Polyolefins: The Ever-Thriving Thermoplastics

A special issue of Polymers (ISSN 2073-4360). This special issue belongs to the section "Polymer Applications".

Deadline for manuscript submissions: closed (20 July 2022) | Viewed by 7313

Special Issue Editor

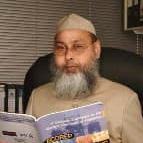

Interests: polyolefin catalyst; synthesis; characterization; and applications; synthetic lubricant; drag-reducing poly(a-olefin)

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

Polyolefins are the largest volume thermoplastics. They are a highly topical and significantly important subject from an academic perspective as well as industrial perspective. Low-density polyethylene (LDPE), synthesized by Imperial Chemical Industry (ICI) scientists Gibson and Fawcett in the early 1930s, was the first and oldest member of polyolefin family. ICI commercialized LDPE production around the same time using a tubular reactor with a free-radical process, operating at very high pressure (20003500 bars) and temperatures above 200 C. Despite very harsh reactor conditions, the industrial level LDPE production has continued since its inception because of its versatile application and competitive market demand. After about two decades, the early 1950s witnessed an ever-memorable era in polyolefin synthesis. Nobel Laureates Karl Ziegler (Germany) and Prof. Giulio Natta (Italy) made a breakthrough in the catalytic synthesis of polyethylene and polypropylene, respectively, using organoaluminum-activated titanium chlorides. On the other hand, Standard Oil and Phillips Petroleum researchers independently introduced a chromium catalyst to prepare high density polyethylene. This transition metal-catalyzed olefin polymerization route made industrial polyolefin synthesis possible at 1525 bars and 90120 C. These pioneering catalyst contributions have eventually revolutionized the emerging olefin polymerization organometallic catalysis and chemistry that we observe, read, and teach today. The overall impact on polyolefin education, research, training, manufacture process, industry, application, and worldwide business is too colossal to report. Polyolefins, as a highly prominent polymer and material science discipline, constitute an unending journey with unreachable destination. Therefore, it is highly necessary to share the growing knowledge and research takeaways and keepsakes with colleagues, researchers, and future generations. This is how polyolefins (an enduring success story, as of today), unlike many other polymer fields, have continued to sustain, expand, and thrive over the past 90 years. This is a rare scientific and technological example. Therefore, this Special Issue entitled “Polyolefins: The Ever-Thriving Thermoplastics” aims at publishing quality reviews and original research articles in the following areas:

- Polyolefin catalysis, synthesis, and characterization;

- Olefin polymerization mechanism, kinetics, and processes;

- Polyolefin rheology and processing;

- Polyolefin blends and composites;

- Application and product design and development;

- Polyolefin waste management.

It is strongly recommended that each contribution reflect new insight, novelty, technical advancement, and a valuable future research direction.

Prof. Dr. Muhammad Atiqullah

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- polyolefin catalysts and synthesis, characterization

- polyolefin rheology and processing

- polyolefin blends/composites

- applications

- polyolefin waste management

- olefin polymerization mechanism, kinetics, and processes