Enhancement of Electrochemical–Anaerobic Digested Palm Oil Mill Effluent Waste Activated Sludge in Solids Minimization and Biogas Production: Bench–Scale Verification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Characterization

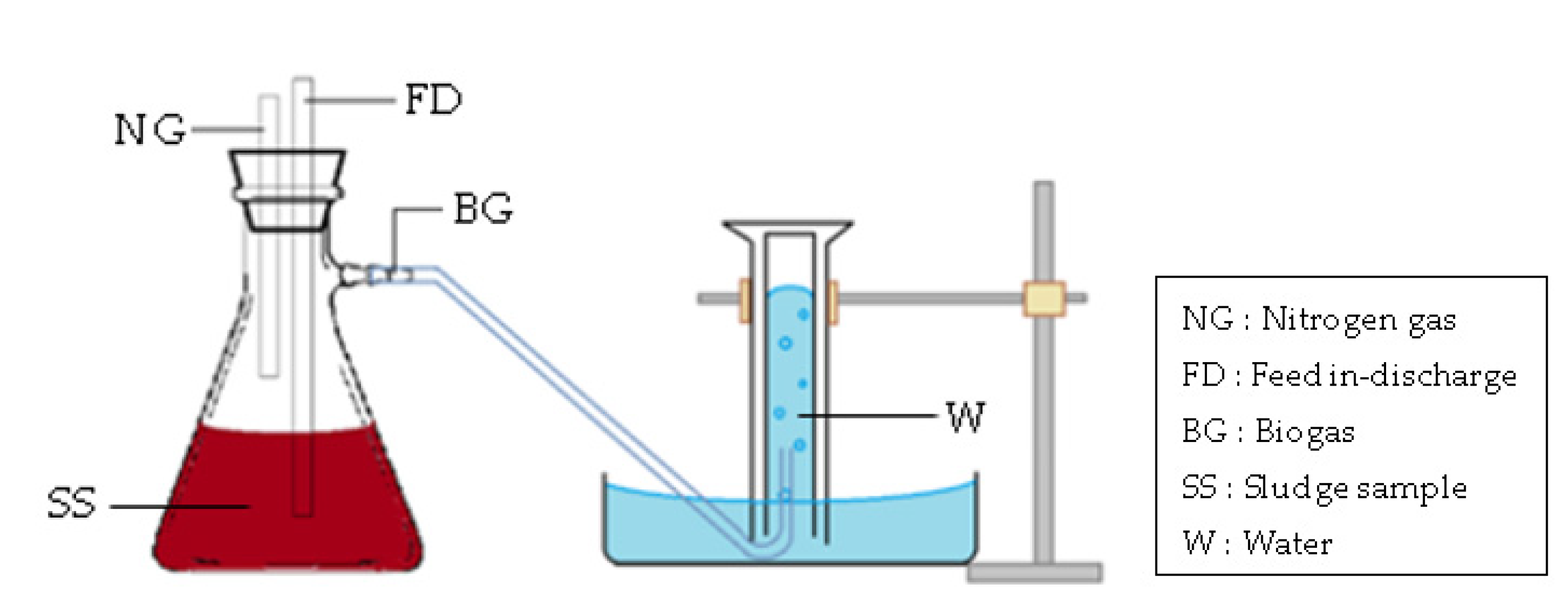

2.2. Bench-Scale Electrochemical Oxidation Pre-Treatment and Anaerobic Digestion

2.2.1. Electrochemical Oxidation (EO) Pre-Treatment

2.2.2. Anaerobic Digestion (AD)

2.3. Analytical Methods

- P = electrical power used (kW)

- t = electrolysis time (s)

- V = volume of pre-treated sludge (L)

- TS = total solids concentration (kg/L)

3. Results and Discussion

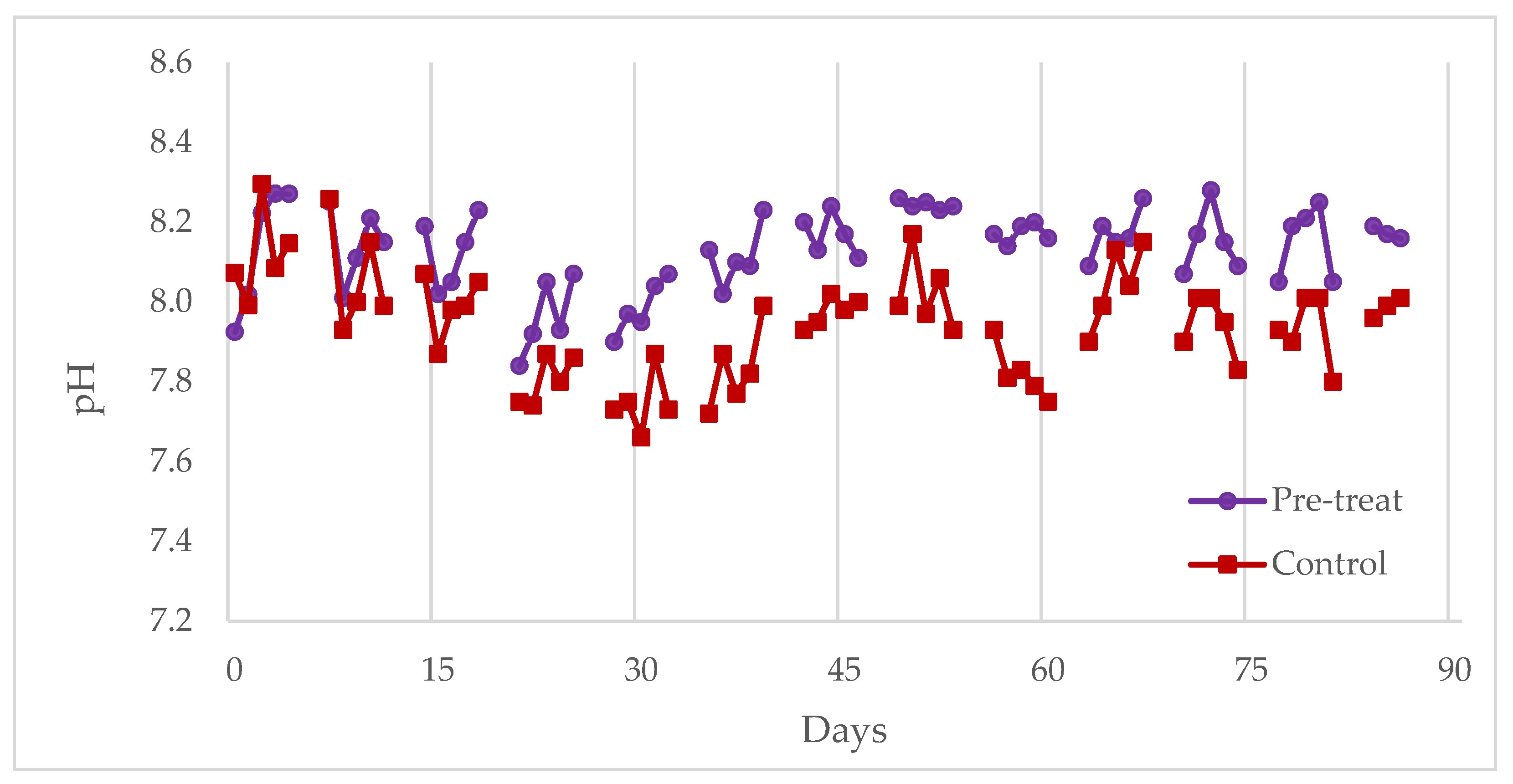

3.1. pH Monitoring

3.2. Volatile Suspended Solids (VSS) Concentration

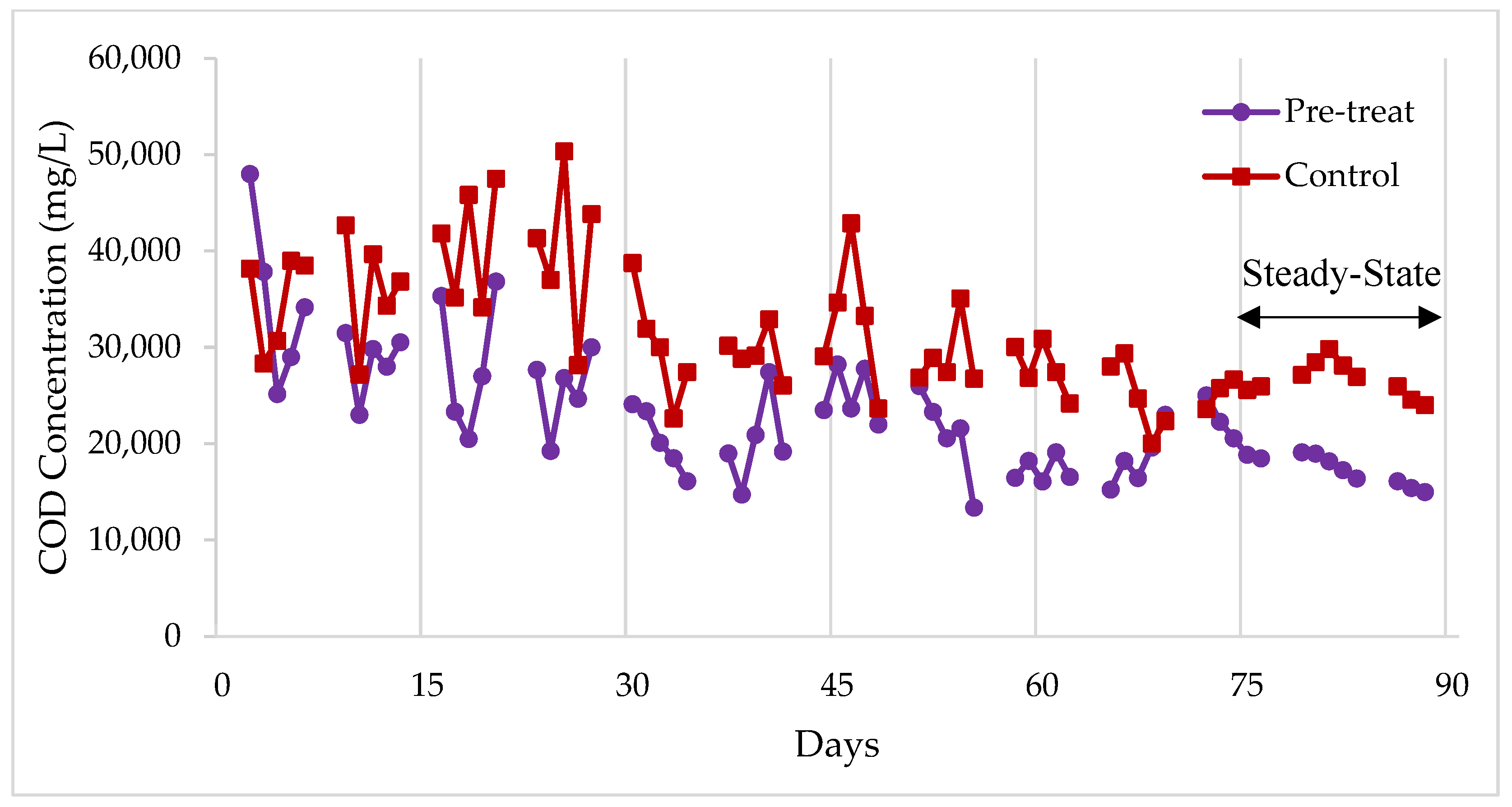

3.3. Chemical Oxygen Demand (COD) Concentration

3.4. Biogas Production and Its Composition

3.5. Energy Consumption

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Latifi, P.; Karrabi, M.; Danesh, S. Anaerobic co-digestion of poultry slaughterhouse wastes with sewage sludge in batch-mode bioreactors (effect of inoculum-substrate ratio and total solids). Renew. Sustain. Energy Rev. 2019, 107, 288–296. [Google Scholar] [CrossRef]

- Liyanage, T.U.H.; Babel, S. Thermal, ultrasonic and electrochemical pretreatment methods to enhance the solubilization of organic substance and methane generation in food waste. J. Mater. Cycles Waste Manag. 2020, 22, 1418–1426. [Google Scholar] [CrossRef]

- Feki, E.; Battimelli, A.; Sayadi, S.; Dhouib, A.; Khoufi, S. High-Rate Anaerobic Digestion of Waste Activated Sludge by Integration of Electro-Fenton Process. Molecules 2020, 25, 626. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Zeng, Q.; Heynderickx, P.M.; Chen, G.-H.; Wu, D. Electrochemical pretreatment (EPT) of waste activated sludge: Extracellular polymeric substances matrix destruction, sludge solubilisation and overall digestibility. Bioresour. Technol. 2021, 330, 125000. [Google Scholar] [CrossRef]

- Abdulsalam, M.; Man, H.C.; Idris, A.I.; Yunos, K.F.; Abidin, Z.Z. Treatment of Palm Oil Mill Effluent Using Membrane Bioreactor: Novel Processes and Their Major Drawbacks. Water 2018, 10, 1165. [Google Scholar] [CrossRef]

- Krishnan, S.; Homroskla, P.; Saritpongteeraka, K.; Suttinun, O.; Nasrullah, M.; Tirawanichakul, Y.; Chaiprapat, S. Specific degradation of phenolic compounds from palm oil mill effluent using ozonation and its impact on methane fermentation. Chem. Eng. J. 2023, 451, 138487. [Google Scholar] [CrossRef]

- Lim, J.W.; Wong, S.W.K.; Dai, Y.; Tong, Y.W. Effect of seed sludge source and start-up strategy on the performance and microbial communities of thermophilic anaerobic digestion of food waste. Energy 2020, 203, 117922. [Google Scholar] [CrossRef]

- Al-Sulaimi, I.N.; Nayak, J.K.; Alhimali, H.; Sana, A.; Al-Mamun, A. Effect of Volatile Fatty Acids Accumulation on Biogas Production by Sludge-Feeding Thermophilic Anaerobic Digester and Predicting Process Parameters. Fermentation 2022, 8, 184. [Google Scholar] [CrossRef]

- Aziz, M.M.A.; Kassim, K.A.; ElSergany, M.; Anuar, S.; Jorat, M.E.; Yaacob, H.; Ahsan, A.; Imteaz, M.A. Arifuzzaman Recent advances on palm oil mill effluent (POME) pretreatment and anaerobic reactor for sustainable biogas production. Renew. Sustain. Energy Rev. 2020, 119, 109603. [Google Scholar] [CrossRef]

- Arenas, C.B.; González, R.; González, J.; Cara, J.; Papaharalabos, G.; Gómez, X.; Martínez, E.J. Assessment of electrooxidation as pre- and post-treatments for improving anaerobic digestion and stabilisation of waste activated sludge. J. Environ. Manag. 2021, 288, 112365. [Google Scholar] [CrossRef]

- Suschka, J.; Grübel, K. Low intensity surplus activated sludge pretreatment before anaerobic digestion. Arch. Environ. Prot. 2017, 43, 50–57. [Google Scholar] [CrossRef]

- Khadaroo, S.N.; Grassia, P.; Gouwanda, D.; Poh, P.E. Is the dewatering of Palm Oil Mill Effluent (POME) feasible? Effect of temperature on POME’s rheological properties and compressive behavior. Chem. Eng. Sci. 2019, 202, 519–528. [Google Scholar] [CrossRef]

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.Ş.; Unalan, S.; et al. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Kamperidou, V.; Terzopoulou, P. Anaerobic Digestion of Lignocellulosic Waste Materials. Sustainability 2021, 13, 12810. [Google Scholar] [CrossRef]

- Ma, Y.; Gu, J.; Liu, Y. Evaluation of anaerobic digestion of food waste and waste activated sludge: Soluble COD versus its chemical composition. Sci. Total Environ. 2018, 643, 21–27. [Google Scholar] [CrossRef]

- Mahmod, S.S.; Arisht, S.N.; Jahim, J.M.; Takriff, M.S.; Tan, J.P.; Luthfi, A.A.I.; Abdul, P.M. Enhancement of biohydrogen production from palm oil mill effluent (POME): A review. Int. J. Hydrog. Energy 2021, 47, 40637–40655. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Li, Y.-Y.; Zhao, Y. Combined electrical-alkali pretreatment to increase the anaerobic hydrolysis rate of waste activated sludge during anaerobic digestion. Appl. Energy 2014, 128, 93–102. [Google Scholar] [CrossRef]

- Yu, B.; Xu, J.; Yuan, H.; Lou, Z.; Lin, J.; Zhu, N. Enhancement of anaerobic digestion of waste activated sludge by electrochemical pretreatment. Fuel 2014, 130, 279–285. [Google Scholar] [CrossRef]

- Heng, G.C.; Isa, M.H.; Lock, S.S.M.; Ng, C.A. Process Optimization of Waste Activated Sludge in Anaerobic Digestion and Biogas Production by Electrochemical Pre-Treatment Using Ruthenium Oxide Coated Titanium Electrodes. Sustainability 2021, 13, 4874. [Google Scholar] [CrossRef]

- Erkan, H.S.; Turan, N.B.; Engin, G.O. Highlighting the cathodic contribution of an electrooxidation pretreatment study on waste activated sludge disintegration. Environ. Prog. Sustain. Energy 2021, 40, e13620. [Google Scholar] [CrossRef]

- Yap, B.J.T.; Heng, G.C.; Ng, C.A. Electrochemical oxidation process on palm oil mill effluent waste activated sludge: Optimization by response surface methodology. Water Sci. Technol. 2022, 86, 1122–1134. [Google Scholar] [CrossRef] [PubMed]

- Heng, G.C.; Isa, M.H.; Lim, J.-W.; Ho, Y.-C.; Zinatizadeh, A.A.L. Enhancement of anaerobic digestibility of waste activated sludge using photo-Fenton pretreatment. Environ. Sci. Pollut. Res. 2017, 24, 27113–27124. [Google Scholar] [CrossRef] [PubMed]

- Barros, R.; Raposo, S.; Morais, E.G.; Rodrigues, B.; Afonso, V.; Gonçalves, P.; Marques, J.; Cerqueira, P.R.; Varela, J.; Teixeira, M.R.; et al. Biogas Production from Microalgal Biomass Produced in the Tertiary Treatment of Urban Wastewater: Assessment of Seasonal Variations. Energies 2022, 15, 5713. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, M.; Cano, A.; Durán, U.; Barrios, J. Solubilization of organic matter by electrochemical treatment of sludge: Influence of operating conditions. J. Environ. Manag. 2019, 236, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Dagnew, M.; Parker, W. Impact of AnMBR operating conditions on anaerobic digestion of waste activated sludge. Water Environ. Res. 2020, 93, 703–713. [Google Scholar] [CrossRef]

- Panigrahi, S.; Dubey, B.K. Electrochemical pretreatment of yard waste to improve biogas production: Understanding the mechanism of delignification, and energy balance. Bioresour. Technol. 2019, 292, 121958. [Google Scholar] [CrossRef]

- Pasalari, H.; Esrafili, A.; Rezaee, A.; Gholami, M.; Farzadkia, M. Electrochemical oxidation pretreatment for enhanced methane potential from landfill leachate in anaerobic co-digestion process: Performance, Gompertz model, and energy assessment. Chem. Eng. J. 2021, 422, 130046. [Google Scholar] [CrossRef]

- Kamal, N.A.; Osman, S.N.; Lee, D.Y.; Ab Wahid, M. Analysis of Biogas Production from Biomass Residue of Palm Oil Mills using an Anaerobic Batch Test. Sains Malays. 2021, 50, 3583–3592. [Google Scholar] [CrossRef]

- Ken, D.S.; Sinha, A. Dimensionally stable anode (Ti/RuO2) mediated electro-oxidation and multi-response optimization study for remediation of coke-oven wastewater. J. Environ. Chem. Eng. 2021, 9, 105025. [Google Scholar] [CrossRef]

- Xiao, X.; Huang, Z.; Ruan, W.; Yan, L.; Miao, H.; Ren, H.; Zhao, M. Evaluation and characterization during the anaerobic digestion of high-strength kitchen waste slurry via a pilot-scale anaerobic membrane bioreactor. Bioresour. Technol. 2015, 193, 234–242. [Google Scholar] [CrossRef]

- Tamar, S.A.; Umer, M.I. Stabilization of Sludge in Zakho Municipal Wastewater by Anaerobic Digestion for Biogas Production in Kurdistan Region, Iraq. Sci. J. Univ. Zakho 2022, 10, 86–92. [Google Scholar] [CrossRef]

- Lee, I.-S.; Parameswaran, P.; Rittmann, B.E. Effects of solids retention time on methanogenesis in anaerobic digestion of thickened mixed sludge. Bioresour. Technol. 2011, 102, 10266–10272. [Google Scholar] [CrossRef] [PubMed]

- Islam, S.; Malcolm, M.; Sharafatul, M. A Novel Study on Biogas Production from Palm Oil Mill Effluent with Two-Stage an-Aerobic Digester and Nano Membrane. Sci. Int. 2019, 31, 811–819. [Google Scholar]

- Liu, X.; Lee, C.; Kim, J.Y. Thermal hydrolysis pre-treatment combined with anaerobic digestion for energy recovery from organic wastes. J. Mater. Cycles Waste Manag. 2020, 22, 1370–1381. [Google Scholar] [CrossRef]

- Isa, M.H.; Wong, L.-P.; Bashir, M.J.; Shafiq, N.; Kutty, S.R.M.; Farooqi, I.H.; Lee, H.C. Improved anaerobic digestion of palm oil mill effluent and biogas production by ultrasonication pretreatment. Sci. Total. Environ. 2020, 722, 137833. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Yuan, H.; Dai, X.; Lou, Z.; Zhu, N. Electrochemical pretreatment of waste activated sludge: Effect of process conditions on sludge disintegration degree and methane production. Environ. Technol. 2016, 37, 2935–2944. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Lu, F.; Kashif, M.; Shen, P. Multiple Effects of Different Nickel Concentrations on the Stability of Anaerobic Digestion of Molasses. Sustainability 2021, 13, 4971. [Google Scholar] [CrossRef]

- Yuan, H.; Yu, B.; Cheng, P.; Zhu, N.; Yin, C.; Ying, L. Pilot-scale study of enhanced anaerobic digestion of waste activated sludge by electrochemical and sodium hypochlorite combination pretreatment. Int. Biodeterior. Biodegrad. 2016, 110, 227–234. [Google Scholar] [CrossRef]

- Singkhala, A.; Mamimin, C.; Reungsang, A.; O-Thong, S. Enhancement of Thermophilic Biogas Production from Palm Oil Mill Effluent by pH Adjustment and Effluent Recycling. Processes 2021, 9, 878. [Google Scholar] [CrossRef]

- Filer, J.; Ding, H.H.; Chang, S. Biochemical Methane Potential (BMP) Assay Method for Anaerobic Digestion Research. Water 2019, 11, 921. [Google Scholar] [CrossRef]

- Ibrahim, A.H.; Dahlan, I.; Adlan, M.O.; Dasti, A.F. Comparative study on characterization of malaysian palm oil mill effluent. Res. J. Chem. Sci. 2012, 2, 1–5. [Google Scholar]

- Fan, J.; Ji, F.; Xu, X.; Wang, Y.; Yan, D.; Xu, X.; Chen, Q.; Xiong, J.; He, Q. Prediction of the effect of fine grit on the MLVSS/MLSS ratio of activated sludge. Bioresour. Technol. 2015, 190, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Ma, D.; Yi, H.; Lai, C.; Liu, X.; Huo, X.; An, Z.; Li, L.; Fu, Y.; Li, B.; Zhang, M.; et al. Critical review of advanced oxidation processes in organic wastewater treatment. Chemosphere 2021, 275, 130104. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Neibling, H. Anaerobic Digestion Basics; University of Idaho Extension: Moscow, ID, USA, 2014. [Google Scholar]

- Feki, E.; Khoufi, S.; Loukil, S.; Sayadi, S. Improvement of anaerobic digestion of waste-activated sludge by using H2O2 oxidation, electrolysis, electro-oxidation and thermo-alkaline pretreatments. Environ. Sci. Pollut. Res. 2015, 22, 14717–14726. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Krimly, M.Z. Palm Oil Mill Effluent Treatment Process Evaluation and Fate of Priority Components in an Open and Closed Digestion System. Curr. World Environ. J. 2014, 9, 321–330. [Google Scholar] [CrossRef]

- Khanh Nguyen, V.; Kumar Chaudhary, D.; Hari Dahal, R.; Hoang Trinh, N.; Kim, J.; Chang, S.W.; Hong, Y.; Duc La, D.; Nguyen, X.C.; Hao Ngo, H.; et al. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 2020, 285, 119105. [Google Scholar] [CrossRef]

- Karne, H.; Mahajan, U.; Ketkar, U.; Kohade, A.; Khadilkar, P.; Mishra, A. A review on biogas upgradation systems. Mater. Today Proc. 2023, 72, 775–786. [Google Scholar] [CrossRef]

| Parameter | Raw WAS | Pre-Treated WAS |

|---|---|---|

| pH | 8.0 ± 0.1 | 8.1 ± 0.1 |

| Total Solids (mg/L) | 44,702 ± 5142 | 41,573 ± 4846 |

| Total Volatile Solids (mg/L) | 27,190 ± 4583 | 21,500 ± 2404 |

| Chemical Oxygen Demand, COD (mg/L) | 14,224 ± 1720 | 15,385 ± 2467 |

| Soluble Chemical Oxygen Demand, sCOD (mg/L) | 7696 ± 1022 | 11,453 ± 1084 |

| Suspended Solids, SS (mg/L) | 34,700 ± 990 | 26,970 ± 381 |

| Volatile Suspended Solids, VSS (mg/L) | 26,250 ± 2616 | 20,839 ± 1077 |

| Control Digester | Pre-Treated Digester | |

|---|---|---|

| Methane, CH4 (%) | 72.9 | 74.3 |

| Carbon Dioxide, CO2 (%) | 27.1 | 25.7 |

| Methane production rate (mL CH4/g CODadded) | 3.90 | 11.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yap, B.J.T.; Heng, G.C.; Ng, C.A.; Bashir, M.J.K.; Lock, S.S.M. Enhancement of Electrochemical–Anaerobic Digested Palm Oil Mill Effluent Waste Activated Sludge in Solids Minimization and Biogas Production: Bench–Scale Verification. Processes 2023, 11, 1609. https://doi.org/10.3390/pr11061609

Yap BJT, Heng GC, Ng CA, Bashir MJK, Lock SSM. Enhancement of Electrochemical–Anaerobic Digested Palm Oil Mill Effluent Waste Activated Sludge in Solids Minimization and Biogas Production: Bench–Scale Verification. Processes. 2023; 11(6):1609. https://doi.org/10.3390/pr11061609

Chicago/Turabian StyleYap, Branda Jian Tong, Gan Chin Heng, Choon Aun Ng, Mohammed J. K. Bashir, and Serene Sow Mun Lock. 2023. "Enhancement of Electrochemical–Anaerobic Digested Palm Oil Mill Effluent Waste Activated Sludge in Solids Minimization and Biogas Production: Bench–Scale Verification" Processes 11, no. 6: 1609. https://doi.org/10.3390/pr11061609