Abnormal Situation Management in Chemical Processes: Recent Research Progress and Future Prospects

Abstract

:1. Introduction

2. Concept of ASM

- (1)

- Prediction of abnormal situations: A warning regarding the occurrence of abnormal situations in advance by predicting the future trend of process parameters. The abnormal situations prediction targets potential deviations or abnormalities in the chemical process and can provide time for operators to take preventive measures in advance, effectively reducing the probability of abnormal situations.

- (2)

- Identification of abnormal situations: Based on expert knowledge, models, and process data, a rapid and concise dynamic evaluation of chemical processes is conducted to determine whether the chemical process is in an abnormal state. Identifying abnormal situations as early as possible and taking effective measures can minimize the potential losses and risks and improve production efficiency and system reliability.

- (3)

- Root cause diagnosis: For the predicted and identified abnormal situations, the analysis of the causal relationship between the variables of the abnormal situations, determination of the propagation path of the abnormal situations, and diagnosis of the root variables leading to the abnormal situations in a timely manner. Root cause diagnosis can provide decision support for operators to correctly deal with abnormal situations, thus quickly cutting off the path from abnormal situations to incidents or accidents.

- (4)

- Risk assessment: The calculation of the probability of occurrence of abnormal situations and evaluation of the expected losses caused by process parameter deviations. The further combination of the probability and consequences to determine the dynamic risk of abnormal situations. The dynamic risk assessment of abnormal situations can capture the dynamic changes of risk with the deviation of process parameters in real time, thus providing decision support for ASM.

- (5)

- Emergency disposal: Based on the results of root cause diagnosis and risk assessment, appropriate preventive or control measures are taken to avoid the occurrence of abnormal situations or restore the chemical process from abnormal situations to a normal state.

3. Review of Research Progress

3.1. Review Method

- (1)

- Literature search

- (2)

- Literature screening

- (3)

- Literature classification and summary

3.2. Fault Detection and Diagnosis

- (1)

- Applying deep learning methods

- (2)

- Establishing new FDD models

- (3)

- Interpretable FDD models

- (4)

- FDD system development

3.3. Early Prediction and Warning

3.4. Root Cause Analysis

3.5. Dynamic Risk Assessment

4. Future Prospects for ASM

4.1. Improving the Adaptability and Generalization of Models

4.2. Establishing the Model Suitable for Long-Term Prediction

4.3. Online Root Causes Diagnosis of Abnormal Situations Based on Real-Time Data

4.4. Establishing the Hybrid Method Combining Process Knowledge and Data-Driven Models

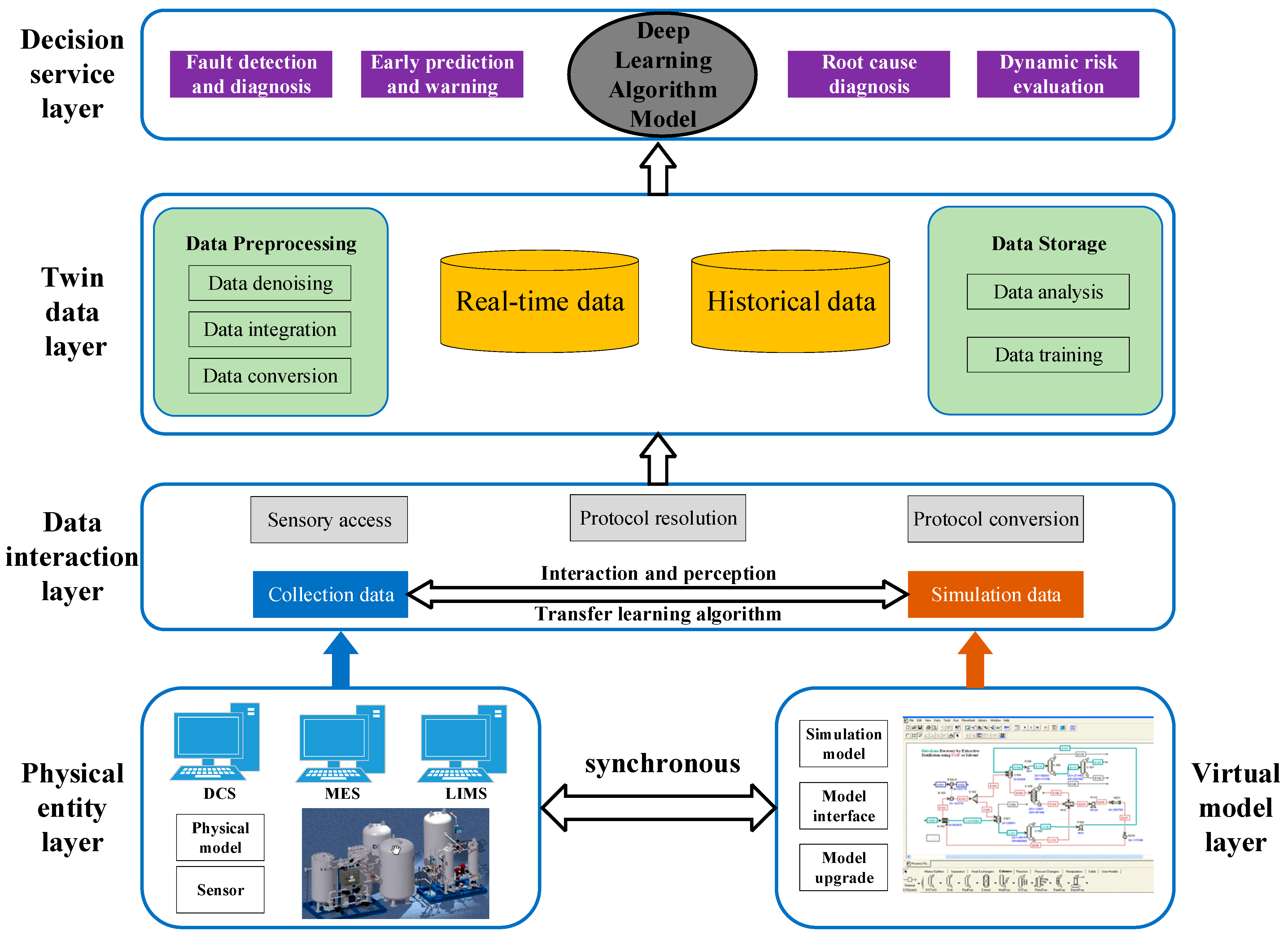

4.5. ASM in Chemical Processes Based on Digital Twins

- (1)

- Physical entity layer

- (2)

- Virtual model layer

- (3)

- Data interaction layer

- (4)

- Twin data layer

- (5)

- Decision service layer

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCPS | Center for Chemical Process Safety |

| AIChE | American Institute of Chemical Engineers |

| ASM | Abnormal situation management |

| PSM | Process safety management |

| NIST | National Institute of Standards and Technology |

| AEGIS | Abnormal Events Guidance and Information Systems |

| CHEM | Advanced Decision Support System for Petrochemical Manufacturing Processes |

| FDD | Fault detection and diagnosis |

| RA | Risk assessment |

| DCS | Distributed control system |

| FSBiGAN | Fault-sensitive bidirectional generative adversarial network |

| TEP | Tennessee Eastman Process |

| CSTR | Continuous stirred tank reactor |

| IPO-ViT | Industrial process optimization vision transformer |

| DSGNN | Dynamic-scale graph neural network |

| XFDDC | Explainable fault detection diagnosis and correction |

| XAI | Explainable artificial intelligence |

| AKPCA | Adaptive kernel principal component analysis |

| GRA | Grey relational analysis |

| OSAVA | Orthogonal self-attentive variational autoencoder |

| PTCN | Process topology convolutional network |

| MS-DSFA | Multistep dynamic slow feature analysis |

| PRSFA | Probability-related randomized slow feature analysis |

| NEDA | Neighborhood embedding discriminative analysis |

| DTW | Dynamic time warping |

| CNN | Convolutional neural network |

| PCA | Principal component analysis |

| DNN | Deep neural network |

| DDSAE | Dynamic deep supervised autoencoder neural networks |

| LRP | Layer-wise relevance propagation |

| TL | Transfer learning |

| LDA | Linear discriminant analysis |

| DTN | Deep transfer network |

| EEMD | Ensemble empirical mode decomposition |

| BiRNN | Bidirectional recurrent neural network |

| TSD-LKPCA | Two-step dynamic local kernel principal component analysis |

| MkNN | Mutual k-nearest neighbor |

| AE | Autoencoder |

| DCNN | Deep convolutional neural networks |

| GAN | Generative adversarial networks |

| DBN | Deep belief network |

| LSTM | Long short-term memory |

| GRU | Gated recurrent units |

| ANN | Artificial neural network |

| DiPCA | Dynamic inner principal component analysis |

| AM | Attention mechanism |

| STA | Spatiotemporal attention |

| SDG | Signed directed graph |

| BN | Bayesian network |

| TCCM | Time-delayed convergent cross mapping |

| TCN | Temporal convolutional network |

| DRA | Dynamic risk assessment |

| POF | Probability of failure |

| COF | Consequence of failure |

| LF | Loss function |

| TAN | Tree augmented naïve Bayes |

| OASIS | Operable adaptive sparse identification of systems |

| SIS | Safety instrument system |

| MES | Manufacturing execution system |

References

- Sun, H.; Wang, H.; Yang, M.; Reniers, G. A STAMP-Based Approach to Quantitative Resilience Assessment of Chemical Process Systems. Reliab. Eng. Syst. Saf. 2022, 222, 108397. [Google Scholar] [CrossRef]

- Ayoubi, M.; Isermann, R. Neuro-Fuzzy Systems for Diagnosis. Fuzzy Sets Syst. 1997, 89, 289–307. [Google Scholar] [CrossRef]

- Kenan, S.; Kadri, S. Process Safety Leading Indicators Survey-February 2013: Center for Chemical Process Safety-White Paper. Process Saf. Prog. 2014, 33, 247–258. [Google Scholar] [CrossRef]

- Nimmo, I. Adequately Address Abnormal Situation Operations. Chem. Eng. Prog. 1995, 91. [Google Scholar]

- Shu, Y.; Ming, L.; Cheng, F.; Zhang, Z.; Zhao, J. Abnormal Situation Management: Challenges and Opportunities in the Big Data Era. Comput. Chem. Eng. 2016, 91, 104–113. [Google Scholar] [CrossRef]

- Arunthavanathan, R.; Khan, F.; Ahmed, S.; Imtiaz, S. An Analysis of Process Fault Diagnosis Methods from Safety Perspectives. Comput. Chem. Eng. 2021, 145, 107197. [Google Scholar] [CrossRef]

- Cochran, E.L.; Miller, C.; Bullemer, P. Abnormal Situation Management in Petrochemical Plants: Can a Pilot’s Associate Crack Crude? In Proceedings of the IEEE 1996 National Aerospace and Electronics Conference NAECON 1996, Dayton, OH, USA, 20–22 May 1996; pp. 806–813. [Google Scholar]

- Dash, S.; Venkatasubramanian, V. Challenges in the Industrial Applications of Fault Diagnostic Systems. Comput. Chem. Eng. 2000, 24, 785–791. [Google Scholar] [CrossRef]

- Cauvin, S.; Celse, B. CHEM: Advanced Decision Support Systems for Chemical/Petrochemical Process Industries. Comput. Aided Chem. Eng. 2004, 18, 1027–1032. [Google Scholar] [CrossRef]

- Ministry of Emergency Management of the PRC. The Guidance of the State Administration of Work Safety on Strengthening Chemical Process Safety Management. China, 2013. Available online: https://www.mem.gov.cn/gk/gwgg/agwzlfl/yj_01/201308/t20130816_242220.shtml (accessed on 18 April 2023).

- Wang, X.; Wang, C.; Shi, H.; Li, C. Research on Technology of Abnormal Condition Warning and Process Safety Management Assessment for Petrochemical Enterprise. Refin. Chem. Ind. 2015, 26, 4. [Google Scholar]

- Dai, Y.; Wang, H.; Khan, F.; Zhao, J. Abnormal Situation Management for Smart Chemical Process Operation. Curr. Opin. Chem. Eng. 2016, 14, 49–55. [Google Scholar] [CrossRef]

- Eljack, F.; Kazi, M.K. Process Safety and Abnormal Situation Management. Curr. Opin. Chem. Eng. 2016, 14, 35–41. [Google Scholar] [CrossRef]

- Goel, P.; Datta, A.; Mannan, M.S. Industrial Alarm Systems: Challenges and Opportunities. J. Loss Prev. Process Ind. 2017, 50, 23–36. [Google Scholar] [CrossRef]

- Bullemer, P.T.; Kiff, L.; Tharanathan, A. Common Procedural Execution Failure Modes during Abnormal Situations. J. Loss Prev. Process Ind. 2011, 24, 814–818. [Google Scholar] [CrossRef]

- Isermann, R.; Ballé, P. Trends in the Application of Model-Based Fault Detection and Diagnosis of Technical Processes. In Control Engineering Practice; Elsevier: Amsterdam, The Netherlands, 1997; Volume 5. [Google Scholar]

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A Review of Process Fault Detection and Diagnosis Part I: Quantitative Model-Based Methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Dai, X.; Gao, Z. From Model, Signal to Knowledge: A Data-Driven Perspective of Fault Detection and Diagnosis. IEEE Trans. Ind. Inform. 2013, 9, 2226–2238. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Kavuri, S.N.; Yin, K. A Review of Process Fault Detection and Diagnosis Part III: Process History Based Methods. Comput. Chem. Eng. 2003, 27, 327–346. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Kavuri, S.N. A Review of Process Fault Detection and Diagnosis Part II: Qualitative Models and Search Strategies. Comput. Chem. Eng. 2003, 27, 313–326. [Google Scholar] [CrossRef]

- Park, Y.J.; Fan, S.K.S.; Hsu, C.Y. A Review on Fault Detection and Process Diagnostics in Industrial Processes. Processes 2020, 8, 1123. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Gu, S.; Chen, T. Process Fault Diagnosis with Model- and Knowledge-Based Approaches: Advances and Opportunities. Control Eng. Pract. 2020, 105, 104637. [Google Scholar] [CrossRef]

- Alauddin, M.; Khan, F.; Imtiaz, S.; Ahmed, S. A Bibliometric Review and Analysis of Data-Driven Fault Detection and Diagnosis Methods for Process Systems. Ind. Eng. Chem. Res. 2018, 57, 10719–10735. [Google Scholar] [CrossRef]

- Md Nor, N.; Che Hassan, C.R.; Hussain, M.A. A Review of Data-Driven Fault Detection and Diagnosis Methods: Applications in Chemical Process Systems. Rev. Chem. Eng. 2020, 36, 513–553. [Google Scholar] [CrossRef]

- Taqvi, S.A.A.; Zabiri, H.; Tufa, L.D.; Uddin, F.; Fatima, S.A.; Maulud, A.S. A Review on Data-Driven Learning Approaches for Fault Detection and Diagnosis in Chemical Processes. ChemBioEng Rev. 2021, 8, 239–259. [Google Scholar] [CrossRef]

- Bi, X.; Qin, R.; Wu, D.; Zheng, S.; Zhao, J. One Step Forward for Smart Chemical Process Fault Detection and Diagnosis. Comput. Chem. Eng. 2022, 164, 107884. [Google Scholar] [CrossRef]

- Tang, X.; Lu, W.; Yan, X. Dual Attention Bidirectional Generative Adversarial Network for Dynamic Uncertainty Process Monitoring and Diagnosis. Process Saf. Environ. Prot. 2023, 171, 214–224. [Google Scholar] [CrossRef]

- Zhou, K.; Tong, Y.; Li, X.; Wei, X.; Huang, H.; Song, K.; Chen, X. Exploring Global Attention Mechanism on Fault Detection and Diagnosis for Complex Engineering Processes. Process Saf. Environ. Prot. 2023, 170, 660–669. [Google Scholar] [CrossRef]

- Lin, Z.; Hu, Z.; Peng, J.; Zhao, H. Dynamic-Scale Graph Neural Network for Fault Detection. Process Saf. Environ. Prot. 2022, 168, 953–970. [Google Scholar] [CrossRef]

- Wei, Z.; Ji, X.; Zhou, L.; Dang, Y.; Dai, Y. A Novel Deep Learning Model Based on Target Transformer for Fault Diagnosis of Chemical Process. Process Saf. Environ. Prot. 2022, 167, 480–492. [Google Scholar] [CrossRef]

- Harinarayan, R.R.A.; Shalinie, S.M. XFDDC: EXplainable Fault Detection Diagnosis and Correction Framework for Chemical Process Systems. Process Saf. Environ. Prot. 2022, 165, 463–474. [Google Scholar] [CrossRef]

- Bian, H.; Jiang, J.; Zhu, Z.; Dou, Z.; Tang, B. Design and Implementation of an Early-Stage Monitoring System for Iron Sulfides Oxidation. Process Saf. Environ. Prot. 2022, 165, 181–190. [Google Scholar] [CrossRef]

- Han, Y.; Song, G.; Liu, F.; Geng, Z.; Ma, B.; Xu, W. Fault Monitoring Using Novel Adaptive Kernel Principal Component Analysis Integrating Grey Relational Analysis. Process Saf. Environ. Prot. 2022, 157, 397–410. [Google Scholar] [CrossRef]

- Bi, X.; Zhao, J. A Novel Orthogonal Self-Attentive Variational Autoencoder Method for Interpretable Chemical Process Fault Detection and Identification. Process Saf. Environ. Prot. 2021, 156, 581–597. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, Y.; Dai, Y.; Ji, X.; Zhou, L.; Dang, Y. Integrating Feature Optimization Using a Dynamic Convolutional Neural Network for Chemical Process Supervised Fault Classification. Process Saf. Environ. Prot. 2021, 155, 473–485. [Google Scholar] [CrossRef]

- Amin, M.T.; Khan, F.; Ahmed, S.; Imtiaz, S. Risk-Based Fault Detection and Diagnosis for Nonlinear and Non-Gaussian Process Systems Using R-Vine Copula. Process Saf. Environ. Prot. 2021, 150, 123–136. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, J. Process Topology Convolutional Network Model for Chemical Process Fault Diagnosis. Process Saf. Environ. Prot. 2021, 150, 93–109. [Google Scholar] [CrossRef]

- Ma, X.; Si, Y.; Yuan, Z.; Qin, Y.; Wang, Y. Multistep Dynamic Slow Feature Analysis for Industrial Process Monitoring. IEEE Trans. Instrum. Meas. 2020, 69, 9535–9548. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, X.; Liu, X.; Cao, Y. Incipient Fault Detection of Nonlinear Chemical Processes Based on Probability-Related Randomized Slow Feature Analysis. Process Saf. Environ. Prot. 2023, 169, 797–807. [Google Scholar] [CrossRef]

- Chen, Y.; Tong, C.; Lan, T. Fault Monitoring for Chemical Processes Using Neighborhood Embedding Discriminative Analysis. Process Saf. Environ. Prot. 2022, 164, 109–118. [Google Scholar] [CrossRef]

- Guo, P.; Rao, S.; Hao, L.; Wang, J. Fault Diagnosis of a Semi-Batch Crystallization Process through Deep Learning Method. Comput. Chem. Eng. 2022, 164, 107807. [Google Scholar] [CrossRef]

- Kopbayev, A.; Khan, F.; Yang, M.; Halim, S.Z. Fault Detection and Diagnosis to Enhance Safety in Digitalized Process System. Comput. Chem. Eng. 2022, 158, 107609. [Google Scholar] [CrossRef]

- Agarwal, P.; Tamer, M.; Budman, H. Explainability: Relevance Based Dynamic Deep Learning Algorithm for Fault Detection and Diagnosis in Chemical Processes. Comput. Chem. Eng. 2021, 154, 107467. [Google Scholar] [CrossRef]

- Li, W.; Gu, S.; Zhang, X.; Chen, T. Transfer Learning for Process Fault Diagnosis: Knowledge Transfer from Simulation to Physical Processes. Comput. Chem. Eng. 2020, 139, 106904. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J. Fault Detection and Diagnosis Based on Transfer Learning for Multimode Chemical Processes. Comput. Chem. Eng. 2020, 135, 106731. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, D.; Yuan, X. LDA-Based Deep Transfer Learning for Fault Diagnosis in Industrial Chemical Processes. Comput. Chem. Eng. 2020, 140, 106964. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J. Deep Convolutional Neural Network Model Based Chemical Process Fault Diagnosis. Comput. Chem. Eng. 2018, 115, 185–197. [Google Scholar] [CrossRef]

- Du, Y.; Du, D. Fault Detection and Diagnosis Using Empirical Mode Decomposition Based Principal Component Analysis. Comput. Chem. Eng. 2018, 115, 1–21. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, J. A Deep Belief Network Based Fault Diagnosis Model for Complex Chemical Processes. Comput. Chem. Eng. 2017, 107, 395–407. [Google Scholar] [CrossRef]

- Zhang, S.; Bi, K.; Qiu, T. Bidirectional Recurrent Neural Network-Based Chemical Process Fault Diagnosis. Ind. Eng. Chem. Res. 2019, 59, 824–834. [Google Scholar] [CrossRef]

- Agarwal, P.; Gonzalez, J.I.M.; Elkamel, A.; Budman, H. Hierarchical Deep LSTM for Fault Detection and Diagnosis for a Chemical Process. Processes 2022, 10, 2557. [Google Scholar] [CrossRef]

- Fang, H.; Tao, W.; Lu, S.; Lou, Z.; Wang, Y.; Xue, Y. Nonlinear Dynamic Process Monitoring Based on Two-Step Dynamic Local Kernel Principal Component Analysis. Processes 2022, 10, 925. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Z.; Li, Z.; Du, S. A Novel Fault Detection Scheme Based on Mutual K-Nearest Neighbor Method: Application on the Industrial Processes with Outliers. Processes 2022, 10, 497. [Google Scholar] [CrossRef]

- Yuan, J.; Tian, Y. An Intelligent Fault Diagnosis Method Using GRU Neural Network towards Sequential Data in Dynamic Processes. Processes 2019, 7, 152. [Google Scholar] [CrossRef]

- Ouyang, H.; Zeng, J.; Li, Y.; Luo, S. Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network. Processes 2020, 8, 391. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, S.; Jin, B. Sequential Fault Diagnosis Based on LSTM Neural Network. IEEE Access 2018, 6, 12929–12939. [Google Scholar] [CrossRef]

- Li, C.; Zhao, D.; Mu, S.; Zhang, W.; Shi, N.; Li, L. Fault Diagnosis for Distillation Process Based on CNN–DAE. Chin. J. Chem. Eng. 2019, 27, 598–604. [Google Scholar] [CrossRef]

- Wang, N.; Yang, F.; Zhang, R.; Gao, F. Intelligent Fault Diagnosis for Chemical Processes Using Deep Learning Multimodel Fusion. IEEE Trans. Cybern. 2022, 52. [Google Scholar] [CrossRef] [PubMed]

- Park, P.; Di Marco, P.; Shin, H.; Bang, J. Fault Detection and Diagnosis Using Combined Autoencoder and Long Short-Term Memory Network. Sensors 2019, 19, 4612. [Google Scholar] [CrossRef]

- Tian, W.; Liu, Z.; Li, L.; Zhang, S.; Li, C. Identification of Abnormal Conditions in High-Dimensional Chemical Process Based on Feature Selection and Deep Learning. Chin. J. Chem. Eng. 2020, 28, 1875–1883. [Google Scholar] [CrossRef]

- Yu, J.; Liu, X.; Ye, L. Convolutional Long Short-Term Memory Autoencoder-Based Feature Learning for Fault Detection in Industrial Processes. IEEE Trans. Instrum. Meas. 2021, 70. [Google Scholar] [CrossRef]

- Xu, Y.; Jia, M.; Mao, Z.; Li, H. A Novel Kernel Dynamic Inner Slow Feature Analysis Method for Dynamic Nonlinear Process Concurrent Monitoring of Operating Point Deviations and Process Dynamics Anomalies. J. Process Control 2022, 110, 59–75. [Google Scholar] [CrossRef]

- Kumar, A.; Bhattacharya, A.; Flores-Cerrillo, J. Data-Driven Process Monitoring and Fault Analysis of Reformer Units in Hydrogen Plants: Industrial Application and Perspectives. Comput. Chem. Eng. 2020, 136, 106756. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention Is All You Need. Adv. Neural Inf. Process. Syst. 2017, 30. [Google Scholar]

- Zhang, S.; Zhao, C. Slow-Feature-Analysis-Based Batch Process Monitoring with Comprehensive Interpretation of Operation Condition Deviation and Dynamic Anomaly. IEEE Trans. Ind. Electron. 2019, 66, 3773–3783. [Google Scholar] [CrossRef]

- Bhadriraju, B.; Kwon, J.S.I.; Khan, F. Risk-Based Fault Prediction of Chemical Processes Using Operable Adaptive Sparse Identification of Systems (OASIS). Comput. Chem. Eng. 2021, 152, 107378. [Google Scholar] [CrossRef]

- Bhadriraju, B.; Kwon, J.S.I.; Khan, F. OASIS-P: Operable Adaptive Sparse Identification of Systems for Fault Prognosis of Chemical Processes. J. Process Control 2021, 107, 114–126. [Google Scholar] [CrossRef]

- Zhao, C.; Gao, F. Online Fault Prognosis with Relative Deviation Analysis and Vector Autoregressive Modeling. Chem. Eng. Sci. 2015, 138, 531–543. [Google Scholar] [CrossRef]

- Zhang, B.; Sconyers, C.; Byington, C.; Patrick, R.; Orchard, M.E.; Vachtsevanos, G. A Probabilistic Fault Detection Approach: Application to Bearing Fault Detection. IEEE Trans. Ind. Electron. 2011, 58, 2011–2018. [Google Scholar] [CrossRef]

- Bai, Y.; Xiang, S.; Zhao, Z.; Yang, B.; Zhao, J. Data-Driven Approaches: Use of Digitized Operational Data in Process Safety. Methods Chem. Process Saf. 2022, 6, 61–99. [Google Scholar] [CrossRef]

- Yang, F.; Dai, C.; Tang, J.; Xuan, J.; Cao, J. A Hybrid Deep Learning and Mechanistic Kinetics Model for the Prediction of Fluid Catalytic Cracking Performance. Chem. Eng. Res. Des. 2020, 155, 202–210. [Google Scholar] [CrossRef]

- Zhong, K.; Han, M.; Han, B. Data-Driven Based Fault Prognosis for Industrial Systems: A Concise Overview. IEEE/CAA J. Autom. Sin. 2020, 7, 330–345. [Google Scholar] [CrossRef]

- Pankratz, A.E. Forecasting with Univariate Box-Jenkins Models: Concepts and Cases; John Wiley & Sons: Hoboken, NJ, USA, 1983. [Google Scholar]

- Büyükşahin, Ü.Ç.; Ertekin, Ş. Improving Forecasting Accuracy of Time Series Data Using a New ARIMA-ANN Hybrid Method and Empirical Mode Decomposition. Neurocomputing 2019, 361, 151–163. [Google Scholar] [CrossRef]

- Zhu, Q.; Jia, Y.; Peng, D.; Xu, Y. Study and Application of Fault Prediction Methods with Improved Reservoir Neural Networks. Chin. J. Chem. Eng. 2014, 22, 812–819. [Google Scholar] [CrossRef]

- Arshad, U.; Taqvi, S.A.A.; Buang, A.; Awad, A. SVM, ANN, and PSF Modelling Approaches for Prediction of Iron Dust Minimum Ignition Temperature (MIT) Based on the Synergistic Effect of Dispersion Pressure and Concentration. Process Saf. Environ. Prot. 2021, 152, 375–390. [Google Scholar] [CrossRef]

- Yuan, X.; Ou, C.; Wang, Y.; Yang, C.; Gui, W. A Novel Semi-Supervised Pre-Training Strategy for Deep Networks and Its Application for Quality Variable Prediction in Industrial Processes. Chem. Eng. Sci. 2020, 217, 115509. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Xiao, F.; Xiao, C.; Wang, F.; Zhang, S. Time-Series Production Forecasting Method Based on the Integration of Bidirectional Gated Recurrent Unit (Bi-GRU) Network and Sparrow Search Algorithm (SSA). J. Pet. Sci. Eng. 2022, 208, 109309. [Google Scholar] [CrossRef]

- Tian, W.; Liu, N.; Sui, D.; Cui, Z.; Liu, Z.; Wang, J.; Zou, H.; Zhao, Y. Early Warning of Internal Leakage in Heat Exchanger Network Based on Dynamic Mechanism Model and Long Short-Term Memory Method. Processes 2021, 9, 378. [Google Scholar] [CrossRef]

- Xu, P.; Du, R.; Zhang, Z. Predicting Pipeline Leakage in Petrochemical System through GAN and LSTM. Knowl. Based Syst. 2019, 175, 50–61. [Google Scholar] [CrossRef]

- Liu, Z.; Tian, W.; Cui, Z.; Wei, H.; Li, C. An Intelligent Quantitative Risk Assessment Method for Ammonia Synthesis Process. Chem. Eng. J. 2021, 420, 129893. [Google Scholar] [CrossRef]

- Arunthavanathan, R.; Khan, F.; Ahmed, S.; Imtiaz, S. A Deep Learning Model for Process Fault Prognosis. Process Saf. Environ. Prot. 2021, 154, 467–479. [Google Scholar] [CrossRef]

- Bai, Y.; Xiang, S.; Cheng, F.; Zhao, J. A Dynamic-Inner LSTM Prediction Method for Key Alarm Variables Forecasting in Chemical Process. Chin. J. Chem. Eng. 2023, 55, 266–276. [Google Scholar] [CrossRef]

- Pang, C.; Duan, D.; Zhou, Z.; Han, S.; Yao, L.; Zheng, C.; Yang, J.; Gao, X. An Integrated LSTM-AM and SPRT Method for Fault Early Detection of Forced-Oxidation System in Wet Flue Gas Desulfurization. Process Saf. Environ. Prot. 2022, 160, 242–254. [Google Scholar] [CrossRef]

- Yuan, Z.; Yang, Z.; Ling, Y.; Wu, C.; Li, C. Spatiotemporal Attention Mechanism-Based Deep Network for Critical Parameters Prediction in Chemical Process. Process Saf. Environ. Prot. 2021, 155, 401–414. [Google Scholar] [CrossRef]

- Xiang, S.; Bai, Y.; Zhao, J. Medium-Term Prediction of Key Chemical Process Parameter Trend with Small Data. Chem. Eng. Sci. 2022, 249, 117361. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, J. A Novel Transformer-Based Multi-Variable Multi-Step Prediction Method for Chemical Process Fault Prognosis. Process Saf. Environ. Prot. 2023, 169, 937–947. [Google Scholar] [CrossRef]

- Li, G.; Qin, S.J.; Yuan, T. Data-Driven Root Cause Diagnosis of Faults in Process Industries. Chemom. Intell. Lab. Syst. 2016, 159, 1–11. [Google Scholar] [CrossRef]

- Han, X.; Tian, S.; Romagnoli, J.A.; Li, H.; Sun, W. PCA-SDG Based Process Monitoring and Fault Diagnosis: Application to an Industrial Pyrolysis Furnace. IFAC-Pap. 2018, 51, 482–487. [Google Scholar] [CrossRef]

- Hong, J.; Qu, J.; Tian, W.; Cui, Z.; Liu, Z.; Lin, Y.; Li, C. Identification of Unknown Abnormal Conditions in Catalytic Cracking Process Based on Two-Step Clustering Analysis and Signed Directed Graph. Processes 2021, 9, 2055. [Google Scholar] [CrossRef]

- Meng, Y.; Song, X.; Zhao, D.; Liu, Q. Alarm Management Optimization in Chemical Installations Based on Adapted HAZOP Reports. J. Loss Prev. Process Ind. 2021, 72, 104578. [Google Scholar] [CrossRef]

- Liu, N.; Hu, M.; Wang, J.; Ren, Y.; Tian, W. Fault Detection and Diagnosis Using Bayesian Network Model Combining Mechanism Correlation Analysis and Process Data: Application to Unmonitored Root Cause Variables Type Faults. Process Saf. Environ. Prot. 2022, 164, 15–29. [Google Scholar] [CrossRef]

- Gharahbagheri, H.; Imtiaz, S.A.; Khan, F. Root Cause Diagnosis of Process Fault Using KPCA and Bayesian Network. Ind. Eng. Chem. Res. 2017, 56, 2054–2070. [Google Scholar] [CrossRef]

- Cheng, F.; Zhao, J. A Novel Method for Real-Time Alarm Root Cause Analysis. Comput. Aided Chem. Eng. 2018, 44, 2323–2328. [Google Scholar] [CrossRef]

- Chen, H.S.; Yan, Z.; Yao, Y.; Huang, T.B.; Wong, Y.S. Systematic Procedure for Granger-Causality-Based Root Cause Diagnosis of Chemical Process Faults. Ind. Eng. Chem. Res. 2018, 57, 9500–9512. [Google Scholar] [CrossRef]

- Fei, H.; Chaojun, W.; Shu-Kai, S.F. Fault Detection and Root Cause Analysis of a Batch Process via Novel Nonlinear Dissimilarity and Comparative Granger Causality Analysis. Ind. Eng. Chem. Res. 2019, 58, 21842–21854. [Google Scholar] [CrossRef]

- He, R.; Chen, G.; Sun, S.; Dong, C.; Jiang, S. Attention-Based Long Short-Term Memory Method for Alarm Root-Cause Diagnosis in Chemical Processes. Ind. Eng. Chem. Res. 2020, 59, 11559–11569. [Google Scholar] [CrossRef]

- Bi, X.; Wu, D.; Xie, D.; Ye, H.; Zhao, J. Large-Scale Chemical Process Causal Discovery from Big Data with Transformer-Based Deep Learning. Process Saf. Environ. Prot. 2023, 173, 163–177. [Google Scholar] [CrossRef]

- Nauta, M.; Bucur, D.; Seifert, C. Causal Discovery with Attention-Based Convolutional Neural Networks. Mach. Learn. Knowl. Extr. 2019, 1, 312–340. [Google Scholar] [CrossRef]

- Khan, F.; Hashemi, S.J.; Paltrinieri, N.; Amyotte, P.; Cozzani, V.; Reniers, G. Dynamic Risk Management: A Contemporary Approach to Process Safety Management. Curr. Opin. Chem. Eng. 2016, 14, 9–17. [Google Scholar] [CrossRef]

- Analouei, R.; Taheriyoun, M.; Amin, M.T. Dynamic Failure Risk Assessment of Wastewater Treatment and Reclamation Plant: An Industrial Case Study. Safety 2022, 8, 79. [Google Scholar] [CrossRef]

- Daley, J.; Khan, F.; Amin, M.T. Process Safety Analysis Using Operational Data and Bayesian Network. Process Saf. Prog. 2023. [Google Scholar] [CrossRef]

- Hashemi, S.J.; Ahmed, S.; Khan, F. Loss Functions and Their Applications in Process Safety Assessment. Process Saf. Prog. 2014, 33, 285–291. [Google Scholar] [CrossRef]

- Hashemi, S.J.; Ahmed, S.; Khan, F.I. Risk-Based Operational Performance Analysis Using Loss Functions. Chem. Eng. Sci. 2014, 116, 99–108. [Google Scholar] [CrossRef]

- Hashemi, S.J.; Ahmed, S.; Khan, F. Operational Loss Modelling for Process Facilities Using Multivariate Loss Functions. Chem. Eng. Res. Des. 2015, 104, 333–345. [Google Scholar] [CrossRef]

- Wang, H.; Khan, F.; Ahmed, S.; Imtiaz, S. Dynamic Quantitative Operational Risk Assessment of Chemical Processes. Chem. Eng. Sci. 2016, 142, 62–78. [Google Scholar] [CrossRef]

- Zadakbar, O.; Khan, F.; Imtiaz, S. Development of Economic Consequence Methodology for Process Risk Analysis. Risk Anal. 2015, 35, 713–731. [Google Scholar] [CrossRef] [PubMed]

- Adedigba, S.A.; Khan, F.; Yang, M. An Integrated Approach for Dynamic Economic Risk Assessment of Process Systems. Process Saf. Environ. Prot. 2018, 116, 312–323. [Google Scholar] [CrossRef]

- Amin, M.T.; Khan, F. Dynamic Process Safety Assessment Using Adaptive Bayesian Network with Loss Function. Ind. Eng. Chem. Res. 2022, 61, 16799–16814. [Google Scholar] [CrossRef]

- Qin, S.J.; Chiang, L.H. Advances and Opportunities in Machine Learning for Process Data Analytics. Comput. Chem. Eng. 2019, 126, 465–473. [Google Scholar] [CrossRef]

- Reis, M.S.; Gins, G. Industrial Process Monitoring in the Big Data/Industry 4.0 Era: From Detection, to Diagnosis, to Prognosis. Processes 2017, 5, 35. [Google Scholar] [CrossRef]

- Bellavista, P.; Bicocchi, N.; Fogli, M.; Giannelli, C.; Mamei, M.; Picone, M. Requirements and Design Patterns for Adaptive, Autonomous, and Context-Aware Digital Twins in Industry 4.0 Digital Factories. Comput Ind 2023, 149, 103918. [Google Scholar] [CrossRef]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Reference Architecture for Digital Twin-Based Predictive Maintenance Systems. Comput. Ind. Eng. 2023, 177, 109099. [Google Scholar] [CrossRef]

- Mo, F.; Rehman, H.U.; Monetti, F.M.; Chaplin, J.C.; Sanderson, D.; Popov, A.; Maffei, A.; Ratchev, S. A Framework for Manufacturing System Reconfiguration and Optimisation Utilising Digital Twins and Modular Artificial Intelligence. Robot. Comput.-Integr. Manuf. 2023, 82, 102524. [Google Scholar] [CrossRef]

- García, Á.; Bregon, A.; Martínez-Prieto, M.A. Towards a Connected Digital Twin Learning Ecosystem in Manufacturing: Enablers and Challenges. Comput. Ind. Eng. 2022, 171, 108463. [Google Scholar] [CrossRef]

- Jin, J.; Hu, J.; Li, C.; Shi, Z.; Lei, P.; Tian, W. A Digital Twin System of Reconfigurable Tooling for Monitoring and Evaluating in Aerospace Assembly. J. Manuf. Syst. 2023, 68, 56–71. [Google Scholar] [CrossRef]

- Meraghni, S.; Terrissa, L.S.; Yue, M.; Ma, J.; Jemei, S.; Zerhouni, N. A Data-Driven Digital-Twin Prognostics Method for Proton Exchange Membrane Fuel Cell Remaining Useful Life Prediction. Int. J. Hydrogen Energy 2021, 46, 2555–2564. [Google Scholar] [CrossRef]

- Mauro, F.; Kana, A.A. Digital Twin for Ship Life-Cycle: A Critical Systematic Review. Ocean. Eng. 2023, 269, 113479. [Google Scholar] [CrossRef]

- Al-Sehrawy, R.; Kumar, B.; Watson, R. The Pluralism of Digital Twins for Urban Management: Bridging Theory and Practice. J. Urban Manag. 2023, 12, 16–32. [Google Scholar] [CrossRef]

- Honghong, S.; Gang, Y.; Haijiang, L.; Tian, Z.; Annan, J. Digital Twin Enhanced BIM to Shape Full Life Cycle Digital Transformation for Bridge Engineering. Autom. Constr. 2023, 147, 104736. [Google Scholar] [CrossRef]

- Liu, S.; Lu, Y.; Shen, X.; Bao, J. A Digital Thread-Driven Distributed Collaboration Mechanism between Digital Twin Manufacturing Units. J. Manuf. Syst. 2023, 68, 145–159. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning Based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

| Research | Method | Feature | Apply |

|---|---|---|---|

| Dual attention bidirectional generative adversarial network for dynamic uncertainty process monitoring and diagnosis [27] | Fault-sensitive bidirectional generative adversarial network (FSBiGAN) | Suitable for dynamic uncertain industrial processes. | Tennessee Eastman Process (TEP) |

| Exploring global attention mechanism on fault detection and diagnosis for complex engineering processes [28] | Industrial Process Optimization Vision Transformer (IPO-ViT) | The transformer-based model is first applied to FDD, showing better performance than other deep learning models. | TEP |

| Dynamic-scale graph neural network for fault detection [29] | Dynamic-scale graph neural network (DSGNN) | Considering the diversity of dynamic characteristics of variables in complex chemical processes. | Nonlinear dynamic numerical case; TEP |

| A novel deep learning model based on target transformer for fault diagnosis of chemical process [30] | Target Transformer | Applying the target attention mechanism to modify the decoder improves the FDD performance. | TEP |

| XFDDC: eXplainable Fault Detection Diagnosis and Correction framework for chemical process systems [31] | eXplainable Fault Detection Diagnosis and Correction (XFDDC) | Using eXplainable Artificial Intelligence (XAI) technology enhances the interpretability of the model. | TEP |

| Design and implementation of an early-stage monitoring system for iron sulfides oxidation [32] | Integrated system | Developed an early monitoring system for iron sulfide oxidation based on the FDD model. | Iron sulfide oxidation |

| Fault monitoring using novel adaptive kernel principal component analysis integrating grey relational analysis [33] | Adaptive kernel principal component analysis integrating grey relational analysis (AKPCA-GRA) | Suitable for dynamic monitoring of nonlinear chemical process faults. | TEP |

| A novel orthogonal self-attentive variational autoencoder method for interpretable chemical process fault detection and identification [34] | Orthogonal self-attentive variational autoencoder (OSAVA) | The method is capable of performing an explanatory analysis of the identified anomalous variables. | TEP |

| Integrating feature optimization using a dynamic convolutional neural network for chemical process supervised fault classification [35] | Dynamic convolutional neural network based on a genetic algorithm | It can not only solve the problem of feature redundancy and irrelevant feature arrangement but also fully extract the frequency and time domain information of the data. | TEP |

| Risk-based fault detection and diagnosis for nonlinear and non-Gaussian process systems using R-vine copula [36] | R-vine copula model | Suitable for nonlinear and non-Gaussian chemical processes | TEP; The RT 580 fault-finding control system; The industrial isomer separator unit. |

| Process topology convolutional network model for chemical process fault diagnosis [37] | Process topology convolutional network (PTCN) | Improved the interpretability of the model. | TEP |

| Multistep Dynamic Slow Feature Analysis for Industrial Process Monitoring [38] | Multistep dynamic slow feature analysis (MS-DSFA) | Fully considering the real dynamic structure during the dimensionality expansion process, and accurately monitoring non-stationary states. | TEP; XJTU-SY bearing data sets |

| Incipient fault detection of nonlinear chemical processes based on probability-related randomized slow feature analysis [39] | Probability-related randomized slow feature analysis (PRSFA) | Achieving efficient nonlinear mapping and more sensitive detection of initial changes. | Simulated continuous stirred tank reactor (CSTR) system |

| Fault monitoring for chemical processes using neighborhood embedding discriminative analysis [40] | Neighborhood embedding discriminative analysis (NEDA) | Adaptively provide different latent feature generation mechanisms for different monitoring samples. | TEP |

| Fault diagnosis of a semi-batch crystallization process through deep learning method [41] | Dynamic Time Warping and Convolutional Neural Network (DTW-CNN) | Suitable for non-Gaussian, nonlinear, and unsteady semi-batch crystallization processes. | The semi-batch crystallization process of acetyl-salicylic acid |

| Fault detection and diagnosis to enhance safety in digitalized process system [42] | A hybrid model that combines KPCA and deep neural networks (KPCA-DNN) | Improved classification accuracy and reduced training time. | TEP |

| Explainability: Relevance based dynamic deep learning algorithm for fault detection and diagnosis in chemical processes [43] | Dynamic Deep Supervised Autoencoder neural networks and Layerwise Relevance Propagation (DDSAE-LRP) | Improved the interpretability of the model. | TEP |

| Transfer learning for process fault diagnosis: Knowledge transfer from simulation to physical processes [44] | Convolutional neural network and transfer learning (CNN-TL) | Solved the problem of lack of fault sample data. | Experiments on simulated CSTR; plant-wide pulp mill processes |

| Fault detection and diagnosis based on transfer learning for multimode chemical processes [45] | DNN-TL | Overcame problems with fault data rarity and lack of labels in some modes. | TEP |

| LDA-based deep transfer learning for fault diagnosis in industrial chemical processes [46] | Linear discriminant analysis-based deep transfer learning (LDA-DTN) | Considering the degree of influence of feature variables on the samples of the source domain and the target domain. | TEP; real hydrocracking process |

| Deep convolutional neural network model based chemical process fault diagnosis [47] | Deep convolutional neural network (DCNN) | Effectively extract spatiotemporal features. | TEP |

| Fault detection and diagnosis using empirical mode decomposition based principal component analysis [48] | Ensemble empirical mode decomposition based principal component analysis (EEMD-PCA) | Suitable for non-stationary data, identifying and diagnosing stochastic faults in TE processes. | TEP |

| A deep belief network based fault diagnosis model for complex chemical processes [49] | An extensible deep belief network (DBN) | Extracting fault features from both spatial and temporal domains simultaneously. | TEP |

| Bidirectional Recurrent Neural Network-Based Chemical Process Fault Diagnosis [50] | Bidirectional recurrent neural network (BiRNN) | Using inverse RNN helps to perceive variable deviations at all time points. | TEP |

| Hierarchical Deep LSTM for Fault Detection and Diagnosis for a Chemical Process [51] | Deep LSTM Supervised Autoencoder Neural Network (Deep LSTM-SAE NN) | Studied the application of deep learning in hierarchical structures. | TEP |

| Nonlinear Dynamic Process Monitoring Based on Two-Step Dynamic Local Kernel Principal Component Analysis [52] | Two-step dynamic local kernel principal component analysis (TSD-LKPCA) | Simultaneous handling of nonlinear and dynamic features. | Numerically simulated dynamic nonlinear process; TEP |

| A Novel Fault Detection Scheme Based on Mutual k-Nearest Neighbor Method: Application on the Industrial Processes with Outliers [53] | Mutual k-nearest neighbor (MkNN) | Eliminates the impact of an outlier on training data. | TEP |

| An Intelligent Fault Diagnosis Method Using GRU Neural Network towards Sequential Data in Dynamic Processes [54] | Gated recurrent units (GRU) | Considering the correlation between sequential data. | TEP; Para-xylene (PX) oxidation process |

| Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network [55] | GRU | Fully capture dynamic characteristics. | Blast Furnace Ironmaking Process |

| Sequential Fault Diagnosis Based on LSTM Neural Network [56] | Long short-term memory (LSTM) | Directly classify the raw process data without specific feature extraction and classifier design, and adaptively learn the dynamic information in raw data. | TEP |

| Fault Diagnosis for Distillation Process Based on CNN–DAE [57] | Convolutional neural network and deep auto-encoder (CNN-DAE) | Combining the feature extraction ability of CNN and the classification ability of DAE. | Distillation process of depropanization |

| Intelligent Fault Diagnosis for Chemical Processes Using Deep Learning Multimodel Fusion [58] | Convolutional neural network and long short-term memory network (CNN-LSTM) | Simultaneously extract temporal and spatial features | TEP; An industrial coking furnace process |

| Fault Detection and Diagnosis Using Combined Autoencoder and Long Short-Term Memory Network [59] | Autoencoder and Long Short-Term Memory Network (AE-LSTM) | Combining the strong low-dimensional nonlinear representation of AE and the powerful time series learning ability of LSTM. | TEP |

| Identification of abnormal conditions in high-dimensional chemical process based on feature selection and deep learning [60] | Generative adversarial network, Spearman’s rank correlation coefficient and deep belief network (GAN-SRCC-DBN) | Solving the insufficient industrial data and missing data, noise variables, redundant process variables and high coupling of data problem. | TEP |

| Convolutional Long Short-Term Memory Autoencoder-Based Feature Learning for Fault Detection in Industrial Processes [61] | Convolutional Long Short-Term Memory Autoencoder (CLSTM-AE) | Learning effective features from complex process signals. | TEP; Simulated CSTR |

| A novel kernel dynamic inner slow feature analysis method for dynamic nonlinear process concurrent monitoring of operating point deviations and process dynamics anomalies [62] | Kernel dynamic inner slow feature analysis method | Considering the nonlinear correlation and serial autocorrelation. | A numerical simulation case; An actual cold rolling mill case |

| Data-driven process monitoring and fault analysis of reformer units in hydrogen plants: Industrial application and perspectives [63] | Partial least squares regression and principal components analysis | Developing a reproducible FD system | Large-scale industrial reformer boxes of hydrogen manufacturing units |

| Method | Principle | Advantages or Disadvantages | References | |

|---|---|---|---|---|

| Knowledge-based method | Signed Directed Graph (SDG) | According to the SDG model, the transmission process of abnormal information is mined to determine its propagation path, and then the root cause of abnormal situations is determined. | The construction of SDG models is usually subjective and time-consuming, which limits their applicability in large-scale and complex processes. In addition, the causal relationship between variables may undergo significant changes under certain process conditions. | [89,90] |

| HAZOP based method | Based on the HAZOP report analysis, identify the causal relationship between variables and construct a topological structure model to trace the root cause of abnormal working conditions. | Relying on high-quality HAZOP analysis reports. | [91] | |

| Data-driven method | Bayesian network (BN) method | Dynamically update the Bayesian network through process data, and then determine the propagation path and root cause of abnormal situations based on the changes in node probabilities before and after the update. | A large amount of historical fault data is required, and the root cause analysis results for unknown faults are unreliable. | [92,93,94] |

| Granger causality method | Based on time series data, examine the causal relationship between two variables. | It is not possible to consider causality between all variables from a global perspective and to deal with indirect causality. | [95,96] | |

| Deep learning methods | Though adding attention mechanisms to evaluate the contribution of variables to the results, the causal relationship between variables can be determined. | Capable of learning complex nonlinear relationships and long-term dependencies. | [97,98,99] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Lei, F.; Zhao, D.; Liu, Q. Abnormal Situation Management in Chemical Processes: Recent Research Progress and Future Prospects. Processes 2023, 11, 1608. https://doi.org/10.3390/pr11061608

Liu S, Lei F, Zhao D, Liu Q. Abnormal Situation Management in Chemical Processes: Recent Research Progress and Future Prospects. Processes. 2023; 11(6):1608. https://doi.org/10.3390/pr11061608

Chicago/Turabian StyleLiu, Shangzhi, Fangyi Lei, Dongfeng Zhao, and Qinglong Liu. 2023. "Abnormal Situation Management in Chemical Processes: Recent Research Progress and Future Prospects" Processes 11, no. 6: 1608. https://doi.org/10.3390/pr11061608