Effect of Repetition Rate on Femtosecond Laser-Induced Homogenous Microstructures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Laser Micromachining

2.3. Structure Analysis

2.3.1. SEM and Optical Microscopy

2.3.2. Lacunarity (λ)

2.4. Accumulated Pulse Fluence (AFP) Model

2.5. Repetition Rate Comparison

3. Results

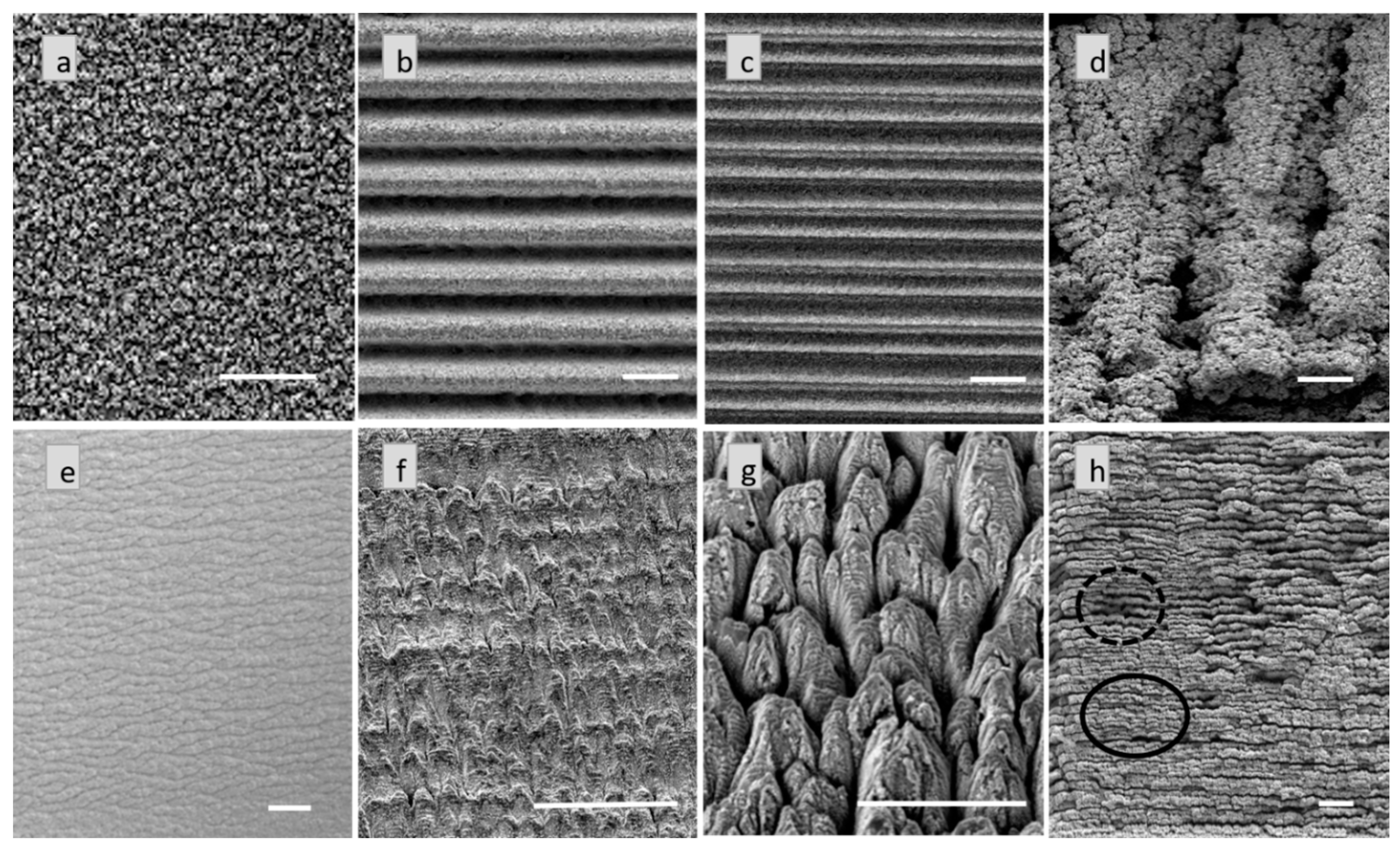

3.1. Microstructures Fabricated at 1 kHz

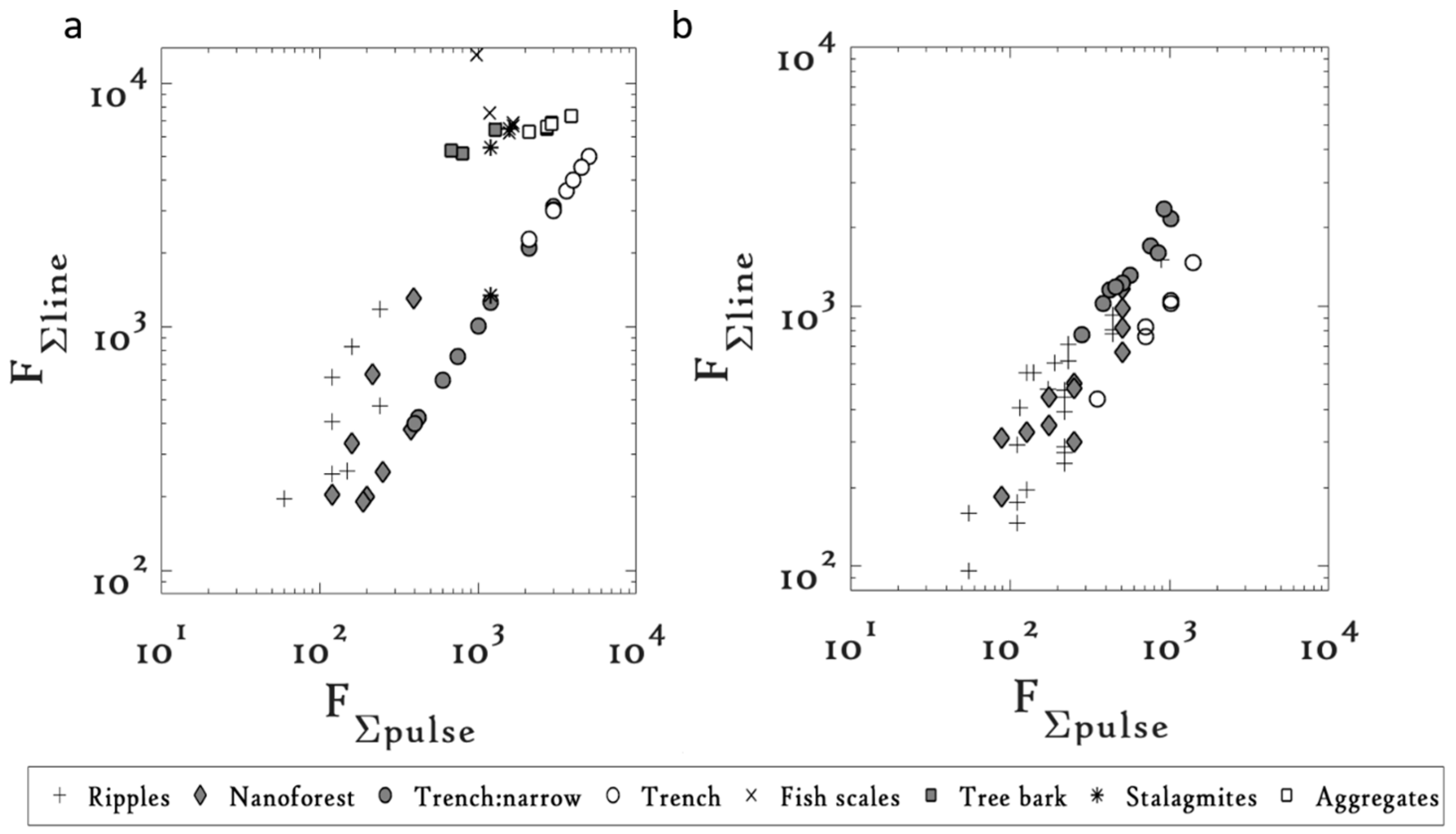

3.1.1. Copper (Cu)

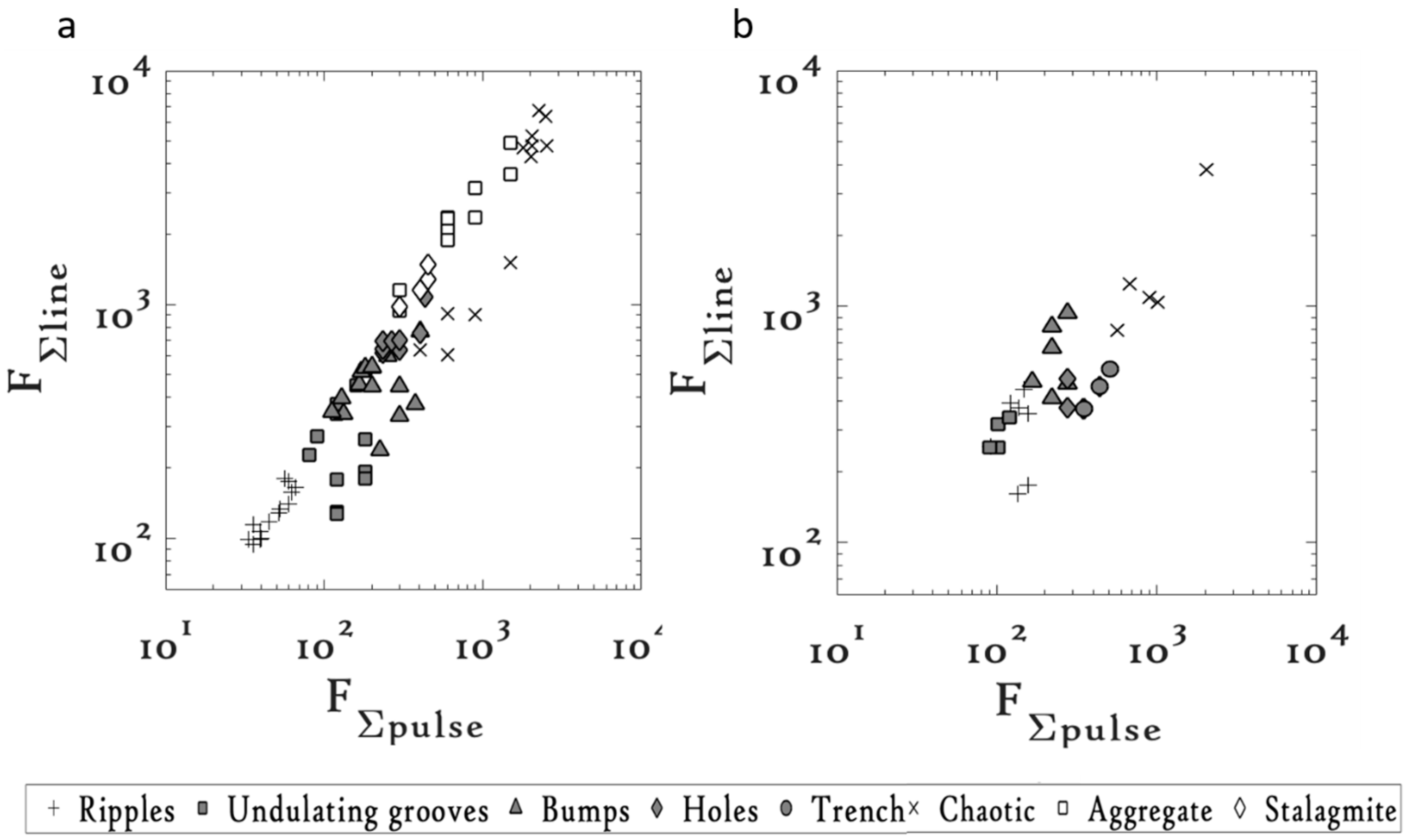

3.1.2. Titanium (Ti)

3.2. Effect of Repetition Rate

3.2.1. Copper (Cu)

3.2.2. Titanium (Ti)

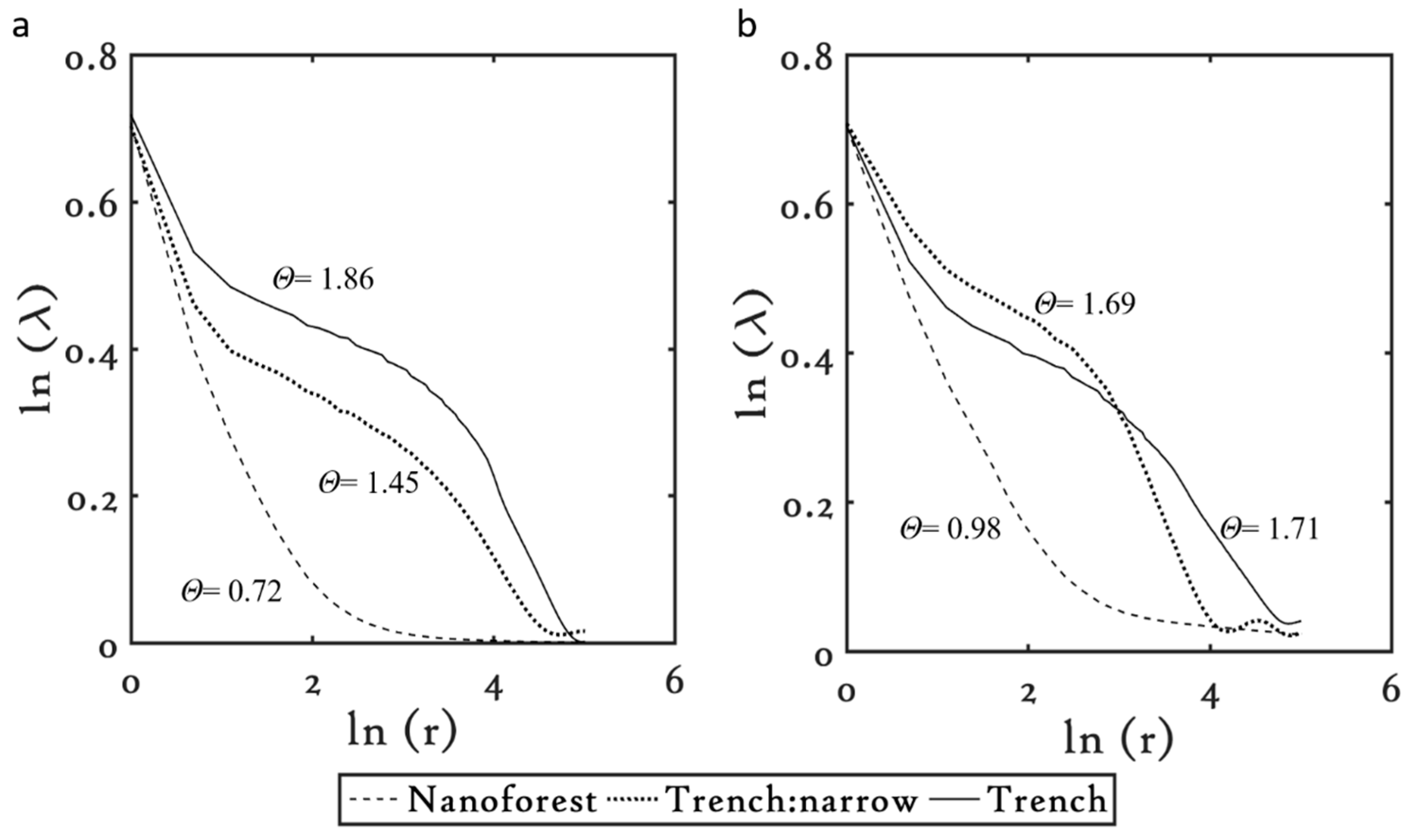

3.3. Lacunarity Analysis

3.3.1. Copper (Cu)

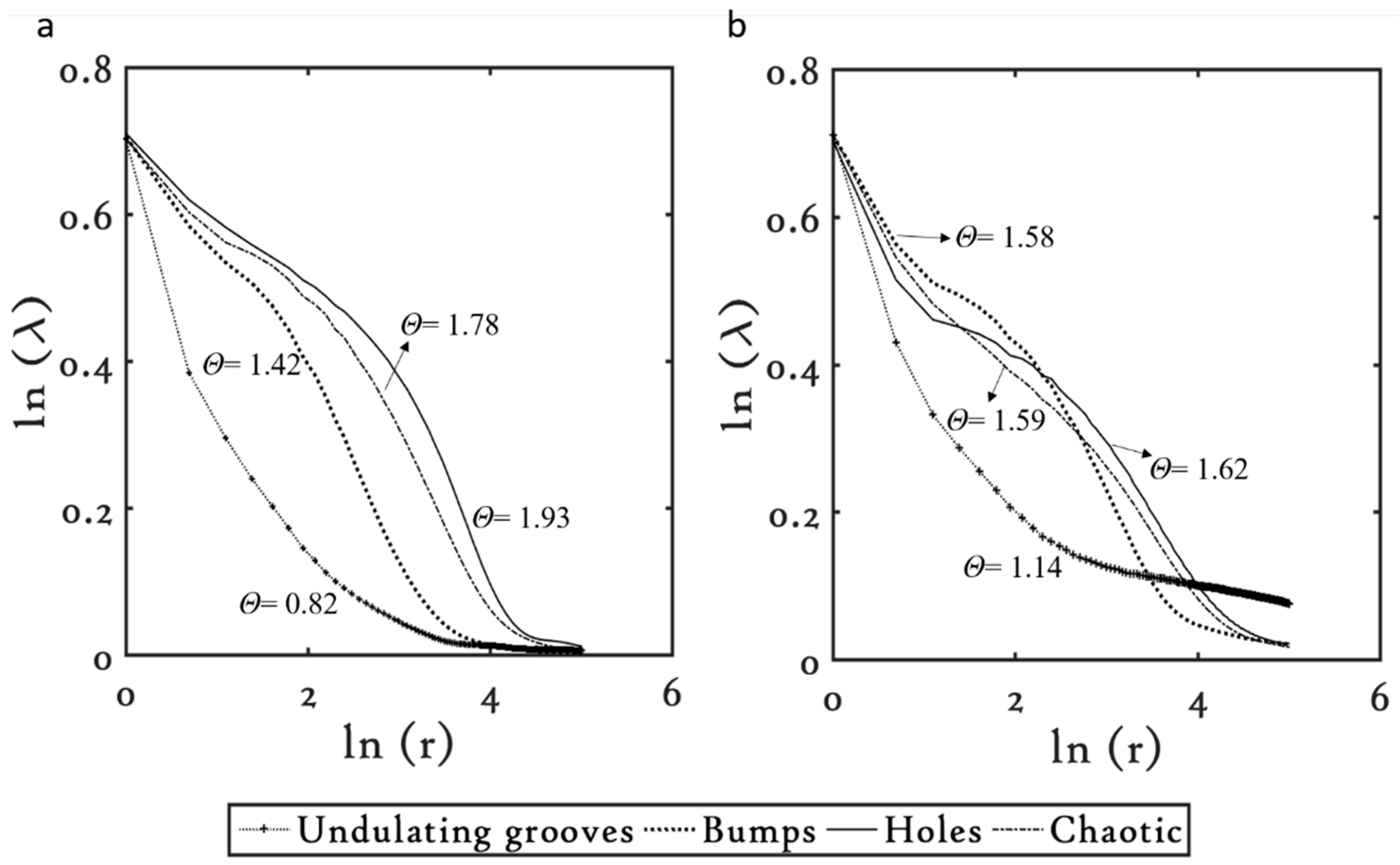

3.3.2. Titanium (Ti)

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zorba, V.; Stratakis, E.; Barberoglou, M.; Spanakis, E.; Tzanetakis, P.; Fotakis, C. Tailoring the wetting response of silicon surfaces via fs laser structuring. Appl. Phys. A Mater. Sci. Process. 2008, 93, 819–825. [Google Scholar] [CrossRef]

- Zhang, Y.; Lowe, R.M.; Harvey, E.; Hannaford, P.; Endo, A. High aspect-ratio micromachining of polymers with an ultrafast laser. Appl. Surf. Sci. 2002, 186, 345–351. [Google Scholar] [CrossRef]

- Kietzig, A.-M.; Hatzikiriakos, S.G.; Englezos, P. Patterned superhydrophobic metallic surfaces. Langmuir 2009, 25, 4821–4827. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, Y.; Zhang, J.; Liu, Y.; Yang, X.; Li, W. Effects of laser repetition rate and fluence on micromachining of TiC ceramic. Mater. Manuf. Process. 2016, 31, 832–837. [Google Scholar] [CrossRef]

- Tanvir Ahmmed, K.M.; Grambow, C.; Kietzig, A.M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Wu, B.; Zhou, M.; Li, J.; Ye, X.; Li, G.; Cai, L. Superhydrophobic surfaces fabricated by microstructuring of stainless steel using a femtosecond laser. Appl. Surf. Sci. 2009, 256, 61–66. [Google Scholar] [CrossRef]

- Nayak, B.K.; Gupta, M.C. Self-organized micro/nano structures in metal surfaces by ultrafast laser irradiation. Opt. Lasers Eng. 2010, 48, 940–949. [Google Scholar] [CrossRef]

- Ling, E.J.Y.; Saïd, J.; Brodusch, N.; Gauvin, R.; Servio, P.; Kietzig, A.-M. Investigating and understanding the effects of multiple femtosecond laser scans on the surface topography of stainless steel 304 and titanium. Appl. Surf. Sci. 2015, 353, 512–521. [Google Scholar] [CrossRef]

- Kam, D.H.; Bhattacharya, S.; Mazumder, J. Control of the wetting properties of an aisi 316l stainless steel surface by femtosecond laser-induced surface modification. J. Micromech. Microeng. 2012, 22, 105019. [Google Scholar] [CrossRef]

- Lopez, J.; Faucon, M.; Devillard, R.; Zaouter, Y.; Honninger, C.; Mottay, E.; Kling, R. Parameters of influence in surface ablation and texturing of metals using high-power ultrafast laser. J. Laser Micro Nanoeng. 2015, 10, 1–10. [Google Scholar] [CrossRef]

- Yong Hwang, T.; Guo, C. Polarization and angular effects of femtosecond laser-induced conical microstructures on Ni. J. Appl. Phys. 2012, 111, 083518. [Google Scholar] [CrossRef]

- Tsukamoto, M.; Asuka, K.; Nakano, H.; Hashida, M.; Katto, M.; Abe, N.; Fujita, M. Periodic microstructures produced by femtosecond laser irradiation on titanium plate. Vacuum 2006, 80, 1346–1350. [Google Scholar] [CrossRef]

- Ancona, A.; Döring, S.; Jauregui, C.; Röser, F.; Limpert, J.; Noite, S.; Tünnermann, A. Femtosecond and picosecond laser drilling of metals at high repetition rates and average powers. Opt. Lett. 2009, 34, 3304–3306. [Google Scholar] [CrossRef] [PubMed]

- Di Niso, F.; Gaudiuso, C.; Sibillano, T.; Mezzapesa, F.P.; Ancona, A.; Lugarà, P.M. Influence of the repetition rate and pulse duration on the incubation effect in multiple-shots ultrafast laser ablation of steel. Phys. Proced. 2013, 41, 698–707. [Google Scholar] [CrossRef]

- Finger, J.; Reininghaus, M. Effect of pulse to pulse interactions on ultra-short pulse laser drilling of steel with repetition rates up to 10 mhz. Opt. Express 2014, 22, 18790–18799. [Google Scholar] [CrossRef] [PubMed]

- Eichstädt, J.; Römer, G.R.B.E.; Huis in‘t Veld, A.J. Determination of irradiation parameters for laser-induced periodic surface structures. Appl. Surf. Sci. 2013, 264, 79–87. [Google Scholar] [CrossRef]

- Lopez, J.; Torres, R.; Zaouter, Y.; Georges, P.; Hanna, M.; Mottay, E.; Kling, R. Study on the influence of repetition rate and pulse duration on ablation efficiency using a new generation of high power ytterbium doped fiber ultrafast laser. Proc. SPIE 2013, 8611. [Google Scholar] [CrossRef]

- Bruneel, D.; Matras, G.; Le Harzic, R.; Huot, N.; König, K.; Audouard, E. Micromachining of metals with ultra-short Ti-Sapphire lasers: Prediction and optimization of the processing time. Opt. Lasers Eng. 2010, 48, 268–271. [Google Scholar] [CrossRef]

- Zuhlke, C.A.; Anderson, T.P.; Alexander, D.R. Fundamentals of layered nanoparticle covered pyramidal structures formed on nickel during femtosecond laser surface interactions. Appl. Surf. Sci. 2013, 283, 648–653. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Colorizing metals with femtosecond laser pulses. Appl. Phys. Lett. 2008, 92. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Makin, V.S.; Guo, C. Periodic ordering of random surface nanostructures induced by femtosecond laser pulses on metals. J. Appl. Phys. 2007, 101, 034903. [Google Scholar] [CrossRef]

- Zuhlke, C.A.; Anderson, T.P.; Alexander, D.R. Formation of multiscale surface structures on nickel via above surface growth and below surface growth mechanisms using femtosecond laser pulses. Opt. Express 2013, 21, 8460–8473. [Google Scholar] [CrossRef] [PubMed]

- Ahmmed, K.M.T.; Ling, E.J.Y.; Servio, P.; Kietzig, A.-M. Introducing a new optimization tool for femtosecond laser-induced surface texturing on titanium, stainless steel, aluminum and copper. Opt. Lasers Eng. 2015, 66, 258–268. [Google Scholar] [CrossRef]

- Allain, C.; Cloitre, M. Characterizing the lacunarity of random and deterministic fractal sets. Phys. Rev. A 1991, 44, 3552–3558. [Google Scholar] [CrossRef] [PubMed]

- Ling, E.J.Y.; Servio, P.; Kietzig, A.-M. Fractal and lacunarity analyses: Quantitative characterization of hierarchical surface topographies. Microsc. Microanal. 2016, 22, 168–177. [Google Scholar] [CrossRef] [PubMed]

- Lehr, J.; Kietzig, A.M. Production of homogenous micro-structures by femtosecond laser micro-machining. Opt. Lasers Eng. 2014, 57, 121–129. [Google Scholar] [CrossRef]

- Guk, I.; Shandybina, G.; Yakovlev, E. Influence of accumulation effects on heating of silicon surface by femtosecond laser pulses. Appl. Surf. Sci. 2015, 353, 851–855. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, C.S.; Shang, S.; Liu, D.; Perrie, W.; Dearden, G.; Watkins, K. A review of ultrafast laser materials micromachining. Opt. Laser Technol. 2013, 46, 88–102. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Von der Linde, D. Laser-solid interaction in the femtosecond time regime. Appl. Surf. Sci. 1997, 109–110, 1–10. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Enhanced absorptance of gold following multipulse femtosecond laser ablation. Phys. Rev. B 2005, 72, 195422. [Google Scholar] [CrossRef]

- Brorson, S.D.; Kazeroonian, A.; Moodera, J.S.; Face, D.W.; Cheng, T.K.; Ippen, E.P.; Dresselhaus, M.S.; Dresselhaus, G. Femtosecond room-temperature measurement of the electron-phonon coupling constant γ in metallic superconductors. Phys. Rev. Lett. 1990, 64, 2172–2175. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Cheng, C.W.; Chen, J.K.; Zhang, Y.; Tzou, D.Y. Thermal ablation of metal films by femtosecond laser bursts. Int. J. Ther. Sci. 2013, 70, 32–40. [Google Scholar] [CrossRef]

- Mannion, P.T.; Magee, J.; Coyne, E.; O’Connor, G.M.; Glynn, T.J. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 2004, 233, 275–287. [Google Scholar] [CrossRef]

- Ni, X.; Wang, C.-Y.; Yang, L.; Li, J.; Chai, L.; Jia, W.; Zhang, R.; Zhang, Z. Parametric study on femtosecond laser pulse ablation of au films. Appl. Surf. Sci. 2006, 253, 1616–1619. [Google Scholar] [CrossRef]

- Semmar, N.; Tebib, M.; Tesar, J.; Puscas, N.N.; Amin-Chalhoub, E. Direct observation of phase transitions by time-resolved pyro/reflectometry of krf laser-irradiated metal oxides and metals. Appl. Surf. Sci. 2009, 255, 5549–5552. [Google Scholar] [CrossRef]

- Xu, X.; Willis, D.A. Non-equilibrium phase change in metal induced by nanosecond pulsed laser irradiation. J. Heat Transf. 2001, 124, 293–298. [Google Scholar] [CrossRef]

- Martynyuk, M.M. Phase explosion of a metastable fluid. Combust. Explos. Shock Waves 1977, 13, 178–191. [Google Scholar] [CrossRef]

- Song, K.H.; Xu, X. Explosive phase transformation in excimer laser ablation. Appl. Surf. Sci. 1998, 127, 111–116. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V.; Luther-Davies, B.; Tikhonchuk, V.T. Ablation of solids by femtosecond lasers: Ablation mechanism and ablation thresholds for metals and dielectrics. Phys. Plasmas 2002, 9, 949–957. [Google Scholar] [CrossRef]

- Koch, J.; von Bohlen, A.; Hergenroder, R.; Niemax, K. Particle size distributions and compositions of aerosols produced by near-ir femto- and nanosecond laser ablation of brass. J. Anal. Atom. Spectrom. 2004, 19, 267–272. [Google Scholar] [CrossRef]

- Tillack, M.S.; Blair, D.W.; Harilal, S.S. The effect of ionization on cluster formation in laser ablation plumes. Nanotechnology 2004, 15, 390. [Google Scholar] [CrossRef]

- Sivayoganathan, M.; Tan, B.; Venkatakrishnan, K. Effect of mega-hertz repetition rate on the agglomerated particle size of femtosecond synthesized nanostructures. Opt. Mater. Express 2012, 2, 987–995. [Google Scholar] [CrossRef]

- Eaton, S.M.; Zhang, H.; Herman, P.R.; Yoshino, F.; Shah, L.; Bovatsek, J.; Arai, A.Y. Heat accumulation effects in femtosecond laser-written waveguides with variable repetition rate. Opt. Express 2005, 13, 4708–4716. [Google Scholar] [CrossRef] [PubMed]

- Piñon, V.; Anglos, D. Optical emission studies of plasma induced by single and double femtosecond laser pulses. Spectrochim. Acta Part B Atom. Spectrosc. 2009, 64, 950–960. [Google Scholar] [CrossRef]

| Microstructures in Metals | Micromachining Parameters (Wavelength, Repetition Rate, Pulse Duration, Fluence) | Reference |

|---|---|---|

| Periodic nanostructures (LIPSS) | ||

| Ni | 800 nm, 1 kHz, 500 fs, 2.04 J/ | Zuhlke et al. 2013 [19] |

| Al | 800 nm, 100 Hz, 65 fs, 0.05 J/ | Vorobyev and Guo 2008 [20] |

| Au | 800 nm, 1 kHz, 65 fs, 0.16 J/ | Vorobyev et al. 2007 [21] |

| Undulated groove microstructures | ||

| Ti | 800 nm, 1 kHz, 100 fs, 0.75 J/ | Tsukamoto et al. 2006 [12] |

| Ni | not reported, 1 kHz, 50 fs, 1.392 J/ | Zuhlke et al. 2013 [22] |

| Columnar microstructures | ||

| Ti | 800 nm, 1 kHz, 130 fs, 0.75 J/ | Nayak and Gupta 2010 [7] |

| Ni | not reported, 1 kHz, 50 fs, 1.392–3.08 J/ | Zuhlke et al. 2013 [22] |

| Al | 800 nm, 1 kHz, 130 fs, <0.16 J/ | Nayak and Gupta 2010 [7] |

| Bumpy microstructures | ||

| Al | 800 nm, 10 kHz, <100 fs, 0.4–1 J/ | Ahmmed et al. 2015 [23] |

| Ti | 800 nm, 10 kHz, <100 fs, 1.5–3 J/ | Ahmmed et al. 2015 [23] |

| Conical microstructures | ||

| Ti | 800 nm, 1 kHz, 130 fs, 0.5–1.2 J/ | Nayak and Gupta 2010 [7] |

| Ni | 800 nm, 1 kHz, 50 fs, 0.12 J/ | Zuhlke et al. 2013 [19] |

| Microstructures | Labels as in Figure 1 and Figure 2 | 1 kHz | 10 kHz | Comment |

|---|---|---|---|---|

| Cu | ||||

| Nanoforest | Figure 1a | √ | √ | Common microstructures |

| Trench: narrow | Figure 1c | √ | √ | |

| Trench | Figure 1b | √ | √ | |

| Tree bark | Figure 1e | √ | × | – |

| Stalagmite | Figure 1f | √ | × | – |

| Fish scale | Figure 1g | √ | × | – |

| Aggregate | Figure 1h | √ | × | – |

| Ti | ||||

| Undulating grooves | Figure 2a | √ | √ | Common microstructures |

| Bumps | Figure 2b | √ | √ | |

| Holes | Figure 2c | √ | √ | |

| Chaotic | Figure 2d | √ | √ | |

| Trench | – | × | √ | – |

| Stalagmite | Figure 2e | √ | × | – |

| Aggregate | Figure 2f | √ | × | – |

| Common Microstructures | Labels as in Figure 1 and Figure 2 | 1 kHz | 10 kHz |

|---|---|---|---|

| Cu | |||

| Nanoforest | Figure 1a | 120 | 88 |

| Trench:narrow | Figure 1c | 400 | 282 |

| Trench | Figure 1b | 2101 | 353 |

| Ti | |||

| Undulating grooves | Figure 2a | 80 | 90 |

| Bumps | Figure 2b | 112 | 165 |

| Holes | Figure 2c | 233 | 275 |

| Chaotic | Figure 2d | 400 | 565 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biswas, S.; Karthikeyan, A.; Kietzig, A.-M. Effect of Repetition Rate on Femtosecond Laser-Induced Homogenous Microstructures. Materials 2016, 9, 1023. https://doi.org/10.3390/ma9121023

Biswas S, Karthikeyan A, Kietzig A-M. Effect of Repetition Rate on Femtosecond Laser-Induced Homogenous Microstructures. Materials. 2016; 9(12):1023. https://doi.org/10.3390/ma9121023

Chicago/Turabian StyleBiswas, Sanchari, Adya Karthikeyan, and Anne-Marie Kietzig. 2016. "Effect of Repetition Rate on Femtosecond Laser-Induced Homogenous Microstructures" Materials 9, no. 12: 1023. https://doi.org/10.3390/ma9121023