1

School of Information Engineering, Jimei University, Xiamen 361021, China

2

Graduate Institute of Optoelectronic Engineering, National Chung Hsing University, Taichung 402, Taiwan

3

Department of Chemical and Materials Engineering, National University of Kaohsiung, Kaohsiung 811, Taiwan

Materials 2018, 11(9), 1501; https://doi.org/10.3390/ma11091501 - 22 Aug 2018

Cited by 17 | Viewed by 4832

Abstract

In this study, a radio frequency magnetron sputtering process was used to deposit F-doped ZnO (FZO) films on polyimide (PI) substrates. The thermal expansion effect of PI substrates induces distortion and bending, causing FZO films to peel and their electrical properties and crystallinity

[...] Read more.

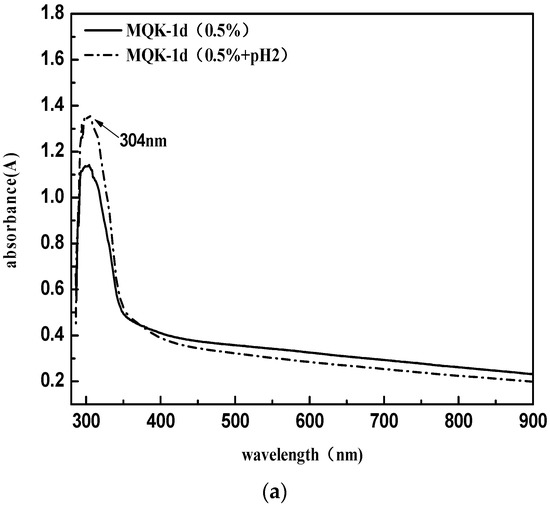

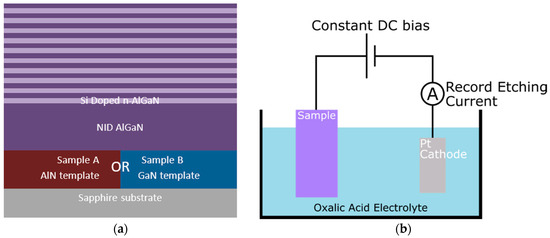

In this study, a radio frequency magnetron sputtering process was used to deposit F-doped ZnO (FZO) films on polyimide (PI) substrates. The thermal expansion effect of PI substrates induces distortion and bending, causing FZO films to peel and their electrical properties and crystallinity to deteriorate. To address these shortcomings, oxygen (O2) plasma was used to pretreat the surface of PI substrates using a plasma-enhanced chemical vapor deposition system before the FZO films were deposited. The effects of O2 plasma pretreatment time on the surface water contact angle, surface morphologies, and optical properties of the PI substrates were investigated. As the pretreatment time increased, so did the roughness of the PI substrates. After the FZO films had been deposited on the PI substrates, variations in the surface morphologies, crystalline structure, composition, electrical properties, and optical properties were investigated as a function of the O2 plasma pretreatment time. When this was 30 s, the FZO films had optimal optical and electrical properties. The resistivity was 3.153 × 10−3 Ω-cm, and the transmittance ratios of all films were greater than 90%. The X-ray photoelectron spectroscopy spectra of the FZO films, particularly the peaks for O1s, Zn 2p1/2, and Zn 2p3/2, were determined for films with O2 plasma pretreatment times of 0 and 30 s. Finally, a HCl solution was used to etch the surfaces of the deposited FZO films, and silicon-based thin-film solar cells were fabricated on the FZO/PI substrates. The effect of O2-plasma pretreatment time on the properties of the fabricated solar cells is thoroughly discussed.

Full article

(This article belongs to the Special Issue Selected Papers from IEEE ICASI 2018)

▼

Show Figures