Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings

Abstract

:1. Introduction

2. Experimental Techniques

2.1. Coating Manufacturing

| Spray Parameter | Powder | |

|---|---|---|

| Al2O3 | Al2O3-13TiO2 | |

| Current [A] | 600 | 530 |

| Argon [slpm] | 41 | 41 |

| Hydrogen [slpm] | 14 | 14 |

| Nozzle diameter [mm] | 6 | 6 |

| Spray distance [mm] | 120 | 120 |

| Powder feed rate [g/min] | 30 | 30 |

| Spray parameter | Powder |

|---|---|

| Al2O3, Al2O3-13TiO2 | |

| Ethylene [slpm] | 93 |

| Oxygen [slpm] | 270 |

| Spray distance [mm] | 150 |

| Chamber/nozzle [mm] | 22/135 |

| Powder feed rate [g/min] | 40 |

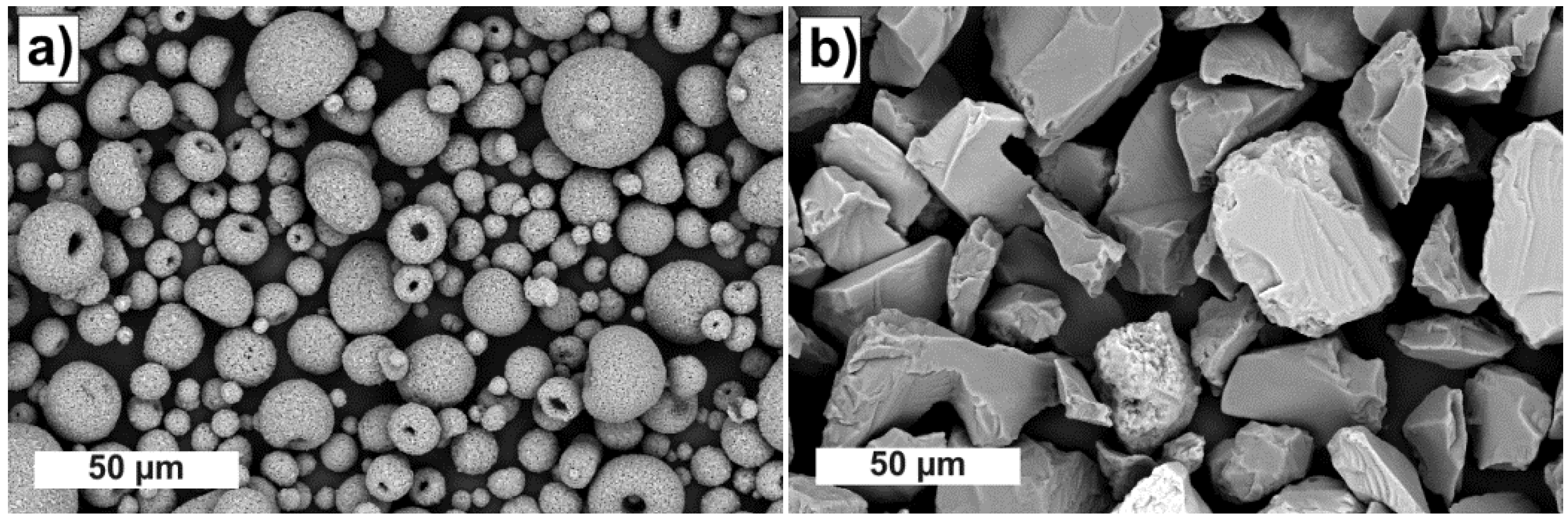

2.2. Powder Materials

| Sample name | Chemical Composition | Manufacturing method | Manufacturer | Trade name | Particle size [μm] | Spray method |

|---|---|---|---|---|---|---|

| APS_A | Al2O3 | F/C | H.C. Starck, Goslar, Germany | Amperit 740.1 | -45+22 | Plasma |

| HVOF_A | Al2O3 | F/C | H.C. Starck, Goslar, Germany | Amperit 740.8 | -20+5 | HVOF |

| APS_AT1 | Al2O3-13TiO2 | F/C | Sulzer Metco, Wohlen, Switzerland | Amdry 6228 | -45+22 | Plasma |

| HVOF_AT1 | Al2O3-13TiO2 | F/C | Sulzer Metco, Wohlen, Switzerland | Amdry 6220 | -22+5 | HVOF |

| APS_AT2 | Al2O3-13TiO2 | A/S | Millidyne, Tampere, Finland | Neoxid A103 | -45+9 | Plasma |

| HVOF_AT2 | Al2O3-13TiO2 | A/S | Millidyne, Tampere, Finland | Neoxid A103 | -32+5 | HVOF |

2.3. Characterisation Techniques

2.4. Wear Tests

3. Results and Discussion

3.1. Coating Microstructure

3.2. Hardness Measurements

| Measured quantity | APS_A | HVOF_A | APS_AT1 | HVOF_AT1 | APS_AT2 | HVOF_AT2 |

|---|---|---|---|---|---|---|

| Hardness [HV0.3] | 1105 | 1117 | 1089 | 1075 | 1009 | 1027 |

| Standard deviation | 171 | 54 | 102 | 58 | 142 | 81 |

3.3. Cavitation Erosion Wear Resistance

3.4. Abrasion Wear Resistance

3.5. Erosion Wear Resistance

4. Conclusions

- Relatively dense coatings were sprayed from all powders with both spray processes. HVOF-sprayed coatings showed denser structure as higher particle velocities were reached in the process. This resulted in dense structure with small number of horizontal cracks. Larger cracks were observed in plasma-sprayed coatings compared to HVOF coatings.

- HVOF coatings, sprayed from fused and crushed powders, outperformed all other coatings in the wear tests. Higher velocity and small particle size resulted in dense and fine microstructure, which provided the coatings with high wear resistance comparable to bulk Al2O3.

- Plasma-sprayed coatings from agglomerated and sintered Al2O3-TiO2 powder showed high wear resistance and outperformed the conventional coatings sprayed with fused and crushed powders. Improved properties were achieved by the agglomeration and sintering powder manufacturing route. This promoted the even distribution of TiO2 in the coating.

- Coating ranking was basically identical between the abrasion and erosion wear tests as coating wear behavior was very similar. The denser HVOF coatings performed better than their APS counterparts. Improved abrasion and erosion resistance was achieved with the TiO2 alloying as agglomerated and sintered powder was used. The TiO2 addition, however, decreased the wear resistance when blended F/C powder was used.

- HVOF-sprayed coatings from F/C powders performed very well compared to other coatings. All the tested coatings showed linear weight loss. Material removal in the cavitation erosion test of the coatings happened purely by brittle fracture revealing the structural differences between thecoatings.

Acknowledgments

Conflicts of Interest

References

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings; John Wiley & Sons, Inc.: Oxford, UK, 1995; p. 626. [Google Scholar]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International: Materials Park, OH, USA, 2004; p. 338. [Google Scholar]

- Bengisu, M. Engineering Ceramics; Springer: New York, NY, USA, 2001; p. 620. [Google Scholar]

- Gell, M.; Jordan, E.H.; Sohn, Y.H.; Goberman, D.; Shaw, L.; Xiao, T.D. Development and implementation of plasma sprayed nanostructured ceramic coatings. Surf. Coatings Technol. 2001, 146–147, 48–54. [Google Scholar]

- Jordan, E.H.; Gell, M.; Sohn, Y.H.; Goberman, D.; Shaw, L.; Jiang, S.; Wang, M.; Xiao, T.D.; Wang, Y.; Strutt, P. Fabrication and evaluation of plasma sprayed nanostructured alumina-titania coatings with superior properties. Mater. Sci. Eng. A 2001, 301, 80–89. [Google Scholar] [CrossRef]

- Varis, T.; Knuuttila, J.; Turunen, E.; Leivo, J.; Silvonen, J.; Oksa, M. Improved protection properties by using nanostructured ceramic powders for HVOF coatings. J. Therm. Spray Technol. 2007, 16, 524–532. [Google Scholar] [CrossRef]

- Shaw, L.L.; Goberman, D.; Ren, R.; Gell, M.; Jiang, S.; Wang, Y.; Xiao, T.D.; Strutt, P.R. The dependency of microstructure and properties of nanostructured coatings on plasma spray conditions. Surf. Coatings Technol. 2000, 130, 1–8. [Google Scholar] [CrossRef]

- Ahn, J.; Hwang, B.; Song, E.P.; Lee, S.; Kim, N.J. Correlation of microstructure and wear resistance of Al2O3-TiO2 coatings plasma sprayed with nanopowders. Met. Mater. Trans. A 2006, 37, 1851–1861. [Google Scholar] [CrossRef]

- Wang, M.; Shaw, L.L. Effects of the powder manufacturing method on microstructure and wear performance of plasma sprayed alumina-titania coatings. Surf. Coatings Technol. 2007, 202, 34–44. [Google Scholar] [CrossRef]

- Lima, R.S.; Moreau, C.; Marple, B.R. HVOF-sprayed coatings engineered from mixtures of nanostructured and submicron Al2O3-TiO2 powders: An enhanced wear performance. J. Therm. Spray Technol. 2007, 16, 866–872. [Google Scholar]

- Fauchais, P. Understanding plasma spraying. J. Phys. D Appl. Phys. 2004, 37, R86–R108. [Google Scholar] [CrossRef]

- Niemi, K.; Vuoristo, P.; Mäntylä, T. Properties of Alumina Based Coatings Deposited by Plasma and High Velocity Combustion Processes. In Proceedings of 1993 National Thermal Spray Conference, Anaheim, CA, USA, 7–11 June 1993; pp. 469–474.

- Niemi, K.; Vuoristo, P.; Mäntylä, T. Properties of alumina-based coatings deposited by plasma spray and detonation gun spray processes. J. Therm. Spray Technol. 1994, 3, 199–203. [Google Scholar] [CrossRef]

- Niemi, K. Abrasion Wear Characteristics of Thermally Sprayed Alumina Based Coatings. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 2009; p. 117. [Google Scholar]

- Niemi, K.; Hakalahti, J.; Hyvärinen, L.; Laurila, J.; Vuoristo, P.; Berger, L.-M.; Toma, F.-L.; Shahkhverdova, I. Influence of chromia alloying on the characteristics of APS and HVOF sprayed alumina coatings. In Proceedings of International Thermal Spray Conference 2011, Hamburg, Germany, 27–29 September 2011.

- Toma, F.-L.; Scheitz, S.; Berger, L.-M.; Sauchuk, V.; Kusnezoff, M.; Thiele, S. Comparative study of electrical properties and characteristics of thermally sprayed alumina and spinel coatings. J. Therm. Spray Technol. 2011, 20, 195–204. [Google Scholar] [CrossRef]

- Kreye, H.; Zimmermann, S.; Heinrich, P. The role of the fuel gas in the HVOF process. In Proceedings of ITSC’95, Kobe, Japan, 22–26 May 1995; ASM International: Materials Park, OH, USA, 1995; pp. 393–398. [Google Scholar]

- Bolelli, G.; Lusvarghi, L.; Manfredini, T.; Mantini, F.P.; Polini, R.; Turunen, E.; Varis, T. Comparison between plasma- and HVOF-sprayed ceramic coatings. Part I: Microstructure and mechanical properties. Int. J. Surf. Sci. Eng. 2007, 1, 38–61. [Google Scholar] [CrossRef]

- Vuoristo, P.; Niemi, K.; Matikainen, V.; Hyvärinen, L.; Koivuluoto, H.; Berger, L.-M.; Scheitz, S.; Shakhverdova, I. Structure and Properties of HVOF and Plasma Sprayed Ceramic Alumina-Chromia Coatings Deposited from Fused and Crushed Powders. In Thermal Spray 2013—Innovative Coating Solutions for the Global Economy, Proceedings of the ITSC2013 Conference, Busan, Korea, 13–15 May 2013; Lima, R.S., Agarwal, A., Hyland, M.M., Lau, Y.-C., Mauer, G., McDonald, A., Toma, F.-L., Eds.; ASM International: Materials Park, OH, USA, 2013; pp. 465–470. [Google Scholar]

- Singh, R.; Tiwari, S.K.; Mishra, S.K. Cavitation erosion in hydraulic turbine components and mitigation by coatings: Current status and future needs. J. Mater. Eng. Perform. 2011, 21, 1539–1551. [Google Scholar] [CrossRef]

- Sugiyama, K.; Nakahama, S.; Hattori, S.; Nakano, K. Slurry wear and cavitation erosion of thermal-sprayed cermets. Wear 2005, 258, 768–775. [Google Scholar] [CrossRef]

- Yuping, W.; Pinghua, L.; Chenglin, C.; Zehua, W.; Ming, C.; Junhua, H. Cavitation erosion characteristics of a Fe-Cr-Si-B-Mn coating fabricated by high velocity oxy-fuel (HVOF) thermal spray. Mater. Lett. 2007, 61, 1867–1872. [Google Scholar] [CrossRef]

- Lima, M.M.; Godoy, C.; Modenesi, P.J.; Avelar-Batista, J.C.; Davison, A.; Matthews, A. Coating fracture toughness determined by vickers identation: An important parameter in cavitation erosion resistance of WC-Co thermally sprayed coatings. Surf. Coatings Technol. 2004, 177–178, 489–496. [Google Scholar]

- Tomlinson, W.J.; Kalitsounakis, N.; Vekinis, G. Cavitation erosion of aluminas. Ceram. Int. 1999, 25, 331–338. [Google Scholar] [CrossRef]

- Niebuhr, D. Cavitation erosion behavior of ceramics in aqueous solutions. Wear 2007, 263, 295–300. [Google Scholar] [CrossRef]

- Fatjó, G.G.; Hadfield, M.; Vieillard, C.; Sekulic, J. Early stage cavitation erosion within ceramics—An experimental investigation. Ceram. Int. 2009, 35, 3301–3312. [Google Scholar] [CrossRef]

- Jafarzadeh, K.; Valefi, Z.; Ghavidel, B. The effect of plasma spray parameters on the cavitation erosion of Al2O3-TiO2 coatings. Surf. Coatings Technol. 2010, 205, 1850–1855. [Google Scholar] [CrossRef]

- Schwetzke, R.; Kreye, H. Cavitation Erosion of HVOF Coatings. In Thermal Spray: Practical Solutions for Engineering Problems; Berndt, C.C., Ed.; ASM International: Materials Park, OH, USA, 1996; pp. 153–158. [Google Scholar]

- Espitia, L.A.; Toro, A. Cavitation resistance, microstructure and surface topography of materials used for hydraulic components. Tribol. Int. 2010, 43, 2037–2045. [Google Scholar] [CrossRef]

- ASTM G32-10 Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Kuroda, S.; Dendo, T.; Kitahara, S. Quenching stress in plasma sprayed coatings and its correlation with the deposit microstructure. J. Therm. Spray Technol. 1995, 4, 75–84. [Google Scholar] [CrossRef]

- Li, L.; Kharas, B.; Zhang, H.; Sampath, S. Suppression of crystallization during high velocity impact quenching of alumina droplets: Observations and characterization. Mater. Sci. Eng. A 2007, 456, 35–42. [Google Scholar] [CrossRef]

- Sakoda, T.; Inaba, M.; Taguchi, K. Microscopic Characteristics and Mechanical Properties of Plasma Sprayed Al2O3 Coatings. In Thermal Spray 2013—Innovative Coating Solutions for the Global Economy, Proceedings of the ITSC2013 Conference, Busan, Korea, 13–15 May 2013; Lima, R.S., Agarwal, A., Hyland, M.M., Lau, Y.-C., Mauer, G., McDonald, A., Toma, F.-L., Eds.; ASM International: Materials Park, OH, USA, 2013; pp. 406–411. [Google Scholar]

- Hurevich, V.; Smurov, I.; Pawlowski, L. Theoretical study of the powder behavior of porous particles in a flame during plasma spraying. Surf. Coatings Technol. 2002, 151–152, 370–376. [Google Scholar] [CrossRef]

- Tsochatzidis, N.A.; Guiraud, P.; Wilhelm, A.M.; Delmas, H. Determination of velocity, size and concentration of ultrasonic cavitation bubbles by the phase-Doppler technique. Chem. Eng. Sci. 2001, 56, 1831–1840. [Google Scholar] [CrossRef]

- Karimi, A.; Martin, J.L. Cavitation erosion of materials. Int. Met. Rev. 1986, 31, 1–26. [Google Scholar] [CrossRef]

- Tucker, R.C. ASM Handbook Volume 5A: Thermal Spray Technology; ASM International: Materials Park, OH, USA, 2013. [Google Scholar]

- American Society for Metals. ASM Handbook Volume 18: Friction, Lubrication, and Wear Technology, 10th ed.; ASM International: Materials Park, OH, USA, 1992. [Google Scholar]

- Westergård, R.; Erickson, L.C.; Axén, N.; Hawthorne, H.M.; Hogmark, S. The erosion and abrasion characteristics of alumina coatings plasma sprayed under different spraying coatings. Tribol. Int. 1998, 31, 271–279. [Google Scholar] [CrossRef]

- Westergård, R.; Axén, N.; Wiklund, U.; Hogmark, S. An evaluation of plasma sprayed ceramic coatings by erosion, abrasion and bend testing. Wear 2000, 246, 12–19. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Matikainen, V.; Niemi, K.; Koivuluoto, H.; Vuoristo, P. Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings. Coatings 2014, 4, 18-36. https://doi.org/10.3390/coatings4010018

Matikainen V, Niemi K, Koivuluoto H, Vuoristo P. Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings. Coatings. 2014; 4(1):18-36. https://doi.org/10.3390/coatings4010018

Chicago/Turabian StyleMatikainen, Ville, Kari Niemi, Heli Koivuluoto, and Petri Vuoristo. 2014. "Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings" Coatings 4, no. 1: 18-36. https://doi.org/10.3390/coatings4010018