Characterizing the Deformation of the Polydimethylsiloxane (PDMS) Membrane for Microfluidic System through Image Processing †

Abstract

:1. Introduction

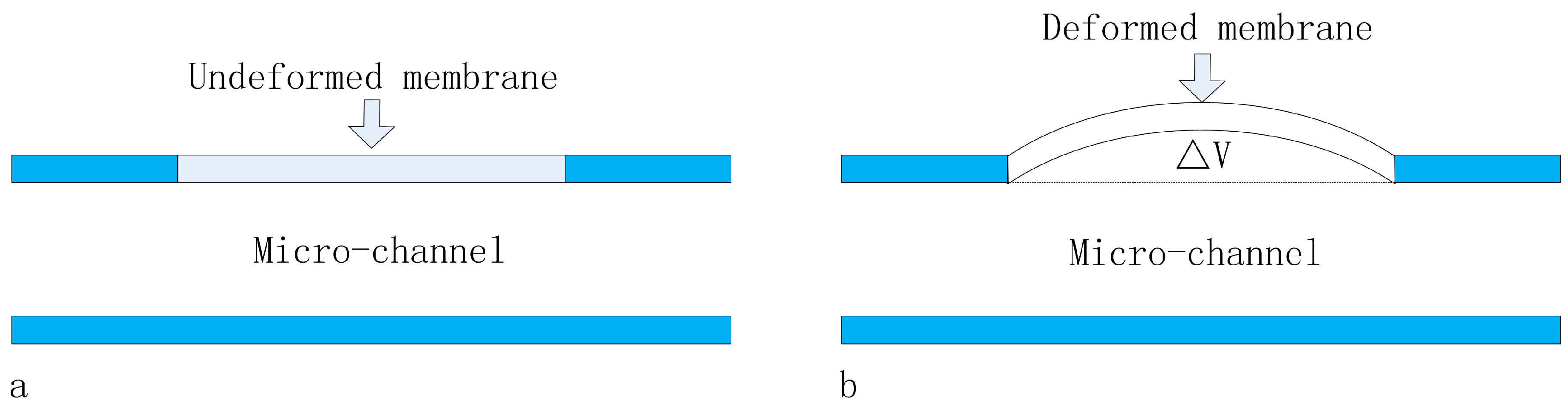

2. Theoretical Analysis

- Equilibrium equation

- Compatibility equation

3. Materials and Methods

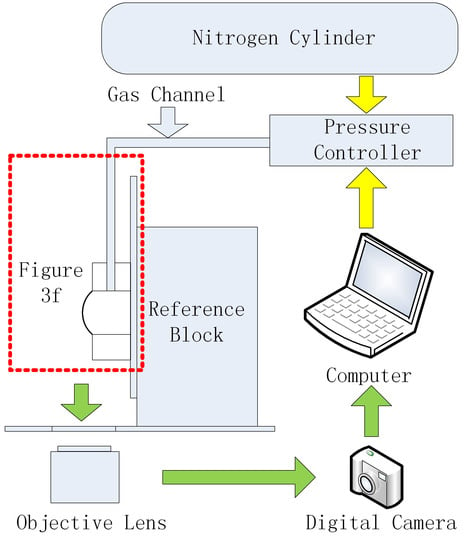

3.1. Experimental Setup

3.2. Image Processing

4. Result and Discussion

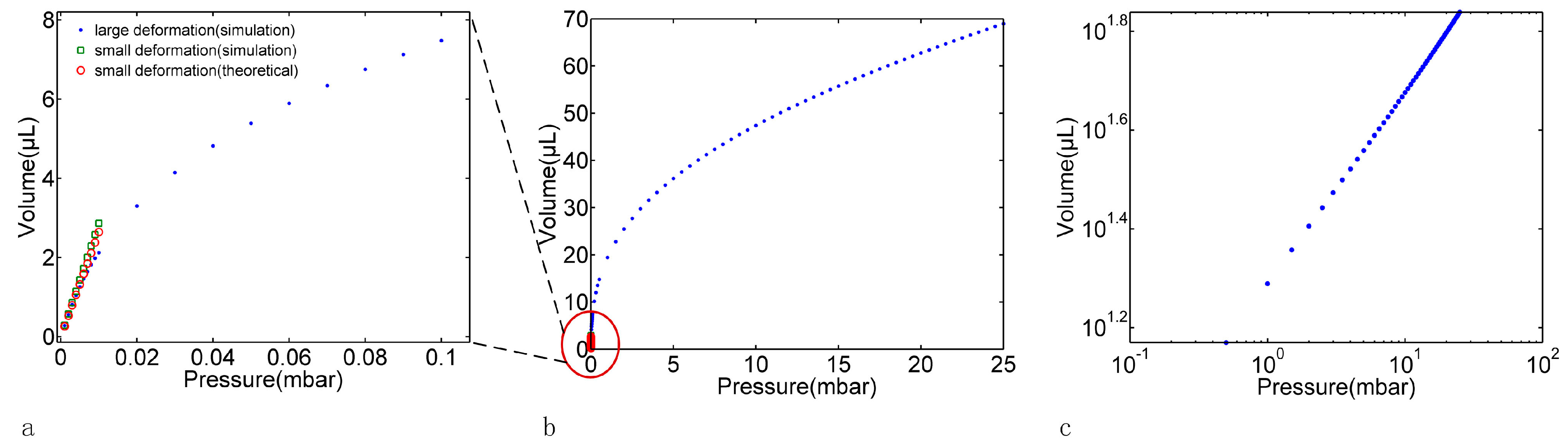

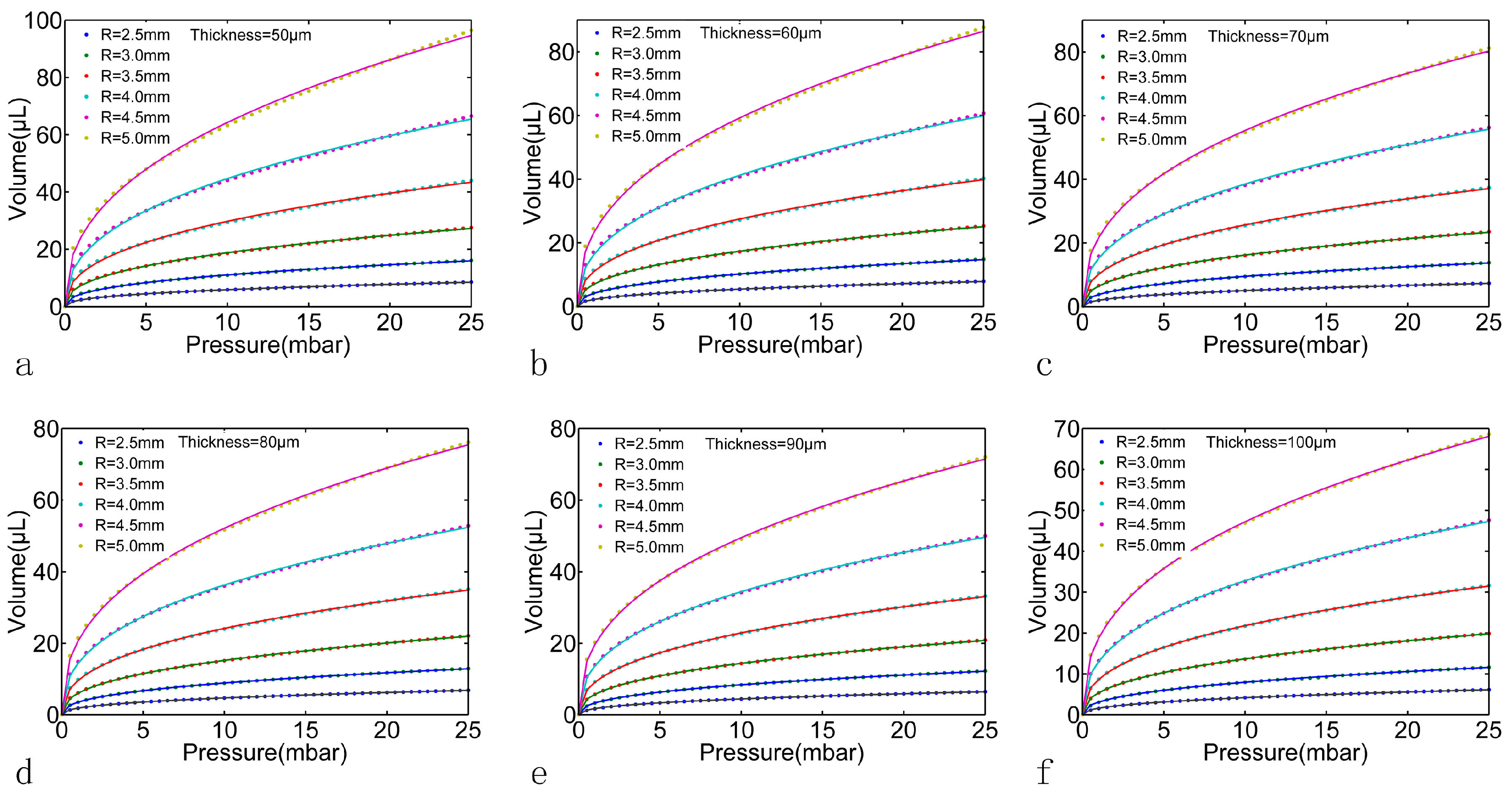

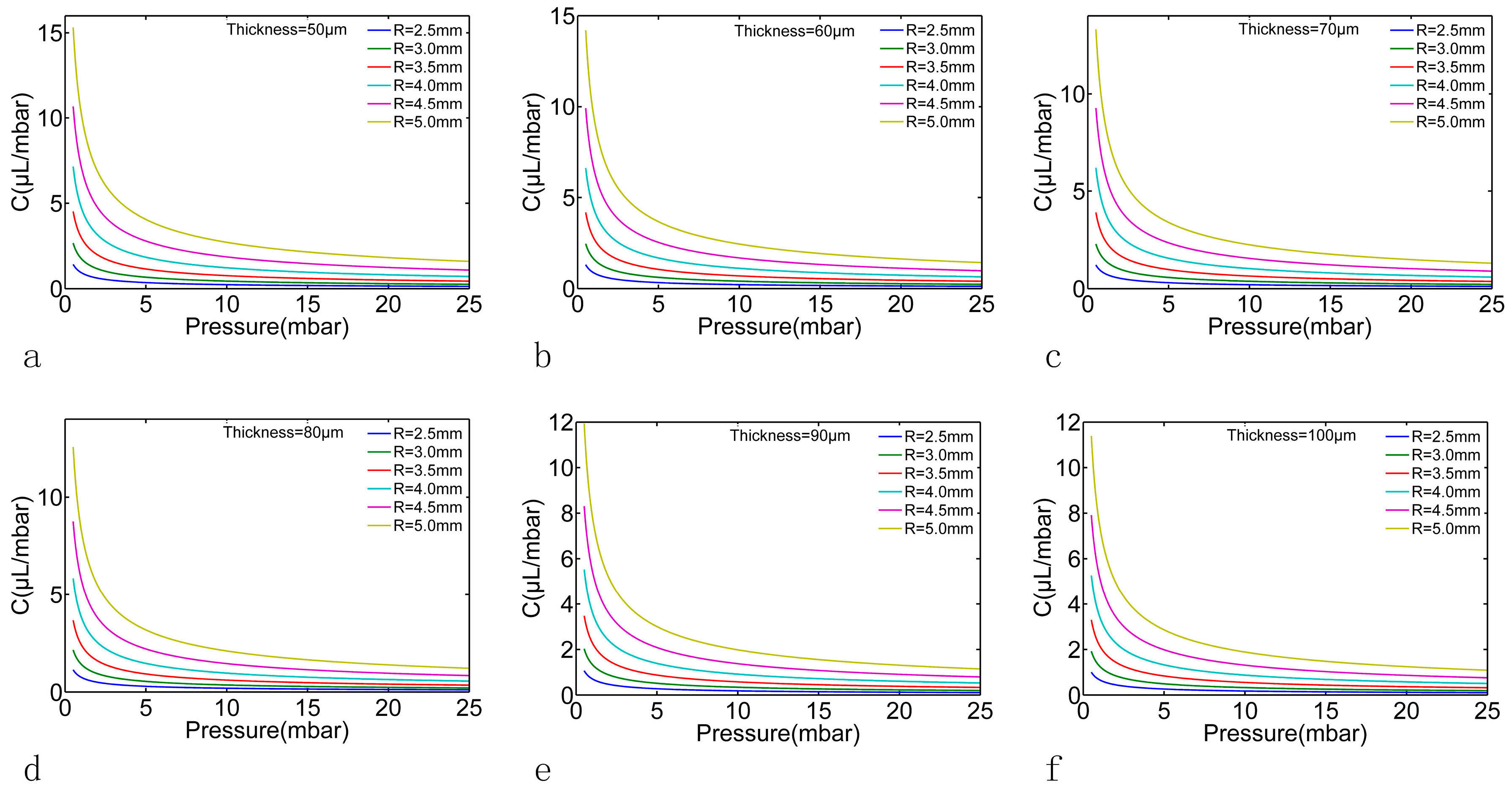

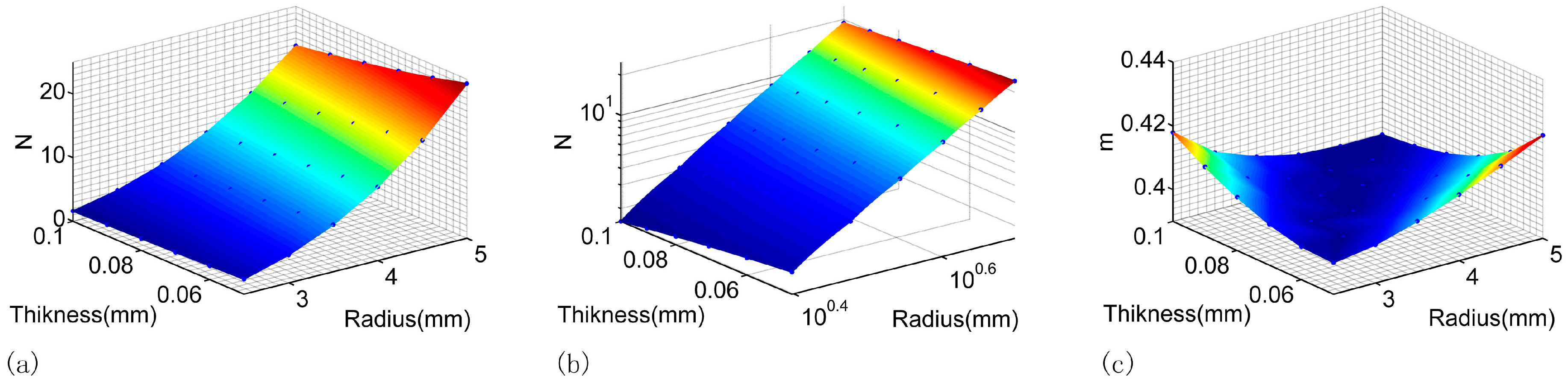

4.1. FEM Results

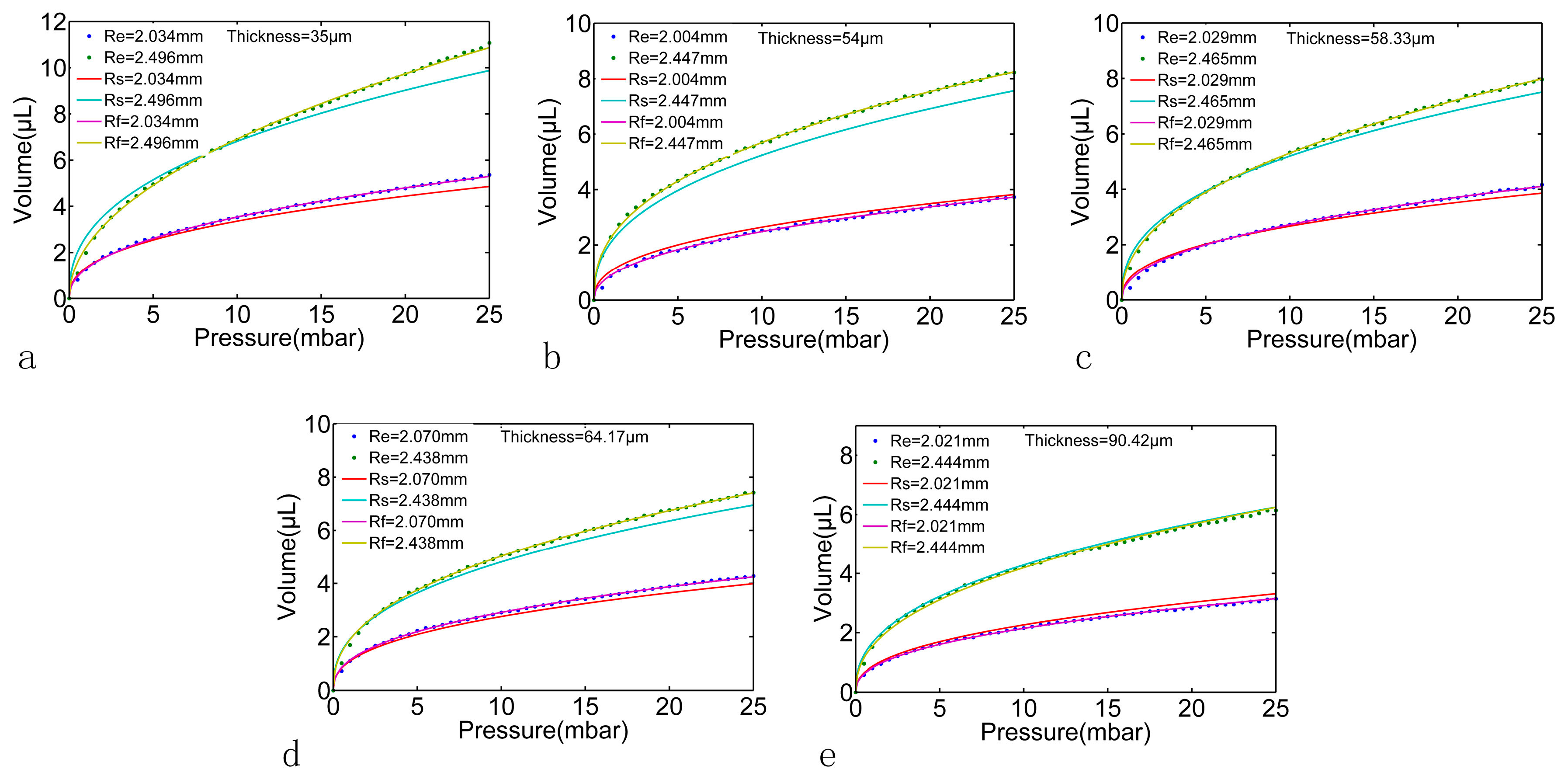

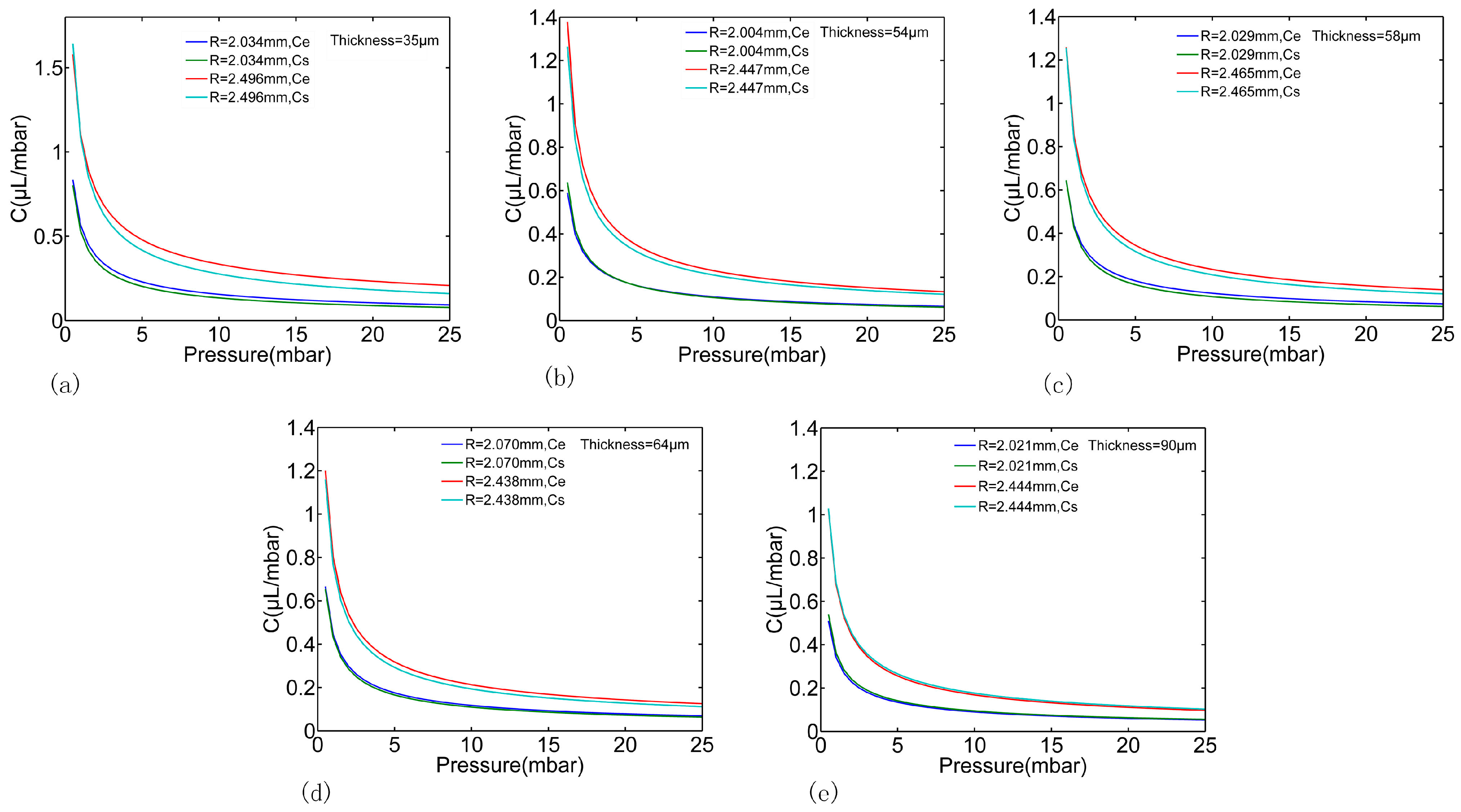

4.2. Experimental Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leslie, D.C.; Easley, C.J.; Seker, E.; Karlinsey, J.M.; Utz, M.; Begley, M.R.; Landers, J.P. Frequency-specific flow control in microfluidic circuits with passive elastomeric features. Nat. Phys. 2009, 5, 231–235. [Google Scholar] [CrossRef]

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.Q.; Horowitz, M.A.; Quake, S.R. Microfluidic serial digital to analog pressure converter for arbitrary pressure generation and contamination-free flow control. Lab Chip 2013, 13, 1911–1918. [Google Scholar] [CrossRef] [PubMed]

- Cheung, P.; Toda-Peters, K.; Shen, A.Q. In situ pressure measurement within deformable rectangular polydimethylsiloxane microfluidic devices. Biomicrofluidics 2012, 6, 026501. [Google Scholar] [CrossRef] [PubMed]

- Qingda, Y.; Kobrin, P.; Seabury, C.; Narayanaswamy, S.; Christian, W. Mechanical modeling of fluid-driven polymer lenses. Appl. Opt. 2008, 47, 3658–3668. [Google Scholar]

- Inman, W.; Domansky, K.; Serdy, J.; Owens, B.; Trumper, D.; Griffith, L.G. Design, modeling and fabrication of a constant flow pneumatic micropump. J. Micromech. Microeng. 2007, 17, 891–899. [Google Scholar] [CrossRef]

- Gong, M.M.; MacDonald, B.D.; Trung Vu, N.; Sinton, D. Hand-powered microfluidics: A membrane pump with a patient-to-chip syringe interface. Biomicrofluidics 2012, 6, 044102. [Google Scholar] [CrossRef] [PubMed]

- Chun-Hui, W.; Chia-Wei, C.; Long-Sheng, K.; Ping-Hei, C. A Novel Approach to Measure the Hydraulic Capacitance of a Microfluidic Membrane Pump. Adv. Mater. Science Eng. 2014, 2014, 198620. [Google Scholar]

- Tesar, V. Pressure Driven Microfluidics; Artech House Publishers: Norwood, MA, USA, 2007. [Google Scholar]

- Landers, J.P. Handbook of Capillary and Microchip Electrophoresis and Associated Microtechniques; CRC Press: New York, NY, USA, 2007. [Google Scholar]

- Elwenspoek, M.; Wiegerink, R. Mechanical Microsensors; Springer: New York, NY, USA, 2001. [Google Scholar]

- Hsu, T.R. MEMS & Microsystems: Design, Manufacture, and Nanoscale Engineering; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Perdigones, F.; Luque, A.; Quero, J.M. Correspondence between Electronics and Fluids in MEMS Designing Microfluidic Systems Using Electronics. IEEE Ind. Electron. Mag. 2014, 8, 6–17. [Google Scholar] [CrossRef]

- Steigmann, D.J. Thin-plate theory for large elastic deformations. Int. J. Non-Linear Mech. 2007, 42, 233–240. [Google Scholar] [CrossRef]

- Ogden, R.W. Large deformation isotropic elasticity—On the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. Lond. B Biol. Sci. 1972, 326, 565–584. [Google Scholar] [CrossRef]

- Seker, E.; Leslie, D.; Haj-Hariri, H.; Landers, J.; Utz, M.; Begley, M. Nonlinear pressure-flow relationships for passive microfluidic valves. Lab Chip 2009, 9, 2691–2697. [Google Scholar] [CrossRef] [PubMed]

- Lau, A.T.H.; Yip, H.M.; Ng, K.C.C.; Cui, X.; Lam, R.H.W. Dynamics of Microvalve Operations in Integrated Microfluidics. Micromachines 2014, 5, 50–65. [Google Scholar] [CrossRef]

- Oh, K.W.; Lee, K.; Ahn, B.; Furlani, E.P. Design of pressure-driven microfluidic networks using electric circuit analogy. Lab Chip 2012, 12, 515–545. [Google Scholar] [CrossRef] [PubMed]

- He, X.-T.; Chen, Q.; Sun, J.-Y.; Zheng, Z.-L. Large-deflection axisymmetric deformation of circular clamped plates with different moduli intension and compression. Int. J. Mech. Sci. 2012, 62, 103–110. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 3rd ed.; Publishing House of Electronics Industry: Beijing, China, 2010. [Google Scholar]

- Chan, T.F.; Vese, L.A. Active contours without edges. IEEE Trans. Image Process. 2001, 10, 266–277. [Google Scholar] [CrossRef] [PubMed]

- Cai, X. Variational image segmentation model coupled with image restoration achievements. Pattern Recognit. 2015, 48, 2029–2042. [Google Scholar] [CrossRef]

| h (μm) | R (mm) | R (mm) | R (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 50 | 2.5 | 2.3479 | 0.39991 | 3 | 4.38163 | 0.40200 | 3.5 | 7.3833 | 0.40593 |

| 60 | 2.1567 | 0.40036 | 4.05922 | 0.3997 | 6.88002 | 0.40156 | |||

| 70 | 1.9934 | 0.40281 | 3.78201 | 0.39986 | 6.45017 | 0.3996 | |||

| 80 | 1.8493 | 0.40677 | 3.53845 | 0.40148 | 6.06283 | 0.39992 | |||

| 90 | 1.7207 | 0.41172 | 3.31882 | 0.40452 | 5.73033 | 0.40065 | |||

| 100 | 1.6020 | 0.41795 | 3.12131 | 0.40811 | 5.41352 | 0.40328 | |||

| 50 | 4 | 11.564 | 0.41082 | 4.5 | 17.1377 | 0.41628 | 5 | 24.3082 | 0.42236 |

| 60 | 10.819 | 0.4046 | 16.0932 | 0.40834 | 22.9083 | 0.41256 | |||

| 70 | 10.189 | 0.40107 | 15.1979 | 0.40361 | 21.6985 | 0.40649 | |||

| 80 | 9.6296 | 0.39962 | 14.4163 | 0.40082 | 20.6314 | 0.40276 | |||

| 90 | 9.1247 | 0.3996 | 13.714 | 0.39960 | 19.6706 | 0.4007 | |||

| 100 | 8.6721 | 0.4004 | 13.0674 | 0.39960 | 18.8048 | 0.39969 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, X.; Zhang, W.; Peng, C.; Liu, X.; Yu, Q.; Ni, K.; Wang, X. Characterizing the Deformation of the Polydimethylsiloxane (PDMS) Membrane for Microfluidic System through Image Processing. Micromachines 2016, 7, 92. https://doi.org/10.3390/mi7050092

Qian X, Zhang W, Peng C, Liu X, Yu Q, Ni K, Wang X. Characterizing the Deformation of the Polydimethylsiloxane (PDMS) Membrane for Microfluidic System through Image Processing. Micromachines. 2016; 7(5):92. https://doi.org/10.3390/mi7050092

Chicago/Turabian StyleQian, Xiang, Wenhui Zhang, Cheng Peng, Xingyang Liu, Quan Yu, Kai Ni, and Xiaohao Wang. 2016. "Characterizing the Deformation of the Polydimethylsiloxane (PDMS) Membrane for Microfluidic System through Image Processing" Micromachines 7, no. 5: 92. https://doi.org/10.3390/mi7050092