Materials 2020, 13(7), 1691; https://doi.org/10.3390/ma13071691 - 4 Apr 2020

Cited by 6 | Viewed by 3562

Abstract

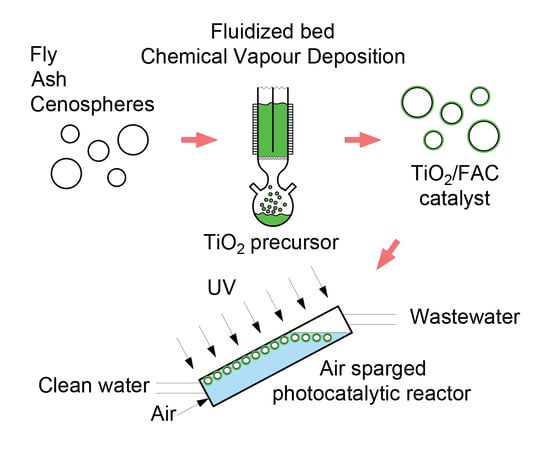

The results of a photocatalytic process performed in a new type of inclined, three-phase fluidised bed reactor with a periodic photocatalyst film are presented. These phases were fly ash cenospheres coated with TiO2, an aqueous solution of methylene blue and an

[...] Read more.

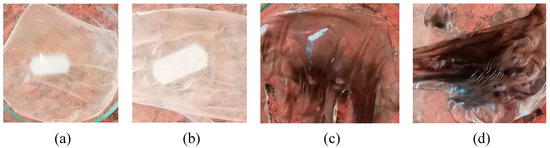

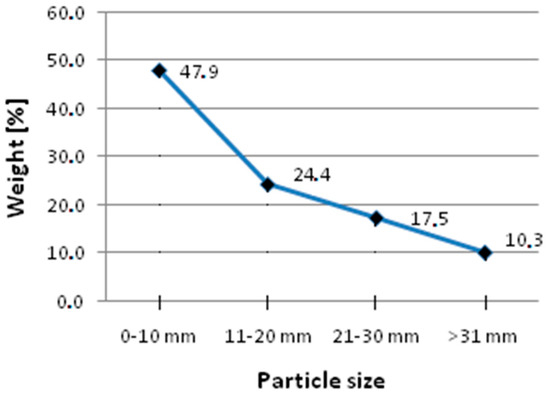

The results of a photocatalytic process performed in a new type of inclined, three-phase fluidised bed reactor with a periodic photocatalyst film are presented. These phases were fly ash cenospheres coated with TiO2, an aqueous solution of methylene blue and an air stream passing from the bottom of the photoreactor. The cenospheres have a density lower than water and could thus form a catalytic film on a top irradiated window. The formed surface film is stable but is easy to break and be reproduced in a cyclic air-sparged process. Mixing was performed in either a cyclic or a continuous manner. From an operational point of view, the best variant of mixing was a 10 s air-sparge/10 s break with a 50% duty cycle, because it provided the same discolouration efficiency and reduced energy demand by 50% in comparison with the continuous mixing. Due to film formation, the proposed catalytic reactor enables a substantial reduction in the energy required for mixing while maintaining the desired degree of discolouration.

Full article

(This article belongs to the Collection Catalysts: Preparation, Catalytic Performance and Catalytic Reaction)

►

Show Figures