Effect of Laser Power on the Quality of Drilled Micro Hole Using Cu50Zr50 Amorphous Alloys Foils

Abstract

:1. Introduction

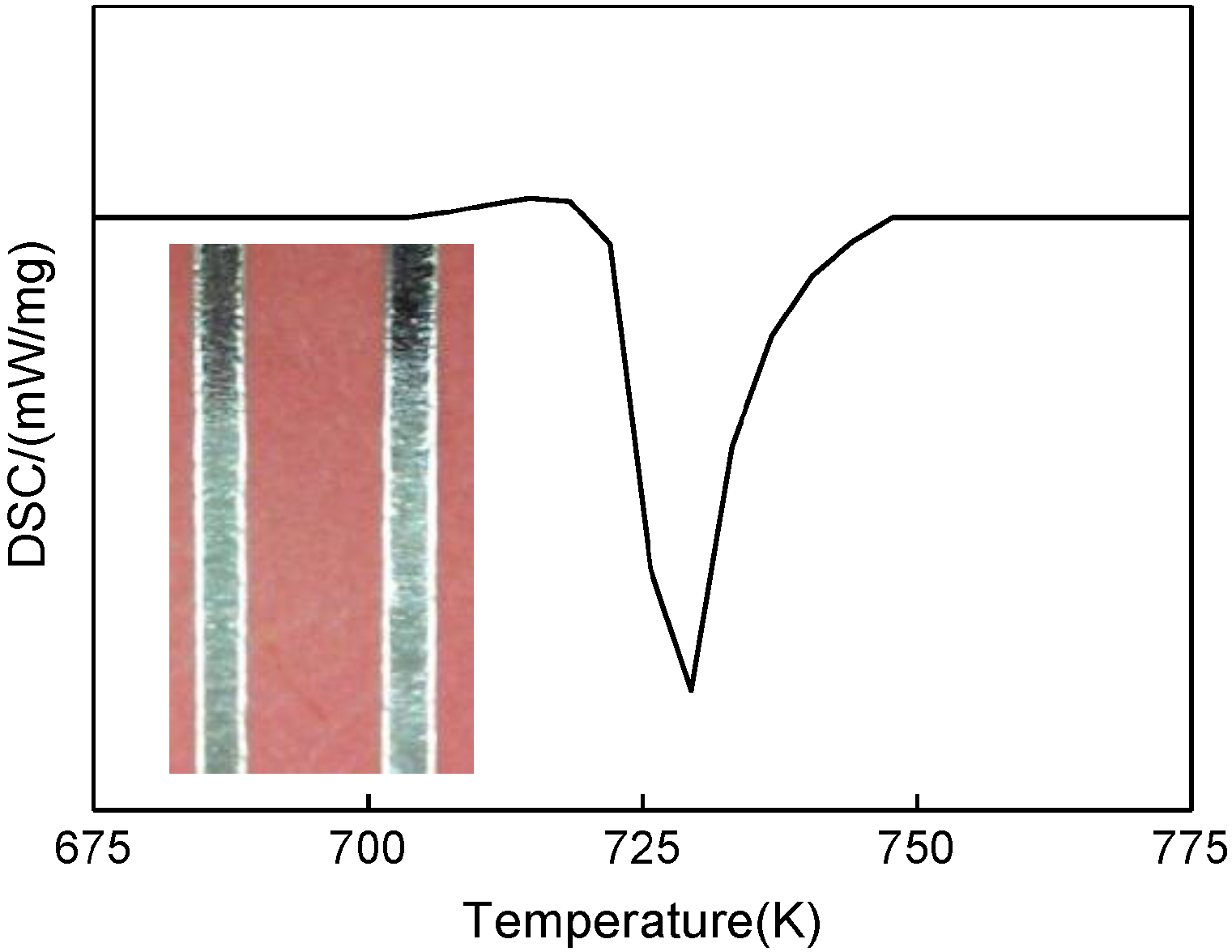

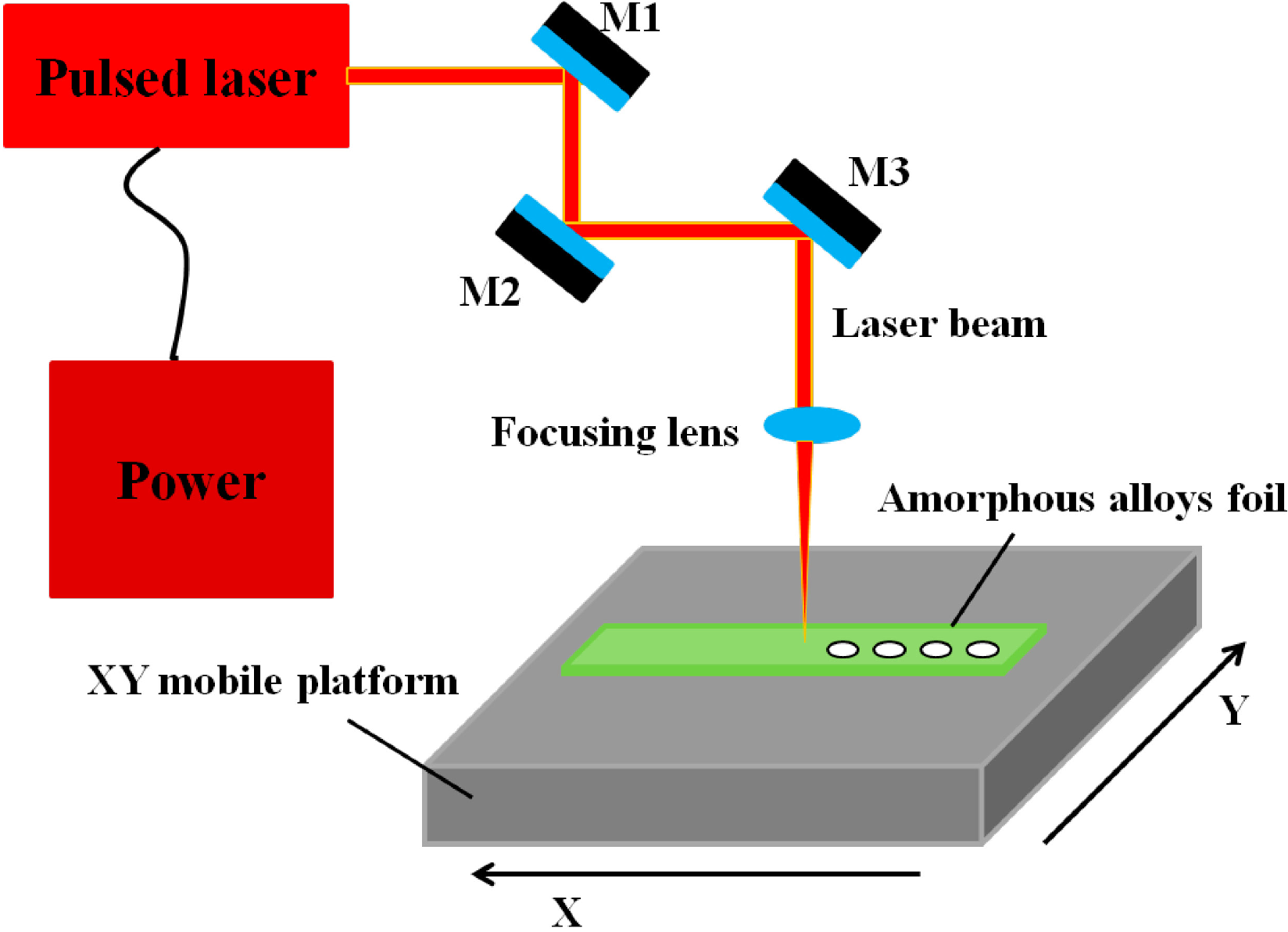

2. Experimental

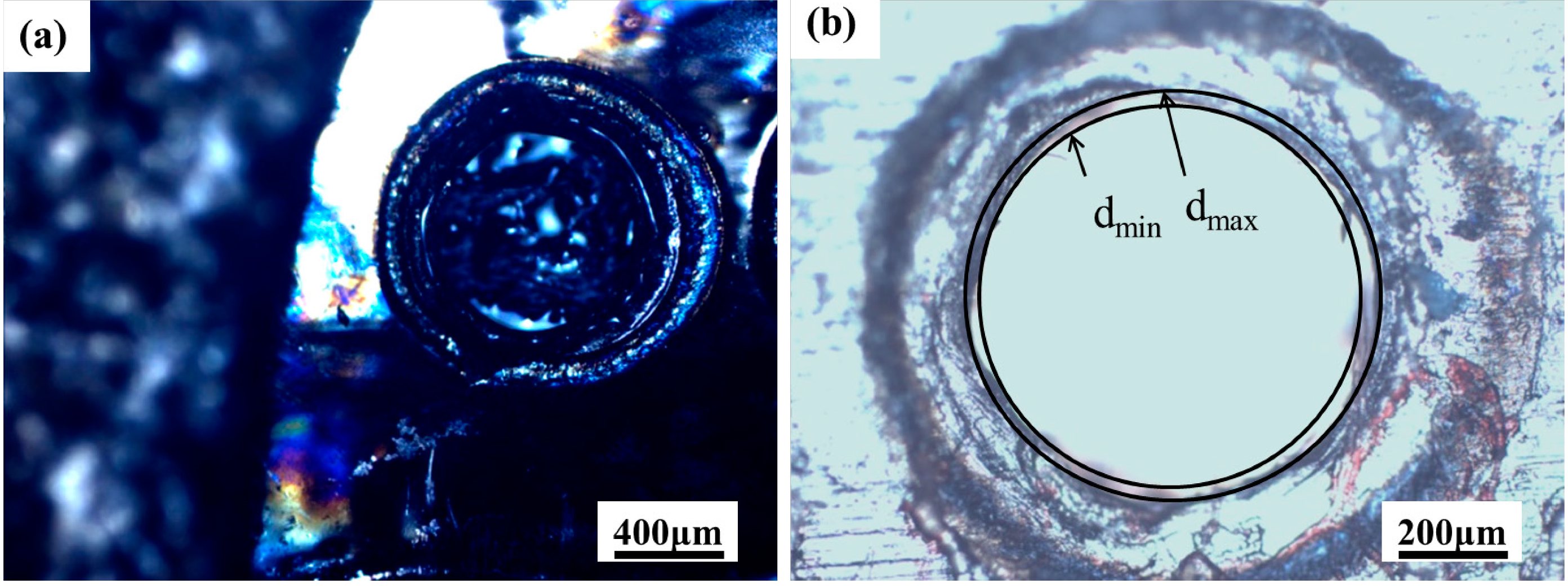

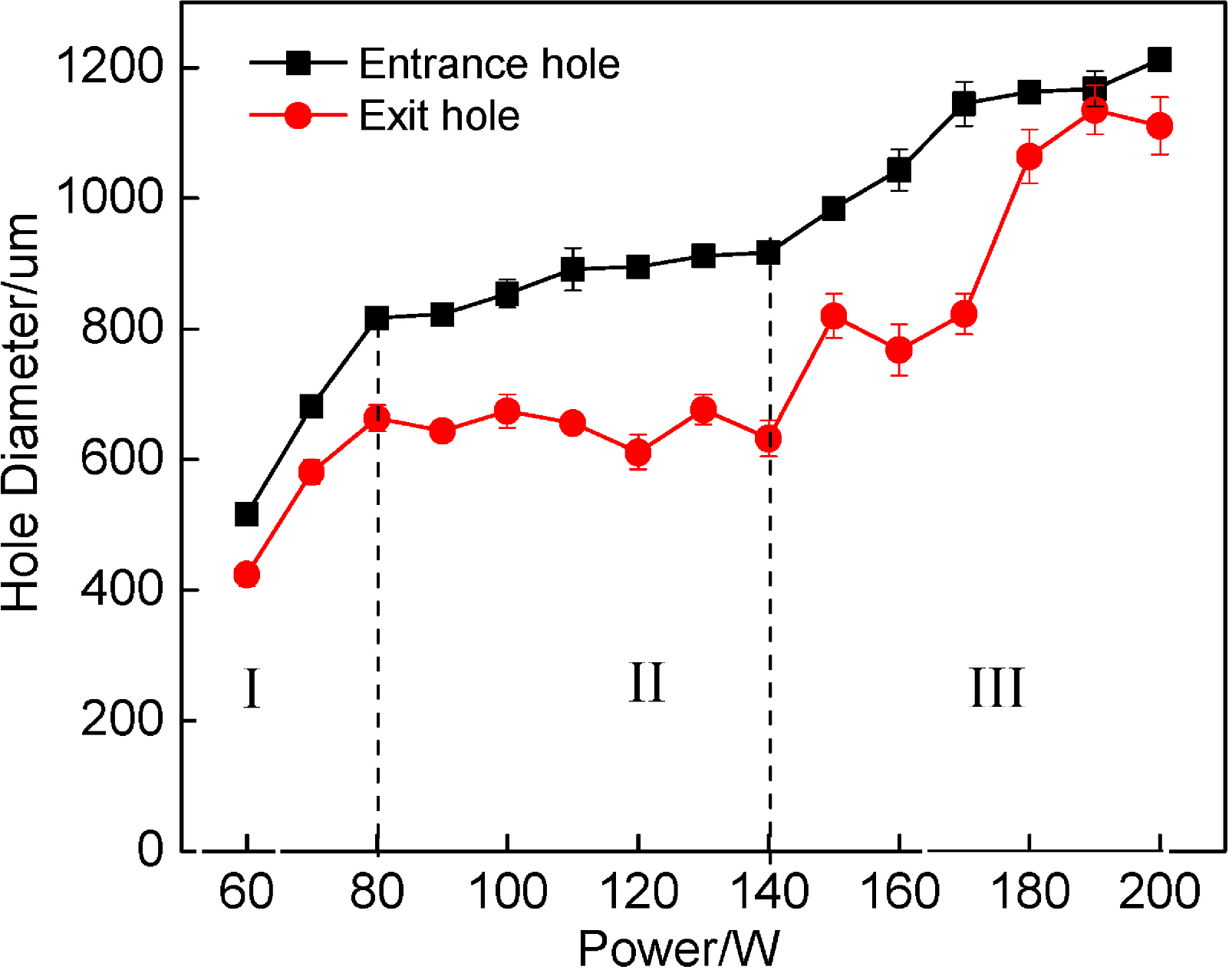

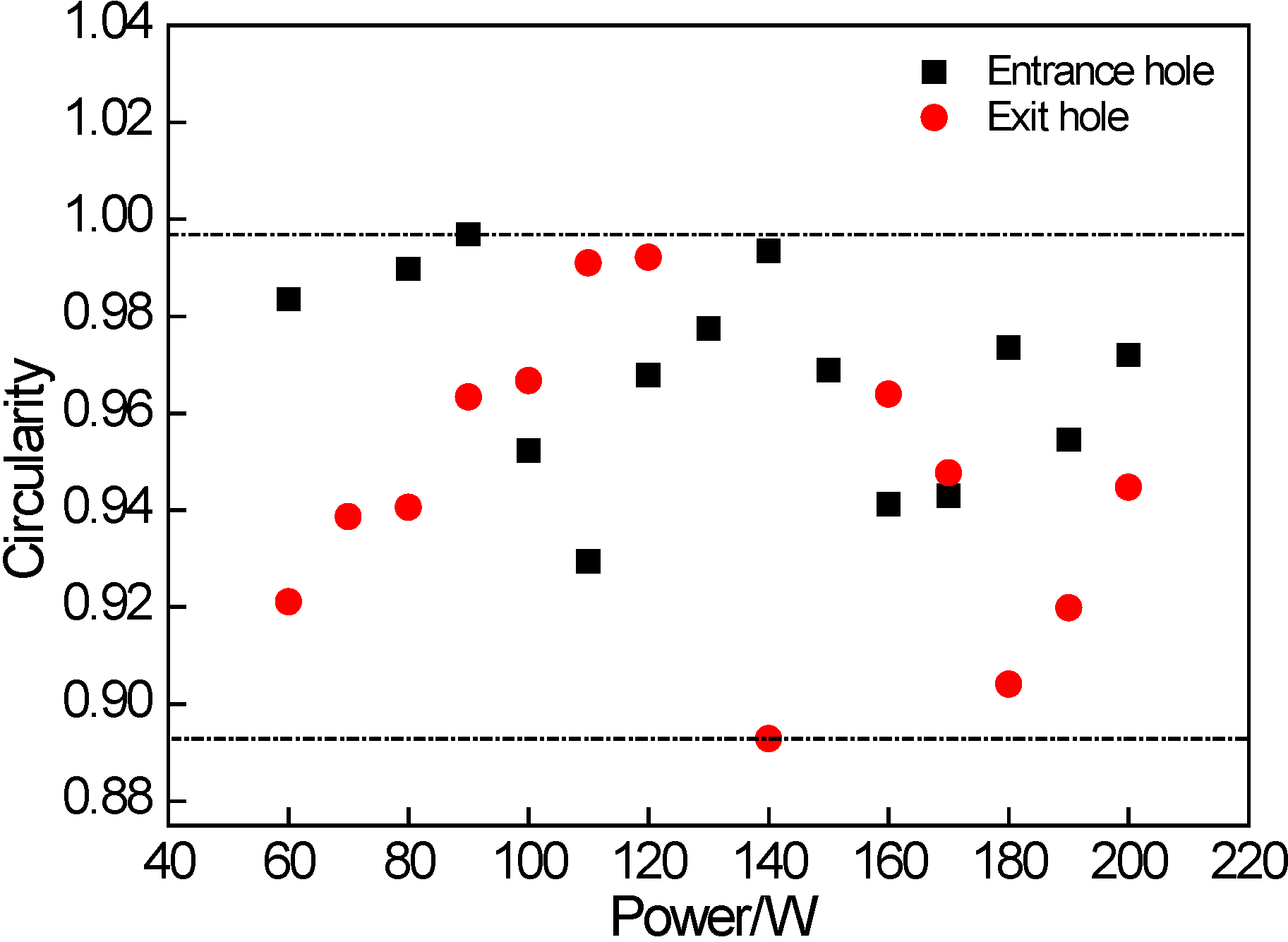

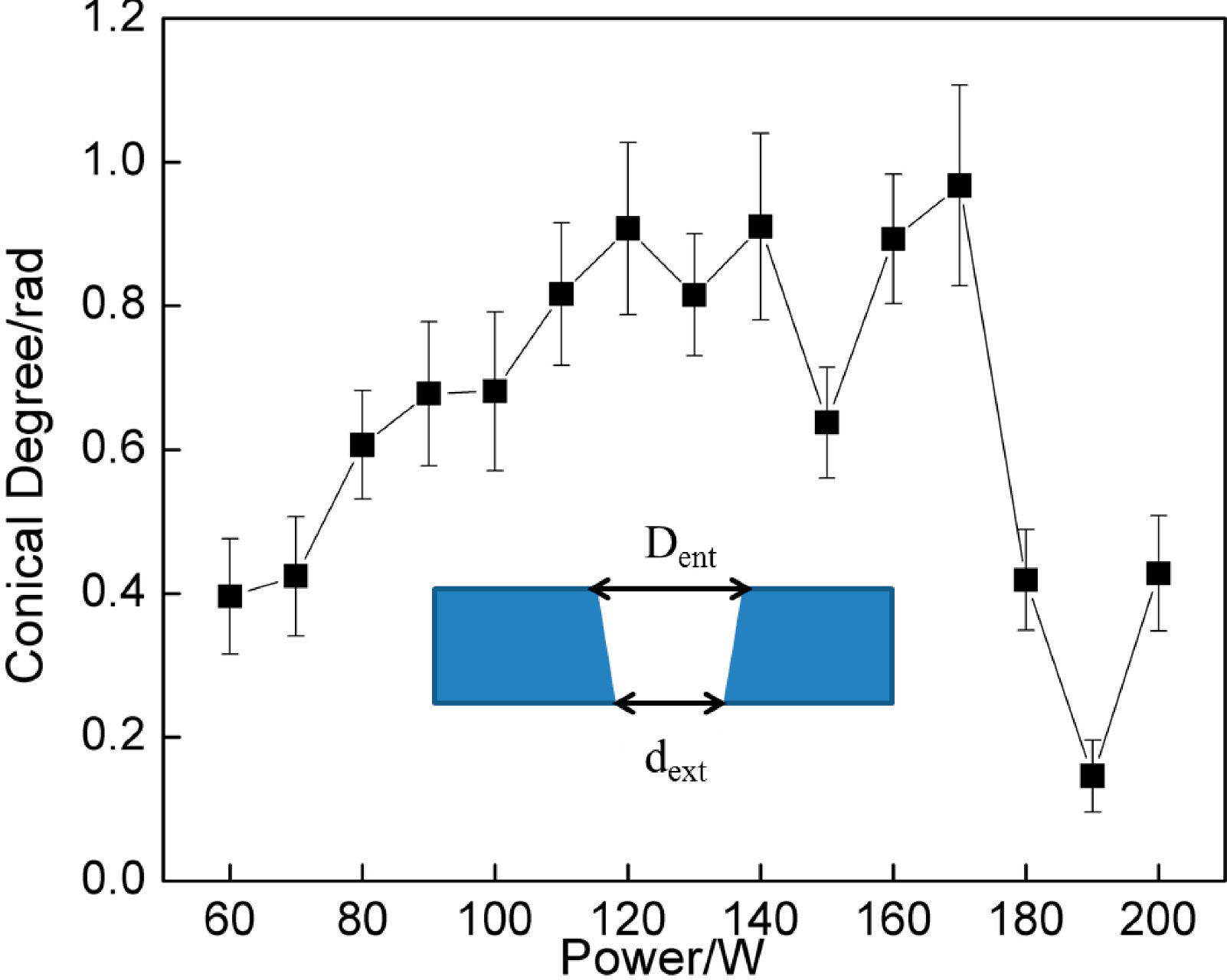

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Engel, U.; Eckstein, R. Microforming-from basic research to its realization. J. Mater. Process. Technol. 2002, 125–126, 35–44. [Google Scholar]

- Gan-Mor, S.; Matthews, G.A. Recent developments in sprayers for application of biopesticides—An overview. Biosyst. Eng. 2003, 84, 119–125. [Google Scholar]

- Rife, J.C.; Bell, M.I.; Horwitz, J.S.; Kabler, M.N.; Auyeung, R.C.Y.; Kim, W.J. Miniature valveless ultrasonic pumps and mixers. Sens. Actuators A Phys. 2000, 86, 135–140. [Google Scholar]

- Zhao, X.; Evans, J.R.G.; Edirisinghe, M.J.; Song, J.H. Formulation of a ceramic ink for a wide-array drop-on-demand ink-jet printer. Ceram. Int. 2003, 29, 887–892. [Google Scholar]

- Xu, J.; Guo, B.; Wang, C.J.; Shan, D.B. Blanking clearance and grain size effects on micro deformation behavior and fracture in micro-blanking of brass foil. Int. J. Mach. Tools Manuf. 2012, 60, 27–34. [Google Scholar]

- Zheng, L.J.; Wang, C.Y.; Yang, L.P.; Song, Y.X.; Fu, L.Y. Characteristics of chip formation in the micro-drilling of multi-material sheets. Int. J. Mach. Tools Manuf. 2012, 52, 40–49. [Google Scholar]

- Ding, K.; Fu, Y.C.; Su, H.H.; Chen, Y.; Yu, X.Z.; Ding, G.Z. Experimental studies on drilling tool load and machining quality of C/SiC composites in rotary ultrasonic machining. J. Mater. Process. Technol. 2014, 214, 2900–2907. [Google Scholar]

- Wang, D.; Zhao, W.S.; Gu, L.; Kang, X.M. A study on micro-hole machining of polycrystalline diamond by micro-electrical discharge machining. J. Mater. Process. Technol. 2011, 211, 3–11. [Google Scholar]

- Wang, C.R.; Xiao, H.; Shao, K.W.; Lu, Z.; Zhang, K.F. Densification and mechanical properties of boron carbide with micro-hole array by micro-powder injection molding. Ceram. Int. 2014, 40, 7915–7921. [Google Scholar]

- Dubey, A.K.; Yadava, V. Laser beam machining—A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar]

- Meijer, J. Laser beam machining (LBM), state of the art and new opportunities. J. Mater. Process. Technol. 2004, 149, 2–17. [Google Scholar]

- Bharatish, A.; Narasimha Murthy, H.N.; Anand, B.; Madhusoodana, C.D.; Praveena, G.S.; Krishna, M. Characterization of hole circularity and heat affected zone in pulsed CO2 laser drilling of alumina ceramics. Opt. Laser Technol. 2013, 53, 22–32. [Google Scholar]

- Jay, T.; Alexander, G.; Paleocrassas, N.R.; Nilesh, R. Experimental characterization of a micro-hole drilling process with short micro-second pulses by a CW single-mode fiber laser. Opt. Laser. Eng. 2014, 55, 275–283. [Google Scholar]

- Romoli, L.; Rashed, C.A.A.; Fiaschi, M. Experimental characterization of the inner surface in micro-drilling of spray holes: A comparison between ultra short pulsed laser and EDM. Opt. Laser. Technol. 2014, 56, 35–42. [Google Scholar]

- Aqida, S.N.; Brabazon, D.; Naher, S.; Kovacs, Z.; Browne, D.J. Laser micro-processing of amorphous and partially crystalline Cu45Zr48Al7 alloy. Appl. Phys. A Mater. Sci. Process. 2010, 101, 357–360. [Google Scholar]

- Wang, X.L.; Lu, P.X.; Dai, N.L.; Li, Y.H.; Liao, C.R.; Zheng, Q.G.; Liu, L. Noncrystalline micromachining of amorphous alloys using femtosecond laser pulses. Mater. Lett. 2007, 61, 4290–4293. [Google Scholar]

- Yao, K.C.; Lin, J.M. The characterization of the hole-contour and plume ejection in the laser drilling with various inclination angles. Opt. Laser. Technol. 2013, 48, 110–116. [Google Scholar]

- Liu, H.X.; Wang, H.J.; Shen, Z.B.; Huang, Z.H.; Li, W.; Zheng, Y.Y.; Wang, X. The research on micro-punching by laser-driven flyer. Int. J. Mach. Tools Manuf. 2012, 54–55, 18–24. [Google Scholar]

- Zheng, C.; Sun, S.; Song, L.B.; Zhang, G.F.; Luan, Y.G.; Ji, Z.; Zhang, J.H. Dynamic fracture characteristics of Fe78Si9B13 metallic glass subjected to laser shock loading. Appl. Surf. Sci. 2013, 286, 121–125. [Google Scholar]

- Jia, H.L.; Muntele, C.I.; Huang, L.; Li, X.; Li, G.; Zhang, T.; He, W.; Liaw, P.K. A study on the surface structures and properties of Ni-free Zr-based bulk metallic glasses after Ar and Ca ion implantation. Intermetallics 2013, 41, 35–43. [Google Scholar]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. Rep. 2004, 44, 45–89. [Google Scholar]

- Zong, H.T.; Ma, M.Z.; Liu, L.; Zhang, X.Y.; Bai, B.W.; Yu, P.F.; Qi, L.; Jing, Q.; Li, G.; Liu, R.P. Wf/Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass composites prepared by a new melt infiltrating method. J. Alloy. Compd. 2010, 504, 106–109. [Google Scholar]

- Schroers, J. Processing of bulk metallic glass. Adv. Mater. 2010, 22, 1566–1597. [Google Scholar]

- Huang, H.H.; Sun, Y.S.; Wu, C.P.; Liu, C.F.; Liaw, P.K.; Kai, W. Corrosion resistance and biocompatibility of Ni-free Zr-based bulk metallic glass for biomedical applications. Intermetallics 2012, 30, 139–143. [Google Scholar]

- Ma, M.Z.; Liu, R.P.; Xiao, Y.; Lou, D.C.; Liu, L.; Wang, Q.; Wang, W.K. Wear resistance of Zr-based bulk metallic glass applied in bearing rollers. Mater. Sci. Eng. A 2004, 386, 326–330. [Google Scholar]

- Inoue, A.; Takeuchi, A. Recent development and application products of bulk glassy alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar]

- International Organization for Standardization (ISO). ISO 1101-2012, Geometrical Product Specifications (GPS)—Geometrical Tolerancing—Tolerances of Form, Orientation, Location and Run-Out. ISO: Geneva, Switzerland, 2012. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.-J.; Chen, G.; Luan, D.; Zhang, P. Effect of Laser Power on the Quality of Drilled Micro Hole Using Cu50Zr50 Amorphous Alloys Foils. Micromachines 2014, 5, 1061-1068. https://doi.org/10.3390/mi5041061

Wang C-J, Chen G, Luan D, Zhang P. Effect of Laser Power on the Quality of Drilled Micro Hole Using Cu50Zr50 Amorphous Alloys Foils. Micromachines. 2014; 5(4):1061-1068. https://doi.org/10.3390/mi5041061

Chicago/Turabian StyleWang, Chuan-Jie, Gang Chen, Dong Luan, and Peng Zhang. 2014. "Effect of Laser Power on the Quality of Drilled Micro Hole Using Cu50Zr50 Amorphous Alloys Foils" Micromachines 5, no. 4: 1061-1068. https://doi.org/10.3390/mi5041061