2.1. Principle, Design, and Function

A high precision 3D Laser Microscope (LM, VK-X210, Keyence, Tokyo, Japan) was used for the measurement of the surface topography with a planar resolution less than 0.01 µm and a height resolution of 0.005 µm. The microscope was equipped with a motorized XY-planar actuator with a scanning range of 100 mm × 100 mm and a resolution of 5 μm. The tribotester was assembled as an autonomous unit and then attached to the motorized XY planar actuator of the microscope. The actuators of the microscope were used for precise positioning of the tribotester system under the lens of the laser microscope. The load capacity of the microscope actuator was 5 kg, which was sufficiently high for supporting the tribotester weight without compromising the positioning accuracy or disrupting the performance of the actuators. The positioning of the tribotester directly under the objective lens of the microscope enabled direct observation of the contact point between the specimen and the pin which is used as a counter surface.

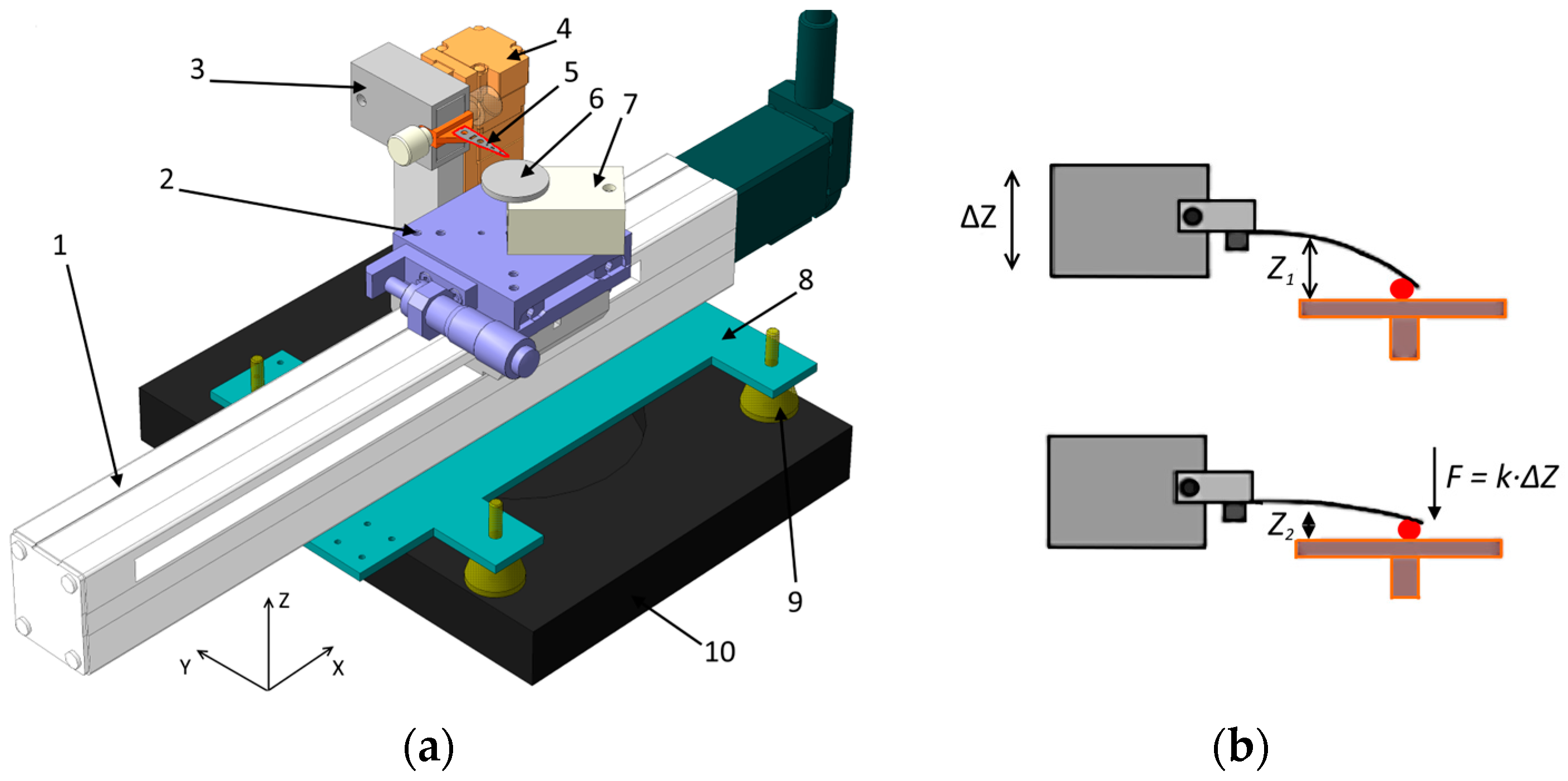

The design of the tribotester system is shown in

Figure 1a. Tests were conducted by reciprocating the test specimen in contact with a tip under a specified normal force. The reciprocating motion along the

X-axis during the friction test was generated by a high-precision linear actuator (EasyLimo, Oriental Motor, Tokyo, Japan). This actuator has a stroke of 200 mm and a maximum reciprocating speed of 300 mm/s. The position was controlled with a resolution of 20 μm. The actuator was attached to an aluminum chassis (8). This chassis was mounted on the

XY-planar actuator of the microscope (10) through four polyurethane shock-absorbers (9). The length of the tribotester

X-axis actuator was ~65 mm longer than the width of the

XY actuators. Long

X-axis allowed the specimen holder to be positioned away from the microscope during manipulation of the specimen holder to preserve the optics of the microscope. The manual stage (2) (PADRL-20, Oriental Motor) was attached to the top of the

X-axis actuator (1). This stage was used for adjusting the position of the contact point along the

Y-axis of the test specimen. The

Y-axis manual stage has a stroke of 30 mm and a resolution of 10 μm.

Two independent sensors were used for the measurement of normal and frictional forces. In this case, two same force sensors were used. High-precision commercial load cells (strain gages, GS0-10, Transducers Techniques, Temecula, CA, USA) were utilized for this purpose. The sensing range of the load cell was 0.1–300 mN. The normal force sensor (7) was attached to the top of the Y-axis actuator. The specimen holder (6) had a threaded cylindrical pin that was inserted into corresponding holes in the normal force sensor. The test specimens were attached to the specimen holder using a two-sided adhesive tape, which was sufficiently strong to ensure that the specimens were rigidly attached and remained static during the sliding tests. The specimen holder could be easily detached from the normal force sensor to provide safe manipulation of the specimens and to avoid overloading the sensor. The frictional force sensor (3) was attached to the Z-axis actuator (4). The actuator had a 28-mm stroke and a resolution of 2 μm. The X- and Z-axis actuators were controlled with a programmable 2-channel controller (PMC-2HSP, Autonics, Seoul, Korea).

The normal force was generated by the elastic deformation of a steel cantilever suspension (5) attached to the frictional force sensor using a custom-built holder. The holder was attached to the frictional force sensor by two knobs that enabled quick replacement of the suspensions between experiments. In tribological experiments, a new tip is typically used for every experiment to ensure geometric integrity as the tip may also become worn during the experiment [

6]. Hence, the ability to quickly replace the suspensions significantly increased the usability of the tribotester.

The suspension had a triangular shape in the plane, and the tip (counter surface) was attached to the end of the suspension with epoxy adhesive.

Figure 1b illustrates the generation of the normal force schematically. By moving the frictional force sensor (3) downward using a linear actuator (4), the suspension was made to contact the specimen surface, and the normal force was generated due to the elastic deformation of the suspension. The amount of force was dependent on the spring constant (

k) of the suspension and vertical displacement (Δ

Z) of the tip holder. The maximum force was limited by both the sensing range of the load cell and the elastic deformation of the suspension. The normal and frictional force sensors were connected to a commercial multichannel analog to digital converter (ADC NI DAQ 9420, National Instruments, Austin, TX, USA) unit using the full-bridge scheme. The ADC resolution was 24 bits, and the sampling rate was 100 kHz.

2.2. Software and Control of the Tribotester

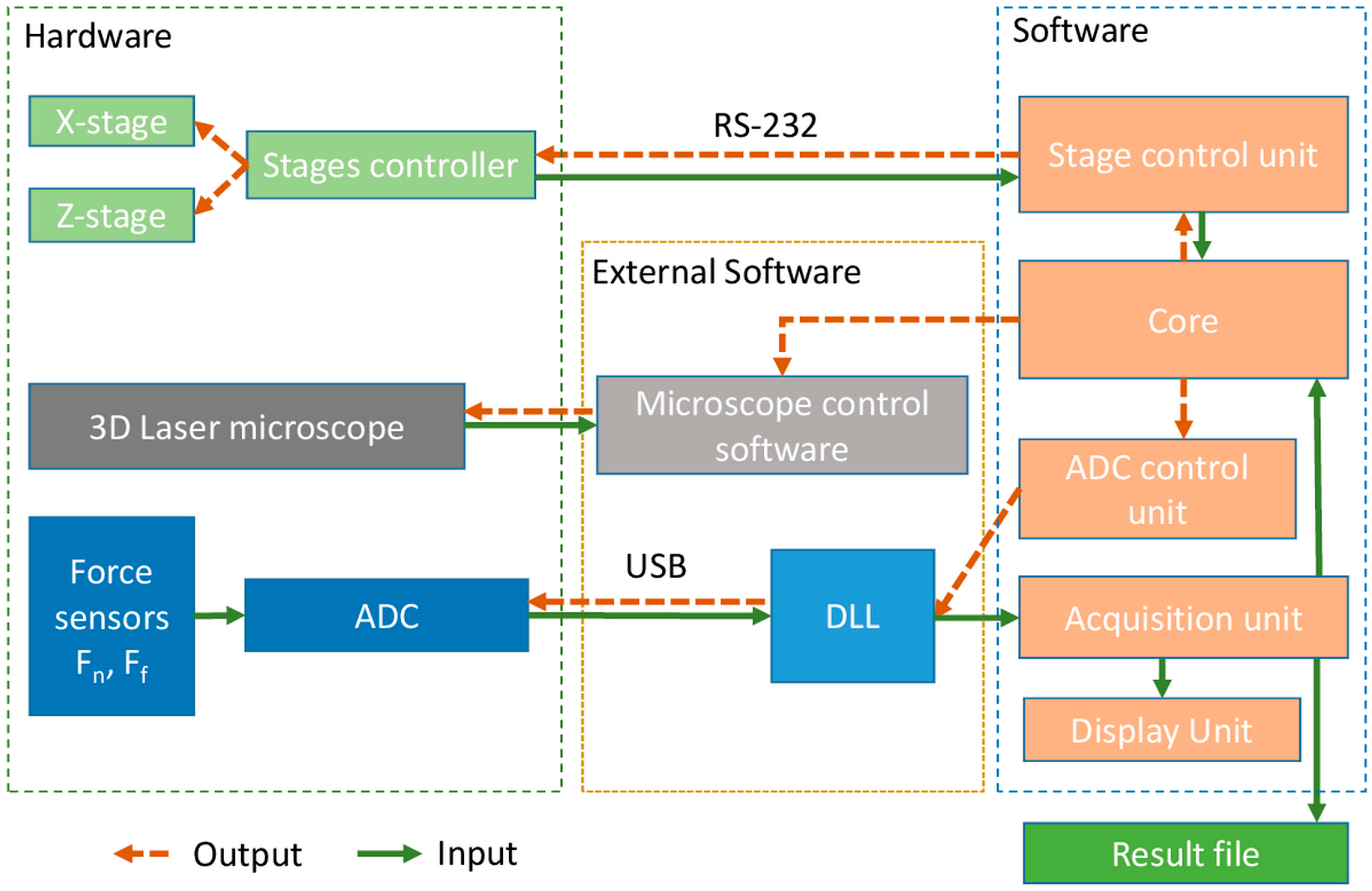

A single workstation controlled the operation of the tribotester. The microscope was controlled by the software supplied by the manufacturer. The friction testing module was controlled by customized software developed by the authors. The control and software diagram for the tribotester is shown in

Figure 2. The core controlled the other components based on signals received from the other units and the operating system. The actuator control unit received commands from the core and transmitted them to the programmable actuator controller. The function of the actuator controller was to send responses containing the information about its status and the positions of the actuators.

The acquisition unit read the buffer and wrote the raw data to the resulting output file. Also, data was processed and sent to the display unit. The display unit roughly calculated the coefficient of friction values based on the measured values of the normal and frictional forces and displayed them on a graph in real time. The communication with the microscope software could be performed in automatic or manual mode. Automatic mode was based on the messages sent to the main window of the microscope control application. This mode enabled the measurement of the wear track topography in a fixed position and saved the results into a file. In the manual mode, the core paused the reciprocating motion and displayed a message for the operator to perform the measurement of the specimen wear track topography through manual operation. After performing the measurements, the operator may resume the reciprocating motion to continue the test.

2.3. Experiment Flowchart

The typical experimental flow chart is shown in

Figure 3. The preparation steps included attachment of the specimen to the substrate holder, mounting of the tip holder onto the frictional force sensor, and alignment of the tip position. The experimental conditions were fully adjustable and included stroke length, linear speed, the number of cycles, and wear track observation intervals. The experiment started by approaching the tip to the specimen. During this step, the

Z-actuator was moved downward, and the force indicated by the normal force sensor was monitored continuously during the movement. The movement was stopped when a contact force between the tip and the specimen was detected. After the tip approach, the loading step was performed. The

Z-actuator was moved downward until the target normal force was applied on the specimen surface by the tip.

The accuracy of the normal load applied to the specimen was dependent on parameters such as the approach speed and the sampling rate. To minimize the preparation time and to maintain high accuracy, the loading process was split into three steps. During the first step, the Z-actuator was moved with a relatively high speed of 1 mm/s until the normal force reached 75% of the target load. Then the speed was reduced to 0.1 mm/s until the load reached 95% of the target load. In the last step, the speed was reduced to 0.02 mm/s until the target load was reached. This three-step procedure enabled the precision of the normal force applied to the specimen to be below 0.5%.

After applying the normal force, the X-axis actuator was triggered to produce the reciprocating motion. After a specified number of reciprocating cycles, the reciprocating motion was paused to allow the investigation of the wear track surface topography. During the examination of the wear track by the microscope, it was important to assure that the tip or the counter surface maintained contact with the specimen. This allowed for the continuation of the test from the same position after the measurement of the wear track surface topography. These steps are repeated until the target total number of cycles would be reached.

2.4. Signal Processing

After the experiment, the raw data was post-processed by separate software to get the final values of the coefficient of friction.

Figure 4 provides an example of the post-processing sequence for the normal and frictional force raw data. The exact sequence of the data processing could be varied depending on the purpose of the experiment. In this case, the purpose was to assess the variation in the coefficient of friction as a function of the sliding distance. Thus, the peak values of the coefficient of friction rather than its variation during a single sliding cycle were analyzed. Initially, the data for normal and frictional forces were processed separately. The normal force was processed by using the moving average (MA) function (

Figure 5a). Large-period oscillations on the graph could be caused by the uneven flatness of the specimen or by misalignment of the specimen attached to the holder.

Figure 6 presents a schematic of these phenomena when the specimen is not perfectly flat. Initially, after application of the normal force at the initial position I, the distance between the normal force sensor and the specimen is

Zl. The initial position of the sensor after the tip approach is

Z0, and hence the normal force in the position I can be expressed as

where

k is the spring constant of the cantilever suspension. When the tip slides to position II, the absolute

Z-position of the tip changes due to the inclination of the surface resulting in a vertical displacement of Δ

Z’. Finally, the normal force at position II can be calculated by the following equation:

Therefore, when the tip slides from the position I to the position II, the normal force would be linearly reduced by Δ

F which is expressed as:

As the pin returns from position II to position I, the force would be increased back to

Fn,I. Hence, oscillation of the normal force with the amplitude of Δ

F is expected to occur for every sliding cycle as can be observed in

Figure 5a. This effect could be minimized by the precise alignment of the specimen and the cantilever before the experiment.

The processing of the frictional force data required more steps than the normal force. Due to the nature of the reciprocating sliding, the frictional force changes its sign from positive to negative (

Figure 5b). Changing of sign occurred due to the change in the direction of motion during the forward and backward strokes in a single reciprocating sliding cycle. Also, as can be seen from

Figure 5b, the signal was not symmetrical on zero. Unsymmetric was attributed to the initial misalignment or bending of the tip holder. This non-symmetry could be easily compensated during the post-processing using the symmetry function (SYM). To compensate for the misalignment, the SYM function shifts the frictional force data by a certain offset value of Δ

F. To calculate Δ

F, the average value of all the data is calculated. The offset value is the deviation of the average value from zero which can be expressed as

where

N is the number of sampled data. After calculating the offset value, all the data was shifted by the adding the offset value to the initial values. The result of processing the original data by the SYM function and smoothing by MA (

Figure 5c). Finally, the data obtained in the previous step were converted to absolute values by using the absolute value function (ABS) (

Figure 5d).

After processing the normal and frictional force values, the coefficient of friction could be calculated. An example of the calculated values for the coefficient of friction is shown in

Figure 5e (gray line). The oscillations on the coefficient of friction were attributed to the transient process caused by the reversal of the sliding direction at two ends of the reciprocating stroke. Thus, the maximum values of the coefficients of friction for every sliding cycle were considered as significant, and the crevasses in the data were ignored. The data was treated using the envelope function (EN) to exclude the effect of the crevasses [

22]. However, another function such as the average function could be employed instead of the envelope function at this step depending on the experiment conditions and goal. The red line shows the resulting coefficient of friction in

Figure 5e. To convert from the number of data points to the number of sliding cycles, the

X-axis of this graph should be normalized based on the number of data points per cycle. The example given in

Figure 5 corresponds to 50 data points/cycle.

2.5. Experiment Reliability and Limitations

Reliability of the experimental results was assured by using high-resolution components as well as statistical analysis of friction and wear data. Precision mechanical and electrical components with high resolution and repeatability were used to build the system. Furthermore, the uncertainty in the tribological data was minimized by statistically processing the data obtained from repeated experiments. For this purpose, the sliding tests were repeated at least three times using a new pin for each test on the fresh surface. The wear area was measured in at least three different locations along the wear track, and at least 100 line scans were averaged during each measurement to quantify the wear amount [

23].

The lower working range of the instrument was limited not only by the resolution of the sensors, stages, and the microscope, but also by the degree of total wear. In other words, the wear track had to be deep enough to obtain a reliable data regarding the wear rate of the test specimens. This test condition was achieved by selecting the proper load range and number of cycles through preliminary tests.

Another important point to consider was the wear of the specimen or the counter surface during the sliding test which led to increase in the distance between the base of the cantilever and the contact point. This may cause a variation in the applied load according to Equation (3). The degree of load variation was estimated by considering the stiffness and deflection of the cantilever. For the given suspension and the normal load of 20 mN, the typical deflection was 2 mm. Thus, based on the acceptable error of 10%, the variation of the depth due to wear of the specimen or the counter surface should not exceed 200 µm. This value was relatively large compared with the typical depth of wear encountered in the wear experiments.