Polymers 2020, 12(10), 2312; https://doi.org/10.3390/polym12102312 - 9 Oct 2020

Cited by 11 | Viewed by 2716

Abstract

The development of mixed matrix membranes (MMMs) for effective gas separation has been gaining popularity in recent years. The current study aimed at the fabrication of MMMs incorporated with various loadings (0–4 wt%) of functionalized KIT-6 (NH2KIT-6) [KIT: Korea Advanced Institute

[...] Read more.

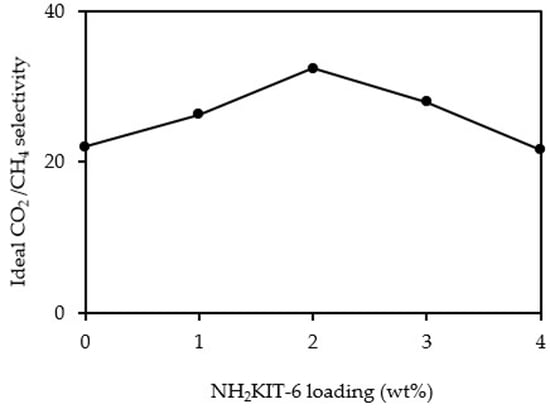

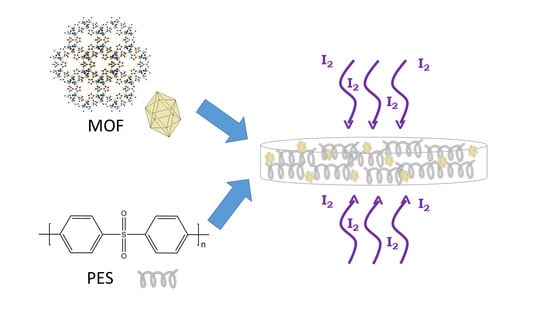

The development of mixed matrix membranes (MMMs) for effective gas separation has been gaining popularity in recent years. The current study aimed at the fabrication of MMMs incorporated with various loadings (0–4 wt%) of functionalized KIT-6 (NH2KIT-6) [KIT: Korea Advanced Institute of Science and Technology] for enhanced gas permeation and separation performance. NH2KIT-6 was characterized by field emission scanning electron microscope (FESEM), X-ray diffraction (XRD), Fourier transform infrared (FTIR), and N2 adsorption–desorption analysis. The fabricated membranes were subjected to FESEM and FTIR analyses. The effect of NH2KIT-6 loading on the CO2 permeability and ideal CO2/CH4 selectivity of the fabricated membranes were investigated in gas permeation and separation studies. The successfulness of (3-Aminopropyl) triethoxysilane (APTES) functionalization on KIT-6 was confirmed by FTIR analysis. As observed from FESEM images, MMMs with no voids in the matrix were successfully fabricated at a low NH2KIT-6 loading of 0 to 2 wt%. The CO2 permeability and ideal CO2/CH4 selectivity increased when NH2KIT-6 loading was increased from 0 to 2 wt%. However, a further increase in NH2KIT-6 loading beyond 2 wt% led to a drop in ideal CO2/CH4 selectivity. In the current study, a significant increase of about 47% in ideal CO2/CH4 selectivity was achieved by incorporating optimum 2 wt% NH2KIT-6 into the MMMs.

Full article

(This article belongs to the Special Issue Polymeric Membrane Materials for Separation Liquid and Gas Mixtures)

►

Show Figures