Using an Atmospheric Pressure Chemical Vapor Deposition Process for the Development of V2O5 as an Electrochromic Material

Abstract

:1. Introduction

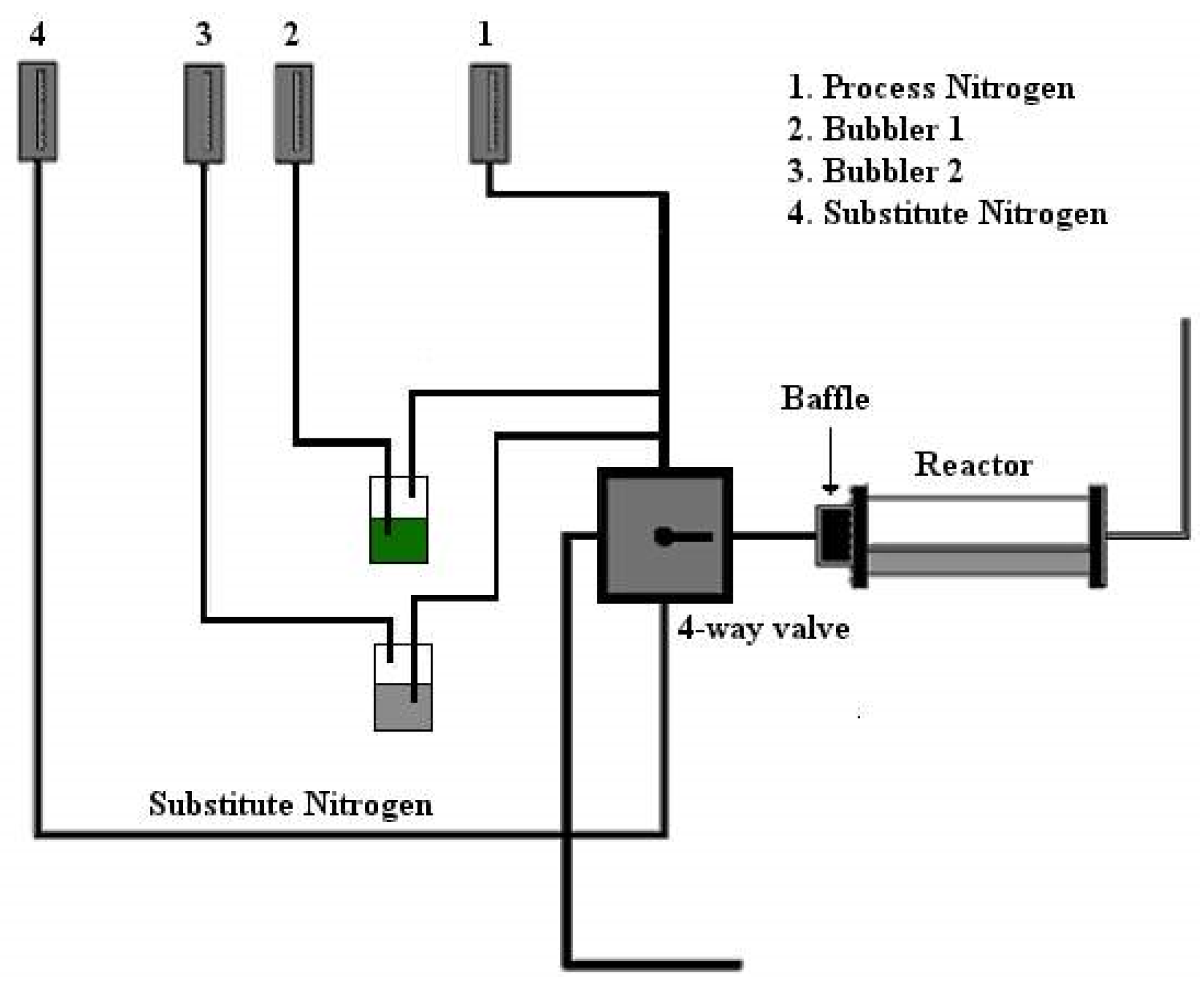

2. Materials and Methods

3. Results and Discussion

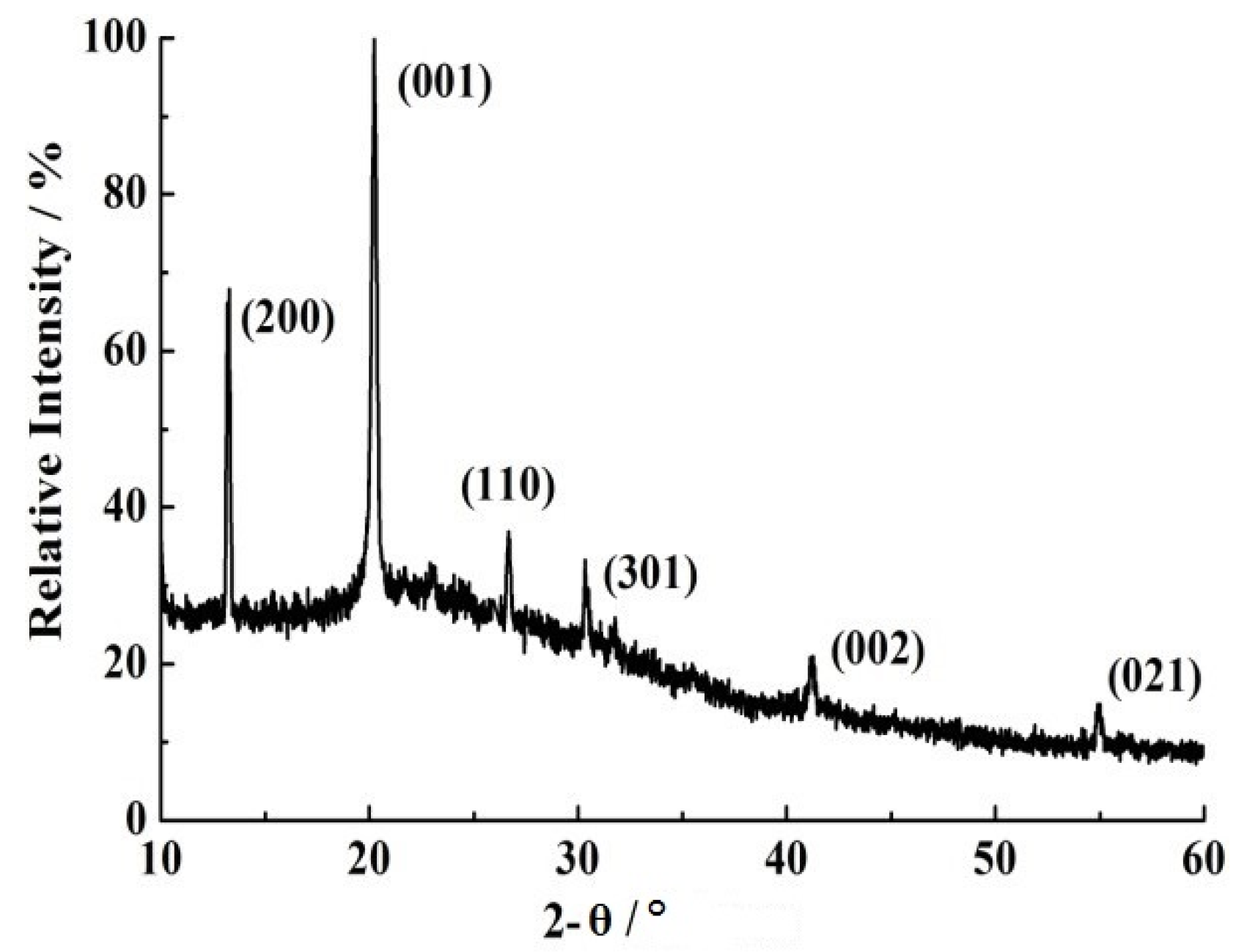

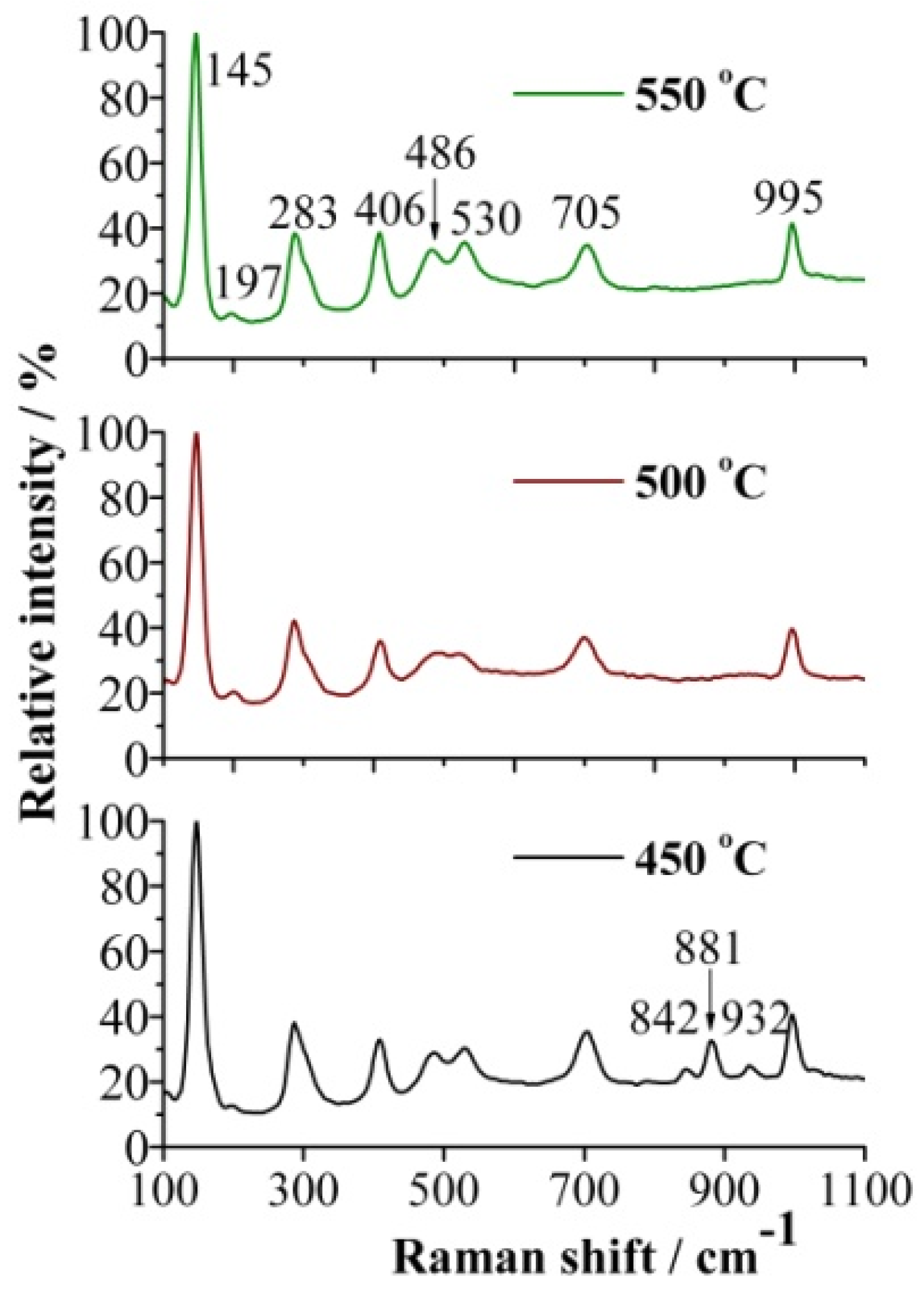

3.1. Structure

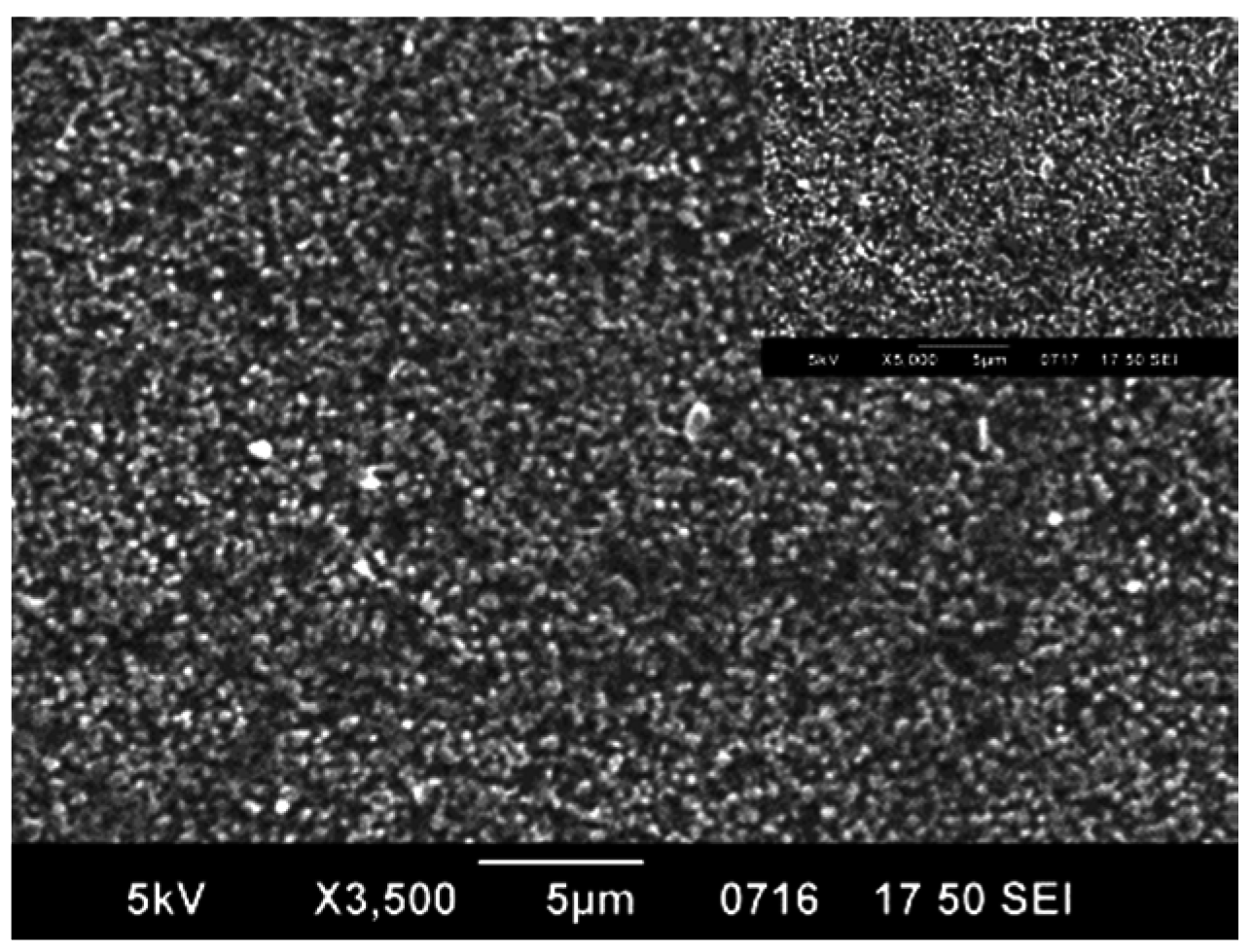

3.2. Morphology

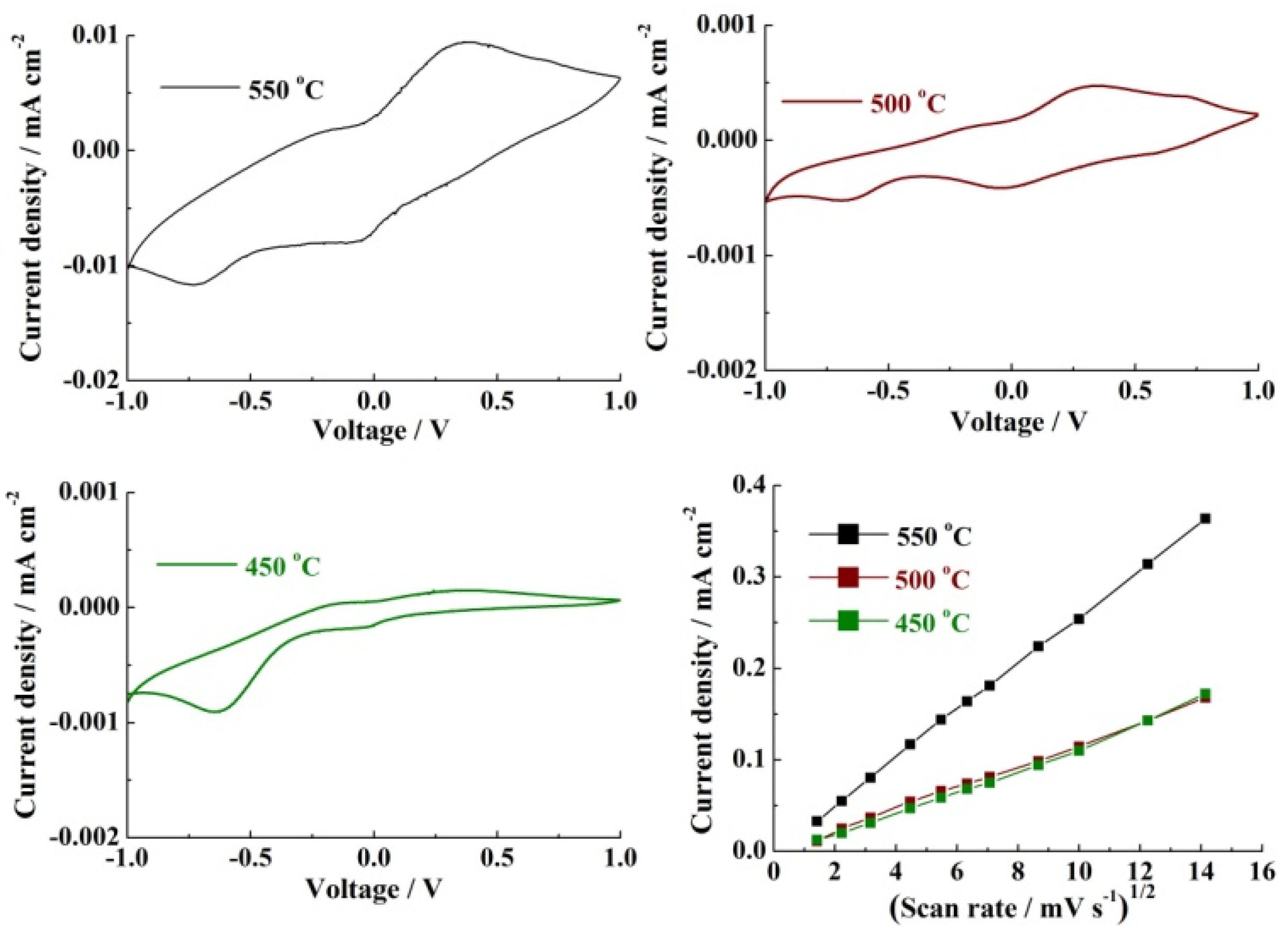

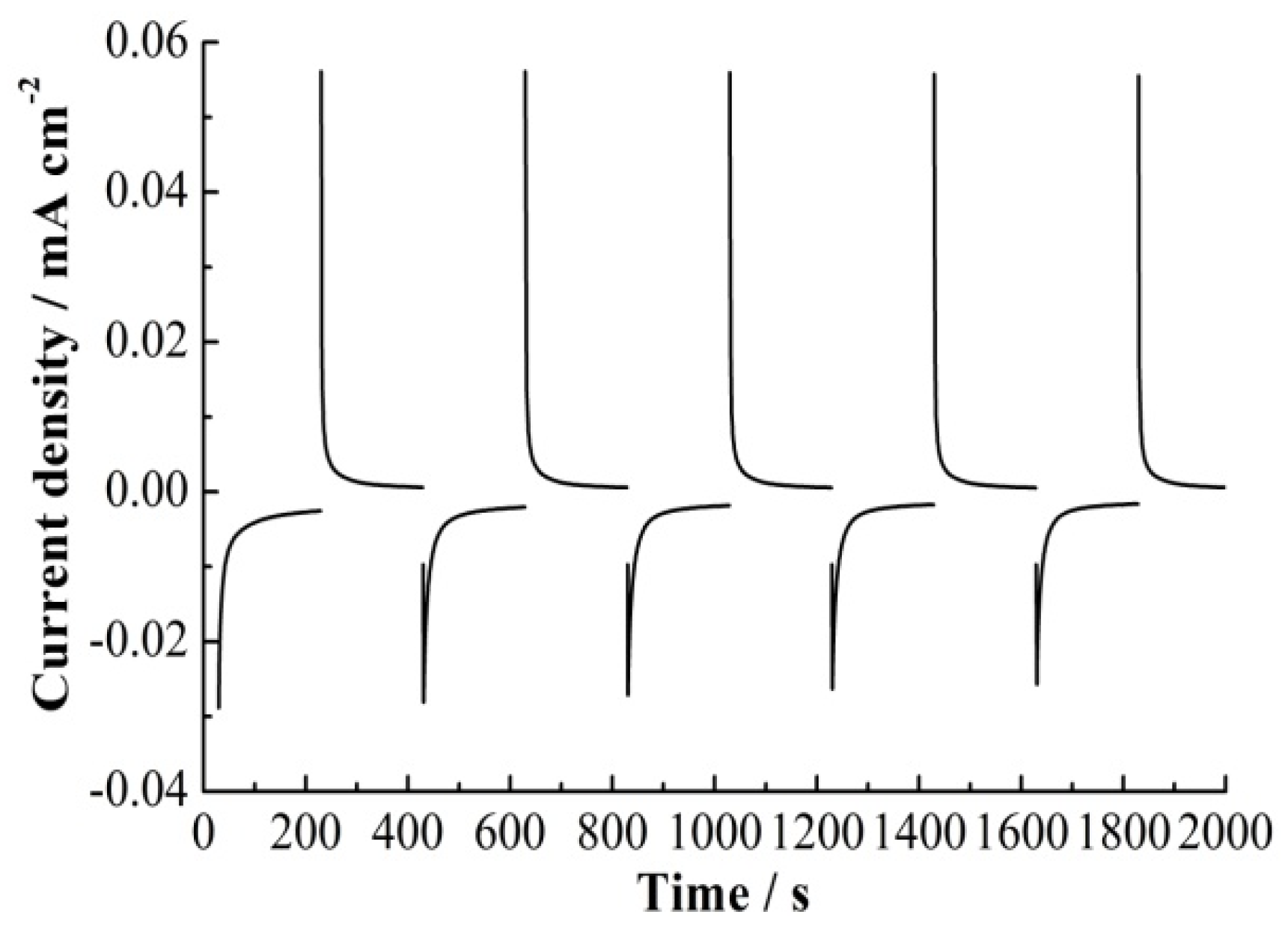

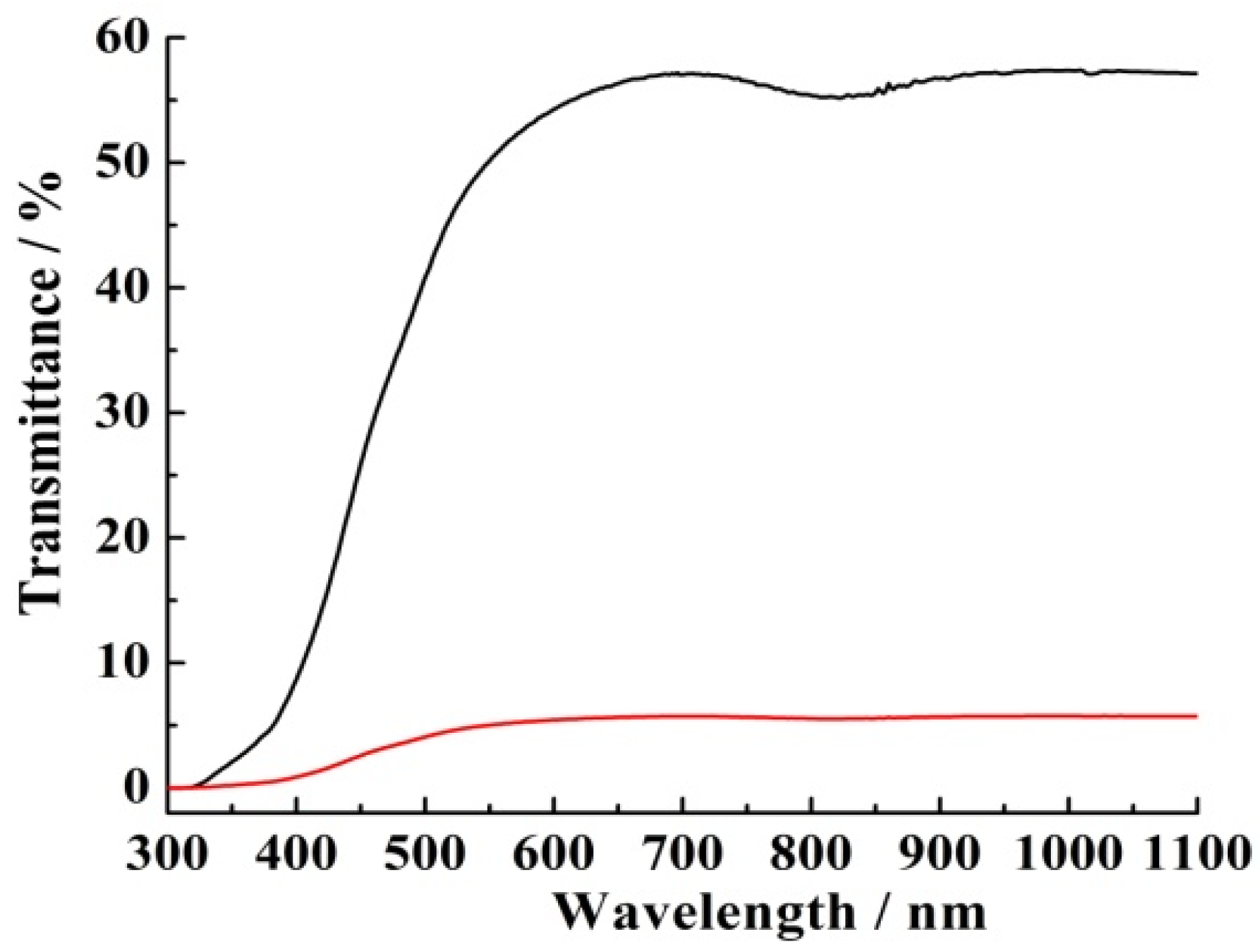

3.3. Electrochemical Performance

3.3.1. Cyclic Voltammetry

3.3.2. Chronoamperometry

3.3.3. Ex-Situ Transmittance Measurements

4. Conclusions

Conflicts of Interest

References

- Brigouleix, C.; Topart, P.; Bruneton, E.; Sabary, F.; Nouhaut, G.; Campet, G. Roll-to-Roll Pulsed dc Magnetron Sputtering Deposition of WO3 for Electrochromic Windows. Electrochim. Acta 2001, 46, 1931–1936. [Google Scholar] [CrossRef]

- Zhai, T.; Liu, H.; Li, H.; Fang, X.; Liao, M.; Li, L.; Zhou, H.; Koide, Y.; Bando, Y.; Golberg, D. Centimeter-Long V2O5 Nanowires: From Synthesis to Field-Emission, Electrochemical, Electrical Transport, and Photoconductive Properties. Adv. Mater. 2010, 22, 2547–2552. [Google Scholar] [CrossRef] [PubMed]

- Tong, Z.; Lv, H.; Zhang, X.; Yang, H.; Tian, Y.; Li, N.; Zhao, J.; Li, Y. Novel Morphology Changes from 3D Ordered Macroporous Structure to V2O5 Nanofiber Grassland and its Application in Electrochromism. Sci. Rep. 2015, 5, 16864. [Google Scholar] [CrossRef] [PubMed]

- Vernardou, D. State-of-the-art of Chemically Grown Vanadium Pentoxide Nanostructures with Enhanced Electrochemical Properties. Adv. Mater. 2013, 4, 798–810. [Google Scholar]

- Drosos, C.; Vernardou, D. Perspectives of Energy Materials Grown by APCVD. Sol. Energy Mater. Sol. Cells 2015, 140, 1–8. [Google Scholar] [CrossRef]

- Talledo, A.; Granqvist, C.G. Electrochromic Vanadium-Pentoxide-Based Films: Structural, Electrochemical and Optical Properties. J. Appl. Phys. 1995, 77, 4655–4666. [Google Scholar] [CrossRef]

- Li, L.; Steiner, U.; Mahajan, S. Improved Electrochromic Performance in Inverse Opal Vanadium Oxide Films. J. Mater. Chem. 2010, 20, 7131–7134. [Google Scholar] [CrossRef]

- Scherer, M.R.J.; Li, L.; Cunha, P.M.S.; Scherman, O.A.; Steiner, U. Enhanced Electrochromism in Gyroid-Structured Vanadium Pentoxide. Adv. Mater. 2012, 24, 1217–1221. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Kim, D.; Schmuki, P. Electrochromic Properties of Anodically Grown Mixed V2O5-TiO2 Nanotubes. Electrochem. Commun. 2011, 13, 1021–1025. [Google Scholar] [CrossRef]

- Chernova, N.A.; Roppolo, M.; Dillon, A.C.; Whittingham, M.S. Layered Vanadium and Molybdenum Oxides: Batteries and Electrochromics. J. Mater. Chem. 2009, 19, 2526–2552. [Google Scholar] [CrossRef]

- He, W.; Liu, Y.; Wan, Z.; Jia, C. Electrodeposition of V2O5 on TiO2 Nanorod Arrays and Their Electrochromic Properties. RSC Adv. 2016, 6, 68997–69006. [Google Scholar] [CrossRef]

- Tong, Z.; Zhang, X.; Lv, H.; Li, N.; Qu, H.; Zhao, J.; Li, Y.; Liu, X.-Y. From Amorphous Macroporous Film to 3D Crystalline Nanorod Architecture: A New Approach to Obtain High-Performance V2O5 Electrochromism. Adv. Mater. Interfaces 2015, 2, 1500230. [Google Scholar] [CrossRef]

- Mjejri, I.; Manceriu, L.M.; Gaudon, M.; Rougier, A.; Sediri, F. Nano-Vanadium Pentoxide Films for Electrochromic Displays. Solid State Ion. 2016, 292, 8–14. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Tsai, C.-W. Reactive Sputtering Deposition of V2O5-z on Flexible PET/ITO Substrates for Electrochromic Devices. Surf. Coat. Technol. 2008, 202, 5641–5645. [Google Scholar] [CrossRef]

- Salek, G.; Bellanger, B.; Mjejri, I.; Gaudon, M.; Rougier, A. Polyol Synthesis of Ti-V2O5 Nanoparticles and Their Use as Electrochromic Films. Inorg. Chem. 2016, 55, 9838–9847. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Lu, S.; Wan, F.; Hu, M.; Wang, Q.; Zhu, Q.; Zakharova, G.S. Synthesis and Electrochromic Characterization of Graphene/V2O5/MoO3 Nanocomposite Films. ECS J. Solid State Sci. Technol. 2016, 5, P572–P577. [Google Scholar] [CrossRef]

- Vernardou, D.; Loudoudakis, D.; Spanakis, E.; Katsarakis, N.; Koudoumas, E. Electrochemical Properties of Vanadium Oxide Coatings Grown by Hydrothermal Synthesis on FTO Substrates. New J. Chem. 2014, 38, 1959–1964. [Google Scholar] [CrossRef]

- Vernardou, D.; Paterakis, P.; Drosos, H.; Spanakis, E.; Povey, I.M.; Pemble, M.E.; Koudoumas, E.; Katsarakis, N. A Study of the Electrochemical Performance of Vanadium Oxide Thin Films Grown by Atmospheric Pressure Chemical Vapour Deposition. Sol. Energy Mater. Sol. Cells 2011, 95, 2842–2847. [Google Scholar] [CrossRef]

- Vernardou, D.; Pemble, M.E.; Sheel, D.W. In-Situ Fourier Transform Infrared Spectroscopy Gas Phase Studies of Vanadium (IV) Oxide Coating by Atmospheric Pressure Chemical Vapour Deposition Using Vanadyl (IV) Acetylacetonate. Thin Solid Films 2008, 516, 4502–4507. [Google Scholar] [CrossRef]

- Vernardou, D.; Pemble, M.E.; Sheel, D.W. In-Situ FTIR Studies of the Growth of Vanadium Dioxide Coatings on Glass by Atmospheric Pressure Chemical Vapour Deposition for VCl4 and H2O System. Thin Solid Films 2007, 515, 8768–8770. [Google Scholar] [CrossRef]

- Vernardou, D.; Louloudakis, D.; Spanakis, E.; Katsarakis, N.; Koudoumas, E. Functional Properties of APCVD VO2 Layers. Int. J. Thin Films Sci. Technol. 2015, 4, 187–191. [Google Scholar]

- Vernardou, D.; Apostolopoulou, M.; Katsarakis, N.; Koudoumas, E.; Drosos, C.; Parkin, I.P. Electrochemical Properties of APCVD α-Fe2O3 Nanoparticles at 300 °C. Chem. Sel. 2016, 1, 2228–2234. [Google Scholar]

- Christou, K.; Louloudakis, D.; Vernardou, D.; Savvakis, C.; Katsarakis, N.; Koudoumas, E.; Kiriakidis, G. Effect of Solution Chemistry on the Characteristics of Hydrothermally Grown WO3 for Electroactive Applications. Thin Solid Films 2015, 594, 333–337. [Google Scholar] [CrossRef]

- Su, Q.; Huang, C.K.; Wang, Y.; Fan, Y.C.; Lu, B.A.; Lan, W.; Wang, Y.Y.; Liu, X.Q. Formation of Vanadium Oxides with Various Morphologies by Chemical Vapor Deposition. J. Alloys Compd. 2009, 475, 518–523. [Google Scholar] [CrossRef]

- Lee, S.-H.; Cheong, H.M.; Seong, M.J.; Liu, P.; Tracy, C.E.; Mascarenhas, A.; Pitts, J.R.; Deb, S.K. Raman Spectroscopic Studies of Amorphous Vanadium Oxide Thin Films. Solid State Ion. 2003, 165, 111–116. [Google Scholar] [CrossRef]

- Abello, L.; Husson, E.; Repelin, Y.; Lucazeau, G. Vibrational Spectra and Valence Force Field of Crystalline V2O5. Spectrochim. Acta A Mol. Spectrosc. 1983, 39, 641–651. [Google Scholar] [CrossRef]

- Julien, C.; Nazri, G.A.; Bergström, O. Raman Scattering Studies of Microcrystalline V6O13. Phys. Status Solidi 1997, 201, 319–326. [Google Scholar] [CrossRef]

- Jehng, J.M.; Hardcastle, F.D.; Wachs, I.E. The Interaction of V2O5 and Nb2O5 with Oxide Surface. Solid State Ion. 1989, 32–33, 904–910. [Google Scholar]

- Cvelbar, U.; Mozetic, M.; Sunkara, M.K.; Vaddiraju, S. A Method for the Rapid Synthesis of Large Quantities of Metal Oxide Nanowires at Low Temperatures. Adv. Mater. 2005, 17, 2138–2142. [Google Scholar]

- Ocãna, M.; Garcia, J.V. Low-Temperature Nucleation of Rutile Observed by Raman Spectroscopy during Crystallization of TiO2. J. Am. Ceram. Soc. 1992, 75, 2010–2012. [Google Scholar] [CrossRef]

- Manning, T.D.; Parkin, I.P.; Clark, R.J.H.; Sheel, D.; Pemble, M.E.; Vernardou, D. Intelligent Window Coatings: Atmospheric Pressure Chemical Vapour Deposition of Vanadium Oxides. J. Mater. Chem. 2002, 12, 2936–2939. [Google Scholar] [CrossRef]

- Awaluddin, A.; Pemble, M.E.; Jones, A.C.; Williams, P.A. Direct Liquid Injection MOCVD Growth of TiO2 Films Using the Precursor Ti(mpd)(dmae)2. J. Phys. IV 2001, 11. [Google Scholar] [CrossRef]

- Crosbie, M.J.; Lane, P.A.; Wright, P.J.; Williams, D.J.; Jones, A.C.; Leedham, T.J.; Reeves, C.L.; Jones, J. Liquid Injection Metal Organic Chemical Vapour Deposition of Lead-Scandium-Tantalate Thin Films for Infrared Devices. J. Cryst. Growth 2000, 219, 390–396. [Google Scholar] [CrossRef]

- Vernardou, D.; Louloudakis, D.; Katsarakis, N.; Koudoumas, E.; Kazadojev, I.I.; O’Brien, S.; Pemble, M.E.; Povey, I.M. Electrochemical Evaluation of Vanadium Pentoxide Coatings Grown by AACVD. Sol. Energy Mater. Sol. Cells 2015, 43, 601–605. [Google Scholar] [CrossRef]

- Pang, Y.; Chen, Q.; Shen, X.; Tang, X.; Tang, L.; Qian, H. Size-Controlled Ag Nanoparticle Modified WO3 Composite Films for Adjustment of Electrochromic Properties. Thin Solid Films 2010, 518, 1920–1924. [Google Scholar] [CrossRef]

- Ivanova, T.; Gesheva, K.A.; Popkirov, G.; Ganchev, M.; Tzvetkova, E. Electrochromic Properties of Atmospheric CVD MoO3 and MoO3-WO3 Films and Their Application in Electrochromic Devices. Mater. Sci. Eng. B 2005, 119, 232–239. [Google Scholar] [CrossRef]

- Brezesinski, T.; Fattakhova Rohlfing, D.; Sallard, S.; Antonietti, M.; Smarsly, B.M. Highly Crystalline WO3 Thin Films with Ordered 3D Mesoporosity and Improved Electrochromic Performance. Small 2006, 2, 1203–1211. [Google Scholar] [CrossRef] [PubMed]

- Psifis, K.; Louloudakis, D.; Vernardou, D.; Spanakis, E.; Papadimitropoulos, G.; Davazoglou, D.; Katsarakis, N.; Koudoumas, E. Effect of O2 Flow Rate on the Electrochromic Response of WO3 Grown by LPCVD. Phys. Status Solidi C 2015, 12, 1011–1015. [Google Scholar] [CrossRef]

- Christou, K.; Louloudakis, D.; Vernardou, D.; Katsarakis, N.; Koudoumas, E. One-Pot Synthesis of WO3 Structures at 95 °C Using HCl. J. Sol-Gel Sci. Technol. 2015, 73, 520–526. [Google Scholar] [CrossRef]

- Jiao, Z.; Wei Sun, X.; Wang, J.; Ke, L.; Volkan Demir, H. Hydrothermally Grown Nanostructured WO3 Films and Their Electrochromic Characteristics. J. Phys. D Appl. Phys. 2010, 43, 285501. [Google Scholar] [CrossRef]

- Lantelme, F.; Mantoux, A.; Groult, H.; Lincot, D. Electrochemical Study of Phase Transition Processes in Lithium Insertion in V2O5 Electrodes. J. Electrochem. Soc. 2003, 150, A1202–A1208. [Google Scholar] [CrossRef]

- Watanabe, T.; Ikeda, Y.; Ono, T.; Hibino, M.; Hododa, M.; Sakai, K.; Kudo, T. Characterization of Vanadium Oxide Sol as a Starting Material for High Rate Intercalation Cathodes. Solid State Ion. 2002, 151, 313–320. [Google Scholar] [CrossRef]

- Sahana, M.B.; Sudakar, C.; Thapa, C.; Lawes, G.; Naik, V.M.; Baird, R.J.; Auner, G.W.; Naik, R.; Padmanabhan, K.R. Electrochemical Properties of V2O5 Thin Films Deposited by Spin Coating. Mater. Sci. Eng. B 2007, 143, 42–50. [Google Scholar] [CrossRef]

- Patil, C.E.; Jadhav, P.R.; Tarwal, N.L.; Deshmukh, H.P.; Karanjkard, M.M.; Patil, P.S. Electrochromic Performance of Mixed V2O5-MoO3 Thin Films Synthesized by Pulsed Spray Pyrolysis Technique. Mater. Chem. Phys. 2011, 126, 711–716. [Google Scholar] [CrossRef]

- Bathe, S.R.; Patil, P.S. Electrochromic Characteristics of Fibrous Reticulated WO3 Thin Films Prepared by Pulsed Spray Pyrolysis Technique. Sol. Energy Mater. Sol. Cells 2007, 91, 1097–1101. [Google Scholar] [CrossRef]

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vernardou, D. Using an Atmospheric Pressure Chemical Vapor Deposition Process for the Development of V2O5 as an Electrochromic Material. Coatings 2017, 7, 24. https://doi.org/10.3390/coatings7020024

Vernardou D. Using an Atmospheric Pressure Chemical Vapor Deposition Process for the Development of V2O5 as an Electrochromic Material. Coatings. 2017; 7(2):24. https://doi.org/10.3390/coatings7020024

Chicago/Turabian StyleVernardou, Dimitra. 2017. "Using an Atmospheric Pressure Chemical Vapor Deposition Process for the Development of V2O5 as an Electrochromic Material" Coatings 7, no. 2: 24. https://doi.org/10.3390/coatings7020024

APA StyleVernardou, D. (2017). Using an Atmospheric Pressure Chemical Vapor Deposition Process for the Development of V2O5 as an Electrochromic Material. Coatings, 7(2), 24. https://doi.org/10.3390/coatings7020024