A Possible Industrial Solution to Ferment Lignocellulosic Hydrolyzate to Ethanol: Continuous Cultivation with Flocculating Yeast

Abstract

:1. Introduction

2. Material and Methods

2.1 Dilute-acid hydrolyzates

2.2 Yeast strain and medium

2.3 Batch cultivation

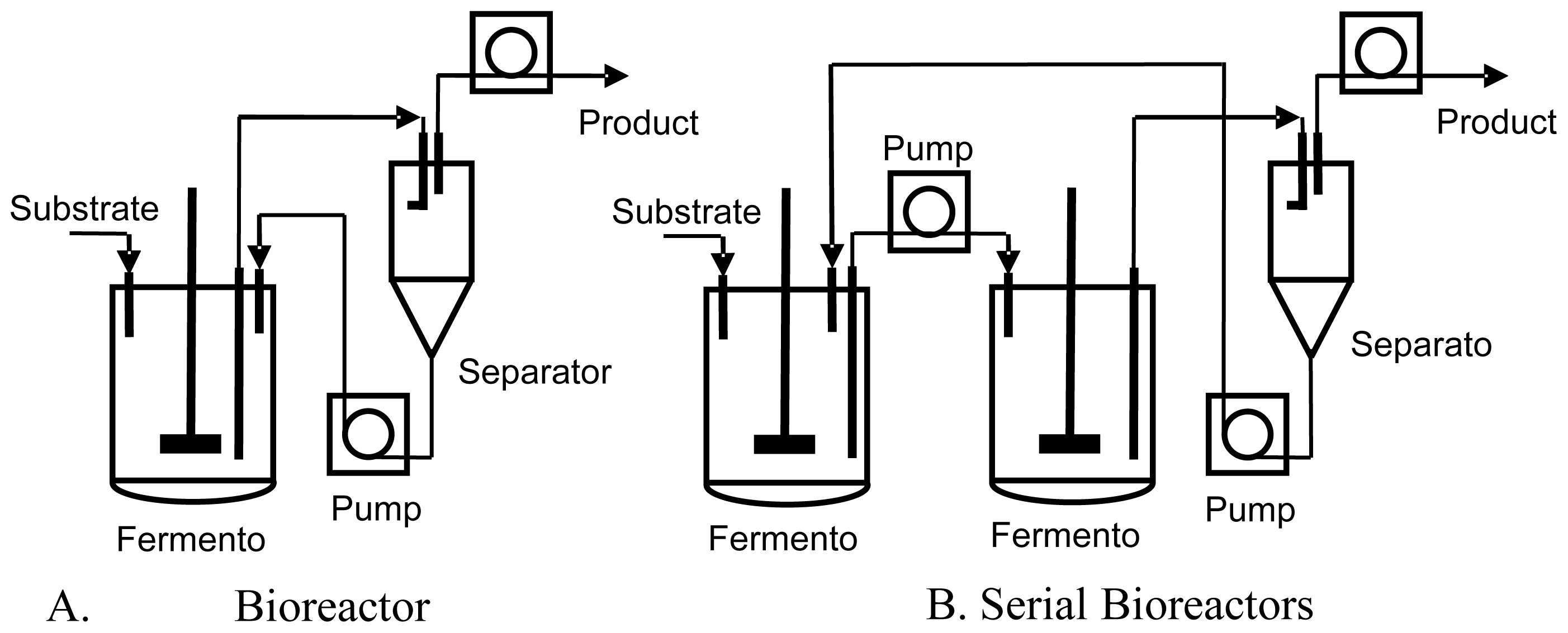

2.4 Continuous cultivation using yeast recycling system

2.5 Analytical methods

3. Results

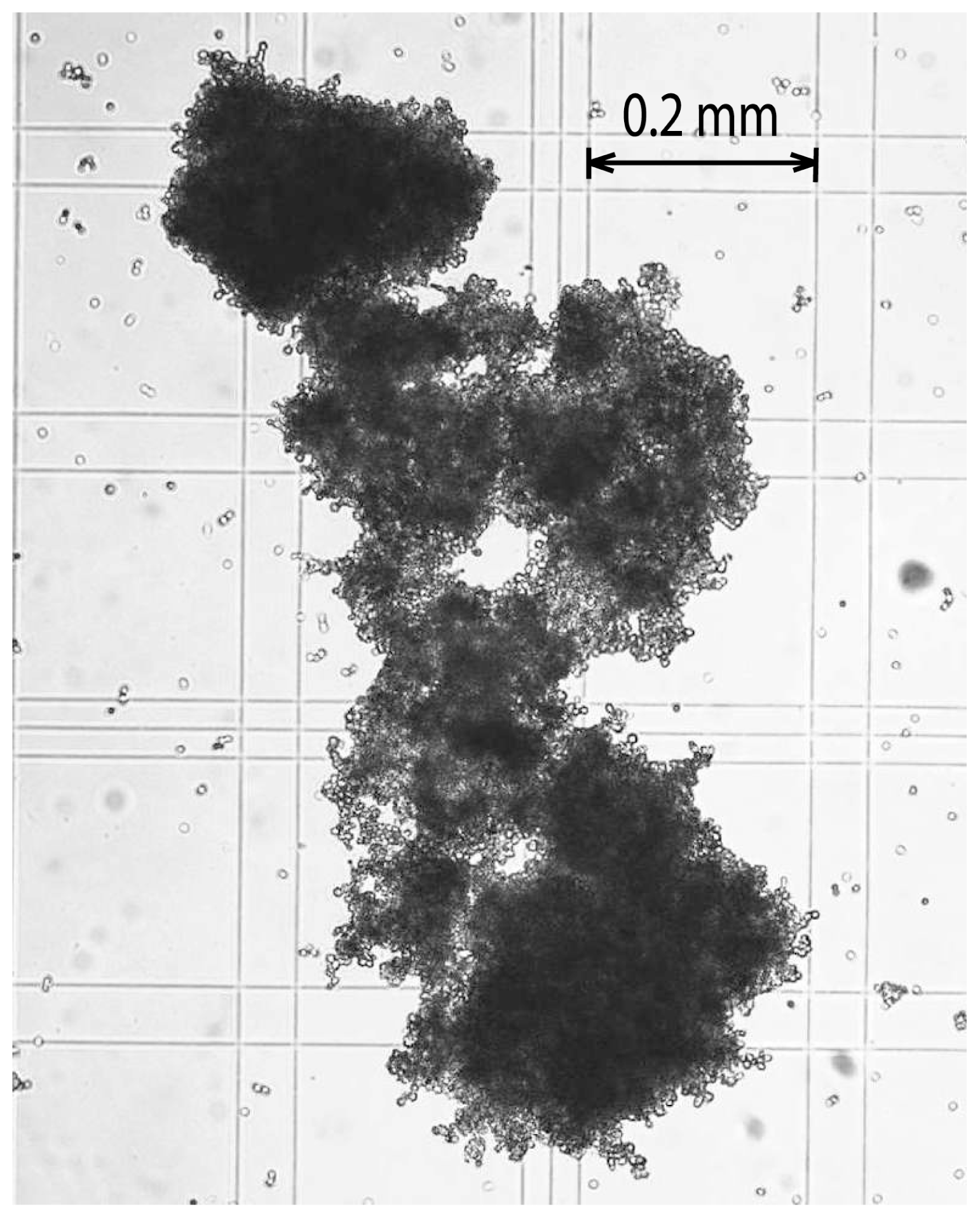

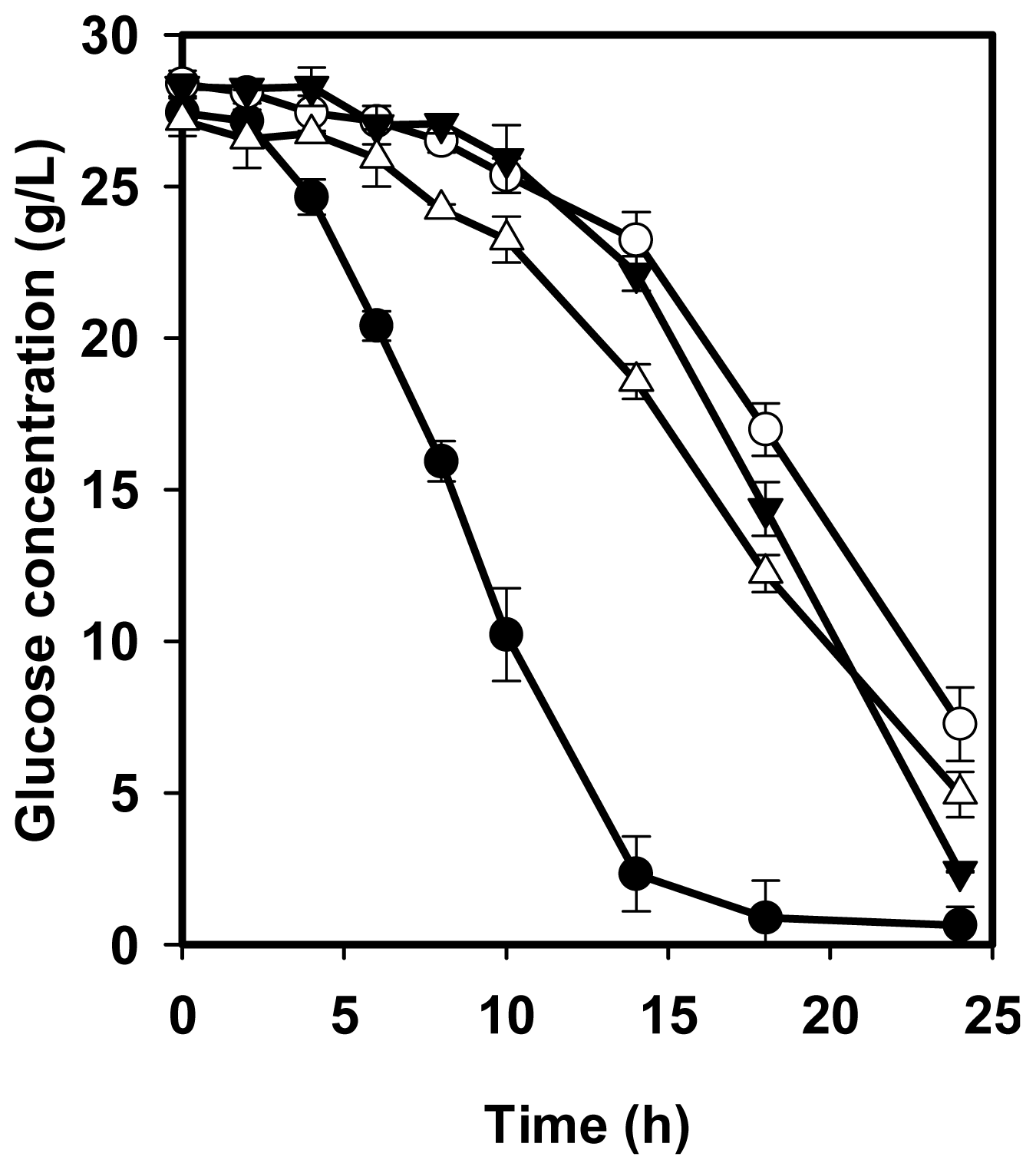

3.1 The performance of flocculating yeast

3.2 Continuous cultivation of hydrolyzates using flocculating yeast

4. Discussion

| Strain and Medium | Anaerobic Yield (g/g) | ||

|---|---|---|---|

| Glycerol | Ethanol | Biomass | |

| CBS + Glu-DSM | 0.04±0.01 | 0.47±0.03 | 0.10±0.00 |

| FY + Glu-DSM | 0.05±0.01 | 0.45±0.02 | 0.09±0.01 |

| FY + Hyd-DSM | 0.04±0.00 | 0.46±0.03 | 0.11±0.01 |

| FY + Glu-YPD | 0.05±0.01 | 0.45±0.03 | 0.14±0.01 |

| D (h−1) | Sugar Assimilation (%) | Biomass g-DW/L | Yields* (g/g) | Conversion (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Inside | Out | Ethanol | glycerol | acetate | HMF | Furfural | ||

| 0.13 | 98.8±0.4 | 27.5±0.02 | 0.35±0.01 | 0.46±0.02 | 0.05±0.03 | (0.03±0.01) | 95.9 ±3.6 | 100.0±0.0 |

| 0.24 | 98.6±0.5 | 23.8±0.04 | 0.37±0.03 | 0.45±0.04 | 0.05±0.04 | (0.03±0.01) | 96.7± 3.2 | 100.0±0.0 |

| 0.38 | 97.7±0.8 | 23.3±0.05 | 0.34±0.01 | 0.44±0.03 | 0.07±0.03 | (0.03±0.00) | 94.2±2.7 | 100.0±0.0 |

| 0.52 | 96.2±1.8 | 30.3±0.01 | 0.31±0.02 | 0.42±0.02 | 0.07±0.02 | (0.04±0.01) | 92.1±3.6 | 100.0±0.0 |

| D (h−1) | Sugar Assimilation (%) | Biomass g-DW/L | Total Yield (g/g) | |||

|---|---|---|---|---|---|---|

| 1st-fermentor | 2nd-fermentor | Inside | Out | Ethanol | Glycerol | |

| 0.24 | 98.2±0.3 | 98.3±0.3 | 25.0±0.06 | 0.29±0.03 | 0.42 ± 0.01 | 0.05 ± 0.00 |

| 0.38 | 92.6±1.3 | 96.3±0.4 | 27.6±0.03 | 0.30±0.01 | 0.43 ± 0.00 | 0.08 ± 0.00 |

| 0.52 | 87.6±0.9 | 94.3±0.5 | 35.1±0.04 | 0.27±0.03 | 0.43 ± 0.01 | 0.08 ± 0.00 |

Acknowledgments

References

- Rosillo-Calle, F.; Walter, A. Global market for bioethanol: historical trends and future prospects. Energy Sustain. Devel 2006, 10, 20–32. [Google Scholar]

- Chen, G.; Li, S.; Jiao, F; Yuan, Q. Catalytic dehydration of bioethanol to ethylene over TiO2/Al2O3 catalysts in microchannel reactors. Catal. Today 2007, 125, 111–119. [Google Scholar]

- Golay, S.; Doepper, R.; Renken, A. Reactor performance enhancement under periodic operation for the ethanol dehydration over γ–alumina, a reaction with a stop-effect. Chem. Eng. Sci 1999, 54, 4469–4474. [Google Scholar]

- Moreira, J.R.; Goldemberg, J. The alcohol program. Energy Policy 1999, 27, 229–245. [Google Scholar]

- Gil, G.H.; Jones, W.J.; Tornabene, T.G. Continuous ethanol production in a two-stage, immobilized/suspended-cell bioreactor. Enzyme Microb. Technol 1991, 13, 390–399. [Google Scholar]

- Deepchand, K.; Baguant, J. Utilization of cane tops and leaves for energy and food -- an integrated system. Biomass 1985, 7, 215–223. [Google Scholar]

- Turhollow, A.F.; Heady, E.O. Large-scale ethanol production from corn and grain sorghum and improving conversion technology. Energy Agric 1986, 5, 309–316. [Google Scholar]

- Mullins, J.T.; NeSmith, C. Integrated ethanol production and utilization system for small farms. Biomass 1984, 6, 155–166. [Google Scholar]

- Bengtson, H.H. Small scale ethanol production from corn -- technology, energy efficiency and economics. Energy Agric 1983, 2, 197–217. [Google Scholar]

- Ladisch, M.R.; Tsao, G. T. Engineering and economics of cellulose saccharification systems. Enzyme Microb. Technol 1986, 8, 66–69. [Google Scholar]

- Meo, M. Economic evaluation of ethanol fuel production from agricultural crops and residues in California. Resour. Conserv 1984, 11, 1–25. [Google Scholar]

- Galbe, M.; Zacchi, G. A review of the production of ethanol from softwood. Appl. Microbiol. Biotechnol 2002, 59, 618–628. [Google Scholar]

- Saeman, J.F. Kinetics of wood saccharification: Hydrolysis of cellulose and decomposition of sugars in dilute acid at high temperature. Ind. Eng. Chem 1945, 37, 43–52. [Google Scholar]

- Jorgensen, H.; Kutter, J.P.; Olsson, L. Separation and quantification of cellulases and hemicellulases by capillary electrophoresis. Anal. Biochem 2003, 317, 85–93. [Google Scholar]

- Zhang, Y.-H.P.; Himmel, M.E.; Mielenz, J.R. Outlook for cellulase improvement: Screening and selection strategies. Biotechnol. Adv 2006, 24, 452–481. [Google Scholar]

- Palmqvist, E.; Hahn-Hägerdal, B. Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour. Technol 2000, 74, 25–33. [Google Scholar]

- Taherzadeh, M.J.; Gustafsson, L.; Niklasson, C.; Liden, G. Inhibition effects of furfural on aerobic batch cultivation of Saccharomyces cerevisiae growing on ethanol and/or acetic acid. J. Biosci. Bioeng 2000, 90, 374–380. [Google Scholar]

- Taherzadeh, M.J.; Gustafsson, L.; Niklasson, C.; Lidén, G. Physiological effects of 5-hydroxymethylfurfural on Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol 2000, 53, 701–708. [Google Scholar]

- Olsson, L.; Hahn-Hägerdal, B. Fermentative performance of bacteria and yeasts in lignocellulose hydrolysates. Process Biochem 1993, 28, 249–257. [Google Scholar]

- Leonard, R.; Hajny, G. Fermentation of wood sugars to ethyl alcohol. Ind. Eng. Chem 1945, 37, 390–395. [Google Scholar]

- Martinez, A.; Rodriguez, M.E.; York, S.W.; Preston, J.F.; Ingram, L.O. Effects of Ca(OH)2 treatments (“overliming”) on the composition and toxicity of bagasse hemicellulose hydrolysates. Biotechnol. Bioeng 2000, 69, 526–536. [Google Scholar]

- Parajo, J.C.; Dominguez, H.; Dominguez, J.M. Charcoal adsorption of wood hydrolysates for improving their fermentability: Influence of the operational conditions. Bioresour. Technol 1996, 57, 179–185. [Google Scholar]

- Taherzadeh, M.J.; Niklasson, C.; Lidén, G. Conversion of dilute-acid hydrolyzates of spruce and birch to ethanol by fed-batch fermentation. Bioresour. Technol 1999, 69, 59–66. [Google Scholar]

- Horvath, I.S.; Taherzadeh, M.J.; Niklasson, C.; Lidén, G. Effects of furfural on anaerobic continuous cultivation of Saccharomyces cerevisiae. Biotechnol. Bioeng 2001, 75, 540–549. [Google Scholar]

- Kishimoto, M.; Nitta, Y.; Kamoshita, Y.; Suzuki, T.; Suga, K.-I. Ethanol production in an immobilized cell reactor coupled with the recycling of effluent from the bottom of a distillation column. J. Ferment. Bioeng 1997, 84, 449–454. [Google Scholar]

- Najafpour, G.; Younesi, H.; Syahidah Ku Ismail, K. Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae. Bioresour. Technol 2004, 92, 251–260. [Google Scholar]

- Ogbonna, J.C.; Mashima, H.; Tanaka, H. Scale up of fuel ethanol production from sugar beet juice using loofa sponge immobilized bioreactor. Bioresour. Technol 2001, 76, 1–8. [Google Scholar]

- Koyama, K.; Seki, M. Cultivation of yeast and plant cells entrapped in the low-viscous liquidcore of an alginate membrane capsule prepared using polyethylene glycol. J. Biosci. Bioeng 2004, 97, 111–118. [Google Scholar]

- Talebnia, F.; Taherzadeh, M.J. In situ detoxification and continuous cultivation of dilute-acid hydrolyzate to ethanol by encapsulated S. cerevisiae. J. Biotechnol 2006, 125, 377–384. [Google Scholar]

- Brandberg, T.; Sanandaji, N.; Gustafsson, L.; Franzen, C.J. Continuous Fermentation of Undetoxified Dilute Acid Lignocellulose Hydrolysate by Saccharomyces cerevisiae ATCC 96581 Using Cell Recirculation. Biotechnol. Prog 2005, 21, 1093–1101. [Google Scholar]

- Bailey, J.E.; Ollis, D.F. Biochemical Engineering Fundamental; McGraw-Hill: New York, 1986. [Google Scholar]

- Verstrepen, K.J.; Derdelinckx, G.; Verachtert, H.; Delvaux, F.R. Yeast flocculation: what brewers should know. Appl. Microbiol. Biotechnol 2003, 61, 197–205. [Google Scholar]

- Taherzadeh, M.J.; Millati, R.; Niklasson, C. Continuous cultivation of dilute-acid hydrolysates to ethanol by immobilized Saccharomyces cerevisiae. Appl. Biochem. Biotechnol 2001, 95, 45–57. [Google Scholar]

- Millati, R.; Niklasson, C.; Taherzadeh, M.J. Effect of pH, time and temperature of overliming on detoxification of dilute-acid hydrolyzates for fermentation by Saccharomyces cerevisiae. Process Biochem 2002, 38, 515–522. [Google Scholar]

- Franzen, C.J.; Albers, E.; Niklasson, C. Use of the inlet gas composition to control the respiratory quotient in microaerobic bioprocesses. Chem. Eng. Sci 1996, 51, 3391–3402. [Google Scholar]

- Purwadi, R.; Niklasson, C.; Taherzadeh, M.J. Kinetic study of detoxification of dilute-acid hydrolyzates by Ca(OH)2. J. Biotechnol 2004, 114, 187–198. [Google Scholar]

- Taherzadeh, M.J.; Niklasson, C.; Lidén, G. Acetic acid--friend or foe in anaerobic batch conversion of glucose to ethanol by Saccharomyces cerevisiae? Chem. Eng. Sci 1997, 52, 2653–2659. [Google Scholar]

- Vicente, A.A.; Dluhy, M.; Ferreira, E.C.; Mota, M.; Teixeira, J.A. Mass transfer properties of glucose and O2 in Saccharomyces cerevisiae flocs. Biochem. Eng. J 1998, 2, 35–43. [Google Scholar]

© 2007 by MDPI Reproduction is permitted for noncommercial purposes.

Share and Cite

Purwadi, R.; Brandberg, T.; Taherzadeh, M.J. A Possible Industrial Solution to Ferment Lignocellulosic Hydrolyzate to Ethanol: Continuous Cultivation with Flocculating Yeast. Int. J. Mol. Sci. 2007, 8, 920-932. https://doi.org/10.3390/i8090920

Purwadi R, Brandberg T, Taherzadeh MJ. A Possible Industrial Solution to Ferment Lignocellulosic Hydrolyzate to Ethanol: Continuous Cultivation with Flocculating Yeast. International Journal of Molecular Sciences. 2007; 8(9):920-932. https://doi.org/10.3390/i8090920

Chicago/Turabian StylePurwadi, Ronny, Tomas Brandberg, and Mohammad J. Taherzadeh. 2007. "A Possible Industrial Solution to Ferment Lignocellulosic Hydrolyzate to Ethanol: Continuous Cultivation with Flocculating Yeast" International Journal of Molecular Sciences 8, no. 9: 920-932. https://doi.org/10.3390/i8090920

APA StylePurwadi, R., Brandberg, T., & Taherzadeh, M. J. (2007). A Possible Industrial Solution to Ferment Lignocellulosic Hydrolyzate to Ethanol: Continuous Cultivation with Flocculating Yeast. International Journal of Molecular Sciences, 8(9), 920-932. https://doi.org/10.3390/i8090920