Fabrication of Dish-Shaped Micro Parts by Laser Indirect Shocking Compound Process

Abstract

:1. Introduction

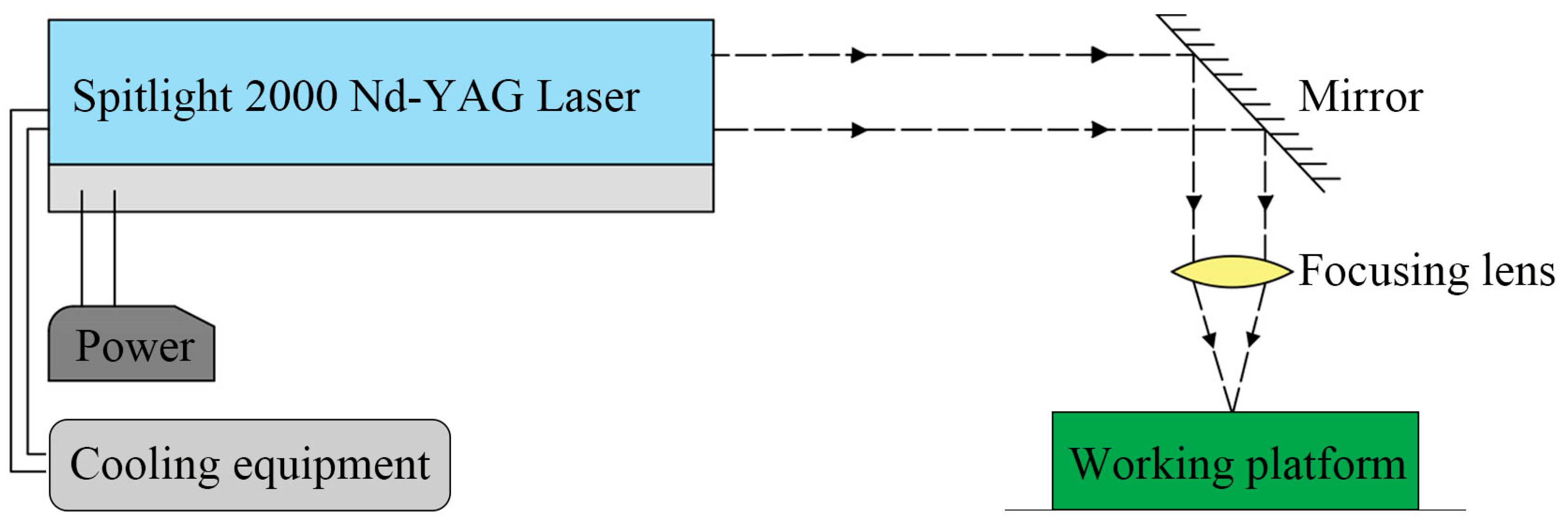

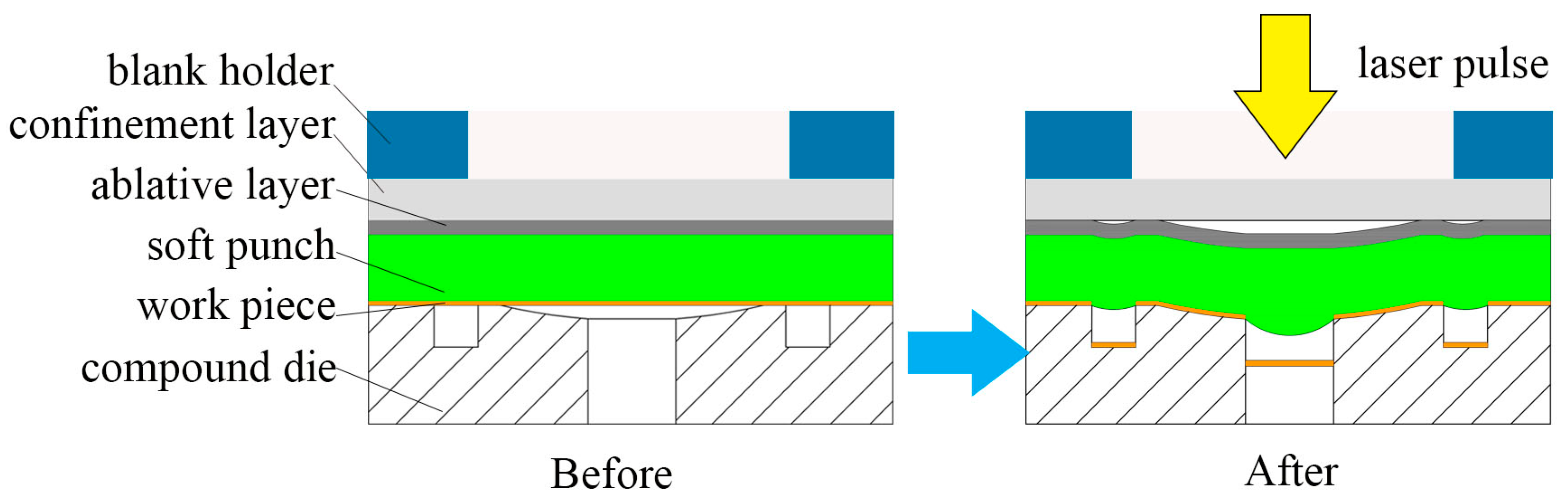

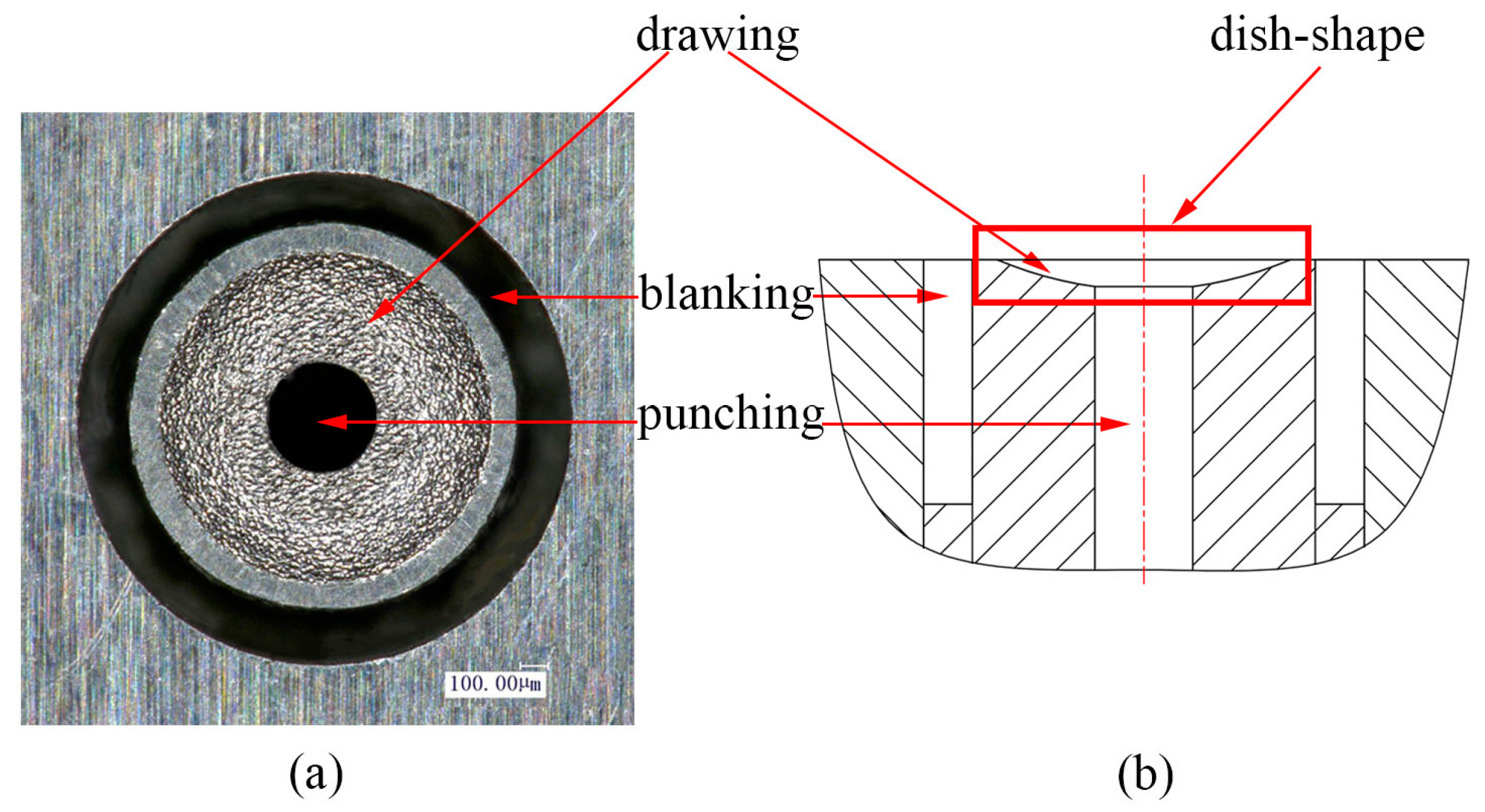

2. Experiment

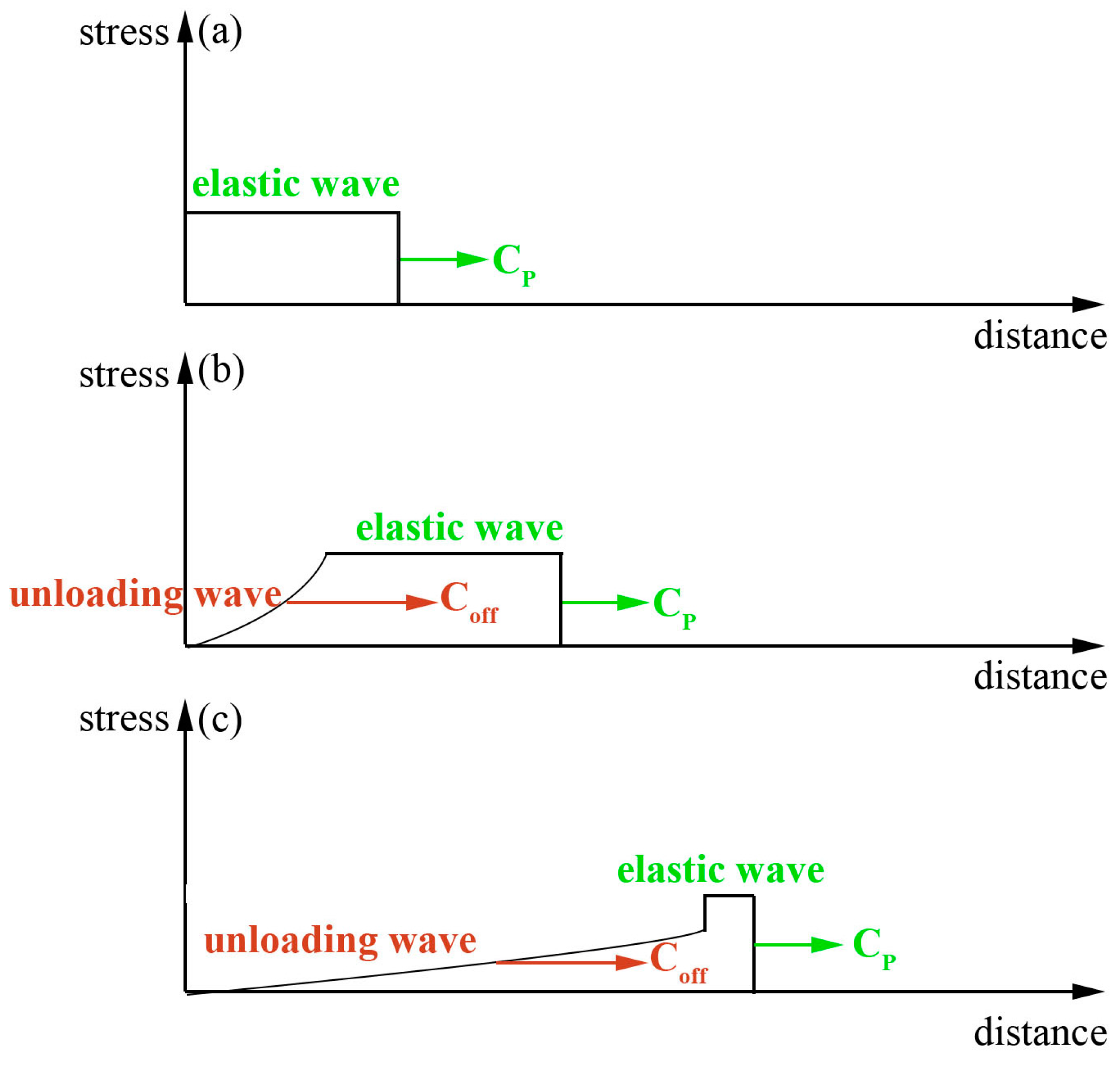

2.1. Principle of the Laser Indirect Shocking Compound Process

2.2. Experimental Preparation

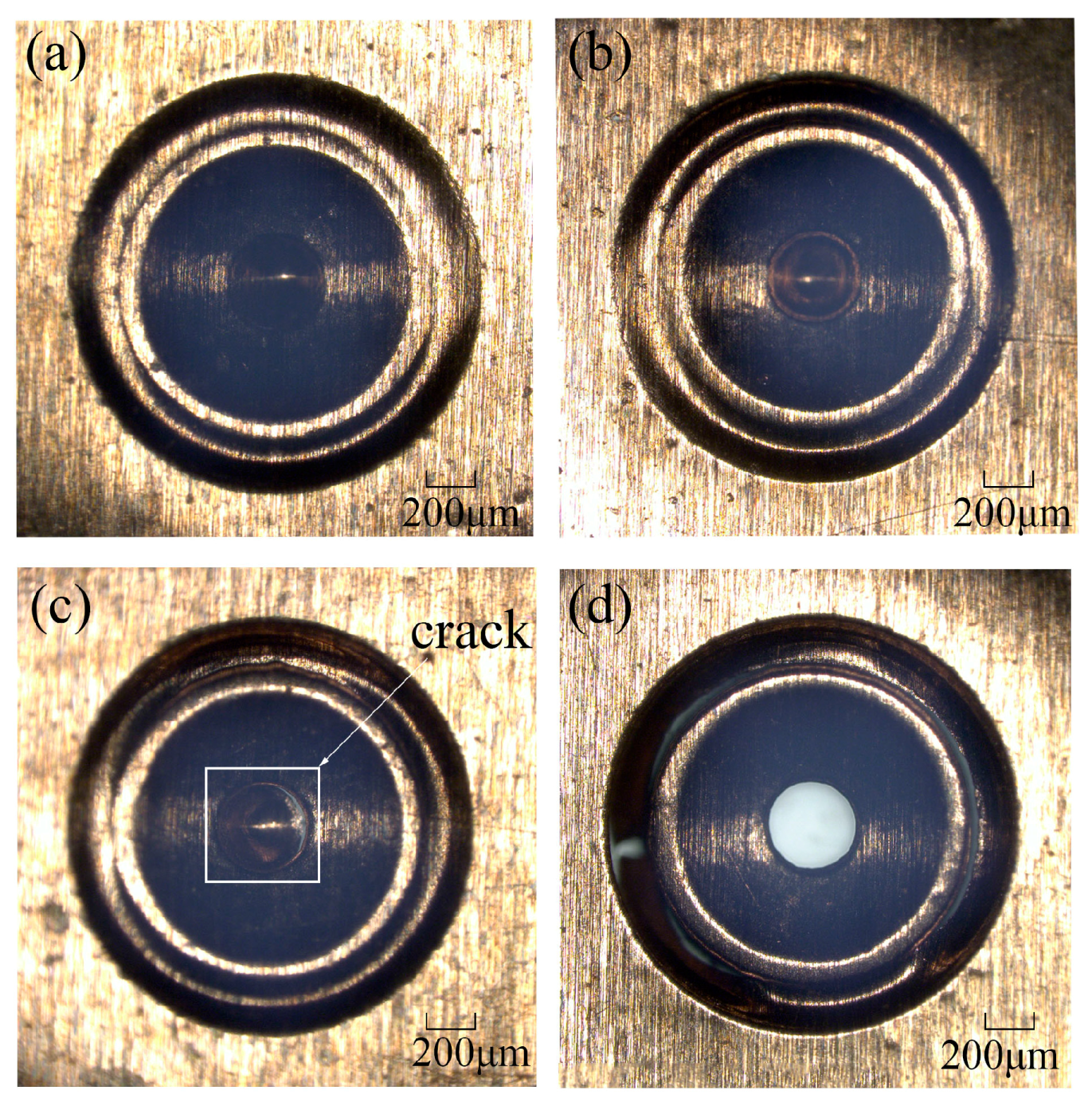

3. Experimental Results and Discussions

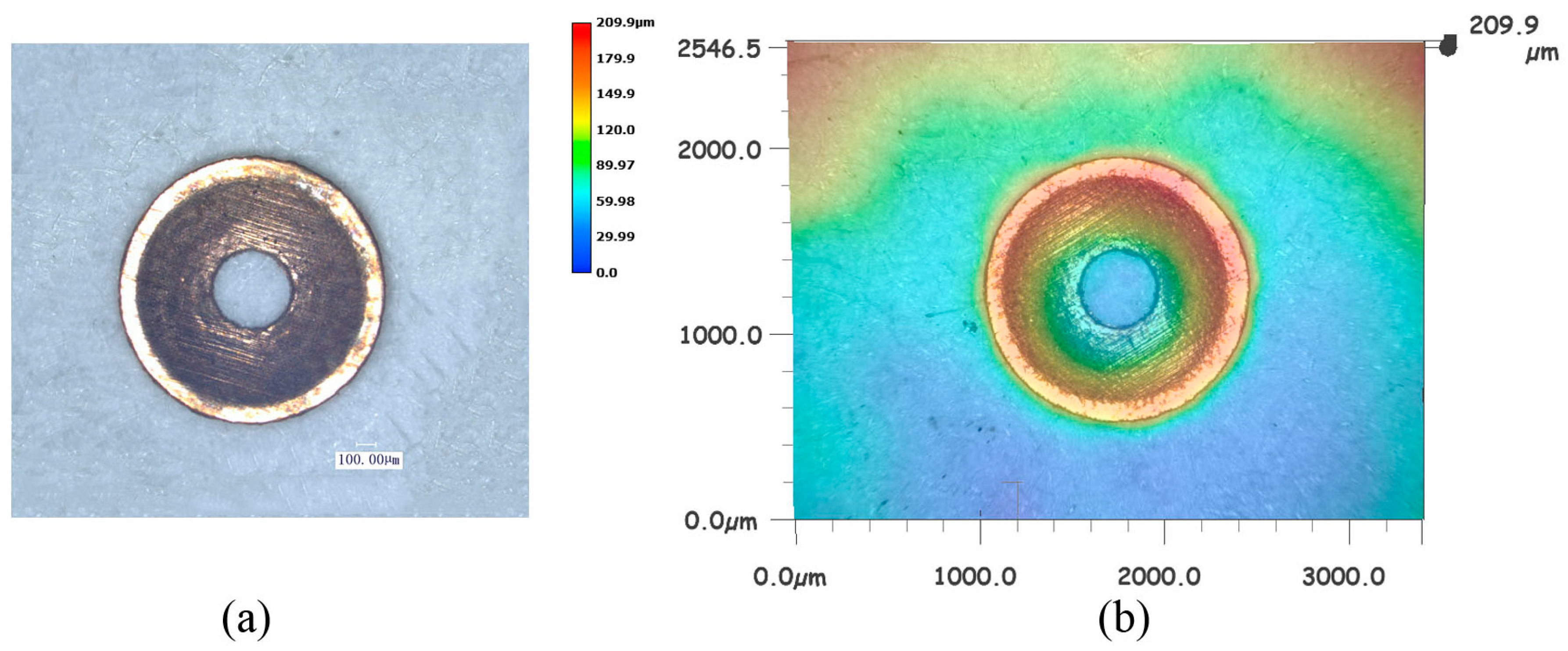

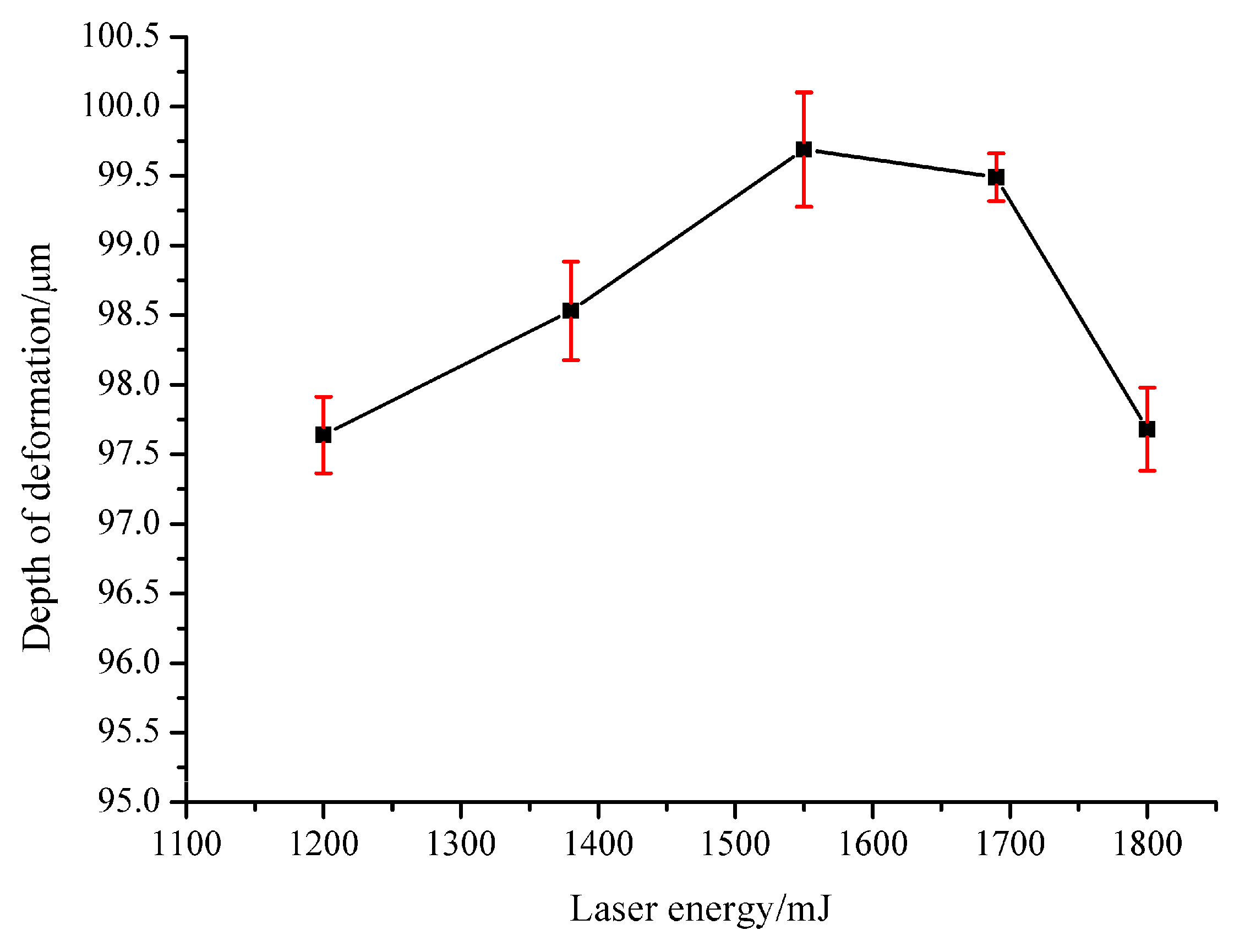

3.1. The Effect of Laser Energy

3.2. The Dimensional Accuracy of the Punched Holes

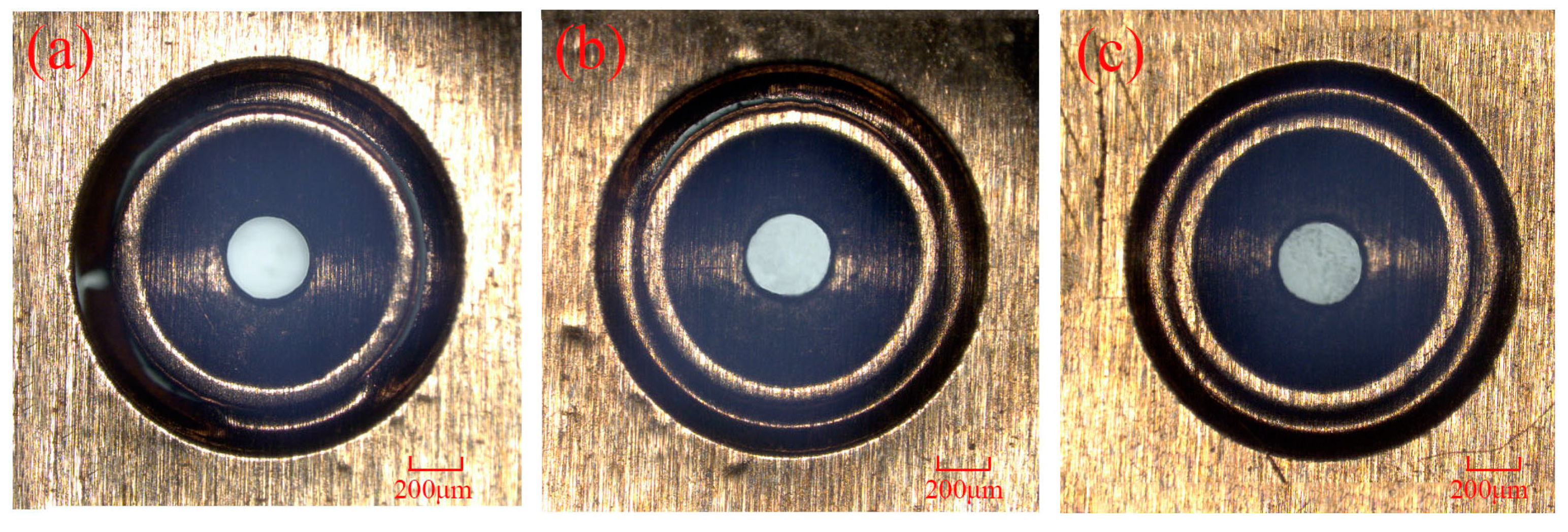

3.3. The Effect of the Soft Punch

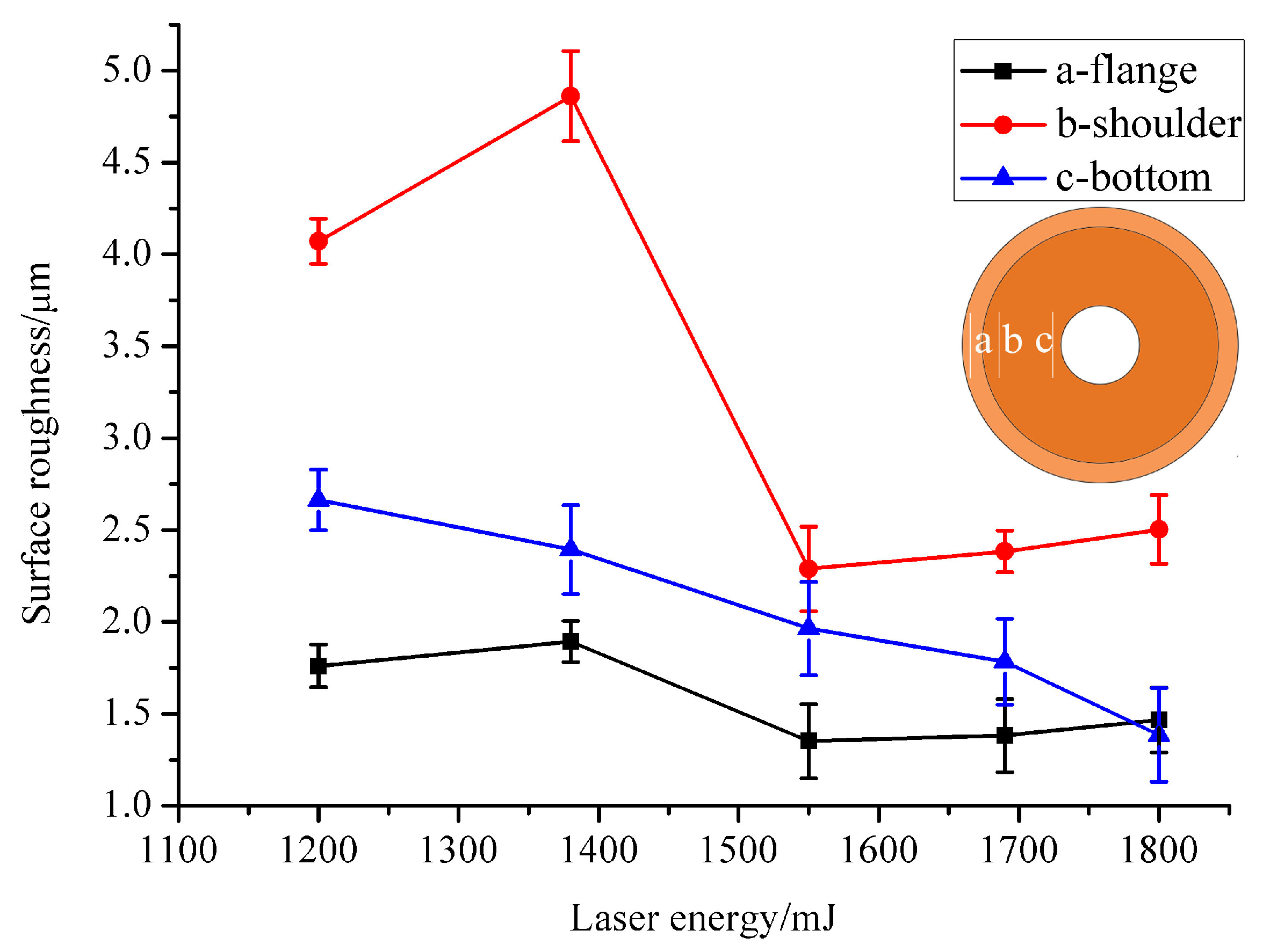

3.4. Surface Roughness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Engel, U.; Eckstein, R. Microforming—From basic research to its realization. J. Mater. Process. Technol. 2002, 125–126, 35–44. [Google Scholar] [CrossRef]

- Geiger, M.; Kleiner, M.; Eckstein, R.; Tiesler, N.; Engel, U. Microforming. CIRP Ann. Manuf. Technol. 2001, 50, 445–462. [Google Scholar] [CrossRef]

- Teyfouri, A.; Ahmadi, M. A Review on micro formings. Mod. Appl. Sci. 2015, 9, 230–239. [Google Scholar] [CrossRef]

- Kolleck, R.; Vollmer, R. Investigation of a combined micro-forming and punching process for the realization of tight geometrical tolerances of conically formed hole patterns. CIRP Ann. Manuf. Technol. 2011, 60, 331–334. [Google Scholar] [CrossRef]

- Fu, M.W.; Yang, B. Experimental and simulation studies of micro blanking and deep drawing compound process using copper sheet. J. Mater. Process. Technol. 2013, 213, 101–110. [Google Scholar] [CrossRef]

- Flosky, H.; Vollertsen, F. Wear behaviour in a combined micro blanking and deep drawing process. CIRP Ann. Manuf. Technol. 2014, 63, 281–284. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, N.K. Research on the modulating of the desktop micro forming system to micro factory. In Proceedings of the International Conference on Smart Manufacturing Application, KINTEX, Gyeonggi-do, Korea, 9–11 April 2008.

- Fu, M.W.; Chan, W.L. A review on the state-of-the-art microforming technologies. Int. J. Adv. Manuf. Technol. 2012, 67, 2411–2437. [Google Scholar] [CrossRef]

- Joo, B.Y.; Oh, S.I. Development of micro punching system. CIRP Ann. Manuf. Technol. 2001, 50, 191–194. [Google Scholar] [CrossRef]

- Niehoff, H.S.; Hu, Z.Y. Mechanical and laser micro deep drawing. In Key Engineering Materials; Trans Tech Publications: Zurich, Switzerland, 2007. [Google Scholar]

- Liu, H.X.; Shen, Z.B. Numerical simulation and experimentation of a novel micro scale laser high speed punching. Int. J. Mach. Tools Manuf. 2010, 50, 491–494. [Google Scholar] [CrossRef]

- Rhim, S.H.; Son, Y.K. Punching of ultra small size hole array. CIRP Ann. Manuf. Technol. 2005, 54, 261–264. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M. Sheet metal forming with the aid of flexible punch, numerical approach and experimental validation. CIRP J. Manuf. Sci. Technol. 2010, 3, 196–203. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D. Research on the micro sheet stamping process using plasticine as soft punch. Materials 2014, 7, 4118–4131. [Google Scholar] [CrossRef]

- Liu, H.X.; Lu, M.M. Micro-punching of aluminum foil by laser dynamic flexible punching process. Int. J. Mater. Form. 2013, 8, 183–196. [Google Scholar] [CrossRef]

- Wang, X.; Du, D.Z. Investigation of microscale laser dynamic flexible forming process—Simulation and experiments. Int. J. Mach. Tools Manuf. 2013, 67, 8–17. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D. Micro scale laser shock forming of pure copper and titanium sheet with forming/blanking compound die. Opt. Lasers Eng. 2015, 67, 83–93. [Google Scholar] [CrossRef]

- Liu, H.X.; Li, J.W. Experimental and numerical simulation research on micro-gears fabrication by laser shock punching process. Micromachines 2015, 6, 969–983. [Google Scholar] [CrossRef]

- Zheng, C.; Sun, S. Effect of laser energy on the deformation behavior in microscale laser bulge forming. Appl. Surf. Sci. 2010, 257, 1589–1595. [Google Scholar] [CrossRef]

- Gao, H.; Ye, C. deformation behaviors and critical parameters in microscale laser dynamic forming. J. Manuf. Sci. Eng. 2009, 131, 051011. [Google Scholar] [CrossRef]

- Zheng, C.; Sun, S. Numerical simulation and experimentation of micro scale laser bulge forming. Int. J. Mach. Tools Manuf. 2010, 50, 1048–1056. [Google Scholar] [CrossRef]

- Zheng, C.; Ji, Z. Variation of fracture mode in micro-scale laser shock punching. Opt. Laser Technol. 2015, 72, 25–32. [Google Scholar] [CrossRef]

- Wang, X.; Shen, Z.B. Laser indirect shock micro-embossing of commercially pure copper and titanium sheet. Opt. Lasers Eng. 2014, 56, 74–82. [Google Scholar] [CrossRef]

- Batani, D.; Nazarov, W. Foam-induced smoothing studied through laser-driven shock waves. Phys. Rev. E 2000, 62, 8573. [Google Scholar] [CrossRef]

- Guo, W.G.; Li, Y.L. Basic Concise Course of Stress Wave; Northwestern Polytechnical University Press: Xi’an, China, 2007; pp. 35–42. [Google Scholar]

- Hu, Y.X.; Yao, Z.Q. Overlapping rate effect on laser shock processing of 1045 steel by small spots with Nd:YAG pulsed laser. Surf. Coat. Technol. 2008, 202, 1517–1525. [Google Scholar] [CrossRef]

- Shen, Z.B.; Gu, C.X. An experimental study of overlapping laser shock micro-adjustment using a pulsed Nd:YAG laser. Opt. Laser Technol. 2013, 54, 110–119. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Single pulse energy | 80–1800 mJ |

| Pulse width | 8 ns |

| Wave length | 1064 nm |

| Energy stability | <±1% |

| Spot diameter | 2–5 mm |

| Parameters | Values |

|---|---|

| PMMA | 3 mm |

| Ablative layer | 10 μm |

| Soft punch | 200, 300, 400 μm |

| Copper | 40 μm |

| Laser Energy/mJ | a-Flange(Ra/μm) | b-Shoulder(Ra/μm) | c-Bottom(Ra/μm) |

|---|---|---|---|

| 1200 | 1.761 | 4.071 | 2.664 |

| 1380 | 1.894 | 4.861 | 2.394 |

| 1550 | 1.351 | 2.289 | 1.965 |

| 1690 | 1.382 | 2.384 | 1.783 |

| 1800 | 1.467 | 2.503 | 1.385 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Sha, C.; Shen, Z.; Li, L.; Gao, S.; Li, C.; Sun, X.; Wang, X. Fabrication of Dish-Shaped Micro Parts by Laser Indirect Shocking Compound Process. Micromachines 2016, 7, 105. https://doi.org/10.3390/mi7060105

Liu H, Sha C, Shen Z, Li L, Gao S, Li C, Sun X, Wang X. Fabrication of Dish-Shaped Micro Parts by Laser Indirect Shocking Compound Process. Micromachines. 2016; 7(6):105. https://doi.org/10.3390/mi7060105

Chicago/Turabian StyleLiu, Huixia, Chaofei Sha, Zongbao Shen, Liyin Li, Shuai Gao, Cong Li, Xianqing Sun, and Xiao Wang. 2016. "Fabrication of Dish-Shaped Micro Parts by Laser Indirect Shocking Compound Process" Micromachines 7, no. 6: 105. https://doi.org/10.3390/mi7060105

APA StyleLiu, H., Sha, C., Shen, Z., Li, L., Gao, S., Li, C., Sun, X., & Wang, X. (2016). Fabrication of Dish-Shaped Micro Parts by Laser Indirect Shocking Compound Process. Micromachines, 7(6), 105. https://doi.org/10.3390/mi7060105