Micromanufacturing in Fused Silica via Femtosecond Laser Irradiation Followed by Gas-Phase Chemical Etching

Abstract

:1. Introduction

2. Experimental Section

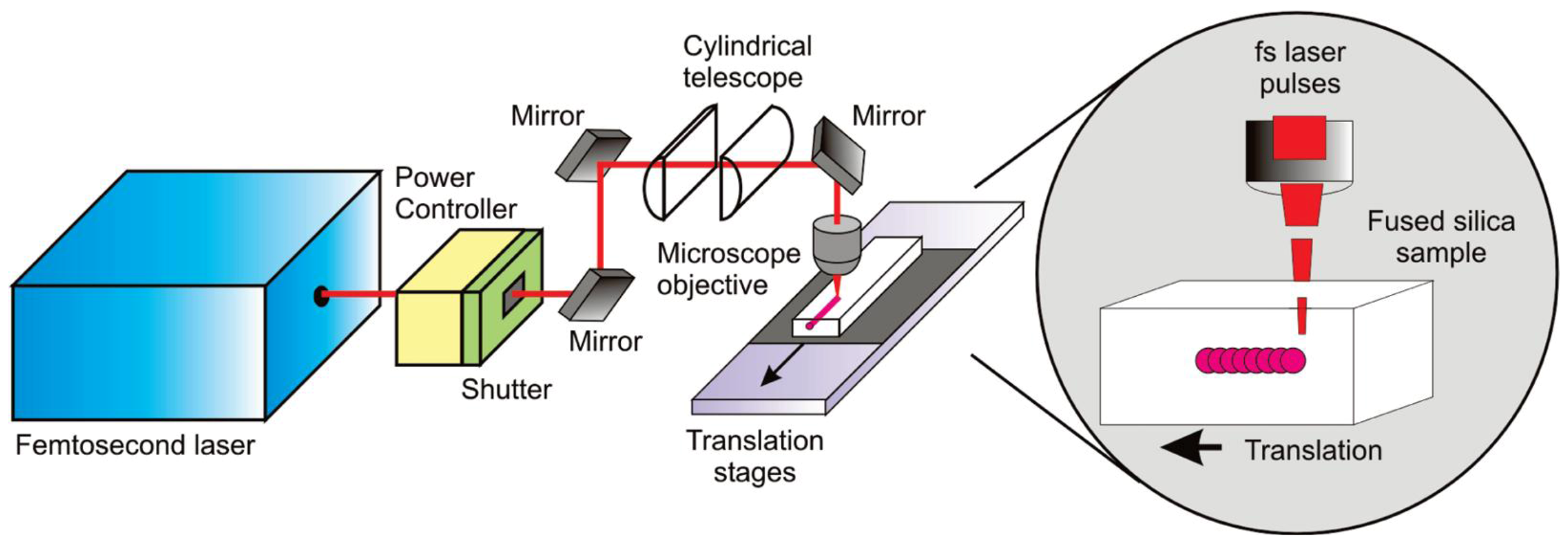

2.1. Femtosecond Laser Irradiation

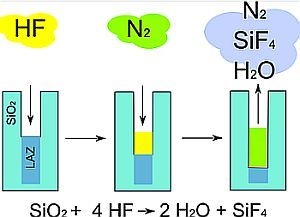

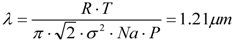

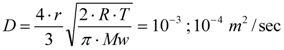

2.2. Gaseous HF Etching

2.3. HF Etching with Dynamic Displacement

3. Results and Discussion

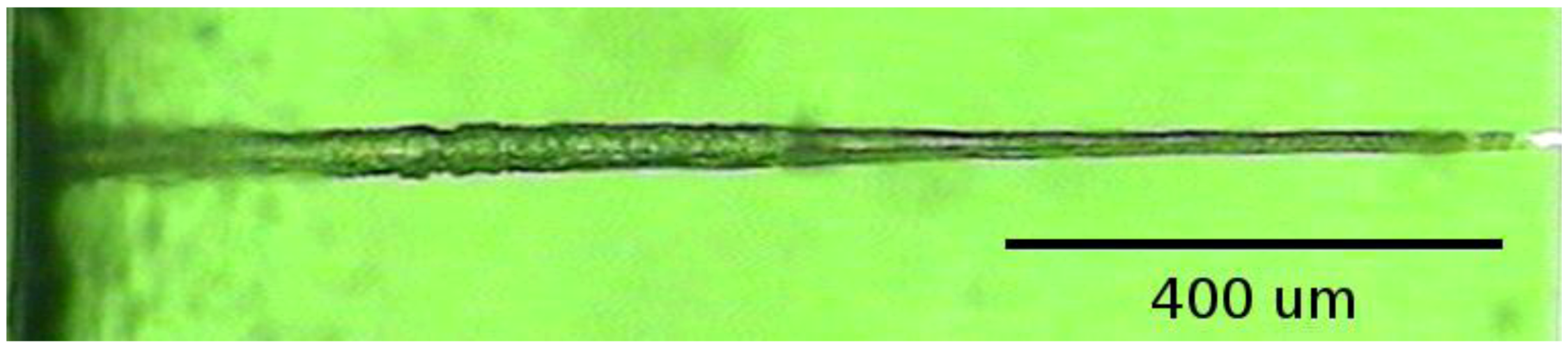

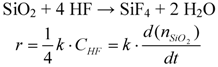

3.1. Gaseous HF Etching

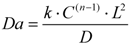

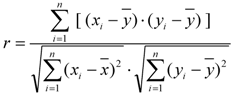

3.2. HF Etching with Dynamic Displacement

| N° | (τR) Reaction Time [s] | (PR) HF Pressure [mBar] | (τN) Nitrogen Time [s] | (PN) Nitrogen Pressure [mBar] | Etching Speed [µm/min] | Aspect Ratio [L/D] |

|---|---|---|---|---|---|---|

| 1 | 120 | 20 | 0 | 0 | 9.1 | 14.7 |

| 2 | 15 | 150 | 105 | 500 | 6.7 | 14.9 |

| 3 | 15 | 100 | 105 | 500 | 5.4 | 18.1 |

| 4 | 15 | 50 | 105 | 500 | 4.8 | 21.4 |

| 5 | 120 | 20 | 0 | 0 | 9.3 | 22.7 |

| 6 | 15 | 150 | 105 | 500 | 5.0 | 23.0 |

| 7 | 15 | 150 | 165 | 500 | 2.5 | 25.9 |

| 8 | 15 | 100 | 105 | 500 | 9.0 | 25.1 |

| 9 | 15 | 50 | 105 | 500 | 4.3 | 28.6 |

| 10 | 15 | 20 | 105 | 500 | 6.3 | 28.7 |

| 11 | 15 | 20 | 165 | 500 | 4.2 | 27.4 |

| 12 | 15 | 20 | 165 | 250 | 4.1 | 23.1 |

| 13 | 120 | 20 | 0 | 0 | 13.0 | 25.8 |

4. Conclusions

References

- Navarrini, W.; Venturini, F.; Tortelli, V.; Basak, S.; Pimparkar, K.P.; Adamo, A.; Jensen, K.F. Direct fluorination of carbon monoxide in microreactors. J. Fluorine Chem. 2012, 142, 19–23. [Google Scholar] [CrossRef]

- Madou, M.J. Manufacturing techniques for microfabrication and nanotechnology. In Fundamentals of Microfabrication and Nanotechnology, 3rd ed; CRC Press: Boca Raton, Florida, USA, 2011; Volume 2. [Google Scholar]

- Sansotera, M.; Navarrini, W.; Resnati, G.; Metrangolo, P.; Famulari, A.; Bianchi, C.L.; Guarda, P.A. Preparation and characterization of superhydrophobic conductive fluorinated carbon blacks. Carbon 2010, 48, 4382–4390. [Google Scholar] [CrossRef]

- Marco, C.D.; Eaton, S.M.; Suriano, R.; Turri, S.; Levi, M.; Ramponi, R.; Cerullo, G.; Osellame, R. Surface properties of femtosecond laser ablated PMMA. ACS Appl. Mater. Interfaces 2010, 2, 2377–2384. [Google Scholar] [CrossRef]

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Khan Malek, C.G. Laser processing for bio-microfluidics applications (part I). Anal. Bioanal. Chem. 2006, 385, 1351–1361. [Google Scholar] [CrossRef]

- Khan Malek, C.G. Laser processing for bio-microfluidics applications (part II). Anal. Bioanal. Chem. 2006, 385, 1362–1369. [Google Scholar] [CrossRef]

- Marcinkevicius, A.; Juodkazis, S.; Watanabe, M.; Miwa, M.; Matsuo, S.; Misawa, H.; Nishii, J. Femtosecond laser-assisted three-dimensional microfabrication in silica. Opt. lett. 2001, 26, 277–279. [Google Scholar] [CrossRef]

- Maselli, V.; Osellame, R.; Cerullo, G.; Ramponi, R.; Laporta, P.; Magagnin, L.; Cavallotti, P.L. Fabrication of long microchannels with circular cross section using astigmatically shaped femtosecond laser pulses and chemical etching. Appl. Phys. Lett. 2006, 88, 191107:1–191107:3. [Google Scholar]

- Osellame, R.; Maselli, V.; Vazquez, R. M.; Ramponi, R.; Cerullo, G. Integration of optical waveguides and microfluidic channels both fabricated by femtosecond laser irradiation. Appl. Phys. Lett. 2007, 90, 231118:1–231118:3. [Google Scholar]

- Kiyama, S.; Matsuo, S.; Hashimoto, S.; Morihira, Y. Examination of etching agent and etching mechanism on femotosecond laser microfabrication of channels inside vitreous silica substrates. J. Phys. Chem. C 2009, 113, 11560–11566. [Google Scholar]

- Venturini, F.; Navarrini, W.; Resnati, G.; Metrangolo, P.; Vazquez, R. M.; Osellame, R.; Cerullo, G. Selective iterative etching of fused silica with gaseous hydrofluoric acid. J. Phys. Chem. C 2010, 114, 18712–18716. [Google Scholar]

- Osellame, R.; Taccheo, S.; Marangoni, M.; Ramponi, R. Femtosecond writing of active optical waveguides with astigmatically shaped beams. JOSA B 2003, 20, 1559–1567. [Google Scholar] [CrossRef]

- Hnatovsky, C.; Taylor, R.S.; Simova, E.; Rajeev, P.P.; Rayner, D.M.; Bhardwaj, V.R.; Corkum, P.B. Fabrication of microchannels in glass using focused femtosecond laser radiation and selective chemical etching. Appl. Phys. A 2006, 84, 47–61. [Google Scholar] [CrossRef]

- Walters, D.B. Safe Handling of Chemical Carcinogens, Mutagens, Teratogens, and Highly Toxic Substances; Ann Arbor Science Publishers: Ann Arbor, Michigan USA, 1980; Volume 1. [Google Scholar]

- Perry’s Chemical Engineers’ Handbook, 7th ed; McGraw-Hill Professional: New York, USA, 1997.

- Redington, R.L. Infrared absorbance of hydrogen fluoride oligomers. J. Phys. Chem. 1982, 86, 561–563. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Venturini, F.; Sansotera, M.; Vazquez, R.M.; Osellame, R.; Cerullo, G.; Navarrini, W. Micromanufacturing in Fused Silica via Femtosecond Laser Irradiation Followed by Gas-Phase Chemical Etching. Micromachines 2012, 3, 604-614. https://doi.org/10.3390/mi3040604

Venturini F, Sansotera M, Vazquez RM, Osellame R, Cerullo G, Navarrini W. Micromanufacturing in Fused Silica via Femtosecond Laser Irradiation Followed by Gas-Phase Chemical Etching. Micromachines. 2012; 3(4):604-614. https://doi.org/10.3390/mi3040604

Chicago/Turabian StyleVenturini, Francesco, Maurizio Sansotera, Rebeca Martinez Vazquez, Roberto Osellame, Giulio Cerullo, and Walter Navarrini. 2012. "Micromanufacturing in Fused Silica via Femtosecond Laser Irradiation Followed by Gas-Phase Chemical Etching" Micromachines 3, no. 4: 604-614. https://doi.org/10.3390/mi3040604

APA StyleVenturini, F., Sansotera, M., Vazquez, R. M., Osellame, R., Cerullo, G., & Navarrini, W. (2012). Micromanufacturing in Fused Silica via Femtosecond Laser Irradiation Followed by Gas-Phase Chemical Etching. Micromachines, 3(4), 604-614. https://doi.org/10.3390/mi3040604