Large-Area Piezoelectric PVDF Fibers Fabricated by Near-Field Electrospinning with Multi-Spinneret Structures †

Abstract

:1. Introduction

2. Materials and Methods

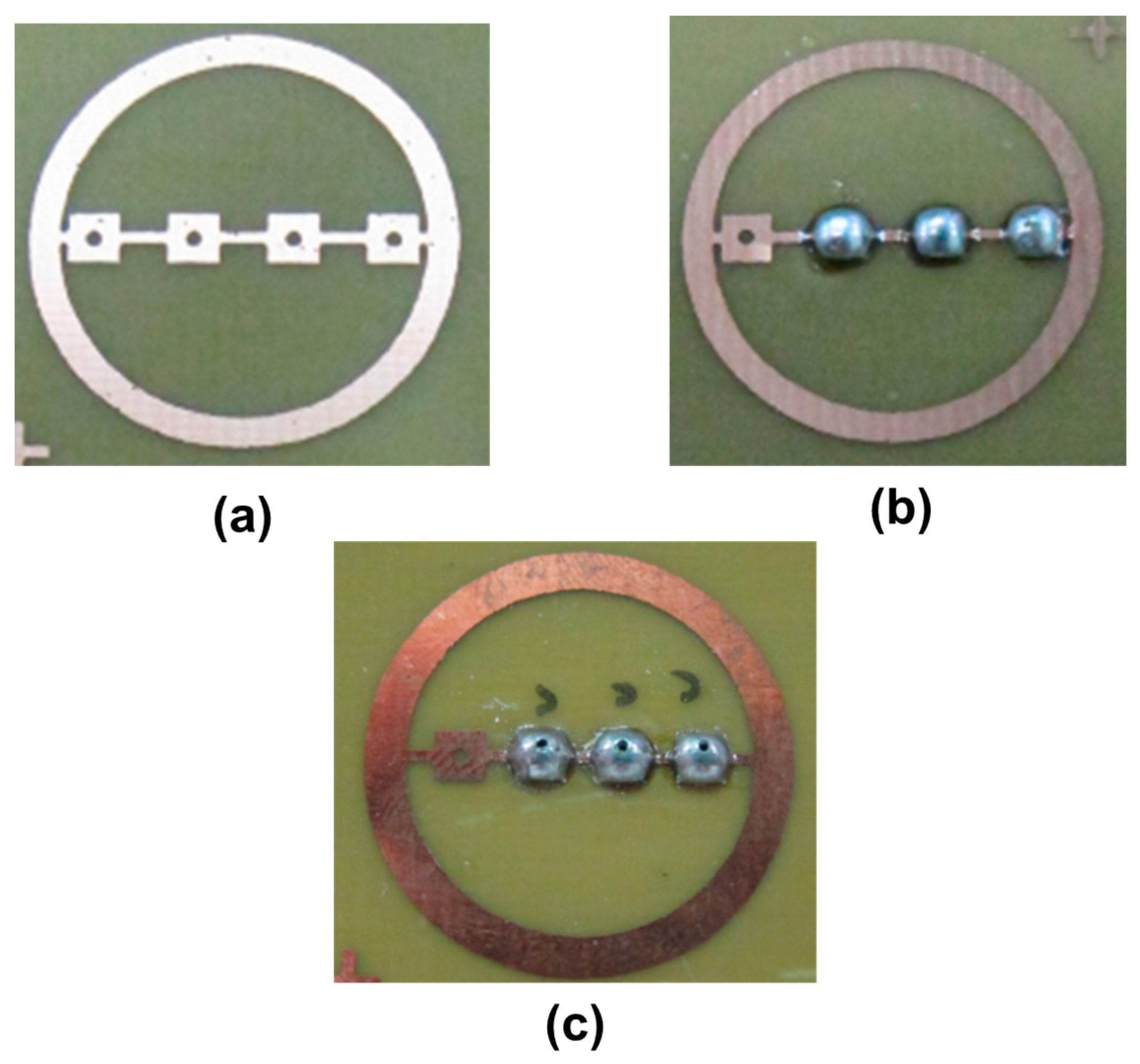

2.1. Multi-Spinneret Structure

2.2. Manufacturing Process of Multi-Spinneret Structure

3. Results and Discussion

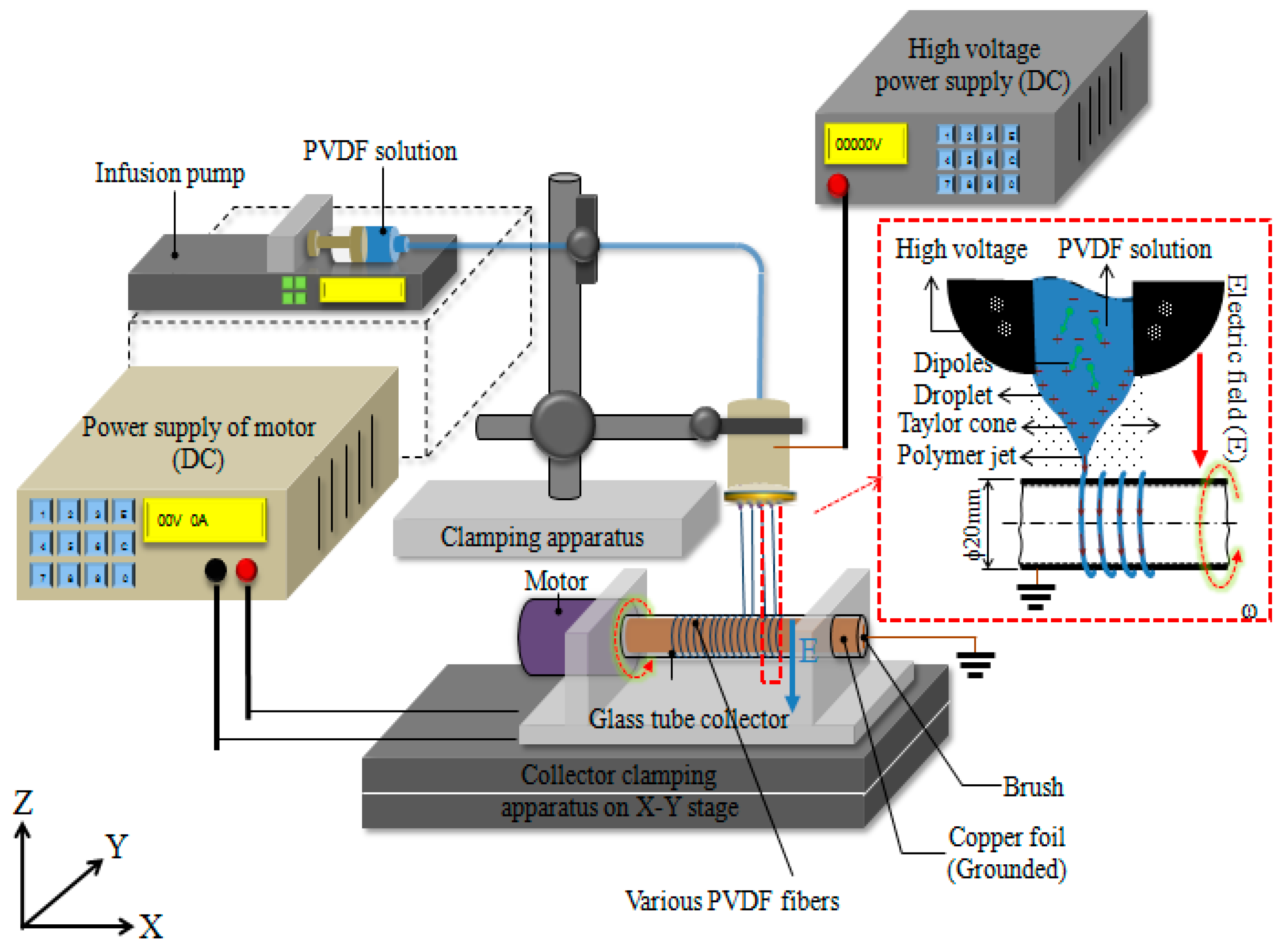

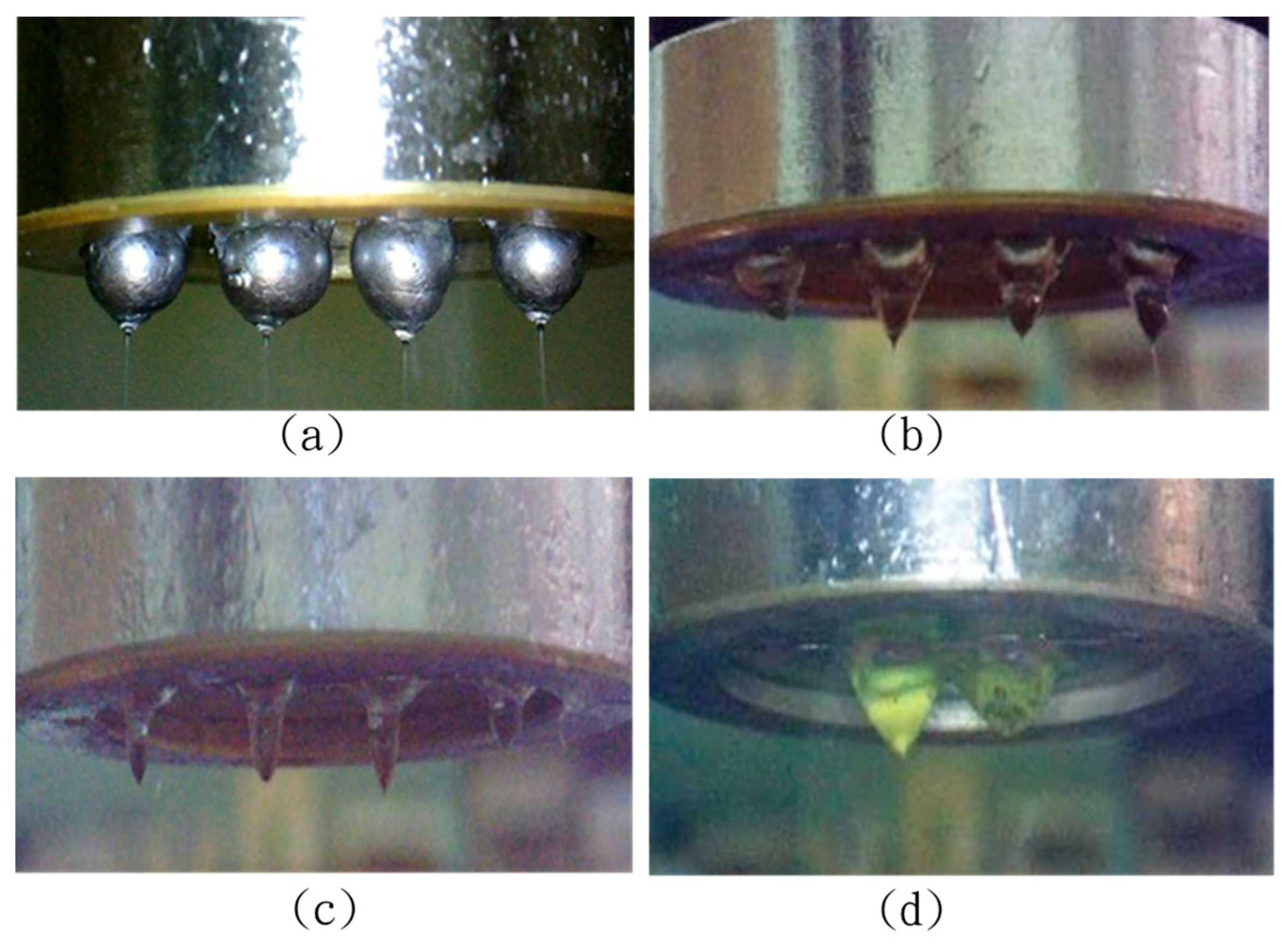

3.1. Near-Field Electrospinning (NFES) Polyvinylidene Fluoride (PVDF) Fiber with a Hollow Cylindrical Collector Process by Multi-Spinneret Structure

3.2. Measurement of PVDF Solution Concentration and Conductivity

3.3. Influence of Solder Balls Size in NFES with Multi-Spinneret Structure

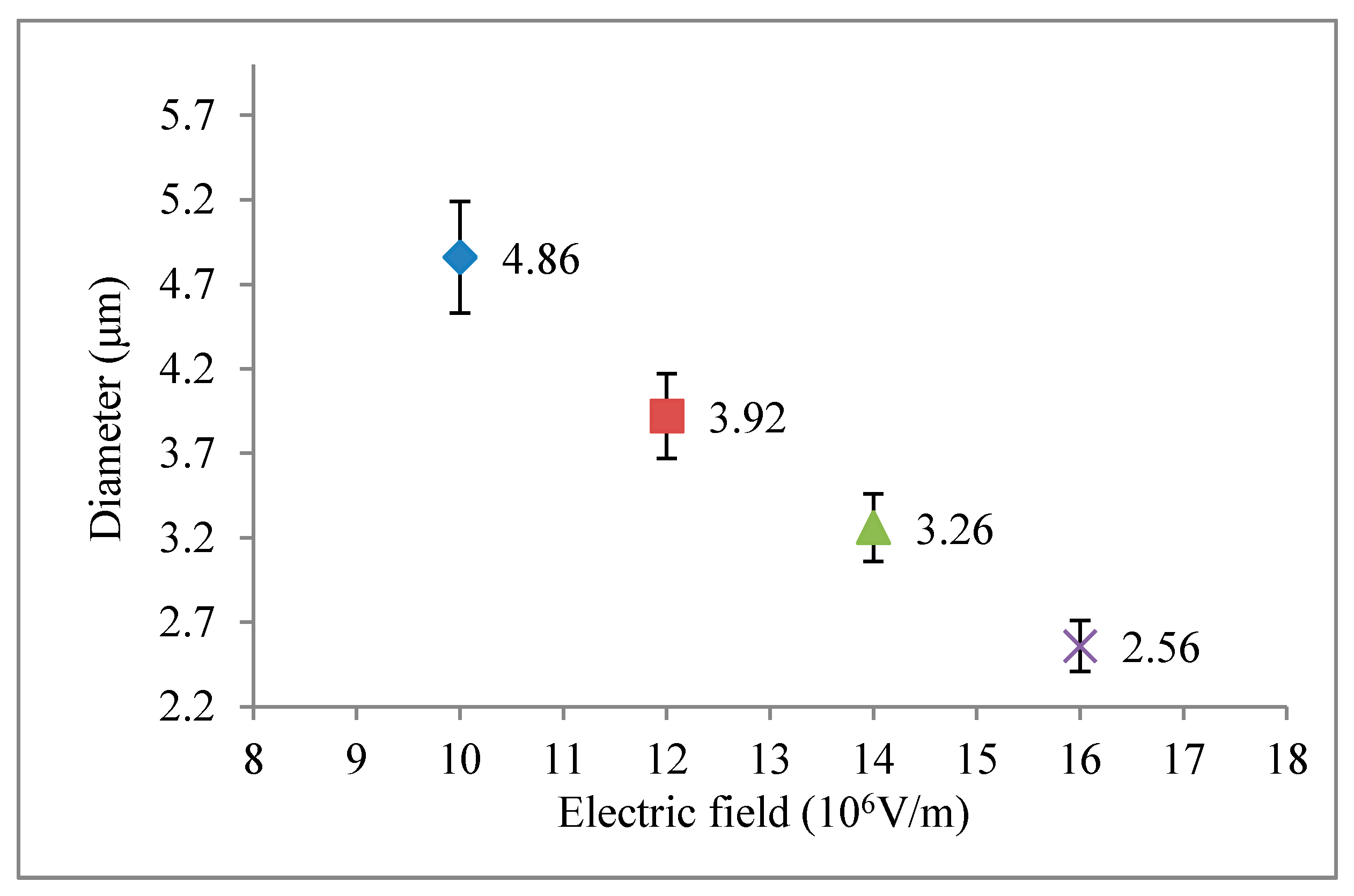

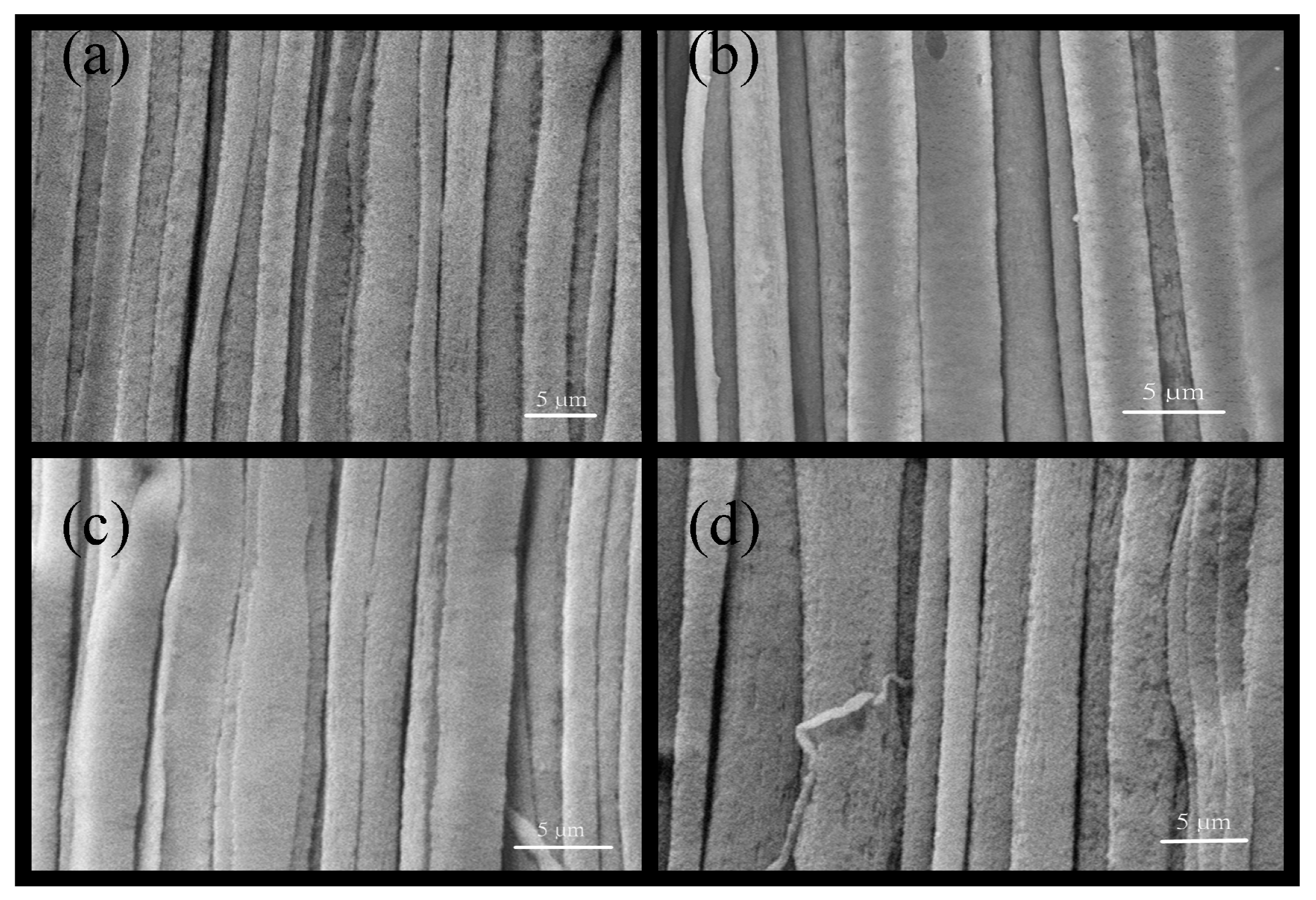

3.4. Influence on the Fibers Diameter from Electrical Field

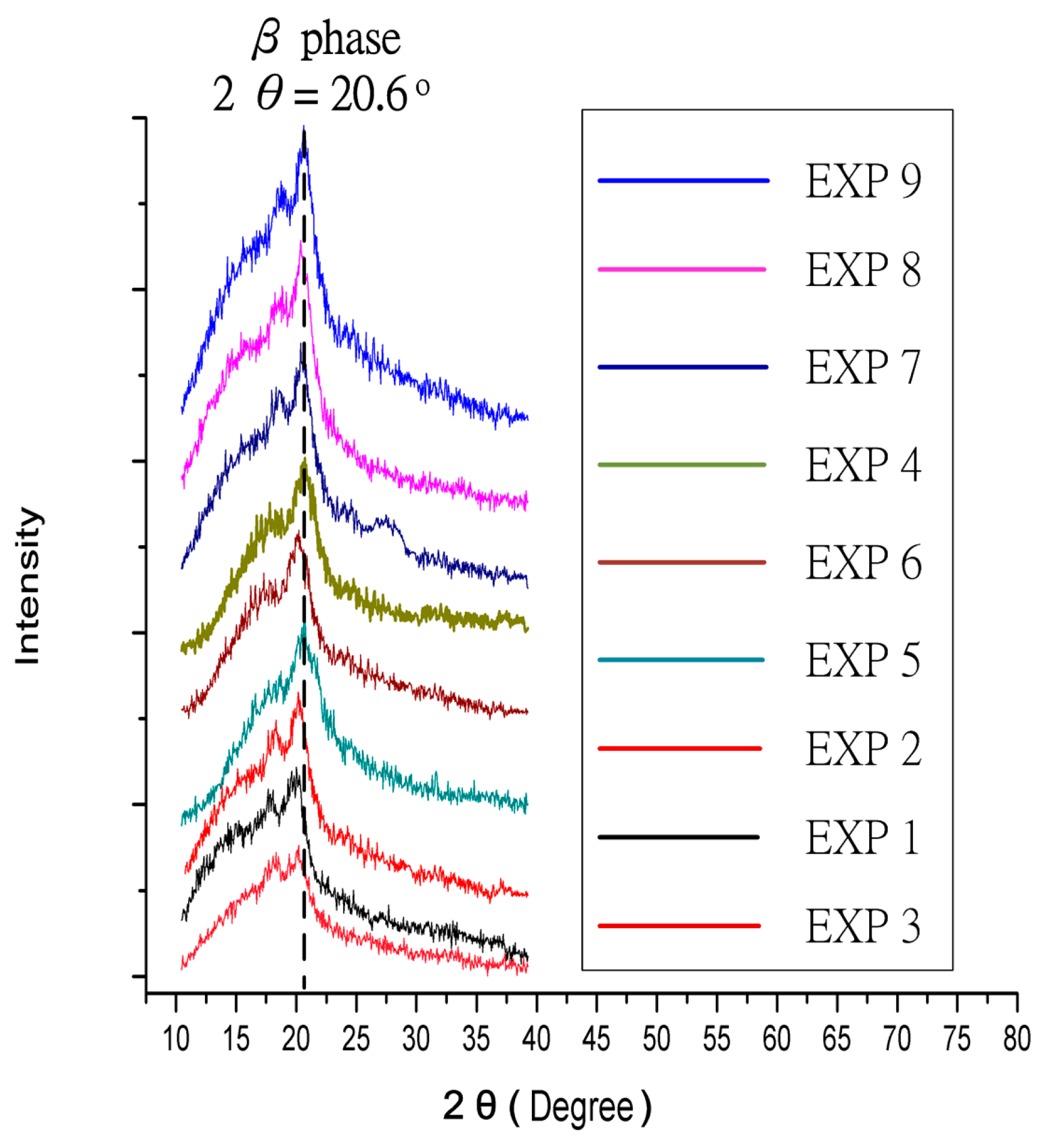

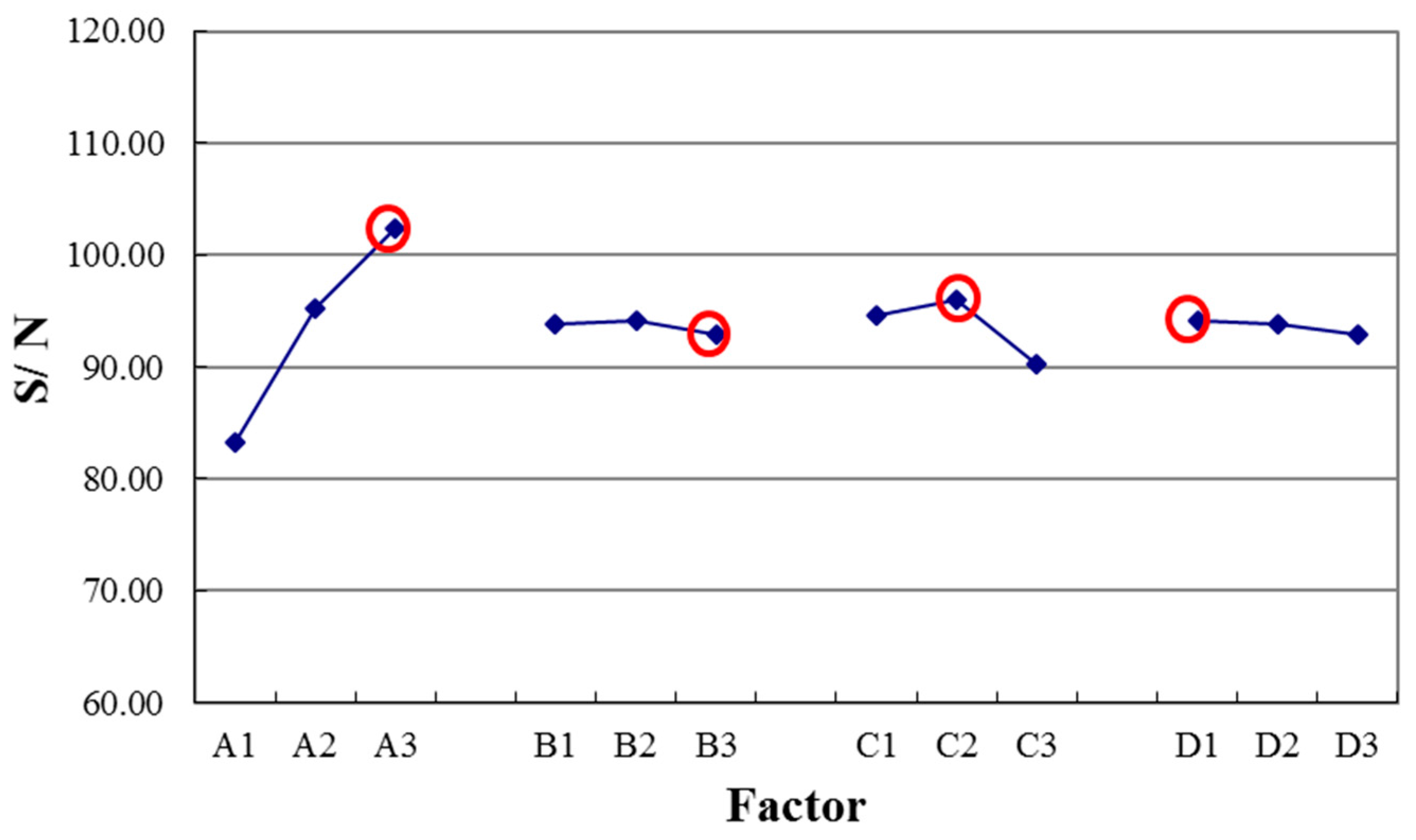

3.5. Analysis of NFES with Multi-Spinneret Structure by Taguchi Method

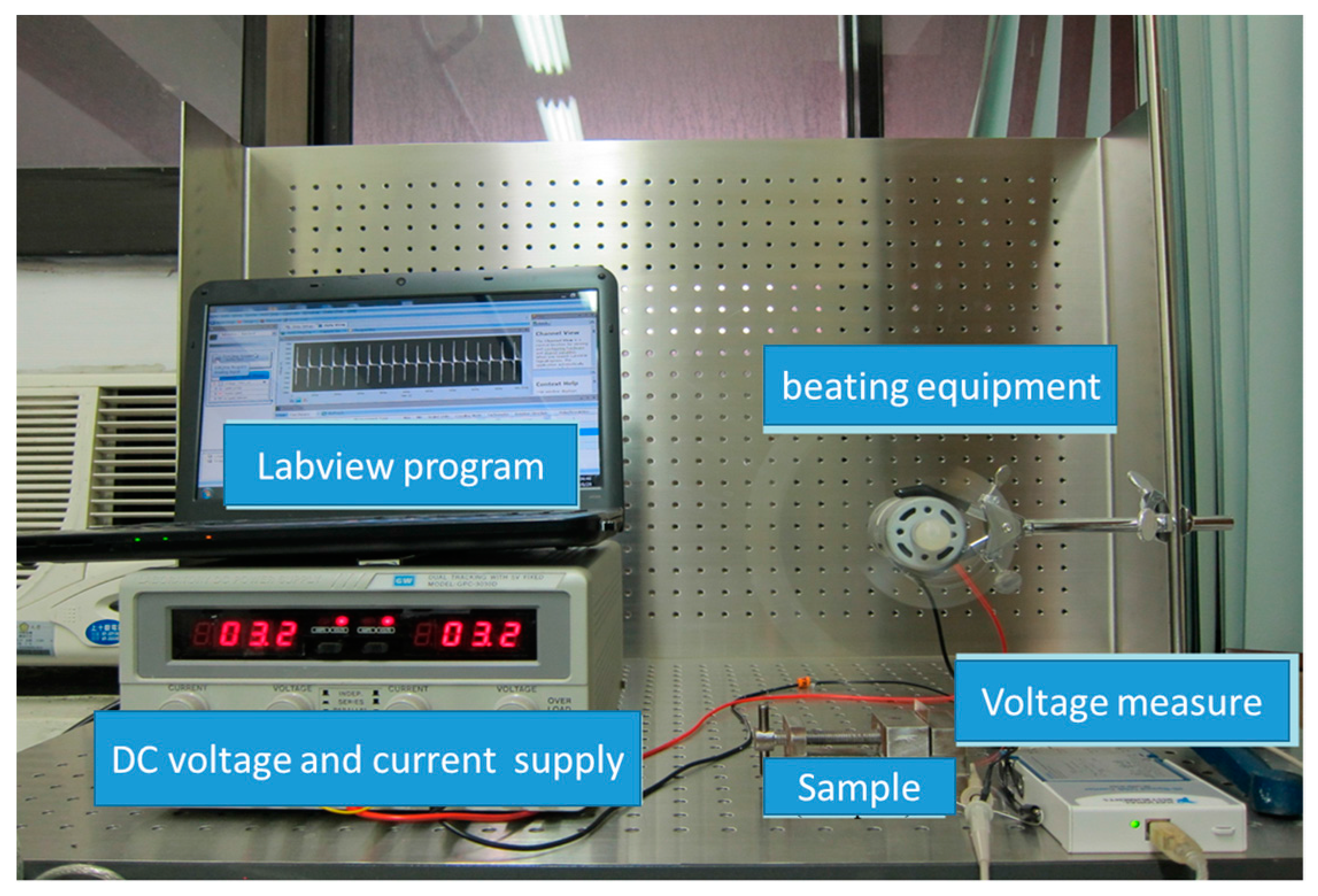

3.6. Voltage Analysis of Nine Groups of PVDF Piezoelectric Fibers by the Taguchi Method

3.7. Parameter Contribution Degree

3.8. Voltage Test of PVDF Fibers at Different Slap Frequencies

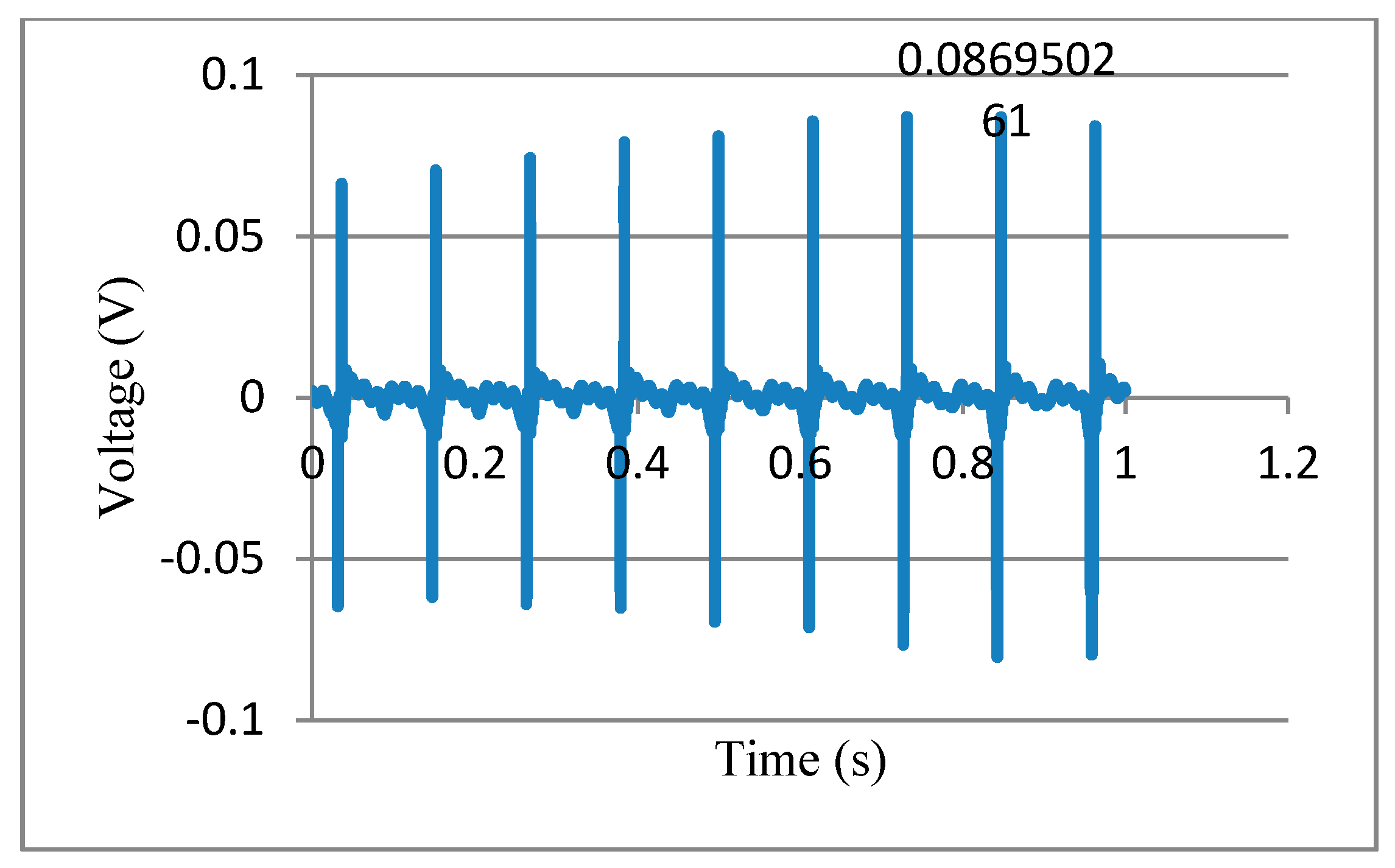

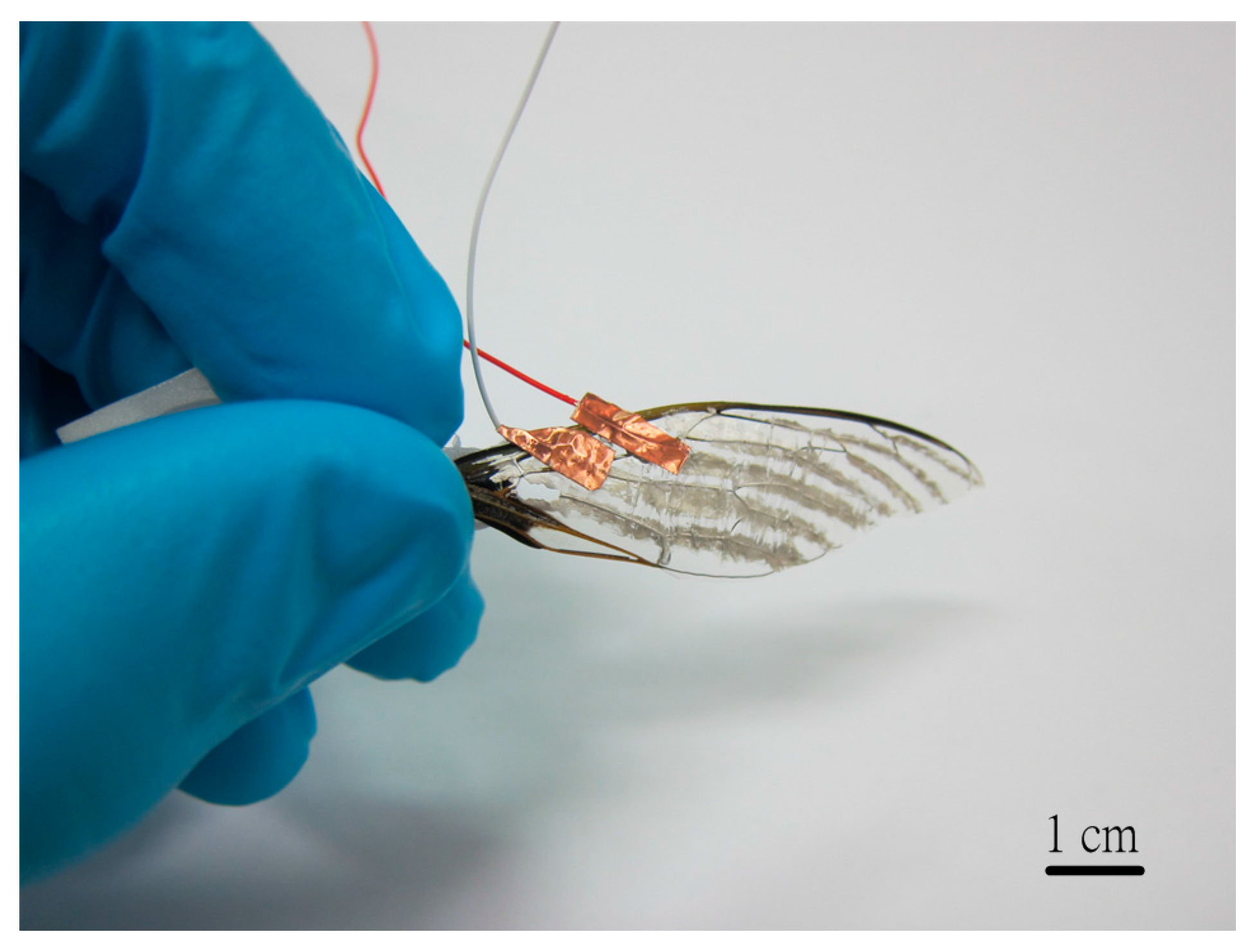

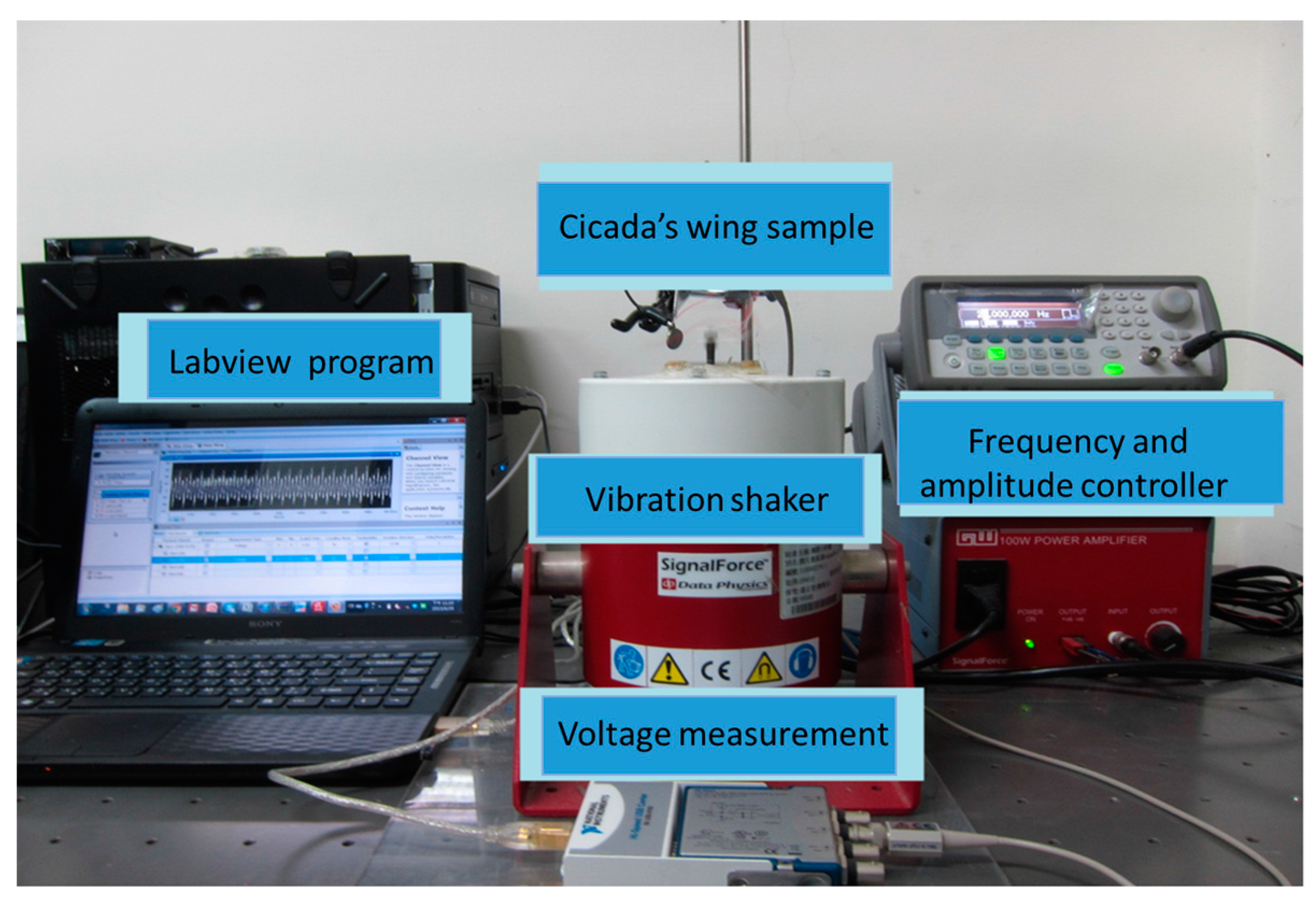

3.9. Cicada’s Wing of Experimental Bionic Voltage Signal Measurements

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. 1.6 V nanogenerator for mechanical energy harvesting using PZT nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef] [PubMed]

- Pu, J.; Yan, X.; Jiang, Y.; Chang, C.; Lin, L. Piezoelectric actuation of direct-write electrospun fibers. Sens. Actuators A Phys. 2010, 164, 131–136. [Google Scholar] [CrossRef]

- Li, F.; Liu, W.; Stefanini, C.; Fu, X.; Dario, P. A novel bioinspired PVDF micro/nano hair receptor for a robot sensing system. Sensors 2010, 10, 994–1011. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.M.; Lim, H.O.; Jo, N.J. Actuation behavior of CP actuator based on polypyrrole and PVDF. Adv. Mater. Res. 2007, 29–30, 363–366. [Google Scholar] [CrossRef]

- Elashmawi, I.S.; Abdelrazek, E.M.; Ragab, H.M.; Hakeem, N.A. Structural, optical and dielectric behavior of PVDF films filled with different concentrations of iodine. Physica B 2010, 405, 94–98. [Google Scholar] [CrossRef]

- Neidhofer, M.; Beaume, F.; Ibos, L.; Bernes, A.; Lacabanne, C. Structural evolution of PVDF during storage or annealing. Polymer 2004, 45, 1679–1688. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, P.Y. A two dimensional infrared correlation spectroscopic study on the structure changes of PVDF during the melting process. Polymer 2004, 45, 5295–5299. [Google Scholar] [CrossRef]

- Sajkiewicz, P.; Wasiak, A.; Goclowski, Z. Phase transitions during stretching of poly(vinylidene fluoride). Eur. Polym. J. 1999, 35, 423–429. [Google Scholar] [CrossRef]

- Chen, Y.; Shew, C.Y. Conformational behavior of polar polymer models under electric fields. Chem. Phys. Lett. 2003, 378, 142–147. [Google Scholar] [CrossRef]

- Anton, F. Process and Apparatus for Preparing Artificial Threads. U.S. Patent 1,975,504, 2 October 1934. [Google Scholar]

- Taylor, G. Electrically driven jets. Proc. R. Soc. Lond. A 1969, 313, 453–475. [Google Scholar] [CrossRef]

- Chang, C.; Fuh, Y.-K.; Lin, L. A direct-write piezoelectric PVDF nanogenerator. Solid State Sens. Actuators Microsyst. 2009, 1485–1488. [Google Scholar]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.K.; Lin, L. Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Chang, C.; Li, S.; Lin, L. Near-field electrospinning. Nano Lett. 2006, 6, 839–842. [Google Scholar] [CrossRef] [PubMed]

- Ding, B.; Kimura, E.; Sato, T.; Fujita, S.; Shiratori, S. Fabrication of blend biodegradable nanofibrous nonwoven mats via multi-jet electrospinning. Polymer 2004, 45, 1895–1902. [Google Scholar] [CrossRef]

- Theron, S.A.; Yarin, A.L.; Zussman, E.; Kroll, E. Multiple jets in electrospinning: Experiment and modeling. Polymer 2005, 46, 2889–2899. [Google Scholar] [CrossRef]

- Liu, Y.; He, J.-H. Bubble electrospinning for mass production of nanofibers. Int. J. Nonlinear Sci. Numer. Simul. 2007, 8, 393–396. [Google Scholar] [CrossRef]

- Wang, X.; Niu, H.; Lin, T.; Wang, X. Needleless electrospinning of nanofibers with a conical wire coil. Polym. Eng. Sci. 2009, 49, 1582–1586. [Google Scholar] [CrossRef]

- Theron, S.A.; Zussman, E.; Yarin, A.L. Experimental investigation of the governing parameters in the electrospinning of polymer solutions. Polymer 2004, 45, 2017–2030. [Google Scholar] [CrossRef]

- Dosunmu, O.O.; Chase, G.G.; Kataphinan, W.; Reneker, D.H. Electrospinning of polymer nanofibres from multiple jets on a porous tubular surface. Nanotechnology 2006, 17, 1123–1127. [Google Scholar] [CrossRef] [PubMed]

- Fuh, Y.-K.; Lien, L.-C.; Chen, S.-Y. High-throughput production of nanofibrous mats via a porous materials electrospinning process. J. Macromol. Sci. Part B 2012, 51, 1742–1749. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Sun, X.-F.; Liu, J.; Fan, J.; Huang, D.-W. Multi-jet electrospinning via auxiliary electrode. Mater. Lett. 2015, 141, 153–156. [Google Scholar] [CrossRef]

- Fang, J.; Niu, H.; Wang, H.; Wang, X.; Lin, T. Enhanced mechanical energy harvesting using needleless electrospun poly(vinylidene fluoride) nanofibre webs. Energy Environ. Sci. 2013, 6, 2196–2202. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Chen, R.; He, J. Active generation of multiple jets for producing nanofibres with high quality and high throughput. Mater. Des. 2016, 94, 496–501. [Google Scholar] [CrossRef]

- Liu, Z.; Ang, K.K.J.; He, J. Needle-disk electrospinning inspired by natural point discharge. J. Mater. Sci. 2016, 52, 1823–1830. [Google Scholar] [CrossRef]

- Parks, P.; Cheng, B.; Hu, Z.; Deng, X. Translational damping on flapping cicada wings. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), San Francisco, CA, USA, 25–30 September 2011; pp. 574–579. [Google Scholar]

| PVDF | PVDF | Solvent (DMSO:Acetone) | Surfactant | |

|---|---|---|---|---|

| Weight Percent (PVDF/Solvent) | Weight (g) | DMSO (g) | Acetone (g) | Weight (g) |

| 16 wt % | 0.80 | 2.5 | 2.5 | 0.2 |

| 17 wt % | 0.85 | 2.5 | 2.5 | 0.2 |

| 18 wt % | 0.90 | 2.5 | 2.5 | 0.2 |

| 19 wt % | 0.95 | 2.5 | 2.5 | 0.2 |

| 20 wt % | 1.00 | 2.5 | 2.5 | 0.2 |

| EXP | Electrical Field (V/m) | Cylindrical Collector Speed (rpm) | Fiber Heat Treatment Temperature (°C) | Temperature Holding Time |

|---|---|---|---|---|

| 1 | 1.2 × 107 | 1300 | 50 | 1 h |

| 2 | 1.2 × 107 | 1500 | 65 | 2 h |

| 3 | 1.2 × 107 | 1700 | 80 | 3 h |

| 4 | 1.4 × 107 | 1300 | 65 | 3 h |

| 5 | 1.4 × 107 | 1500 | 80 | 1 h |

| 6 | 1.4 × 107 | 1700 | 50 | 2 h |

| 7 | 1.6 × 107 | 1300 | 80 | 2 h |

| 8 | 1.6 × 107 | 1500 | 50 | 3 h |

| 9 | 1.6 × 107 | 1700 | 65 | 1 h |

| The Contribution of all Parameters | ||||

|---|---|---|---|---|

| Factors | Degree of Freedom | Standard Deviation(S) | Variation (V) | Contribution (%) |

| Electric field | 2 | 62.95 | 31.48 | 90.23 |

| Rotating speed | 2 | 0.28 | 0.14 | 0.40 |

| Heating temperature | 2 | 6.28 | 3.14 | 9.00 |

| Heating time | 2 | 0.26 | 0.13 | 0.37 |

| Total | 8 | 69.77 | 34.89 | 100.00 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, C.-T.; Tsai, K.-C.; Wang, S.-Y.; Yen, C.-K.; Lin, Y.-L. Large-Area Piezoelectric PVDF Fibers Fabricated by Near-Field Electrospinning with Multi-Spinneret Structures. Micromachines 2017, 8, 97. https://doi.org/10.3390/mi8040097

Pan C-T, Tsai K-C, Wang S-Y, Yen C-K, Lin Y-L. Large-Area Piezoelectric PVDF Fibers Fabricated by Near-Field Electrospinning with Multi-Spinneret Structures. Micromachines. 2017; 8(4):97. https://doi.org/10.3390/mi8040097

Chicago/Turabian StylePan, Cheng-Tang, Kuo-Chang Tsai, Shao-Yu Wang, Chung-Kun Yen, and Yan-Liang Lin. 2017. "Large-Area Piezoelectric PVDF Fibers Fabricated by Near-Field Electrospinning with Multi-Spinneret Structures" Micromachines 8, no. 4: 97. https://doi.org/10.3390/mi8040097