Polymers 2020, 12(7), 1549; https://doi.org/10.3390/polym12071549 - 13 Jul 2020

Cited by 25 | Viewed by 5437

Abstract

Epoxy adhesives are widely used in various industries because of their high heat and chemical resistance, high cohesion, and minimal shrinkage. Recently, epoxy adhesives have been applied in the automotive industry as structural adhesives for lightweight vehicles. However, the brittleness of the epoxy

[...] Read more.

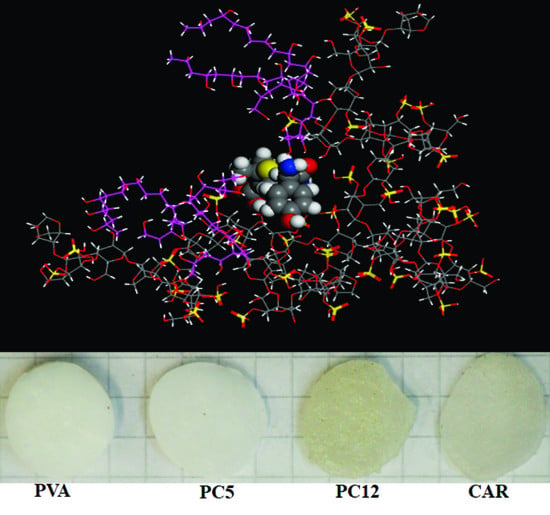

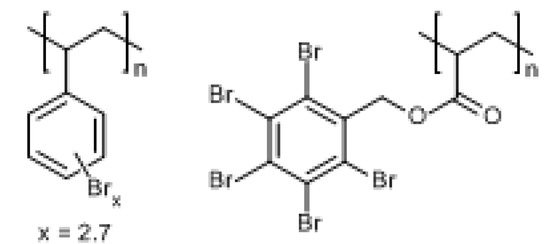

Epoxy adhesives are widely used in various industries because of their high heat and chemical resistance, high cohesion, and minimal shrinkage. Recently, epoxy adhesives have been applied in the automotive industry as structural adhesives for lightweight vehicles. However, the brittleness of the epoxy is an obstacle for this application, since the automotive industry requires epoxy-based structural adhesives to have a high level of high-speed impact resistance. Hence, we used phenol-terminated polyurethane (PTPU) as a toughening agent for epoxy adhesives and compared the results with those that were obtained with carboxyl-terminated butadiene acrylonitrile copolymer (CTBN). The high-energy impact resistance of the epoxy adhesives was measured by the impact wedge-peel (IWP) test, and the shear strength was measured by the single lap joint test. As a result, the 20 wt % PTPU-modified epoxy adhesive showed remarkably higher total absorbed energy (25.8 J) during the IWP test and shear strength (32.3 MPa) as compared with the control epoxy adhesive (4.1 J and 20.6 MPa, respectively). In particular, the total absorbed energy of the PTPU-modified epoxy adhesive was much larger than that of the CTBN-modified epoxy adhesive (5.8 J). When more than 10 wt % PTPU was added, the modified epoxy adhesives showed stable crack growth and effectively transferred external stress to the substrate. These results were explained by changes in the glass transition temperature, crosslinking density, and morphology due to the toughening agents.

Full article

(This article belongs to the Section Polymer Processing and Engineering)

►

Show Figures