Experimental Study of Polypropylene with Additives of Bi2O3 Nanoparticles as Radiation-Shielding Materials

Abstract

:1. Introduction

2. Materials

2.1. Polypropylene (PP)

2.2. Bismuth Oxide (Bi2O3)

2.3. Polymer Mix Design

3. Methodology

3.1. Morphological Test

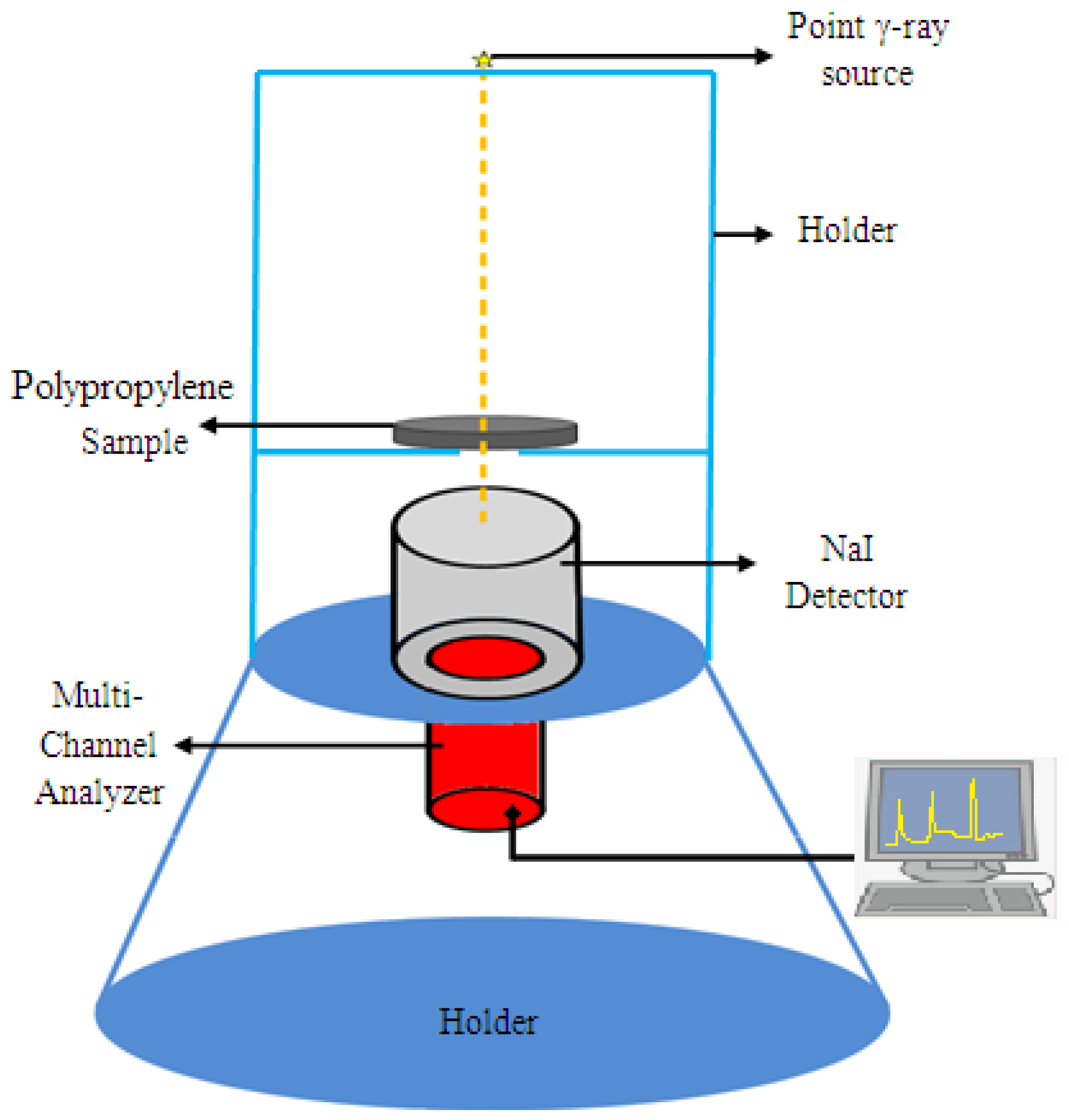

3.2. Radiation Shielding Test

4. Results and Discussion

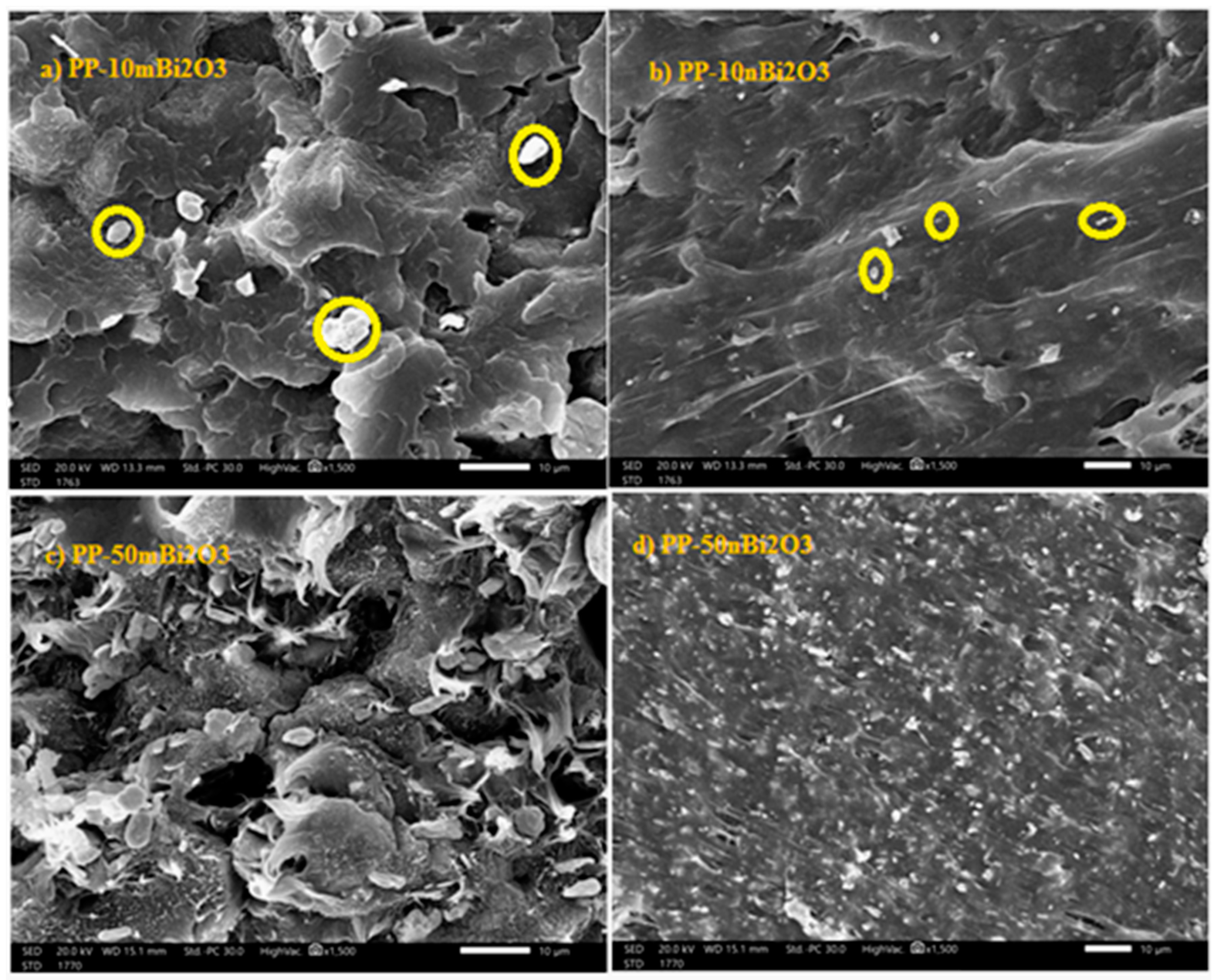

4.1. TEM and SEM Results

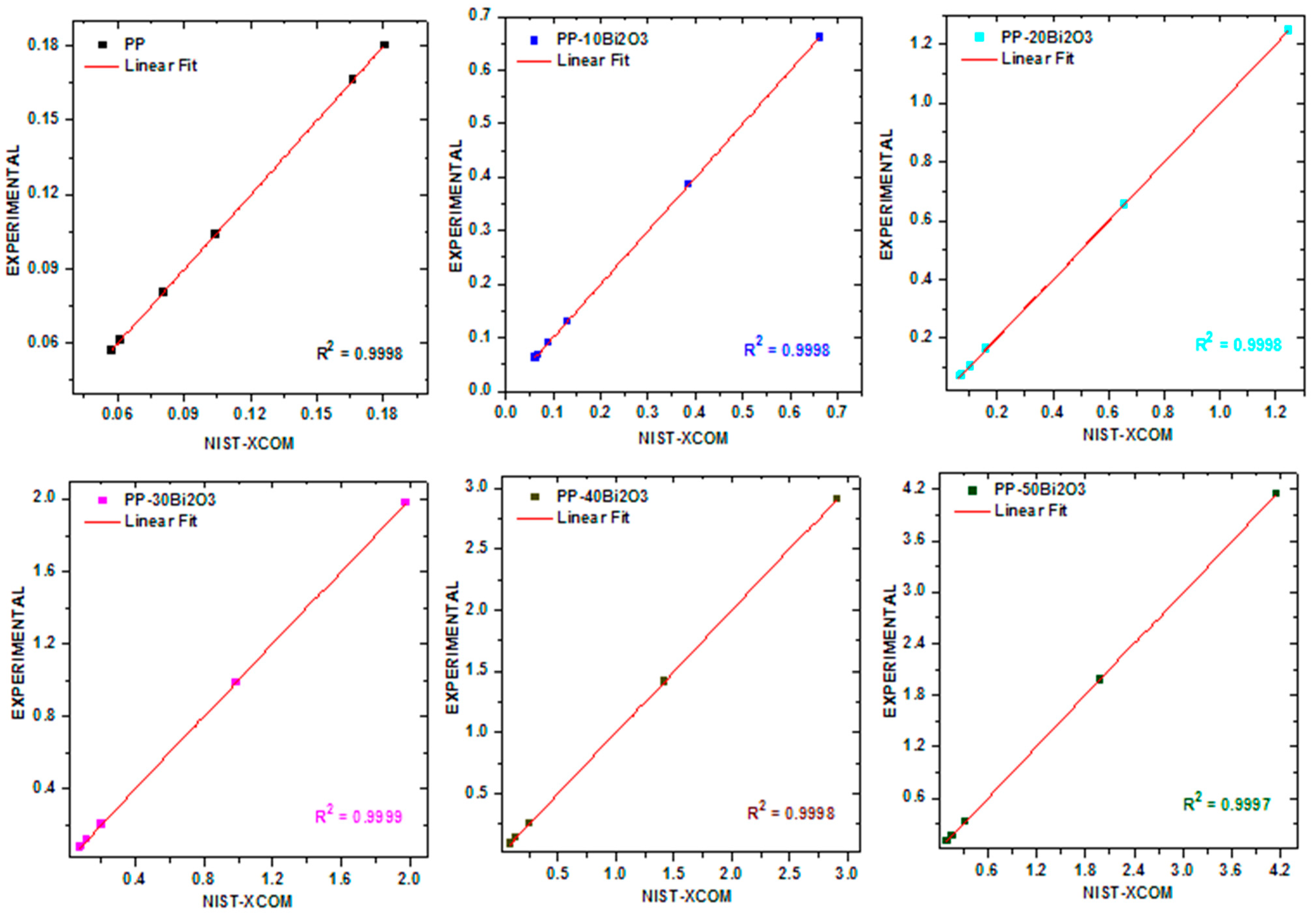

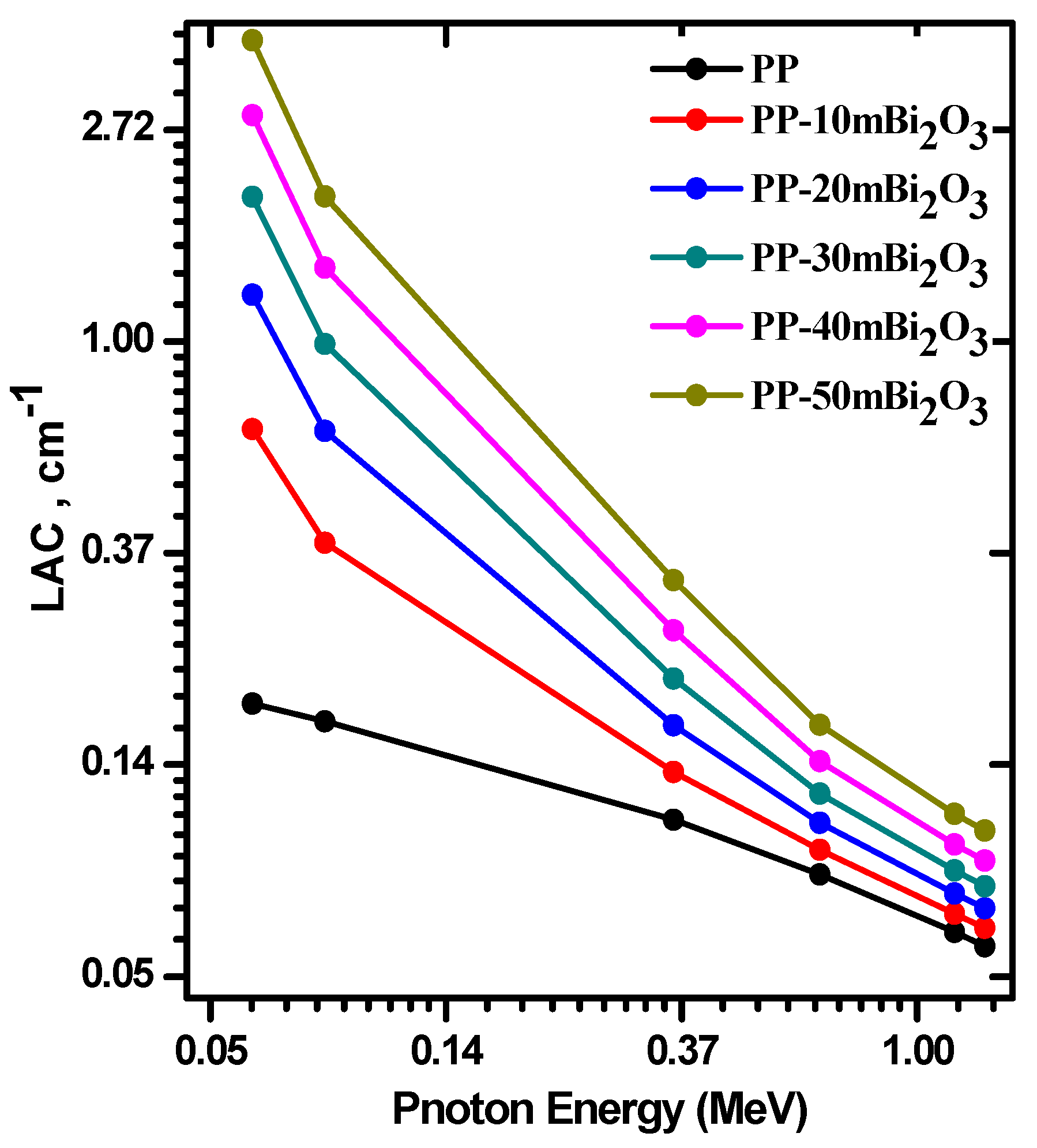

4.2. Attenuation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, J.; Zhao, M.; Wang, C.; Yong, Y.; Gu, Z.; Zhao, Y. Rational Design of Nanomaterials for Various Radiation-Induced Diseases Prevention and Treatment. Adv. Health Mater. 2021, 10, 2001615. [Google Scholar] [CrossRef] [PubMed]

- Ferry, M.; Ngono, Y. Energy transfer in polymers submitted to ionizing radiation: A review. Radiat. Phys. Chem. 2021, 180, 109320. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; El-Khatib, A.M.; Halbas, A.M.; El-Sharkawy, R.M. Investigation of physical, mechanical and gamma-ray shielding properties using ceramic tiles incorporated with powdered lead oxide. Ceram. Int. 2020, 46, 15686–15694. [Google Scholar] [CrossRef]

- Sutanto, H.; Wjaya, G.; Hidayanto, E.; Arifin, Z. Characteristic of silicone rubber as radioprotection materials on radiodiagnostic using x-ray conventional. J. Phys. Conf. Ser. 2019, 1217, 012044. [Google Scholar] [CrossRef]

- Schlattl, H.; Zankl, M.; Eder, H.; Hoeschen, C. Shielding properties of lead-free protective clothing and their impact on radiation doses. Med. Phys. 2007, 34, 4270–4280. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Yalçınkaya, Ç.; Tuyan, M. Optimization of reactive powder concrete by means of barite aggregate for both neutrons and gamma rays. Constr. Build. Mater. 2018, 189, 470–477. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; El-Khatib, A.M.; El-Sharkawy, R.; Rashad, A.R.; Badawi, M.S.; Gepreel, M.A. Design and testing of high-density polyethylene nanocomposites filled with lead oxide micro- and nano-particles: Mechanical, thermal, and morphological properties. J. Appl. Polym. Sci. 2019, 136, 47812. [Google Scholar] [CrossRef]

- Almurayshid, M.; Alsagabi, S.; Alssalim, Y.; Alotaibi, Z.; Almsalam, R. Feasibility of polymer-based composite materials as radiation shield. Radiat. Phys. Chem. 2021, 183, 109425. [Google Scholar] [CrossRef]

- Singh, K.K.; Nanda, T.; Mehta, R. Compatibilization of polypropylene fibers in epoxy based GFRP/clay nanocomposites for improved impact strength. Compos. Part A Appl. Sci. Manuf. 2017, 98, 207–217. [Google Scholar] [CrossRef]

- Ju, S.-P.; Chen, C.-C.; Huang, T.-J.; Liao, C.-H.; Chen, H.-L.; Chuang, Y.-C.; Wu, Y.-C. Investigation of the structural and mechanical properties of polypropylene-based carbon fiber nanocomposites by experimental measurement and molecular dynamics simulation. Comput. Mater. Sci. 2016, 115, 1–10. [Google Scholar] [CrossRef]

- Ibrahim, A.M.; Mohamed, A.R.; El-Khatib, A.M.; Alabsy, M.T.; Elsalamawy, M. Effect of hematite and iron slag as aggregate replacement on thermal, mechanical, and gamma-radiation shielding properties of concrete. Constr. Build. Mater. 2021, 310, 125225. [Google Scholar] [CrossRef]

- Tjong, S.C.; Shen, J.S.; Li, R.K.Y. Mechanical behavior of injection molded β-crystalline phase polypropylene. Polym. Eng. Sci. 1996, 36, 100–105. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Mao, Z.; Zhao, W. Effects of gamma radiation on the impact strength of polypropylene (PP)/high density polyethylene (HDPE) blends. Results Phys. 2019, 12, 2169–2174. [Google Scholar] [CrossRef]

- Toommee, S.; Pratumpong, P. PEG-template for surface modification of zeolite: A convenient material to the design of polypropylene based composite for packaging films. Results Phys. 2018, 9, 71–77. [Google Scholar] [CrossRef]

- Khozemy, E.E.; Salem, E.F.; Ali, A.E.-H. Radiation shielding and enhanced thermal characteristics of high-density polyethylene reinforced with Al(OH)3/Pb2O3 for radioactive waste management. Radiat. Phys. Chem. 2022, 193, 109976. [Google Scholar] [CrossRef]

- Körpınar, B.; Saltan, F. Preparation of poly(styrene-co-acrylic acid)-zinc oxide composites: Experimental and theoretical investigation of gamma radiation shielding properties. Appl. Radiat. Isot. 2022, 181, 110114. [Google Scholar] [CrossRef]

- Rashidi, M.; Rezaei, A.; Bijari, S.; Jaymand, M.; Samadian, H.; Arkan, E.; Zahabi, S.S.; Hosseini, M. Microfibers nanocomposite based on polyacrylonitrile fibers/bismuth oxide nanoparticles as X-ray shielding material. J. Appl. Polym. Sci. 2021, 138, 50755. [Google Scholar] [CrossRef]

- Popov, A.; Lushchik, A.; Shablonin, E.; Vasil’Chenko, E.; Kotomin, E.; Moskina, A.; Kuzovkov, V. Comparison of the F-type center thermal annealing in heavy-ion and neutron irradiated Al2O3 single crystals. Nucl. Instrum. Methods Phys. Res. Sect. B 2018, 433, 93–97. [Google Scholar] [CrossRef]

- Luchechko, A.; Vasyltsiv, V.; Kostyk, L.; Tsvetkova, O.; Popov, A. Shallow and deep trap levels in X-ray irradiated β-Ga2O3: Mg. Nucl. Instrum. Methods Phys. Res. Sect. B 2019, 441, 12–17. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Xiao, X.; Zhong, R.; Liao, J.; Guo, J.; Liao, X.; Shi, B. Research on X-ray shielding performance of wearable Bi/Ce-natural leather composite materials. J. Hazard. Mater. 2020, 398, 122943. [Google Scholar] [CrossRef]

- Gholamzadeh, L.; Asari-Shik, N.; Aminian, M.K.; Ghasemi-Nejad, M. A study of the shielding performance of fibers coated with high-Z oxides against ionizing radiations. Nucl. Instrum. Methods Phys. Res. Sect. A 2020, 973, 164174. [Google Scholar] [CrossRef]

- Dubey, K.; Chaudhari, C.; Suman, S.; Raje, N.; Mondal, R.; Grover, V.; Murali, S.; Bhardwaj, Y.; Varshney, L. Synthesis of flexible polymeric shielding materials for soft gamma rays: Physicomechanical and attenuation characteristics of radiation crosslinked polydimethylsiloxane/Bi2O3 composites. Polym. Compos. 2016, 37, 756–762. [Google Scholar] [CrossRef]

- Thabet, A.; Mobarak, Y.A. Predictable Models and Experimental Measurements for Electric Properties of Polypropylene Nanocomposite Films. Int. J. Electr. Comput. Eng. 2016, 6, 120–129. [Google Scholar] [CrossRef]

- Thabet, A. Experimental investigation on thermal electric and dielectric characterization for polypropylene nanocomposites using cost-fewer nanoparticles. Int. J. Electr. Eng. Technol. 2013, 4, 1–12. [Google Scholar]

- El-Khatib, A.M.; Elsafi, M.; Sayyed, M.; Abbas, M.; El-Khatib, M. Impact of micro and nano aluminium on the efficiency of photon detectors. Results Phys. 2021, 30, 104908. [Google Scholar] [CrossRef]

- Eid, M.S.; Bondouk, I.; Saleh, H.M.; Omar, K.M.; Sayyed, M.; El-Khatib, A.M.; Elsafi, M. Implementation of waste silicate glass into composition of ordinary cement for radiation shielding applications. Nucl. Eng. Technol. 2021, 54, 1456–1463. [Google Scholar] [CrossRef]

- Elsafi, M.; Sayyed, M.; Almuqrin, A.H.; Gouda, M.; El-Khatib, A. Analysis of particle size on mass dependent attenuation capability of bulk and nanoparticle PbO radiation shields. Results Phys. 2021, 26, 104458. [Google Scholar] [CrossRef]

- Alabsy, M.T.; Alzahrani, J.S.; Sayyed, M.I.; Abbas, M.I.; Tishkevich, D.I.; El-Khatib, A.M.; Elsafi, M. Gamma-Ray Attenuation and Exposure Buildup Factor of Novel Polymers in Shielding Using Geant4 Simulation. Materials 2021, 14, 5051. [Google Scholar] [CrossRef]

- El-Khatib, A.M.; Elsafi, M.; Almutiri, M.N.; Mahmoud, R.M.M.; Alzahrani, J.S.; Sayyed, M.I.; Abbas, M.I. Enhancement of Bentonite Materials with Cement for Gamma-Ray Shielding Capability. Materials 2021, 14, 4697. [Google Scholar] [CrossRef]

- Sayyed, M.; Albarzan, B.; Almuqrin, A.; El-Khatib, A.; Kumar, A.; Tishkevich, D.; Trukhanov, A.; Elsafi, M. Experimental and Theoretical Study of Radiation Shielding Features of CaO-K2O-Na2O-P2O5 Glass Systems. Materials 2021, 14, 3772. [Google Scholar] [CrossRef]

- Elsafi, M.; El-Nahal, M.A.; Sayyed, M.I.; Saleh, I.H.; Abbas, M.I. Effect of bulk and nanoparticle Bi2O3 on attenuation capability of radiation shielding glass. Ceram. Int. 2021, 47, 19651–19658. [Google Scholar] [CrossRef]

- El-Nahal, M.A.; Elsafi, M.; Sayyed, M.I.; Khandaker, M.U.; Osman, H.; Elesawy, B.H.; Saleh, I.H.; Abbas, M.I. Understanding the Effect of Introducing Micro- and Nanoparticle Bismuth Oxide (Bi2O3) on the Gamma Ray Shielding Performance of Novel Concrete. Materials 2021, 14, 6487. [Google Scholar] [CrossRef] [PubMed]

- Al-Harbi, N.; Sayyed, M.; Al-Hadeethi, Y.; Kumar, A.; Elsafi, M.; Mahmoud, K.; Khandaker, M.U.; Bradley, D. A novel CaO-K2O-Na2O-P2O5 Glass Systems for Radiation Shielding Applications. Radiat. Phys. Chem. 2021, 188, 109645. [Google Scholar] [CrossRef]

- Mhareb, M.H.A.; Zeama, M.; Elsafi, M.; Alajerami, Y.S.; Sayyed, M.I.; Saleh, G.; Hamad, R.M.; Hamad, M.K. Radiation shielding features for various tellurium-based alloys: A comparative study. J. Mater. Sci. Mater. Electron. 2021, 32, 26798–26811. [Google Scholar] [CrossRef]

| Codes | Compositions (wt%) | Density (g·cm−3) | ||

|---|---|---|---|---|

| PP | Bi2O3 | |||

| Micro | Nano | |||

| PP | 100 | — | 0.911 ± 0.005 | |

| PP-10mPbO10 | 90 | 10 | 1.003 ± 0.004 | |

| PP-10nPbO10 | 90 | — | 10 | 1.078 ± 0.009 |

| PP-20mPbO30 | 80 | 20 | — | 1.112 ± 0.009 |

| PP-30mPbO50 | 70 | 30 | — | 1.251 ± 0.006 |

| PP-40mPbO50 | 60 | 40 | — | 1.427 ± 0.003 |

| PP-50mPbO50 | 50 | 50 | — | 1.659 ± 0.008 |

| PP-50nPbO50 | 50 | — | 50 | 1.701 ± 0.006 |

| PTB Nuclide | Energy MeV | Emission Probability | Initial Activity Bq | Uncertainty kBq |

|---|---|---|---|---|

| Am-241 | 0.060 | 35.9 | 259,000 | ±2.6 |

| Cs-137 | 0.662 | 84.99 | 385,000 | ±4.0 |

| Ba-133 | 0.081 | 32.9 | 275,300 | ±1.5 |

| 0.356 | 62.05 | |||

| Co-60 | 1.173 | 99.90 | 212,100 | ±1.5 |

| 1.333 | 99.982 |

| Attenuation Parameters | Energy (MeV) | 0.060 | 0.081 | 0.356 | 0.662 | 1.173 | 1.333 |

|---|---|---|---|---|---|---|---|

| HVL, cm | PP-10m Bi2O3 | 1.048 | 1.795 | 5.287 | 7.609 | 10.364 | 11.126 |

| PP-10n Bi2O3 | 0.889 | 1.538 | 4.643 | 6.837 | 9.507 | 10.269 | |

| PP-50m Bi2O3 | 0.167 | 0.350 | 2.147 | 4.250 | 6.484 | 7.001 | |

| PP-50n Bi2O3 | 0.124 | 0.265 | 1.675 | 3.435 | 5.492 | 6.009 | |

| MFP, cm | PP-10m Bi2O3 | 1.512 | 2.590 | 7.628 | 10.977 | 14.952 | 16.051 |

| PP-10n Bi2O3 | 1.283 | 2.219 | 6.699 | 9.864 | 13.716 | 14.816 | |

| PP-50m Bi2O3 | 0.241 | 0.505 | 3.097 | 6.131 | 9.355 | 10.101 | |

| PP-50n Bi2O3 | 0.179 | 0.382 | 2.416 | 4.956 | 7.923 | 8.669 | |

| TVL, cm | PP-10m Bi2O3 | 3.482 | 5.964 | 17.564 | 25.275 | 34.429 | 36.960 |

| PP-10n Bi2O3 | 2.954 | 5.109 | 15.424 | 22.713 | 31.583 | 34.114 | |

| PP-50m Bi2O3 | 0.555 | 1.162 | 7.131 | 14.118 | 21.540 | 23.258 | |

| PP-50n Bi2O3 | 0.413 | 0.879 | 5.564 | 11.411 | 18.243 | 19.961 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Khatib, A.M.; Shalaby, T.I.; Antar, A.; Elsafi, M. Experimental Study of Polypropylene with Additives of Bi2O3 Nanoparticles as Radiation-Shielding Materials. Polymers 2022, 14, 2253. https://doi.org/10.3390/polym14112253

El-Khatib AM, Shalaby TI, Antar A, Elsafi M. Experimental Study of Polypropylene with Additives of Bi2O3 Nanoparticles as Radiation-Shielding Materials. Polymers. 2022; 14(11):2253. https://doi.org/10.3390/polym14112253

Chicago/Turabian StyleEl-Khatib, Ahmed M., Thanaa I. Shalaby, Ali Antar, and Mohamed Elsafi. 2022. "Experimental Study of Polypropylene with Additives of Bi2O3 Nanoparticles as Radiation-Shielding Materials" Polymers 14, no. 11: 2253. https://doi.org/10.3390/polym14112253