Polymers 2020, 12(7), 1504; https://doi.org/10.3390/polym12071504 - 7 Jul 2020

Cited by 12 | Viewed by 6057

Abstract

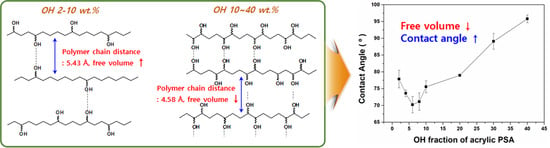

Hydrophilic acrylic pressure-sensitive adhesives (PSAs) were synthesized by controlling the contents of 2-ethylhexyl acrylate (EHA), isobornyl acrylate (IBOA), and 2-hydroxyethyl acrylate (HEA); especially, the characteristic change of the HEA content was analyzed. Surface contact angle of acrylic PSA film decreased from 77.87° to

[...] Read more.

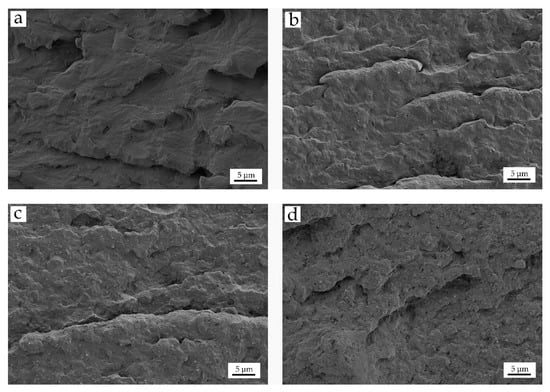

Hydrophilic acrylic pressure-sensitive adhesives (PSAs) were synthesized by controlling the contents of 2-ethylhexyl acrylate (EHA), isobornyl acrylate (IBOA), and 2-hydroxyethyl acrylate (HEA); especially, the characteristic change of the HEA content was analyzed. Surface contact angle of acrylic PSA film decreased from 77.87° to 70.23° in the case of Acryl-2 to Acryl-8 (below HEA 10 wt %). However, the surface contact angle of Acryl-10 to Acryl-40 (HEA 10 wt % to 40 wt %) increased up to 92.29°, indicating hydrophobicity. All acrylic PSA films showed high adhesive force above 1800 gf/25 mm. According to X-ray diffraction (XRD) measurement, hydrophilic acrylic PSAs exhibited amorphous property and it was confirmed that the morphology of acrylic PSA film was significantly affected by the flexibility of the polymer chain and the strength of hydrogen bonding. The affinity with hydrophilic materials for acrylic PSA films was evaluated by T-type peel test, confirming that the affinity with hydrophilic materials is determined by the hydrophilicity of the acrylic PSA film. The synthesized acrylic PSA film is non-toxic regardless of the hydrophilicity.

Full article

(This article belongs to the Collection Polymeric Adhesives)

►

Show Figures