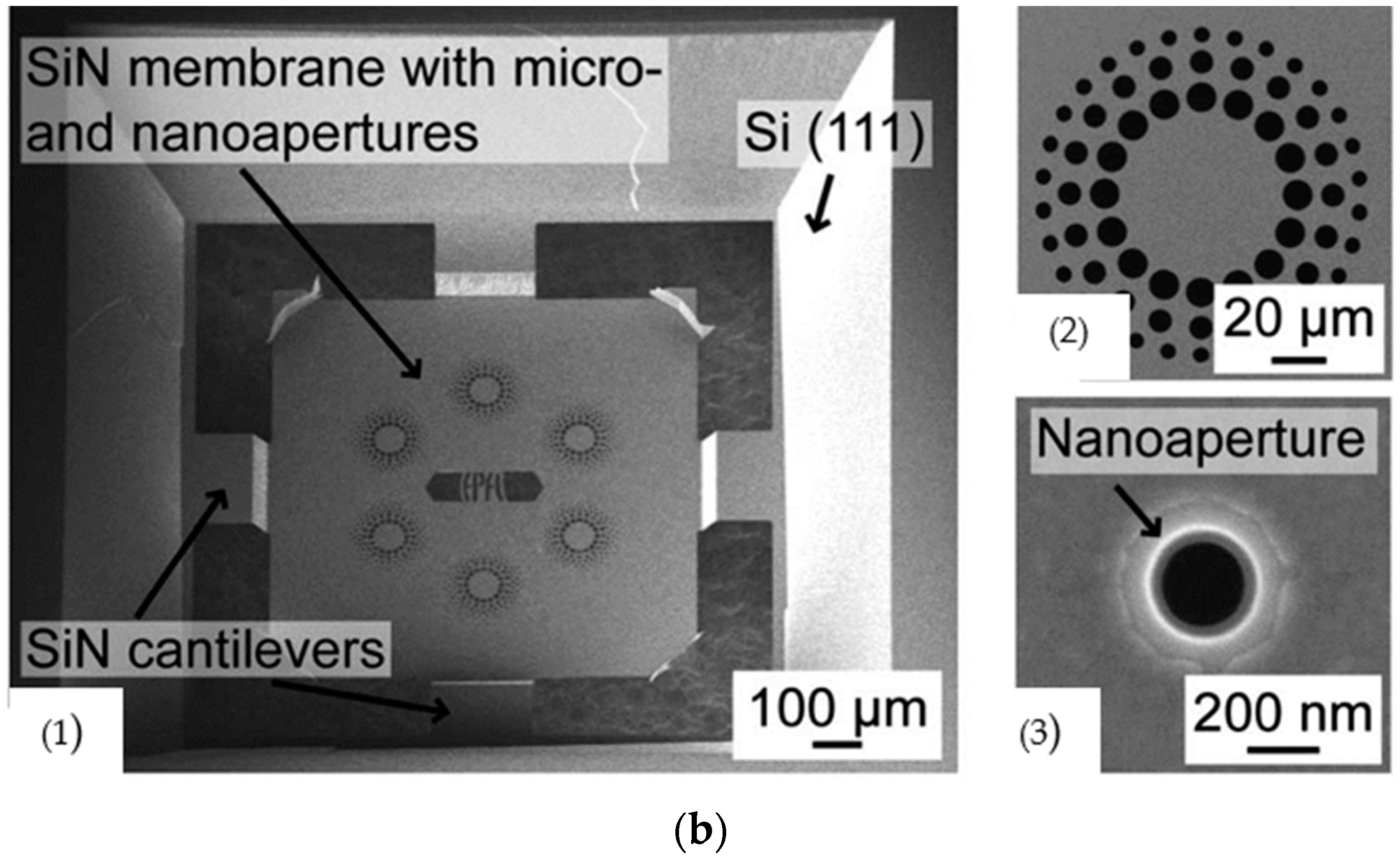

2.1. Silicon Nitride Membrane

2.2. Silicon Membrane

2.3. Rigid Stencil Stacking

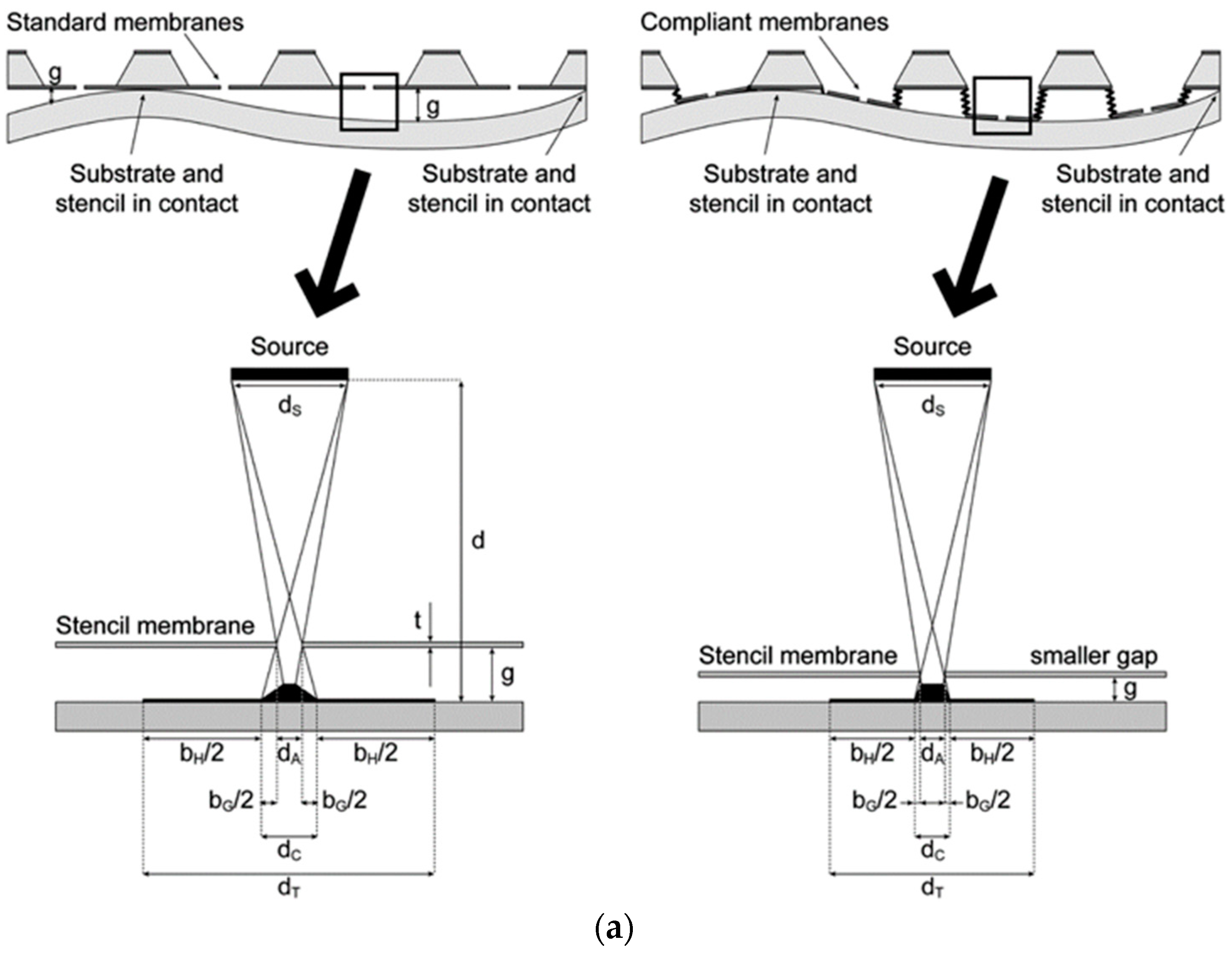

3. Closing and Blurring Effects

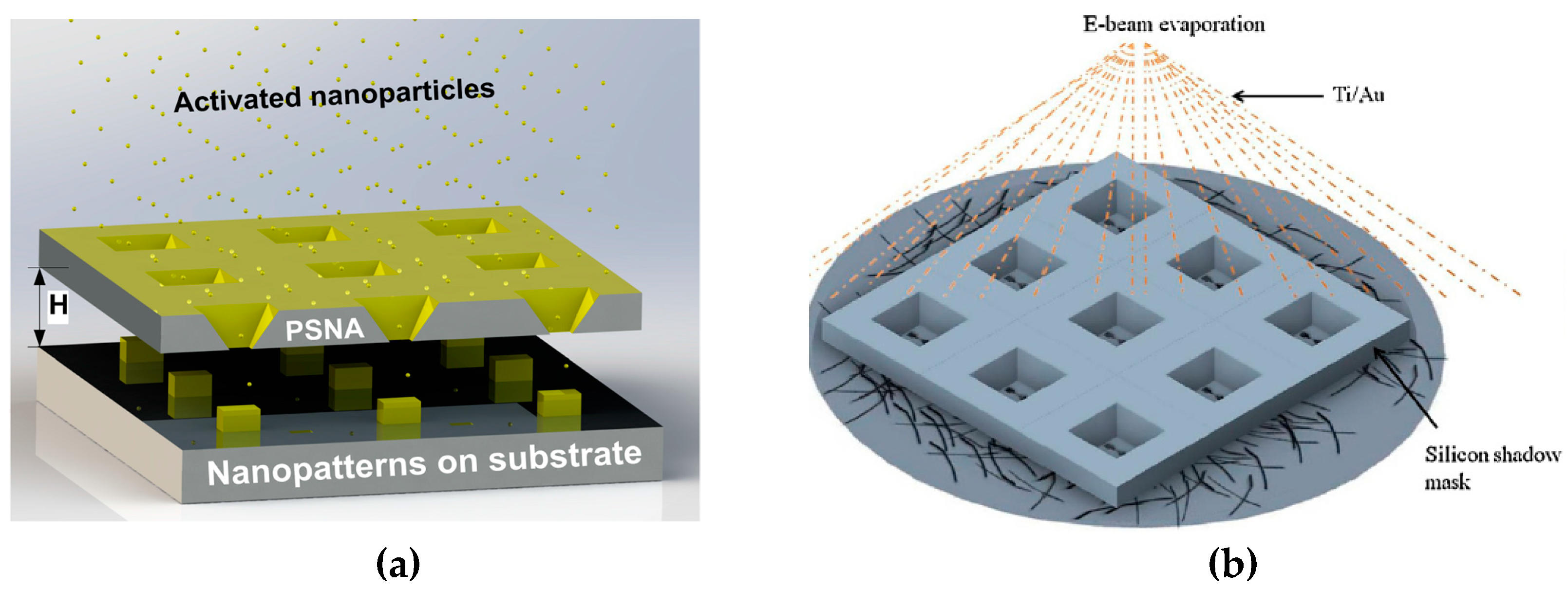

4. Compliant Stencil Mask

4.1. Rigid Membrane with Compliant Cantilevers

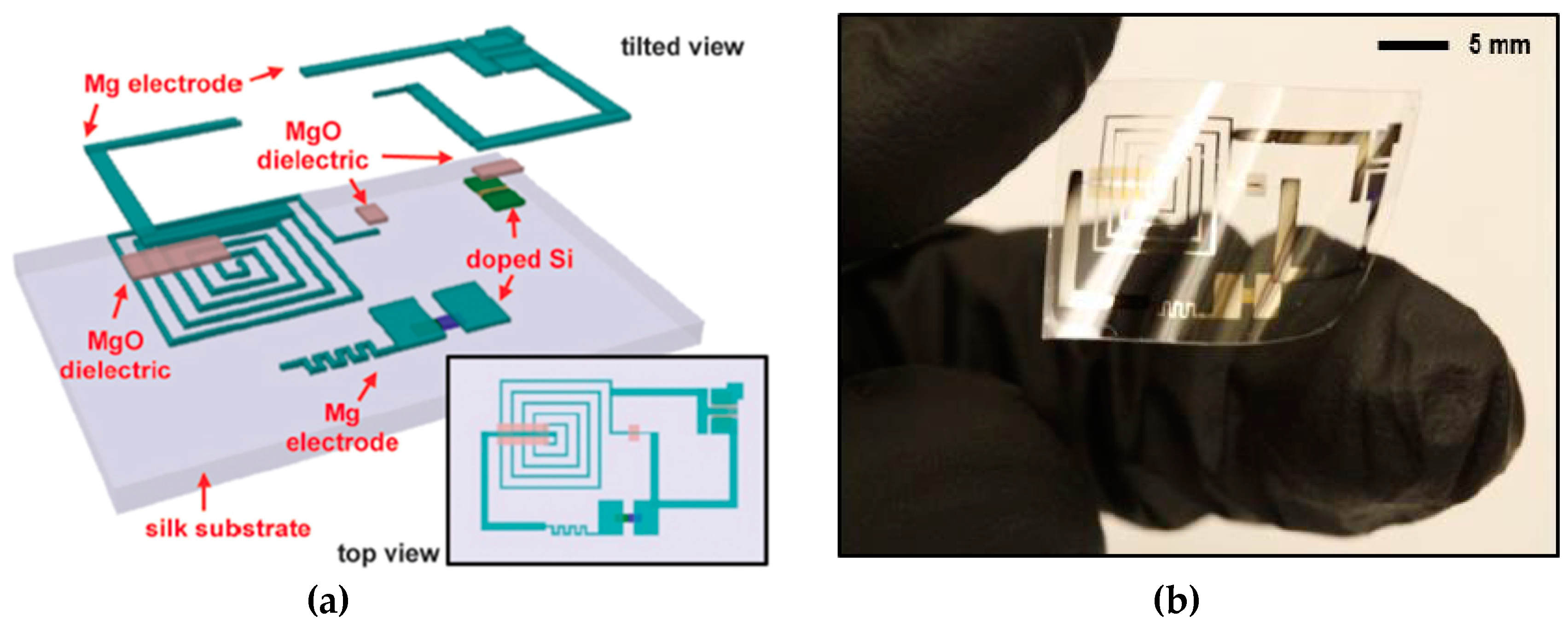

4.2. Polyimide Film

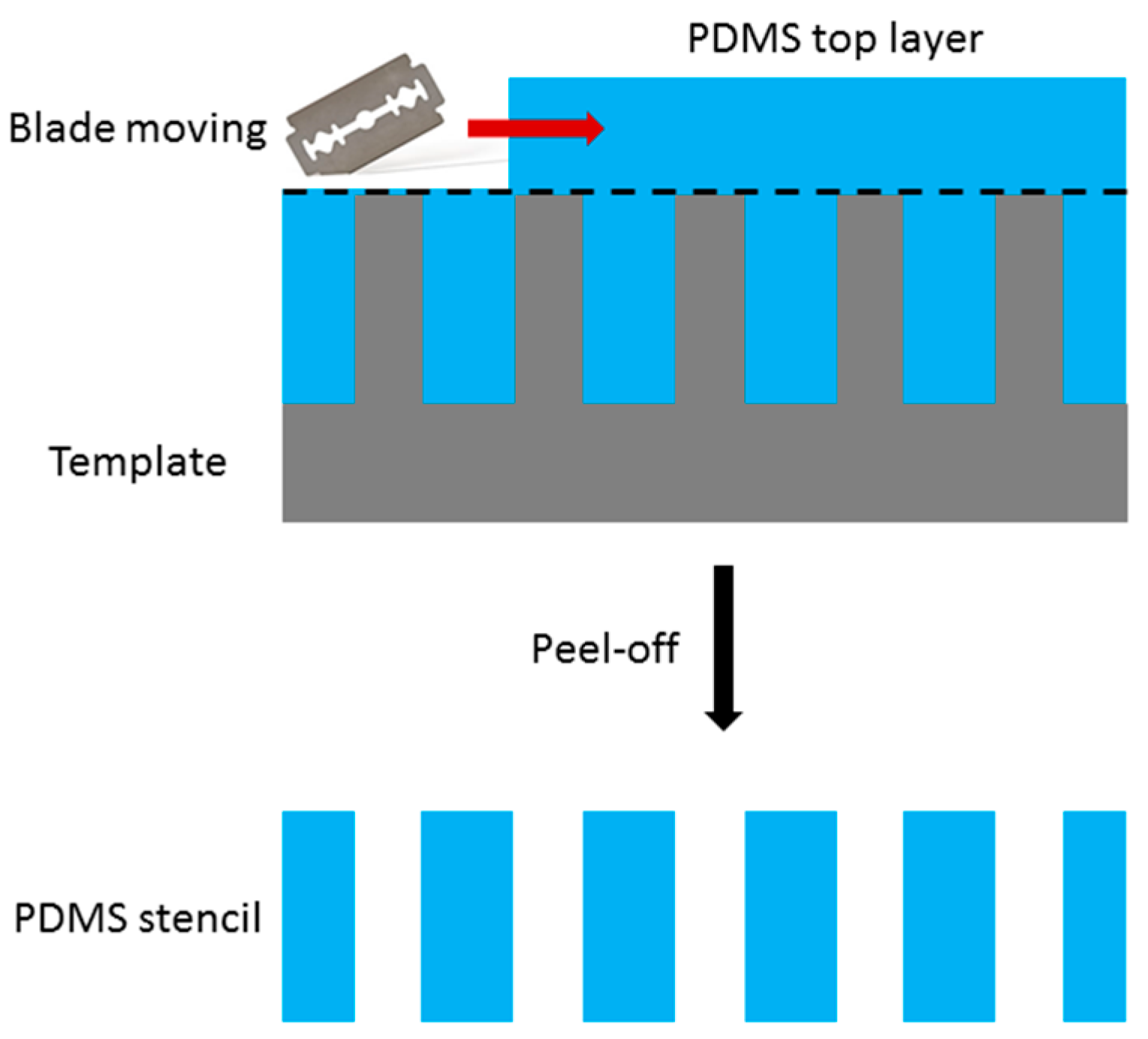

4.3. PDMS Membrane

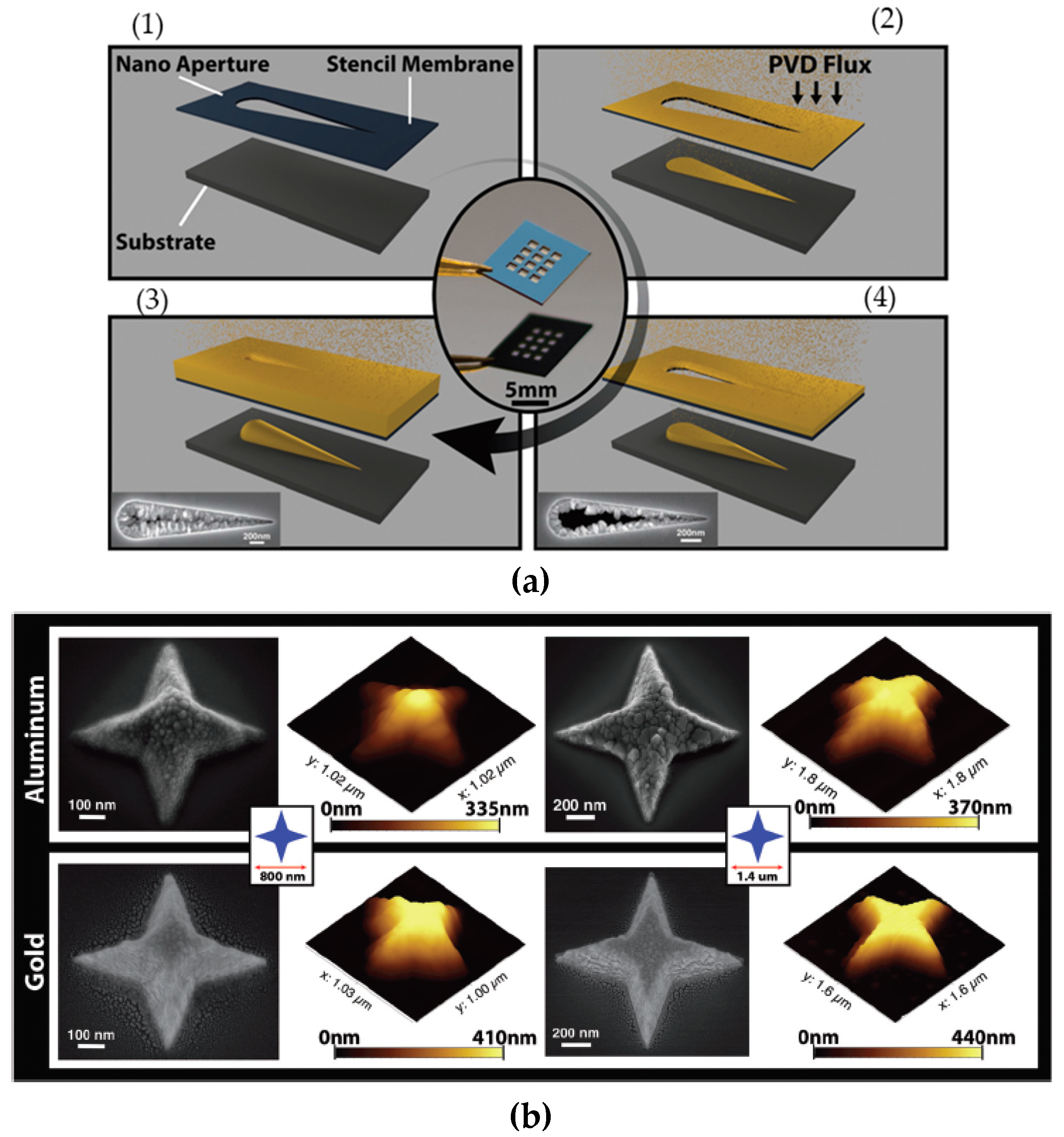

4.4. Photoresist Membrane

4.4.1. Curved Substrate Patterning

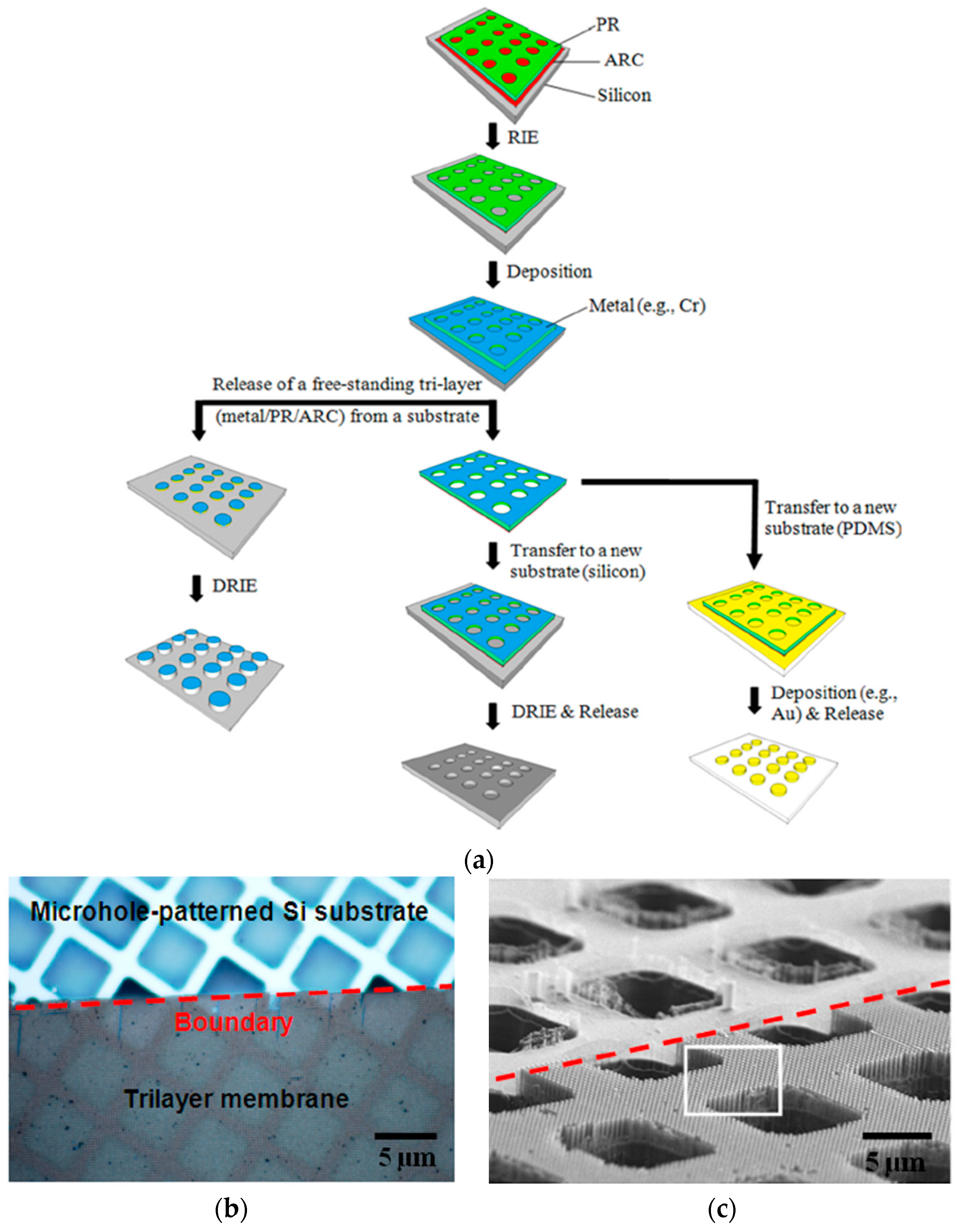

4.4.2. Dual Applications of Tri-Layer Membrane

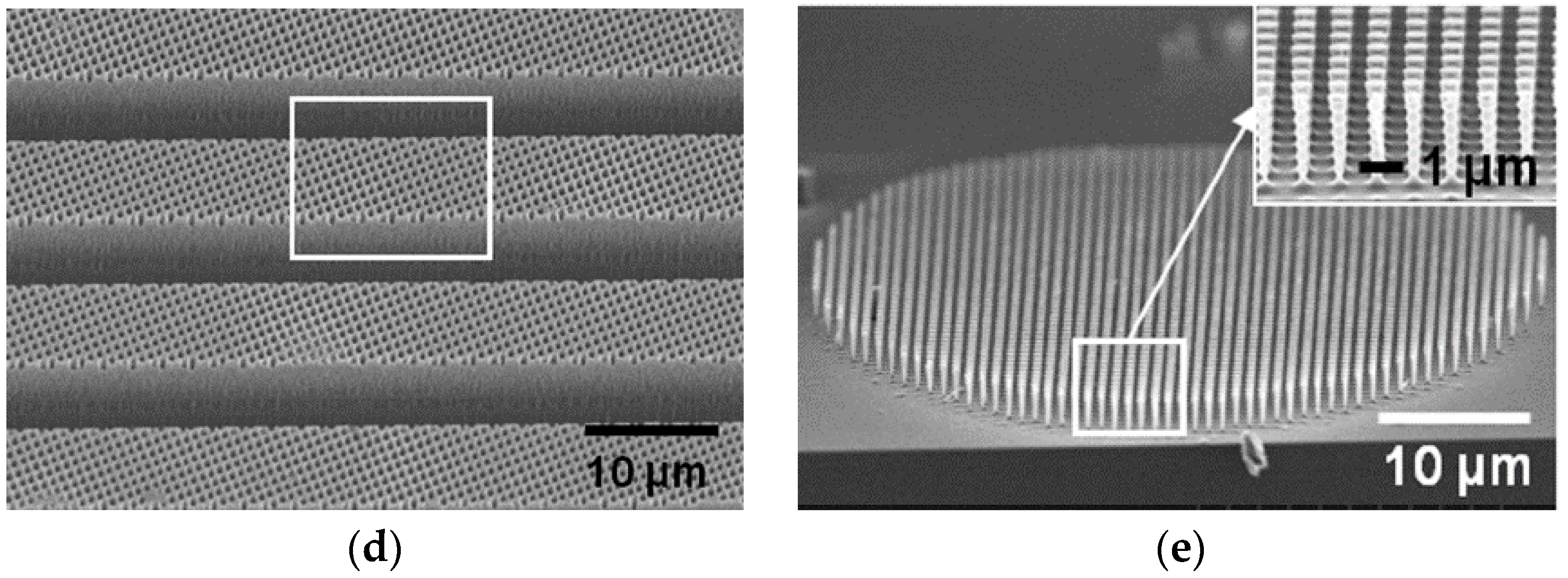

4.4.3. Hierarchical Nanostructures Patterning

5. Dynamic Stencil Lithography

6. Conclusions

Acknowledgments

Conflicts of Interest

References

- Basha, S.J.; Krishna, M.H.S.; Praharsha, C.A.; Babu, P.H.; Karthikeya, V.; Srinivas, Y.; Lakshmi, D.R.; Rao, S. Microcantilever based RF MEMS switch for wireless communication. Microelectron. Solid State Electron. 2016, 5, 1–6. [Google Scholar]

- Glushko, B.; Shar, A.; Medina, M.; Kin, D.; Krylov, S. MEMS-based tracking for an indoor optical wireless communication bidirectional link. IEEE Photonics Technol. Lett. 2016, 28, 550–553. [Google Scholar] [CrossRef]

- Kourepenis, A.; Borenstein, J.; Connelly, J.; Elliott, R.; Ward, P.; Weinberg, M. Performance of MEMS inertial sensors. In Proceedings of the IEEE 1998 Position Location and Navigation Symposium, Palm Springs, CA, USA, 20–23 April 1996; pp. 1–8. [Google Scholar]

- Serrano, D.E.; Ayazi, F. MEMS inertial sensors. In Resonant MEMS: Fundamentals, Implementation, and Application; Wiley-VCH Verlag GmbH & Co. KGa: Weinheim, Germany, 2015. [Google Scholar]

- Dong, B.; Cai, H.; Tang, M.; Gu, Y.; Yang, Z.; Jin, Y.; Hao, Y.; Kwong, D.; Liu, A. NEMS integrated photonic system using nano-silicon-photonic circuits. In Proceedings of the 2015 Transducers-2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 997–1000. [Google Scholar]

- Kumar, T.; Banavar, R.N. Forward and inverse solution for the MEMS deformable mirrors in adaptive optics. In Proceedings of the 2015 10th Asian Control Conference (ASCC), Kota Kinabalu, Malaysia, 31 May–3 June 2015; pp. 1–6. [Google Scholar]

- Bhattacharjee, S.; Maity, S. Miniaturization of MEMS-based smart patch antennas for biomedical applications. In Proceedings of the International Conference on Recent Cognizance in Wireless Communication & Image Processing, Jaipur, India, 16–17 January 2015; pp. 279–285. [Google Scholar]

- Lu, Y.; Cottone, F.; Boisseau, S.; Marty, F.; Galayko, D.; Basset, P. A nonlinear MEMS electrostatic kinetic energy harvester for human-powered biomedical devices. Appl. Phys. Lett. 2015, 107, 253902. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.L. Tribotronics—A new field by coupling triboelectricity and semiconductor. Nano Today 2016, 11, 521–536. [Google Scholar] [CrossRef]

- Wang, S.; Chinnasamy, T.; Lifson, M.A.; Inci, F.; Demirci, U. Flexible substrate-based devices for point-of-care diagnostics. Trends Biotechnol. 2016, 34, 909–921. [Google Scholar] [CrossRef] [PubMed]

- Etor, D.; Dodd, L.E.; Wood, D.; Balocco, C. High-performance rectifiers fabricated on a flexible substrate. Appl. Phys. Lett. 2016, 109, 193110. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Zi, Y.; Wang, S.; Li, Z.; Zheng, L.; Yi, F.; Li, S.; Wang, Z.L. A flexible fiber-based supercapacitor–triboelectric-nanogenerator power system for wearable electronics. Adv. Mater. 2015, 27, 4830–4836. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.-K.; Park, G.; Kim, K.; Hwang, S.-W.; Cheng, H.; Shin, J.; Chung, S.; Kim, M.; Yin, L.; Lee, J.C. Dissolution chemistry and biocompatibility of silicon-and germanium-based semiconductors for transient electronics. ACS Appl. Mater. Interfaces 2015, 7, 9297–9305. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Halder, A.; Hou, C.; Ulstrup, J.; Chi, Q. Free-standing and flexible graphene papers as disposable non-enzymatic electrochemical sensors. Bioelectrochemistry 2016, 109, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint lithography. J. Vac. Sci. Technol. B 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Hulteen, J.C.; Van Duyne, R.P. Nanosphere lithography: A materials general fabrication process for periodic particle array surfaces. J. Vac. Sci. Technol. A 1995, 13, 1553–1558. [Google Scholar] [CrossRef]

- Haynes, C.L.; Van Duyne, R.P. Nanosphere lithography: A versatile nanofabrication tool for studies of size-dependent nanoparticle optics. J. Phys. Chem. B 2001, 105, 5599–5611. [Google Scholar] [CrossRef]

- Heuberger, A. X-ray lithography. J. Vac. Sci. Technol. B 1988, 6, 107–121. [Google Scholar] [CrossRef]

- Heuberger, A. X-ray lithography. Microelectron. Eng. 1986, 5, 3–38. [Google Scholar] [CrossRef]

- Moon, J.H.; Ford, J.; Yang, S. Fabricating three-dimensional polymeric photonic structures by multi-beam interference lithography. Polym. Adv. Technol. 2006, 17, 83–93. [Google Scholar] [CrossRef]

- Jang, J.H.; Ullal, C.K.; Maldovan, M.; Gorishnyy, T.; Kooi, S.; Koh, C.; Thomas, E.L. 3D micro-and nanostructures via interference lithography. Adv. Funct. Mater. 2007, 17, 3027–3041. [Google Scholar] [CrossRef]

- Hu, H.; Yeom, J.; Mensing, G.; Chen, Y.; Shannon, M.A.; King, W.P. Nano-fabrication with a flexible array of nano-apertures. Nanotechnology 2012, 23, 175303. [Google Scholar] [CrossRef] [PubMed]

- Weinberger, D.A.; Hong, S.; Mirkin, C.A.; Wessels, B.; Higgins, T.B. Combinatorial generation and analysis of nanometer-and micrometer-scale silicon features via “dip-pen” nanolithography and wet chemical etching. Adv. Mater. 2000, 12, 1600–1603. [Google Scholar] [CrossRef]

- Vazquez-Mena, O.; Gross, L.; Xie, S.; Villanueva, L.; Brugger, J. Resistless nanofabrication by stencil lithography: A review. Microelectron. Eng. 2015, 132, 236–254. [Google Scholar] [CrossRef]

- Yun, H.; Kim, S.; Kim, H.; Lee, J.; McAllister, K.; Kim, J.; Pyo, S.; Kim, J.S.; Campbell, E.E.; Lee, W.H. Stencil nano lithography based on a nanoscale polymer shadow mask: Towards organic nanoelectronics. Sci. Rep. 2015, 5, 10220. [Google Scholar] [CrossRef] [PubMed]

- Taçon, P.S.; Langley, M.; May, S.K.; Lamilami, R.; Brennan, W.; Guse, D. Ancient bird stencils discovered in Arnhem Land, Northern Territory, Australia. Antiquity 2010, 84, 416–427. [Google Scholar] [CrossRef]

- Vagliasindi, F.G.; Poulsom, S.R. Waste generation and management in the semiconductor industry: A case study. Water Sci. Technol. 1994, 29, 331–341. [Google Scholar]

- Vazquez-Mena, O.; Villanueva, G.; Savu, V.; Sidler, K.; Van Den Boogaart, M.; Brugger, J. Metallic nanowires by full wafer stencil lithography. Nano Lett. 2008, 8, 3675–3682. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-T.; Padilla, W.J.; Zide, J.M.; Gossard, A.C.; Taylor, A.J.; Averitt, R.D. Active terahertz metamaterial devices. Nature 2006, 444, 597–600. [Google Scholar] [CrossRef] [PubMed]

- Wen, Q.-Y.; Zhang, H.-W.; Yang, Q.-H.; Xie, Y.-S.; Chen, K.; Liu, Y.-L. Terahertz metamaterials with VO2 cut-wires for thermal tunability. Appl. Phys. Lett. 2010, 97, 1111. [Google Scholar] [CrossRef]

- Tao, H.; Chieffo, L.R.; Brenckle, M.A.; Siebert, S.M.; Liu, M.; Strikwerda, A.C.; Fan, K.; Kaplan, D.L.; Zhang, X.; Averitt, R.D. Metamaterial on paper as a sensing platform. Adv. Mater. 2011, 23, 3197–3201. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Brenckle, M.A.; Yang, M.; Zhang, J.; Liu, M.; Siebert, S.M.; Averitt, R.D.; Mannoor, M.S.; McAlpine, M.C.; Rogers, J.A. Silk-based conformal, adhesive, edible food sensors. Adv. Mater. 2012, 24, 1067–1072. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Amsden, J.J.; Strikwerda, A.C.; Fan, K.; Kaplan, D.L.; Zhang, X.; Averitt, R.D.; Omenetto, F.G. Metamaterial silk composites at terahertz frequencies. Adv. Mater. 2010, 22, 3527–3531. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-H.; Viventi, J.; Amsden, J.J.; Xiao, J.; Vigeland, L.; Kim, Y.-S.; Blanco, J.A.; Panilaitis, B.; Frechette, E.S.; Contreras, D. Dissolvable films of silk fibroin for ultrathin conformal bio-integrated electronics. Nat. Mater. 2010, 9, 511–517. [Google Scholar] [CrossRef] [PubMed]

- Omenetto, F.G.; Kaplan, D.L. A new route for silk. Nat. Photonics 2008, 2, 641–643. [Google Scholar] [CrossRef]

- Liu, M.; Hwang, H.Y.; Tao, H.; Strikwerda, A.C.; Fan, K.; Keiser, G.R.; Sternbach, A.J.; West, K.G.; Kittiwatanakul, S.; Lu, J. Terahertz-field-induced insulator-to-metal transition in vanadium dioxide metamaterial. Nature 2012, 487, 345–348. [Google Scholar] [CrossRef] [PubMed]

- Vazquez-Mena, O.; Sannomiya, T.; Villanueva, L.G.; Voros, J.; Brugger, J. Metallic nanodot arrays by stencil lithography for plasmonic biosensing applications. ACS Nano 2010, 5, 844–853. [Google Scholar] [CrossRef] [PubMed]

- Shiohara, A.; Langer, J.; Polavarapu, L.; Liz-Marzán, L.M. Solution processed polydimethylsiloxane/gold nanostar flexible substrates for plasmonic sensing. Nanoscale 2014, 6, 9817–9823. [Google Scholar] [CrossRef] [PubMed]

- Aksu, S.; Huang, M.; Artar, A.; Yanik, A.A.; Selvarasah, S.; Dokmeci, M.R.; Altug, H. Flexible plasmonics on unconventional and nonplanar substrates. Adv. Mater. 2011, 23, 4422–4430. [Google Scholar] [CrossRef] [PubMed]

- Loo, Y.-L.; Willett, R.L.; Baldwin, K.W.; Rogers, J.A. Interfacial chemistries for nanoscale transfer printing. J. Am. Chem. Soc. 2002, 124, 7654–7655. [Google Scholar] [CrossRef] [PubMed]

- Du, K.; Wathuthanthri, I.; Liu, Y.; Xu, W.; Choi, C.-H. Wafer-scale pattern transfer of metal nanostructures on polydimethylsiloxane (PDMS) substrates via holographic nanopatterns. ACS Appl. Mater. Interfaces 2012, 4, 5505–5514. [Google Scholar] [CrossRef] [PubMed]

- Du, K.; Wathuthanthri, I.; Mao, W.; Xu, W.; Choi, C.-H. Large-area pattern transfer of metallic nanostructures on glass substrates via interference lithography. Nanotechnology 2011, 22, 285306. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-H.; Yu, T.-H.; Lee, Y.-C. Direct patterning of metallic micro/nano-structures on flexible polymer substrates by roller-based contact printing and infrared heating. J. Micromech. Microeng. 2010, 20, 025034. [Google Scholar] [CrossRef]

- Azimi, S.; Song, J.; Li, C.; Mathew, S.; Breese, M.; Venkatesan, T. Nanoscale lithography of LaAlO3/SrTiO3 wires using silicon stencil masks. Nanotechnology 2014, 25, 445301. [Google Scholar] [CrossRef] [PubMed]

- Hyun, W.J.; Secor, E.B.; Hersam, M.C.; Frisbie, C.D.; Francis, L.F. High-resolution patterning of graphene by screen printing with a silicon stencil for highly flexible printed electronics. Adv. Mater. 2015, 27, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Deng, T.; Li, M.; Chen, J.; Wang, Y.; Liu, Z. Controllable fabrication of pyramidal silicon nanopore arrays and nanoslits for nanostencil lithography. J. Phys. Chem. C 2014, 118, 18110–18115. [Google Scholar] [CrossRef]

- Ding, J.; Fisher, F.T.; Yang, E.-H. Direct transfer of corrugated graphene sheets as stretchable electrodes. J. Vac. Sci. Technol. B 2016, 34, 051205. [Google Scholar] [CrossRef]

- Chen, C.; Yan, L.; Kong, E.S.-W.; Zhang, Y. Ultrasonic nanowelding of carbon nanotubes to metal electrodes. Nanotechnology 2006, 17, 2192. [Google Scholar] [CrossRef]

- Waleed Shinwari, M.; Jamal Deen, M.; Starikov, E.B.; Cuniberti, G. Electrical conductance in biological molecules. Adv. Funct. Mater. 2010, 20, 1865–1883. [Google Scholar] [CrossRef]

- Agarwal, P.B.; Pawar, S.; Reddy, S.M.; Mishra, P.; Agarwal, A. Reusable silicon shadow mask with sub-5 μm gap for low cost patterning. Sens. Actuators A 2016, 242, 67–72. [Google Scholar] [CrossRef]

- Vlasov, Y.A.; O’Boyle, M.; Hamann, H.F.; McNab, S.J. Active control of slow light on a chip with photonic crystal waveguides. Nature 2005, 438, 65–69. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Cappelli, M. A tunable microwave plasma photonic crystal filter. Appl. Phys. Lett. 2015, 107, 171107. [Google Scholar] [CrossRef]

- Patel, A.A.; Fucetola, C.P.; Moon, E.E.; Smith, H.I. 3D fabrication by stacking prepatterned, rigidly held membranes. J. Vac. Sci. Technol. B 2011, 29, 06F402. [Google Scholar] [CrossRef]

- Patel, A.A.; Smith, H.I. Membrane stacking: A new approach for three-dimensional nanostructure fabrication. J. Vac. Sci. Technol. B 2007, 25, 2662–2664. [Google Scholar] [CrossRef]

- Ghadarghadr, S.; Fucetola, C.P.; Cheong, L.L.; Moon, E.E.; Smith, H.I. 3D nanostructures by stacking pre-patterned fluid-supported single-crystal Si membranes. J. Vac. Sci. Technol. B 2011, 29, 06F401. [Google Scholar] [CrossRef]

- Lu, L.; Joannopoulos, J.D.; Soljačić, M. Waveguiding at the edge of a three-dimensional photonic crystal. Phys. Rev. Lett. 2012, 108, 243901. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Joannopoulos, J.D.; Soljačić, M. Topological photonics. Nat. Photonics 2014, 8, 821–829. [Google Scholar] [CrossRef]

- Lishchynska, M.; Bourenkov, V.; van den Boogaart, M.A.; Doeswijk, L.; Brugger, J.; Greer, J.C. Predicting mask distortion, clogging and pattern transfer for stencil lithography. Microelectron. Eng. 2007, 84, 42–53. [Google Scholar] [CrossRef]

- Vazquez-Mena, O.; Sidler, K.; Savu, V.; Park, C.W.; Villanueva, L.G.; Brugger, J. Reliable and improved nanoscale stencil lithography by membrane stabilization, blurring, and clogging corrections. IEEE Trans. Nanotechnol. 2011, 10, 352–357. [Google Scholar] [CrossRef]

- Kölbel, M.; Tjerkstra, R.W.; Brugger, J.; van Rijn, C.J.; Nijdam, W.; Huskens, J.; Reinhoudt, D.N. Shadow-mask evaporation through monolayer-modified nanostencils. Nano Lett. 2002, 2, 1339–1343. [Google Scholar] [CrossRef]

- Savu, V.; Kivioja, J.; Ahopelto, J.; Brugger, J. Quick and clean: Stencil lithography for wafer-scale fabrication of superconducting tunnel junctions. IEEE Trans. Appl. Supercond. 2009, 19, 242–244. [Google Scholar] [CrossRef]

- Yesilkoy, F.; Flauraud, V.; Rüegg, M.; Kim, B.; Brugger, J. 3D nanostructures fabricated by advanced stencil lithography. Nanoscale 2016, 8, 4945–4950. [Google Scholar] [CrossRef] [PubMed]

- Vazquez-Mena, O.; Villanueva, L.G.; Savu, V.; Sidler, K.; Langlet, P.; Brugger, J. Analysis of the blurring in stencil lithography. Nanotechnol. 2009, 20, 415303. [Google Scholar] [CrossRef] [PubMed]

- Rácz, Z.; Seabaugh, A. Characterization and control of unconfined lateral diffusion under stencil masks. J. Vac. Sci. Technol. B 2007, 25, 857–861. [Google Scholar] [CrossRef]

- Sidler, K.; Villanueva, G.; Vazquez-Mena, O.; Brugger, J. Minimized blurring in stencil lithography using a compliant membrane. In Proceedings of the 2009 International Solid-State Sensors, Actuators and Microsystems Conference (TRANSDUCERS 2009), Denver, CO, USA, 21–25 June 2009; pp. 1612–1615. [Google Scholar]

- Sidler, K.; Villanueva, L.G.; Vazquez-Mena, O.; Savu, V.; Brugger, J. Compliant membranes improve resolution in full-wafer micro/nanostencil lithography. Nanoscale 2012, 4, 773–778. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Choi, J.-R.; Lee, K.J.; Stott, N.E.; Kim, D. Large-scale synthesis of copper nanoparticles by chemically controlled reduction for applications of inkjet-printed electronics. Nanotechnology 2008, 19, 415604. [Google Scholar] [CrossRef] [PubMed]

- Noguchi, Y.; Sekitani, T.; Someya, T. Organic-transistor-based flexible pressure sensors using ink-jet-printed electrodes and gate dielectric layers. Appl. Phys. Lett. 2006, 89, 253507. [Google Scholar] [CrossRef]

- Bauer, S.; Bauer-Gogonea, S.; Graz, I.; Kaltenbrunner, M.; Keplinger, C.; Schwödiauer, R. 25th anniversary article: A soft future: From robots and sensor skin to energy harvesters. Adv. Mater. 2014, 26, 149–162. [Google Scholar] [CrossRef] [PubMed]

- Rivnay, J.; Owens, R.I.M.; Malliaras, G.G. The rise of organic bioelectronics. Chem. Mater. 2013, 26, 679–685. [Google Scholar] [CrossRef]

- Hwang, S.-W.; Tao, H.; Kim, D.-H.; Cheng, H.; Song, J.-K.; Rill, E.; Brenckle, M.A.; Panilaitis, B.; Won, S.M.; Kim, Y.-S. A physically transient form of silicon electronics. Science 2012, 337, 1640–1644. [Google Scholar] [CrossRef] [PubMed]

- Boland, J.J. Flexible electronics: Within touch of artificial skin. Nat. Mater. 2010, 9, 790–792. [Google Scholar] [CrossRef] [PubMed]

- Kung, Y.-C.; Huang, K.-W.; Fan, Y.-J.; Chiou, P.-Y. Fabrication of 3D high aspect ratio PDMS microfluidic networks with a hybrid stamp. Lab Chip 2015, 15, 1861–1868. [Google Scholar] [CrossRef] [PubMed]

- Chang-Yen, D.A.; Eich, R.K.; Gale, B.K. A monolithic PDMS waveguide system fabricated using soft-lithography techniques. J. Lightwave Technol. 2005, 23, 2088. [Google Scholar] [CrossRef]

- Meng, L.; Mahpeykar, S.M.; Xiong, Q.; Ahvazi, B.; Wang, X. Strain sensors on water-soluble cellulose nanofibril paper by polydimethylsiloxane (PDMS) stencil lithography. RSC Adv. 2016, 6, 85427–85433. [Google Scholar] [CrossRef]

- Folch, A.; Jo, B.-H.; Hurtado, O.; Beebe, D.J.; Toner, M. Microfabricated elastomeric stencils for micropatterning cell cultures. J. Biomed. Mater. Res. 2000, 52, 346–353. [Google Scholar] [CrossRef]

- Choi, J.H.; Lee, H.; Jin, H.K.; Bae, J.-S.; Kim, G.M. Micropatterning of neural stem cells and purkinje neurons using a polydimethylsiloxane (PDMS) stencil. Lab Chip 2012, 12, 5045–5050. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Du, K.; Wathuthanthri, I.; Choi, C.-H.; Fisher, F.T.; Yang, E.-H. Transfer patterning of large-area graphene nanomesh via holographic lithography and plasma etching. J. Vac. Sci. Technol. B 2014, 32, 06FF01. [Google Scholar] [CrossRef]

- Wathuthanthri, I.; Liu, Y.; Du, K.; Xu, W.; Choi, C.H. Simple holographic patterning for high-aspect-ratio three-dimensional nanostructures with large coverage area. Adv. Funct. Mater. 2013, 23, 608–618. [Google Scholar] [CrossRef]

- Liu, Y.; Du, K.; Wathuthanthri, I.; Choi, C.-H. From nanocone to nanodisc: Structural transformation of gold nanoarrays via simple mechanical stresses. J. Vac. Sci. Technol. B 2012, 30, 06FF10. [Google Scholar] [CrossRef]

- El Mel, A.-A.; Molina-Luna, L.; Buffiere, M.; Tessier, P.-Y.; Du, K.; Choi, C.-H.; Kleebe, H.-J.; Konstantinidis, S.; Bittencourt, C.; Snyders, R. Electron beam nanosculpting of kirkendall oxide nanochannels. ACS Nano 2014, 8, 1854–1861. [Google Scholar] [CrossRef] [PubMed]

- Chauvin, A.; Delacôte, C.; Molina-Luna, L.; Duerrschnabel, M.; Boujtita, M.; Thiry, D.; Du, K.; Ding, J.; Choi, C.-H.; Tessier, P.-Y. Planar arrays of nanoporous gold nanowires: When electrochemical dealloying meets nanopatterning. ACS Appl. Mater. Interfaces 2016, 8, 6611–6620. [Google Scholar] [CrossRef] [PubMed]

- Mel, E.; Buffière, M.; Tessier, P.Y.; Konstantinidis, S.; Xu, W.; Du, K.; Wathuthanthri, I.; Choi, C.H.; Bittencourt, C.; Snyders, R. Highly ordered hollow oxide nanostructures: The kirkendall effect at the nanoscale. Small 2013, 9, 2838–2843. [Google Scholar] [CrossRef] [PubMed]

- Thiry, D.; Molina-Luna, L.; Gautron, E.; Stephant, N.; Chauvin, A.; Du, K.; Ding, J.; Choi, C.-H.; Tessier, P.-Y.; El Mel, A.-A. The kirkendall effect in binary alloys: Trapping gold in copper oxide nanoshells. Chem. Mater. 2015, 27, 6374–6384. [Google Scholar] [CrossRef]

- Bläsi, B.; Tucher, N.; Höhn, O.; Kübler, V.; Kroyer, T.; Wellens, C.; Hauser, H. Large-area patterning using interference and nanoimprint lithography. Proc. SPIE 2016, 98880, 98880H. [Google Scholar] [CrossRef]

- Liu, Y.; Du, K.; Wathuthanthri, I.; Xu, W.; Choi, C.-H. 3-D nanofabrication using nanostructured photoresist film as free-standing appliqué. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 192–195. [Google Scholar]

- Pham, P.; Vo, T.; Luo, X. Steering air bubbles with an add-on vacuum layer for biopolymer membrane biofabrication in PDMS microfluidics. Lab Chip 2017, 17, 248–255. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Ren, W.; Xu, H.; Jin, L.; Wang, Z.; Ma, T.; Ma, L.-P.; Zhang, Z.; Fu, Q.; Peng, L.-M. Repeated growth and bubbling transfer of graphene with millimetre-size single-crystal grains using platinum. Nat. Commun. 2012, 3, 699. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Tan, S.; Oo, M.K.K.; Pristinski, D.; Sukhishvili, S.; Du, H. Towards full-length accumulative surface-enhanced raman scattering-active photonic crystal fibers. Adv. Mater. 2010, 22, 2647–2651. [Google Scholar] [CrossRef] [PubMed]

- Jeon, H.; Kim, D.; Kim, M.; Nguyen, X.; Park, D.; Go, J. Development of a 3D circular microfluidic centrifuge for the separation of mixed particles by using their different centrifuge times. J. Micromech. Microeng. 2015, 25, 114001. [Google Scholar] [CrossRef]

- Fan, X.; White, I.M. Optofluidic microsystems for chemical and biological analysis. Nat. Photonics 2011, 5, 591–597. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Con, C.; Cui, B. Electron beam lithography on irregular surfaces using an evaporated resist. ACS Nano 2014, 8, 3483–3489. [Google Scholar] [CrossRef] [PubMed]

- Con, C.; Zhang, J.; Cui, B. Nanofabrication of high aspect ratio structures using an evaporated resist containing metal. Nanotechnology 2014, 25, 175301. [Google Scholar] [CrossRef] [PubMed]

- Hatzakis, M.; Canavello, B.; Shaw, J. Single-step optical lift-off process. IBM J. Res. Dev. 1980, 24, 452–460. [Google Scholar] [CrossRef]

- Ha, J.-S.; Lee, S.; Lee, H.-J.; Lee, H.-J.; Lee, S.; Goto, H.; Kato, T.; Fujii, K.; Cho, M.; Yao, T. The fabrication of vertical light-emitting diodes using chemical lift-off process. IEEE Photonics Technol. Lett. 2008, 20, 175–177. [Google Scholar] [CrossRef]

- Du, K.; Liu, Y.; Wathuthanthri, I.; Choi, C.-H. Dual applications of free-standing holographic nanopatterns for lift-off and stencil lithography. J. Vac. Sci. Technol. B 2012, 30, 06FF04. [Google Scholar] [CrossRef]

- Watson, G.S.; Cribb, B.W.; Watson, J.A. How micro/nanoarchitecture facilitates anti-wetting: An elegant hierarchical design on the termite wing. ACS Nano 2010, 4, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chen, Y.; Shi, L.; Li, J.; Guo, Z. Recent progress of double-structural and functional materials with special wettability. J. Mater. Chem. 2012, 22, 799–815. [Google Scholar] [CrossRef]

- Xiong, J.; Das, S.N.; Shin, B.; Kar, J.P.; Choi, J.H.; Myoung, J.-M. Biomimetic hierarchical ZnO structure with superhydrophobic and antireflective properties. J. Colloid Interface Sci. 2010, 350, 344–347. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.J.; Huh, S.Y. Direct structuring of a biomimetic anti-reflective, self-cleaning surface for light harvesting in organic solar cells. Macromol. Rapid Commun. 2010, 31, 539–544. [Google Scholar] [CrossRef] [PubMed]

- Ikkala, O.; ten Brinke, G. Hierarchical self-assembly in polymeric complexes: Towards functional Materials. Chem. Commun. 2004, 19, 2131–2137. [Google Scholar] [CrossRef] [PubMed]

- Lopes, W.A.; Jaeger, H.M. Hierarchical self-assembly of metal nanostructures on diblock copolymer scaffolds. Nature 2001, 414, 735–738. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Tuominen, M.T.; Rothstein, J.P. Hierarchical superhydrophobic surfaces fabricated by dual-scale electron-beam-lithography with well-ordered secondary nanostructures. Adv. Funct. Mater. 2011, 21, 3715–3722. [Google Scholar] [CrossRef]

- Murphy, M.P.; Kim, S.; Sitti, M. Enhanced adhesion by gecko-inspired hierarchical fibrillar adhesives. ACS Appl. Mater. Interfaces 2009, 1, 849–855. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Low, H.Y. Ordered three-dimensional hierarchical nanostructures by nanoimprint lithography. Nanotechnology 2006, 17, 1884. [Google Scholar] [CrossRef]

- Du, K.; Wathuthanthri, I.; Liu, Y.; Kang, Y.T.; Choi, C.-H. Fabrication of polymer nanowires via maskless O2 plasma etching. Nanotechnology 2014, 25, 165301. [Google Scholar] [CrossRef] [PubMed]

- Morber, J.R.; Wang, X.; Liu, J.; Snyder, R.L.; Wang, Z.L. Wafer-level patterned and aligned polymer nanowire/micro-and nanotube arrays on any substrate. Adv. Mater. 2009, 21, 2072–2076. [Google Scholar] [CrossRef]

- Du, K.; Liu, Y.; Wathuthanthri, I.; Choi, C.-H. Fabrication of hierarchical nanostructures using free-standing trilayer membrane. J. Vac. Sci. Technol. B 2013, 31, 06FF04. [Google Scholar] [CrossRef]

- Wang, C.; Bruce, R.L.; Duch, E.A.; Patel, J.V.; Smith, J.T.; Astier, Y.; Wunsch, B.H.; Meshram, S.; Galan, A.; Scerbo, C. Hydrodynamics of diamond-shaped gradient nanopillar arrays for effective DNA translocation into nanochannels. ACS Nano 2015, 9, 1206–1218. [Google Scholar] [CrossRef] [PubMed]

- Hashim, U.; Arshad, M.M.; Kasjoo, S.; Rahman, S.; Ruslinda, A.; Fathil, M.; Adzhri, R.; Shahimin, M. Electrical detection of dengue virus (DENV) DNA oligomer using silicon nanowire biosensor with novel molecular gate control. Biosens. Bioelectron. 2016, 83, 106–114. [Google Scholar]

- Stockman, M.I. Nanoplasmonic sensing and detection. Science 2015, 348, 287–288. [Google Scholar] [CrossRef] [PubMed]

- Savu, V.; van den Boogaart, M.A.; Brugger, J.; Arcamone, J.; Sansa, M.; Perez-Murano, F. Dynamic stencil lithography on full wafer scale. J. Vac. Sci. Technol. B 2008, 26, 2054–2058. [Google Scholar] [CrossRef]

- Schneider, H.-C. Dynamic Stencil Lithography. 2006. Available online: https://infoscience.epfl.ch/record/83885 (accessed on 14 April 2017).

- Egger, S.; Ilie, A.; Fu, Y.; Chongsathien, J.; Kang, D.-J.; Welland, M.E. Dynamic shadow mask technique: A universal tool for nanoscience. Nano Lett. 2005, 5, 15–20. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Imboden, M.; Stark, T.; Del Corro, P.G.; Pardo, F.; Bolle, C.A.; Lally, R.W.; Bishop, D.J. Programmable solid state atom sources for nanofabrication. Nanoscale 2015, 7, 10735–10744. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xing, D.; Li, Y. Micropumps, microvalves, and micromixers within PCR microfluidic chips: Advances and trends. Biotechnol. Adv. 2007, 25, 483–514. [Google Scholar] [CrossRef] [PubMed]

- Thorsen, T.; Maerkl, S.J.; Quake, S.R. Microfluidic large-scale integration. Science 2002, 298, 580–584. [Google Scholar] [CrossRef] [PubMed]

- Du, K.; Cai, H.; Park, M.; Wall, T.; Stott, M.; Alfson, K.; Griffiths, A.; Carrion, R.; Patterson, J.; Hawkins, A. Multiplexed efficient on-chip sample preparation and sensitive amplification-free detection of ebola virus. Biosens. Bioelectron. 2017, 91, 489–496. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Tian, J.; Wu, J.; Cao, W.; Zhou, B.; Shen, R.; Wen, W. Digital microfluidic programmable stencil (DMPS) for protein and cell patterning. RSC Adv. 2016, 6, 101760–101769. [Google Scholar] [CrossRef]

- Vazquez-Mena, O.; Sannomiya, T.; Tosun, M.; Villanueva, L.G.; Savu, V.; Voros, J.; Brugger, J. High-resolution resistless nanopatterning on polymer and flexible substrates for plasmonic biosensing using stencil masks. ACS Nano 2012, 6, 5474–5481. [Google Scholar] [CrossRef] [PubMed]

- Villanueva, L.G.; Vazquez-Mena, O.; Martin-Olmos, C.; Savu, V.; Sidler, K.; Brugger, J. Resistless fabrication of nanoimprint lithography (NIL) stamps using nano-stencil lithography. Micromachines 2013, 4, 370–377. [Google Scholar] [CrossRef]

- Kim, S. Lego-like microassembly using reversible dry adhesion. IEEE Potentials 2016, 35, 14–17. [Google Scholar] [CrossRef]

- Keum, H.; Yang, Z.; Han, K.; Handler, D.E.; Nguyen, T.N.; Schutt-Aine, J.; Bahl, G.; Kim, S. Microassembly of heterogeneous materials using transfer printing and thermal processing. Sci. Rep. 2016, 6, 29925. [Google Scholar] [CrossRef] [PubMed]

- Diagne, C.T.; Brun, C.; Gasparutto, D.; Baillin, X.; Tiron, R. DNA origami mask for sub-ten nanometer lithography. ACS Nano 2016, 10, 6458–6463. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.H.; Hwang, W.S.; Lin, Z.; Kwon, S.H.; Hong, S.W. A robust highly aligned DNA nanowire array-enabled lithography for graphene nanoribbon transistors. Nano Lett. 2015, 15, 7913–7920. [Google Scholar] [CrossRef] [PubMed]

- Merry, R.J.; De Kleijn, N.C.; Van De Molengraft, M.J.; Steinbuch, M. Using a walking piezo actuator to drive and control a high-precision stage. IEEE/ASME Trans. Mechatron. 2009, 14, 21–31. [Google Scholar] [CrossRef]

- Ding, J.; Zhai, Z.; He, J.; Li, J.; Wang, X.; Huang, W. Micro device mould fabrication based on two-photon polymerization and electroforming. In Proceedings of the 2010 5th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 20–23 January 2010; pp. 1074–1078. [Google Scholar]

- Adib, F.; Kumar, S.; Aryan, O.; Gollakota, S.; Katabi, D. Interference alignment by motion. In Proceedings of the 19th annual international conference on Mobile computing & networking, Miami, FL, USA, 30 September–4 October 2013; pp. 279–290. [Google Scholar]

- Eisenhaure, J.D.; Rhee, S.I.; Ala’a, M.; Carlson, A.; Ferreira, P.M.; Kim, S. The use of shape memory polymers for microassembly by transfer printing. J. Microelectromech. Syst. 2014, 23, 1012–1014. [Google Scholar] [CrossRef]

- Kim, G.; Van Den Boogaart, M.; Brugger, J. Fabrication and application of a full wafer size micro/nanostencil for multiple length-scale surface patterning. Microelectron. Eng. 2003, 67, 609–614. [Google Scholar] [CrossRef]

- Inagaki, M.; Harada, S.; Sato, T.; Nakajima, T.; Horino, Y.; Morita, K. Carbonization of polyimide film “kapton”. Carbon 1989, 27, 253–257. [Google Scholar] [CrossRef]

- Odom, T.W.; Love, J.C.; Wolfe, D.B.; Paul, K.E.; Whitesides, G.M. Improved pattern transfer in soft lithography using composite stamps. Langmuir 2002, 18, 5314–5320. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, K.; Ding, J.; Liu, Y.; Wathuthanthri, I.; Choi, C.-H. Stencil Lithography for Scalable Micro- and Nanomanufacturing. Micromachines 2017, 8, 131. https://doi.org/10.3390/mi8040131

Du K, Ding J, Liu Y, Wathuthanthri I, Choi C-H. Stencil Lithography for Scalable Micro- and Nanomanufacturing. Micromachines. 2017; 8(4):131. https://doi.org/10.3390/mi8040131

Chicago/Turabian StyleDu, Ke, Junjun Ding, Yuyang Liu, Ishan Wathuthanthri, and Chang-Hwan Choi. 2017. "Stencil Lithography for Scalable Micro- and Nanomanufacturing" Micromachines 8, no. 4: 131. https://doi.org/10.3390/mi8040131