Effects of Cultivar and Process Variables on Dynamic-Mechanical and Sensorial Behavior of Value-Added Grape-Based Smoothies

Abstract

:1. Introduction

2. Results and Discussion

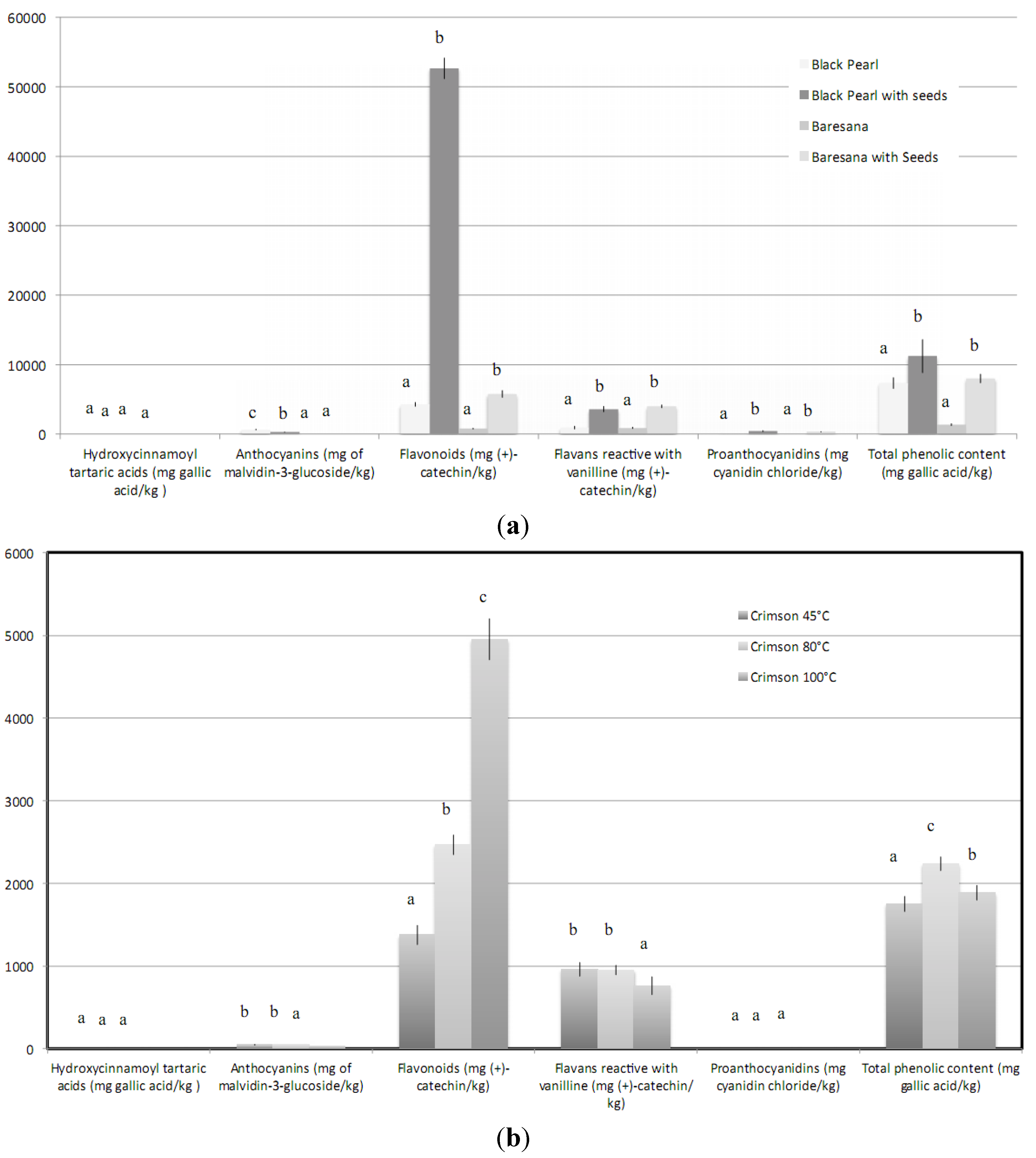

2.1. Phenolic Content

2.2. Sensorial Aspects

| Cultivar | Process variables | Presence of seeds parts | Presence of lumps | Astringency | Overall Likeability Score |

|---|---|---|---|---|---|

| Black Pearl | Without seed enrichment | 0.0 ± 0.0 a | - | 1.75 ± 1.71 a | 2.6 ± 1.52 a |

| With seed enrichment | 2.0 ± 1.58 b | - | 1.8 ± 1.10 a | 3.8 ± 0.84 a | |

| Baresana | Without seed enrichment | 0.0 ± 0.0 a | - | 0.75 ± 0.96 a | 4.0 ± 2.0 a |

| With seed enrichment | 2.2 ± 0.84 b | - | 2.0 a ± 1.22 b | 2.8 ± 1.64 a | |

| Crimson seedless | 45 °C | - | 1.2 ± 2.17 a | - | 3.6 ± 1.52 a |

| 80 °C | - | 0.8 ± 1.79 a | - | 4.0 ± 1.73 a | |

| 100 °C | - | 1.2 ± 1.79 a | - | 2.6 ± 2.19 a |

2.3. Rheological Aspects

| Cultivar | Process variables | G’ | G” | tanδ |

|---|---|---|---|---|

| Black Pearl | Without seed enrichment | 1,302.81 ± 145.5 a | 419.60 ± 45.29 a | 0.32 ± 0.002 a |

| With seed enrichment | 18,081.51 ± 5,819.02 b | 6,977.30 ± 241.41 b | 0.46 ± 0.029 b | |

| Baresana | Without seed enrichment | 238.80 ± 69.31 a | 77.38 ± 21.80 a | 0.32 ± 0.002 b |

| With seed enrichment | 1,762.25 ± 274.89 b | 511.72 ± 95.30 b | 0.28 ± 0.009 a | |

| Crimson | 45 °C | 1,271.26 ± 410.14 b | 290.51 ± 104.31 b | 0.29 ± 0.003 a |

| 80 °C | 824.08 ± 115.13 b | 293.78 ± 88.83 b | 0.29 ± 0.007 a | |

| 100 °C | 73.37 ± 10.18 a | 21.77 ± 2.93 a | 0.29 ± 0.001 a |

2.4. Correlation between Sensorial and Rheological Characteristics

| Black Pearl/Baresana | G’ | G” | tanδ | Presence of seeds parts | Overall Likeability Score |

|---|---|---|---|---|---|

| G’ | 1.000000 | - | - | - | - |

| G” | 0.999804 | 1.000000 | - | - | - |

| tand | 0.955220 | 0.960616 | 1.000000 | - | - |

| Presence of seed particles | −0.514591 | −0.529541 | −0.670555 | 1.000000 | - |

| Overall Liking Score | 0.413307 | 0.427125 | 0.540992 | −0.976354 | 1.000000 |

| Crimson | G’ | G” | tan | Presence of lumps | Overall Liking Score |

| G’ | 1.000000 | - | - | - | - |

| G” | 0.925361 | 1.000000 | - | - | - |

| tand | −0.989468 | −0.860741 | 1.000000 | - | - |

| Presence of lumps | −0.144752 | −0.509043 | 0.000000 | 1.000000 | - |

| Overall Liking Score | 0.790378 | 0.963621 | −0.693375 | −0.720577 | 1.000000 |

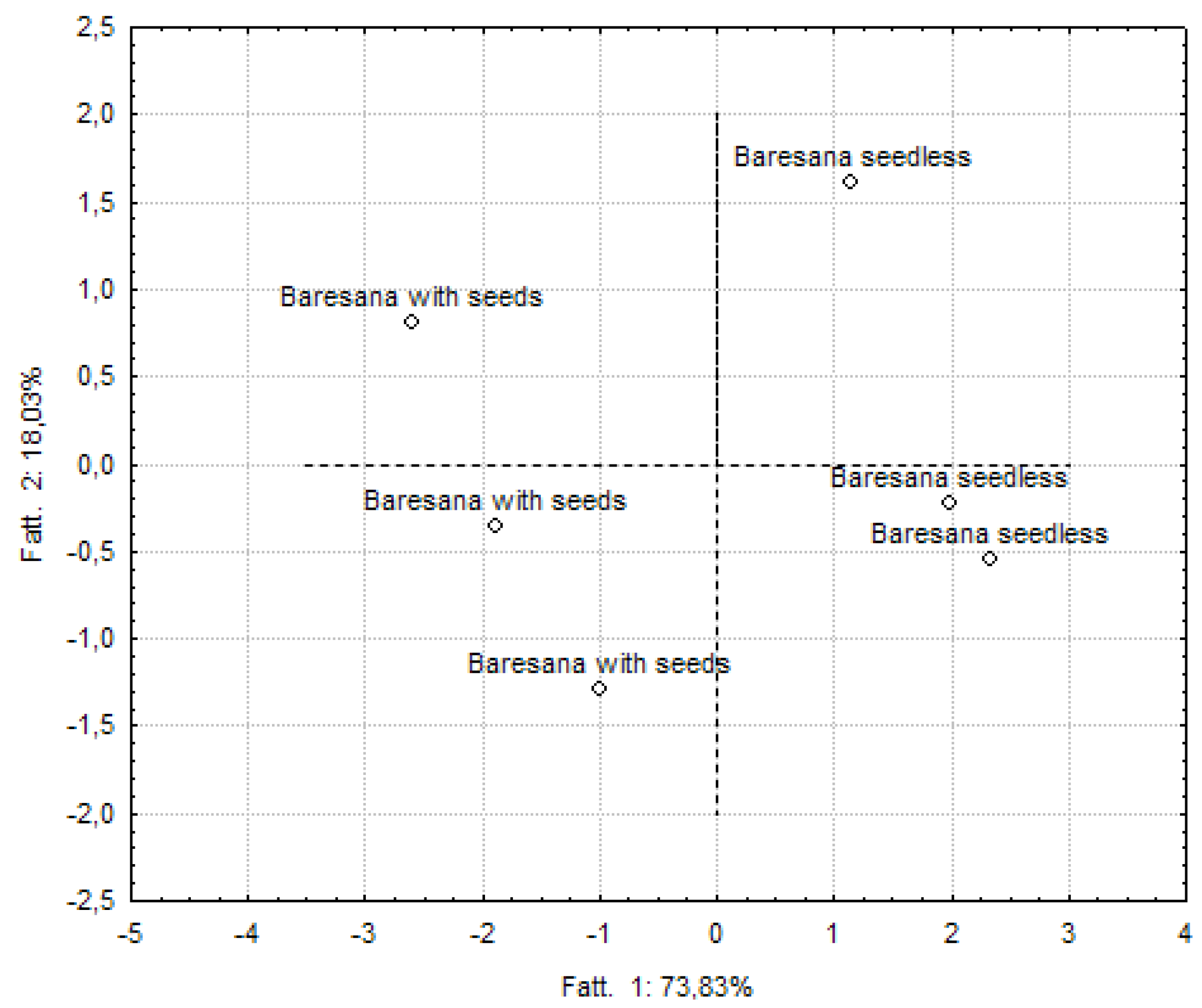

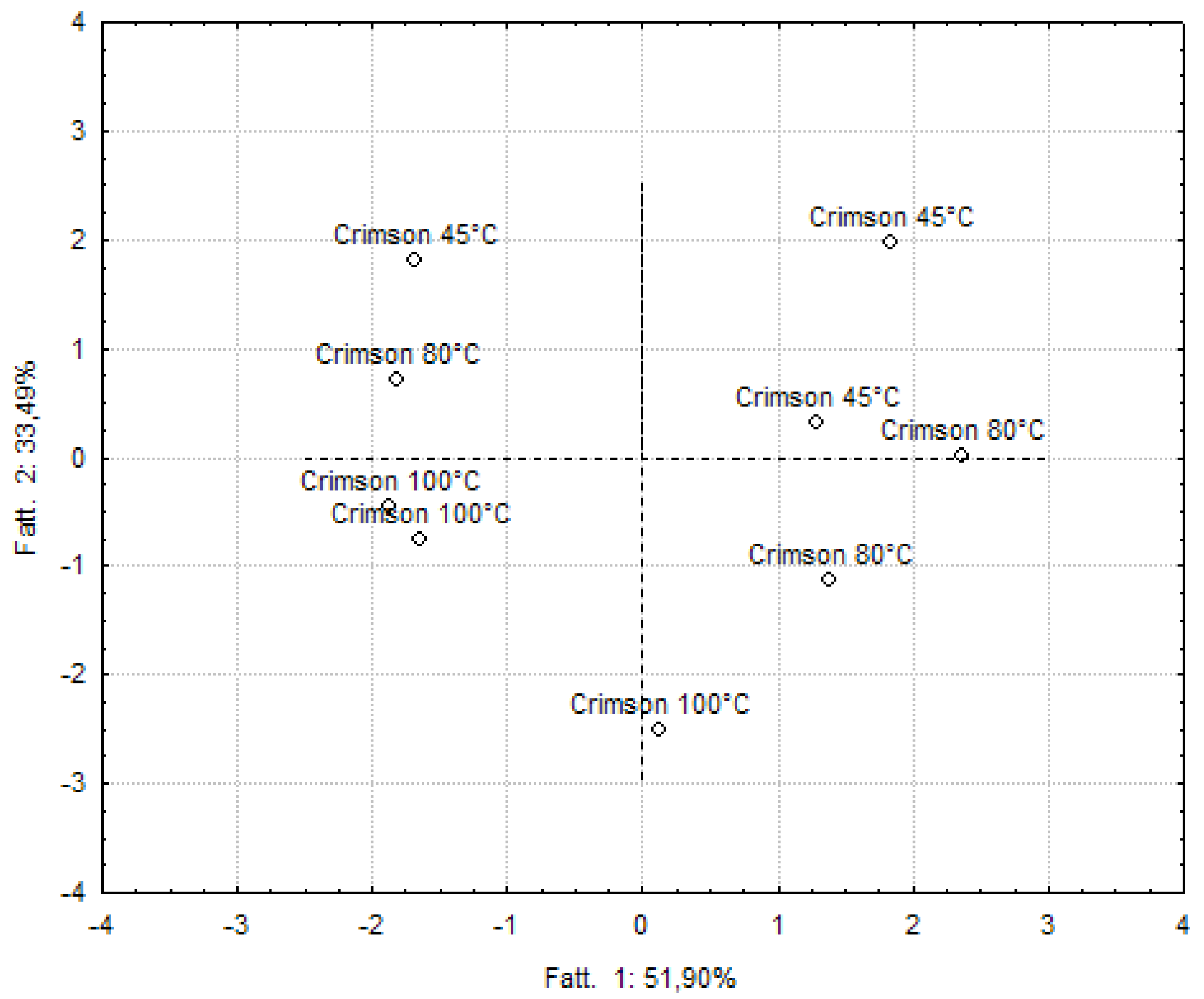

2.5. Classification of Samples Based On Formulations or Processing Conditions

3. Experimental

3.1. Grape Production

3.2. Smoothie Processing

3.3. Extraction and Determination of the Phenolic Content

3.4. Sensorial Analysis

3.5. Rheological Analyses

3.6. Data Analysis

4. Conclusions

References and Notes

- Hermann, K. Occurrence and content of hydroxycinnamic and hydroxybenzoic acid compounds in foods. Crit. Rev. Food Sci. Nutr. 1989, 28, 315–347. [Google Scholar]

- Iriti, M.; Rossoni, M.; Borgo, M.; Ferrara, L.; Faoro, F. Induction of resistance to gray mold with benzothiadiazole modifies amino acids profile and increases proanthocyanidins in grape: Primary versus secondary metabolism. J. Agric. Food Chem. 2005, 53, 9133–9139. [Google Scholar] [CrossRef]

- Shi, J.; Yu, J.; Pohorly, J.E.; Kakuda, Y. Polyphenolics in grape seeds-biochemistry and functionality. J. Med. Food 2003, 6, 291–299. [Google Scholar] [CrossRef]

- Qian, N. Fruit and vegetable smoothies, and its processing method. Faming Zhuanli Shenqing Gongkai Shuomingshu, CN 1817192, 2006. [Google Scholar]

- Ferracane, R.; Pellegrini, N.; Visconti, A.; Graziani, G.; Chiavaro, E.; Miglio, C.; Fogliano, V. Effects of different cooking methods on antioxidant profile, antioxidant capacity, and physical characteristics of artichoke. J. Agric. Food Chem. 2008, 57, 5734–5742. [Google Scholar]

- Rickman, J.C.; Barrett, D.M.; Bruhn, C.M. Nutritional comparison of fresh, frozen and canned fruits and vegetables. Part 1. Vitamins C and B and phenolic compounds. J. Sci. Food Agric. 2007, 87, 930–944. [Google Scholar] [CrossRef]

- Basu, S.; Shivhare, U.S.; Singh, T.V.; Beniwal, V.S. Rheological, textural and spectral characteristics of sorbitol substituted mango jam. J. Food Eng. 2011, 105, 503–512. [Google Scholar] [CrossRef]

- Kokini, J.L.; Plutchok, G.J. Viscoelastic properties of semisolid foods and their biopolymers components. Food Technol. 1987, 41, 89–95. [Google Scholar]

- Dervisi, P.; Lamb, J.; Zabetakis, I. High pressure processing in jam manufacture: Effect on textural and colour properties. Food Chem. 2001, 73, 85–91. [Google Scholar] [CrossRef]

- Carbonell, E.; Costell, E.; Duran, L. Rheological behavior of sheared jams: Relation with fruit content. J. Texture Stud. 1991, 22, 33–34. [Google Scholar] [CrossRef]

- Carbonell, E.; Costell, E.; Duran, L. Rheological indices of fruit content in jams: Influence of formulation on time-dependent flow of sheared strawberry and peach jam. J. Texture Stud. 1991, 22, 457–471. [Google Scholar] [CrossRef]

- Gabriele, D.; de Cindio, B.; D’Antona, P. A weak gel model for foods. Rheol. Acta 2001, 40, 120–127. [Google Scholar] [CrossRef]

- lvarez, E.; Cancela, M.A.; Maceiras, R. Effect of temperature on rheological properties of different jams. Int. J. Food Prop. 2006, 9, 135–146. [Google Scholar] [CrossRef]

- Rababah, T.M.; Al-Mahasneh, M.A.; Kilani, I.; Yang, W.; Alhamad, M.N.; Ereifej, K.; Al-u’datt, A. Effect of jam processing and storage on total phenolics, antioxidant activity, and anthocyanins of different fruits. J. Sci. Food Agric. 2011, 91, 1096–1102. [Google Scholar] [CrossRef]

- Corona, O.; Squadrito, M.; Borsa, D.; di Stefano, R. Behaviour of some compounds with λMAX at 280 nm in the determination of total flavonoids of grape skin extracts made from a hydroalcoholic SO2-rich solvent. Ital. J. Food Sci. 2010, 22, 347–351. [Google Scholar]

- Häkkinen, S.H.; Kärenlampi, S.O.; Mykkänen, H.M.; Törrönen, A.R. Influence of domestic processing and storage on flavonol contents in berries. J. Agric. Food Chem. 2000, 48, 2960–2965. [Google Scholar] [CrossRef]

- Amakura, Y.; Umino, Y.; Tsuji, S.; Tonogai, Y. Influence of jam processing on the radical scavenging activity and phenolic content in berries. J. Agric. Food Chem. 2000, 48, 6292–6297. [Google Scholar]

- Howard, L.R.; Castrodale, C.; Brownmiller, C.; Mauromoustakos, A. Jam processing and storage effects on blueberry polyphenolics and antioxidant capacity. J. Agric. Food Chem. 2010, 58, 4022–4029. [Google Scholar] [CrossRef]

- Zafrilla, P.; Ferreres, F.; Tomás-Barberán, F.A. Effect of processing and storage on the antioxidant ellagic acid derivatives and flavonoids of red raspberry (Rubus idaeus) jams. J. Agric. Food Chem. 2001, 49, 3651–3655. [Google Scholar] [CrossRef]

- Poiana, M.-A.; Moigradean, D.; Dogaru, D. Constantin mateescu, diana raba, iosif gergen Processing and storage impact on the antioxidant properties and color quality of some low sugar fruit jams. Rom. Biotechnol. Lett. 2011, 16, 6505–6512. [Google Scholar]

- Cheynier, V. Flavonoids in Wine. In Flavonoids—Chemistry, Biochemistry and Applications; Andersen, O.M., Markham, K.R., Eds.; Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Nakamura, K.; Kiriyama, M.; Takada, A.; Maeda, H.; Nemoto, N. Structure and dynamics of ovalbumin gel III. Solvent effect. Rheol. Acta 1997, 36, 252–261. [Google Scholar]

- Rosalina, I.; Bhattacharya, M. Flow curves, stress relaxation and creep measurements of starch gels. J. Texture Stud. 2001, 32, 247–269. [Google Scholar] [CrossRef]

- Goncalves, M.P.; Sittikijyothin, W.; da Silva, M.V.; Lefebvre, J. A study of the effect of locust bean gum on the rheological behaviour and microstructure of a b-lactoglobulin gel at pH 7. Rheol. Acta 2004, 43, 472–481. [Google Scholar] [CrossRef]

- Igual, M.; Contreras, C.; Martínez-Navarrete, N. Non-conventional techniques to obtain grapefruit jam. Innovat. Food Sci. Emerg. Technol. 2010, 11, 335–341. [Google Scholar] [CrossRef]

- Mounsey, J.S.; O’Riordan, E.D. Characteristics of imitation cheese containing native starches. J. Food Sci. 2001, 66, 586–591. [Google Scholar] [CrossRef]

- Castelló, M.L.; Heredia, A.; Domínguez, E.; Ortolá, M.D.; Tarrazó, J. Influence of thermal treatment and storage on astringency and quality of a spreadable product from persimmon fruit. Food Chem. 2011, 12, 323–329. [Google Scholar]

- Guerrero, S.N.; Alzamora, S.M. Effect of pH, Temperature and Glucose Addition on Flow Behaviour of Fruit Purees: II. Peach, Papaya and Mango Purèes. J. Food Eng. 1998, 37, 77–101. [Google Scholar] [CrossRef]

- Saravacos, G.D. Effect of temperature on viscosity of fruit juices and purees. J. Food Sci. 1970, 35, 123–125. [Google Scholar]

- Chin, N.L.; Chan, S.M.; Yusof, Y.A.; Chuah, T.G.; Talib, R.A. Modelling of rheological behaviour of pummelo juice concentrates using master-curve. J. Food Eng. 2009, 93, 134–140. [Google Scholar] [CrossRef]

- Vitali, A.A.; Rao, M.A. Flow behaviour of guava puree as a function of temperature and concentration. J. Texture Stud. 1982, 13, 275–289. [Google Scholar] [CrossRef]

- Duran, I.; Costell, E. Rheology of apricot puree: Characterisation of flow. J. Texture Stud. 1982, 13, 43–58. [Google Scholar] [CrossRef]

- Ibarz, A.; Gonzalez, C.; Esplugas, S.; Vicente, M. Rheology of clarified fruit juices I: Peach juices. J. Food Eng. 1992, 15, 49–61. [Google Scholar]

- Ibarz, A.; Gonzalez, C.; Esplugas, S. Rheology of clarified fruit juices III: Orange juices. J. Food Eng. 1994, 17, 320–323. [Google Scholar]

- Constenla, D.T.; Lozano, J.E.; Crapiste, G.H. Thermophysical properties of clarified apple juice as a function of concentration and temperature. J. Food Sci. 1989, 54, 663–668. [Google Scholar] [CrossRef]

- Bayindirli, L. Density and viscosity of grape juice as a function of concentration and temperature. J. Food Process. Pres. 1993, 17, 147–151. [Google Scholar] [CrossRef]

- Di Stefano, R.; Cravero, M.C. Metodi per lo studio dei polifenoli delle uve. Rivista di Viticoltura ed Enologia 1991, 2, 37–43. [Google Scholar]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Sample Availability: Not available.

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Baiano, A.; Mastromatteo, M.; Del Nobile, M.A. Effects of Cultivar and Process Variables on Dynamic-Mechanical and Sensorial Behavior of Value-Added Grape-Based Smoothies. Molecules 2012, 17, 11421-11434. https://doi.org/10.3390/molecules171011421

Baiano A, Mastromatteo M, Del Nobile MA. Effects of Cultivar and Process Variables on Dynamic-Mechanical and Sensorial Behavior of Value-Added Grape-Based Smoothies. Molecules. 2012; 17(10):11421-11434. https://doi.org/10.3390/molecules171011421

Chicago/Turabian StyleBaiano, Antonietta, Marcella Mastromatteo, and Matteo Alessandro Del Nobile. 2012. "Effects of Cultivar and Process Variables on Dynamic-Mechanical and Sensorial Behavior of Value-Added Grape-Based Smoothies" Molecules 17, no. 10: 11421-11434. https://doi.org/10.3390/molecules171011421

APA StyleBaiano, A., Mastromatteo, M., & Del Nobile, M. A. (2012). Effects of Cultivar and Process Variables on Dynamic-Mechanical and Sensorial Behavior of Value-Added Grape-Based Smoothies. Molecules, 17(10), 11421-11434. https://doi.org/10.3390/molecules171011421