Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials and Coating Manufacturing

| Element | Powder | ||||

|---|---|---|---|---|---|

| Fe-Ni-Cr-B-C | Fe-Ni-Cr-Mo-B-C | Ni-Cr-Fe-Si-B-C | WC-CoCr_1 (Diamalloy 5834) | WC-CoCr_2 (Amdry 5843) | |

| Fe | bal. | bal. | 4 | – | – |

| Ni | 9 | 12 | bal. | 1 | – |

| Cr | 32 | 31 | 17 | 4 | 4 |

| Mo | – | 2 | – | – | – |

| B | 4 | 3.6 | 3.5 | – | – |

| C | 0.6 | 0.6 | 1 | – | – |

| Si | – | – | 4 | – | – |

| WC | – | – | – | 85 | 86 |

| Co | – | – | – | 10 | 10 |

| Parameters | Powder | ||||

|---|---|---|---|---|---|

| Fe-Ni-Cr-B-C | Fe-Ni-Cr-Mo-B-C | Ni-Cr-Fe-Si-B-C | WC-CoCr_1 | WC-CoCr_2 | |

| Air flow rate (SL/min) | 375 | 375 | 375 | 375 | 375 |

| O2 flow rate (SL/min) | 190 | 240 | 190 | 240 | 240 |

| Propane flow rate (SL/min) | 70 | 70 | 70 | 70 | 70 |

| Powder feed rate (g/min) | 60 | 60 | 60 | 60 | 60 |

| Spray distance (mm) | 230 | 230 | 230 | 230 | 230 |

2.2. Microstructural and Mechanical Characterization

2.3. Wear Test

2.3.1. Dry Sliding Wear Resistance

2.3.2. Abrasion Wear Resistance

2.3.3. Cavitation Erosion Wear Resistance

3. Results and Discussion

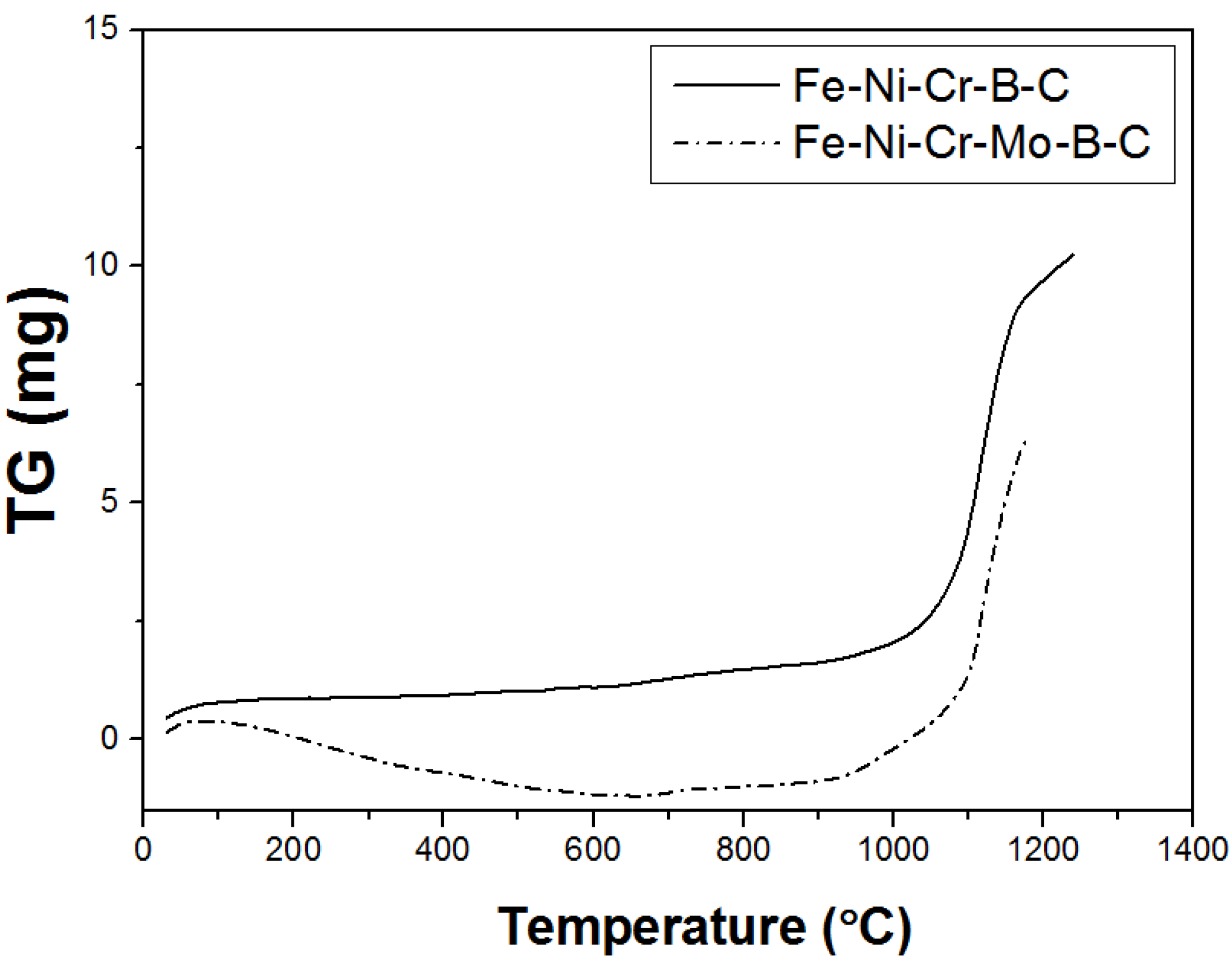

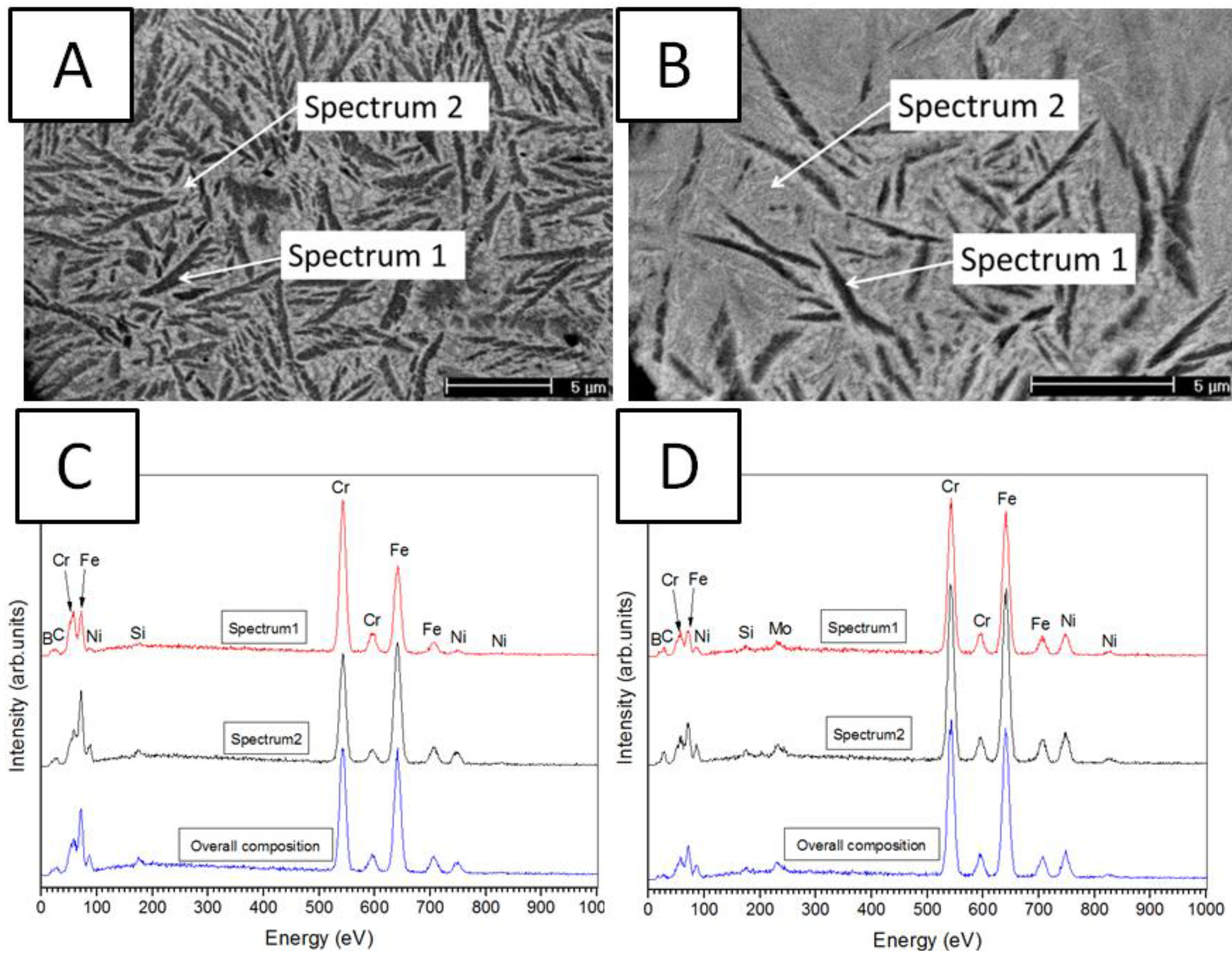

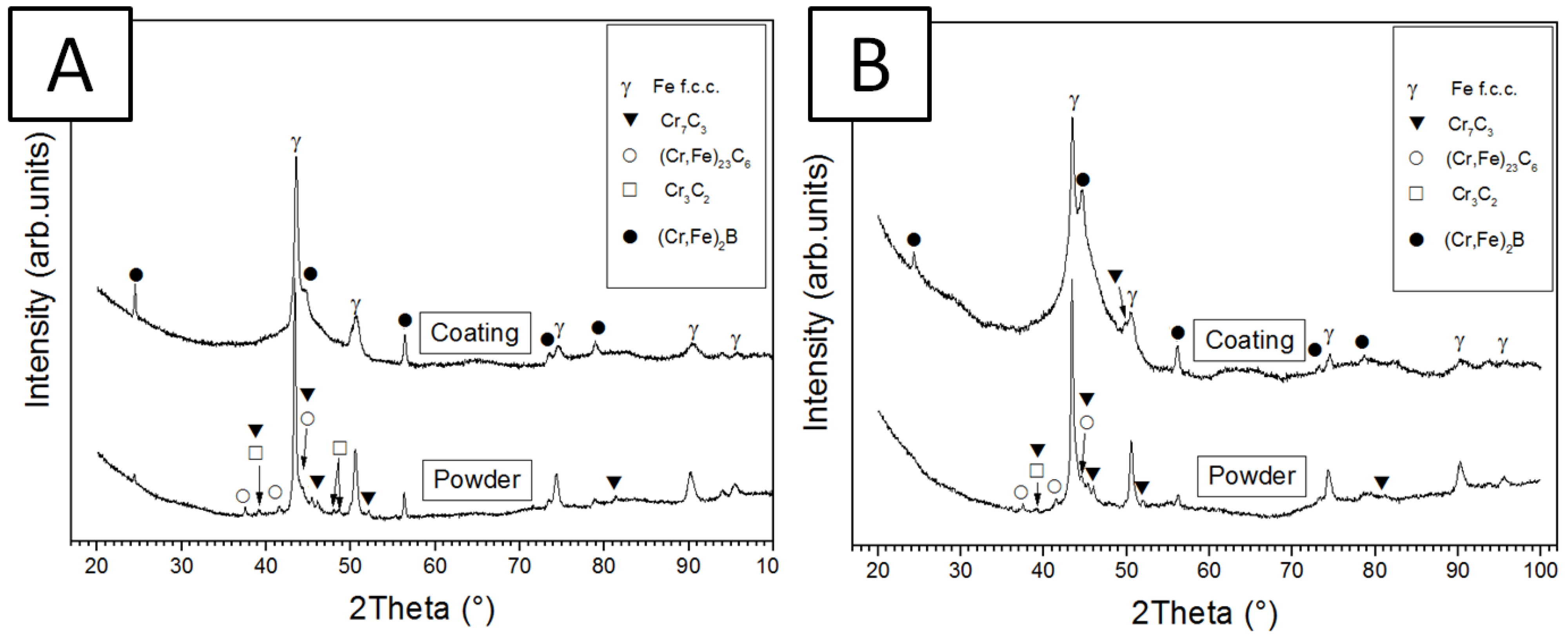

3.1. Microstructural Characterization of Fe-Based Powders

3.2. Microstructural and Mechanical Characterization of Coatings

| Coating | Bond strength (MPa) |

|---|---|

| Fe-Ni-Cr-B-C | 31.9 ± 7.2 |

| Fe-Ni-Cr-Mo-B-C | 25.1 ± 4.5 |

3.3. Wear Properties

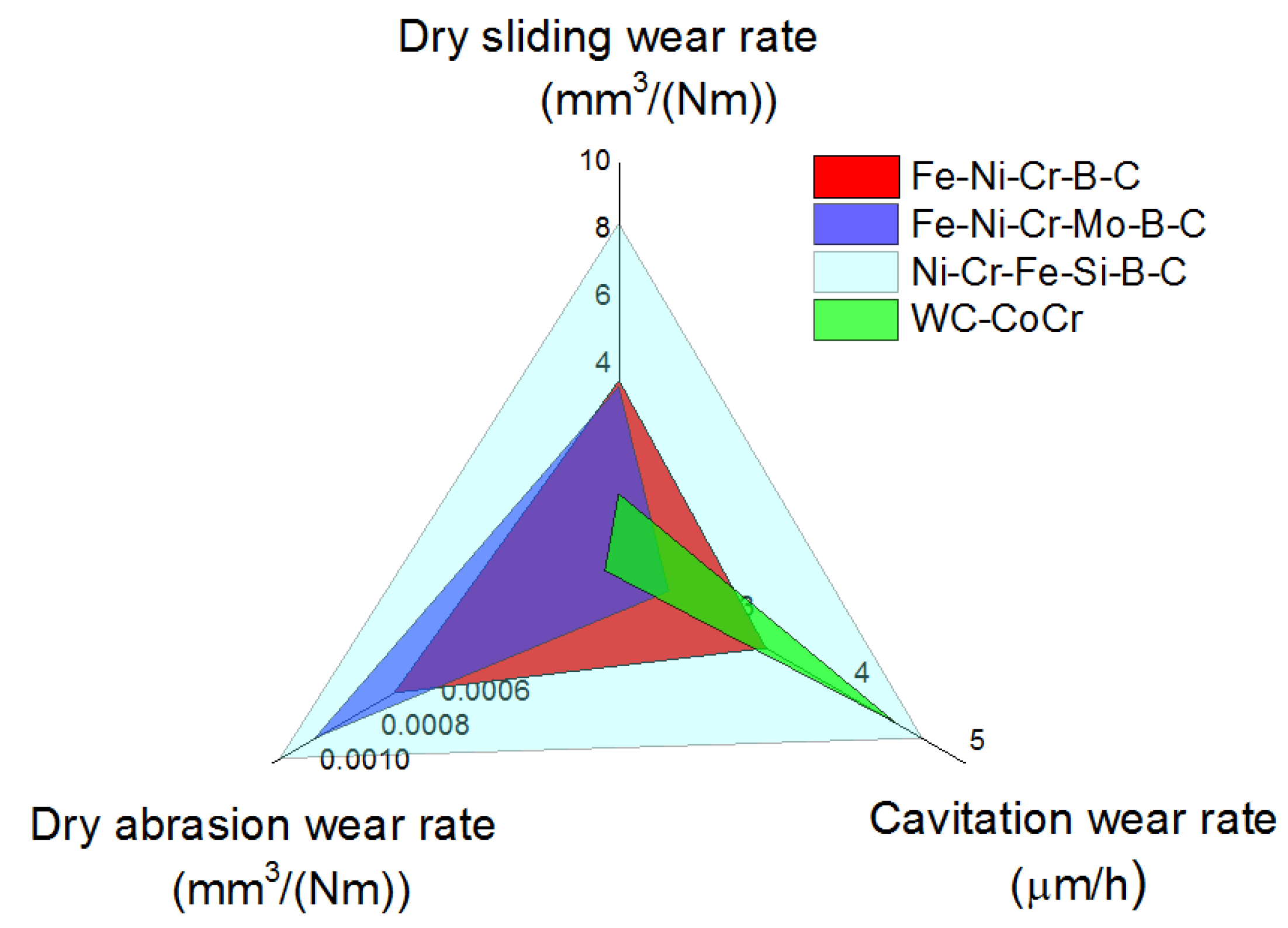

3.3.1. Dry Sliding Wear Resistance

| Coating | Sample wear rate (×10−6 mm3/Nm) | Alumina ball wear rate (×10−6 mm3/Nm) |

|---|---|---|

| Fe-Ni-Cr-B-C | 3.45 ± 0.81 | 0.101 ± 0.008 |

| Fe-Ni-Cr-Mo-B-C | 3.25 ± 0.44 | 0.095 ± 0.004 |

| Ni-Cr-Fe-Si-B-C | 8.13 ± 0.75 | 0.203 ± 0.037 |

| WC-CoCr_2 | 0.06 ± 0.01 | 1.151 ± 0.131 |

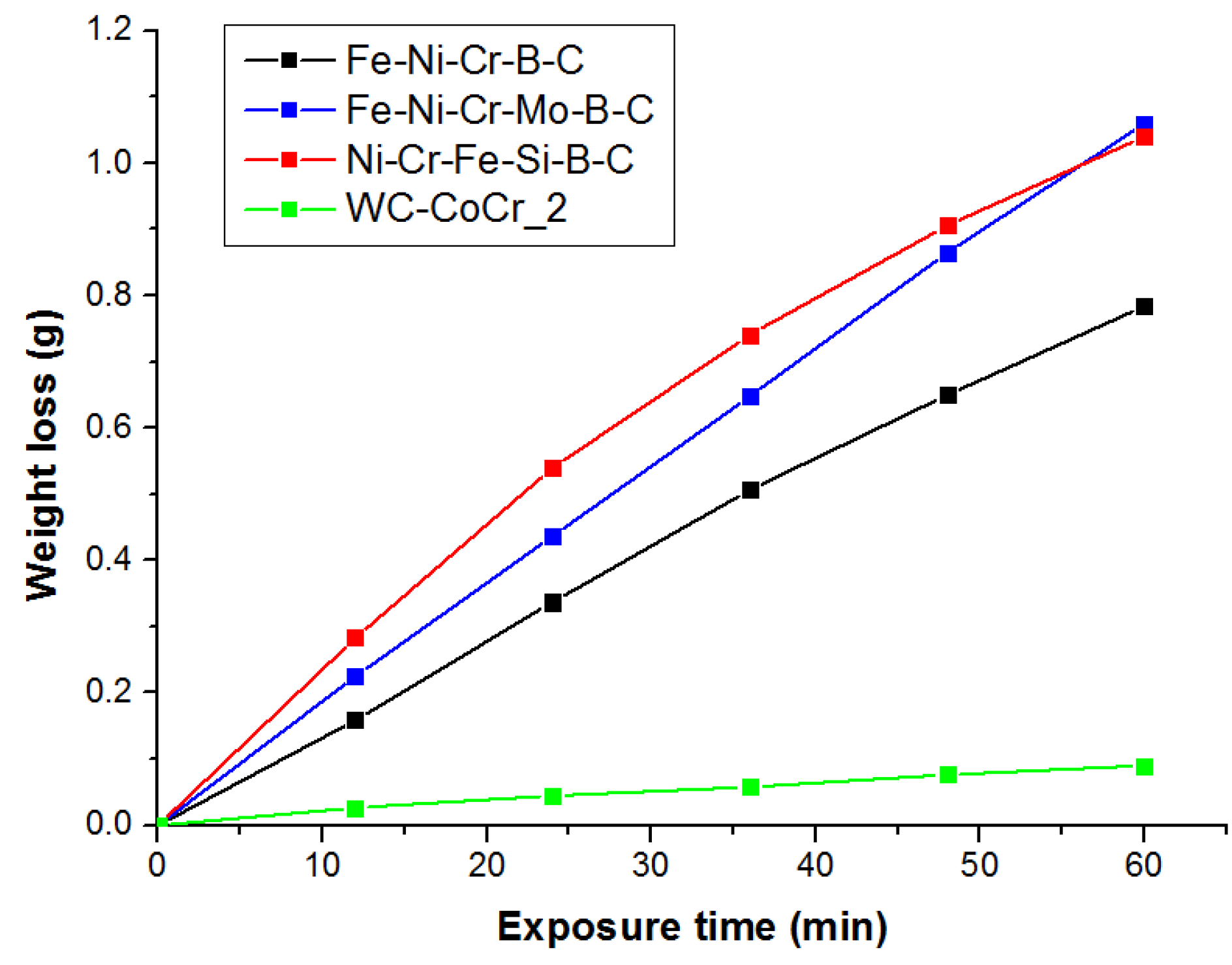

3.3.2. Cavitation Erosion Wear Resistance

| Coating | SER (μm/h) | Re (h/μm) |

|---|---|---|

| Fe-Ni-Cr-B-C | 3.87 | 0.26 |

| Fe-Ni-Cr-Mo-B-C | 2.43 | 0.41 |

| Ni-Cr-Fe-Si-B-C | 4.62 | 0.22 |

| WC-CoCr_1 | 4.39 | 0.23 |

3.3.3. Abrasion Wear Resistance

| Measured quantity | Coating | |||

|---|---|---|---|---|

| Fe-Ni-Cr-B-C | Fe-Ni-Cr-Mo-B-C | Ni-Cr-Fe-Si-B-C | WC-CoCr_2 | |

| weight loss (mg) | 784 | 1060 | 1040 | 90 |

| wear rate (*10−5 mm3/Nm) | 74.3 | 100.5 | 112.0 | 4.6 |

4. Conclusions

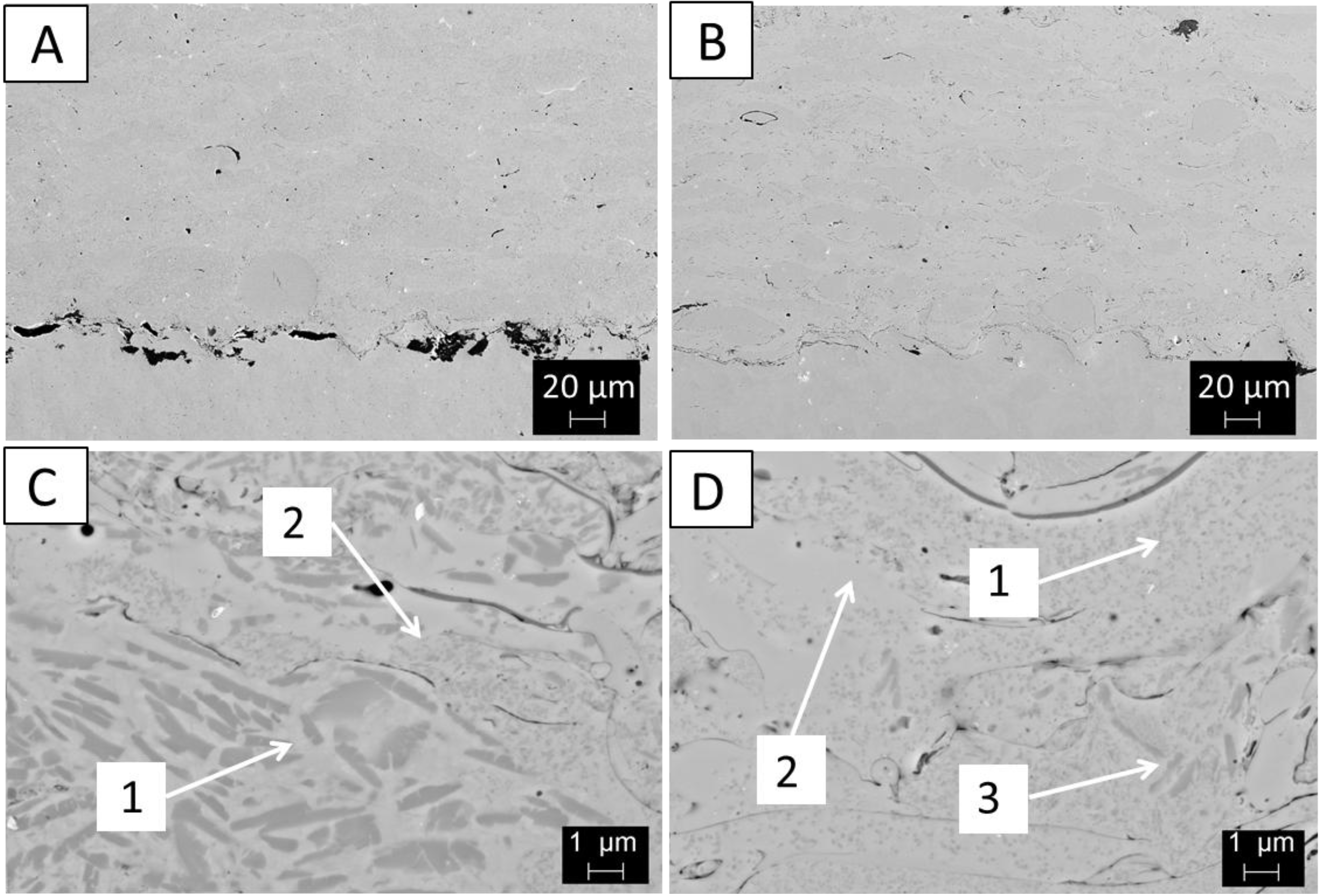

- Fe-based coatings showed a dense microstructure with negligible porosity (<1% calculated through image analysis). The powder microstructure is only partly retained in the coatings after deposition. High flame temperature resulted in in-flight melting of several particles and in their deposition in the molten or semi-molten state. The rapid quenching and solidification led to precipitation of fine-grained Cr- and B-rich compounds embedded into a supersaturated Fe-rich solid solution. Higher microstructural alteration was detected in Fe-Ni-Cr-Mo-B-C due to finer particle size distribution and a warmer set of spraying parameters. No significant oxide inclusions were detected in the coatings.

- Fe-based coatings possess remarkably high nano-hardness revealing high intrinsic hardness of the sprayed material, comparable to that of Ni-Cr-Fe-Si-B-C. Moreover, considering the ratio between micro- and nano- hardness as an estimation of cohesion strength, the Fe-Ni-Cr-Mo-B-C coating was found to have similar micromechanical properties compared to a conventional HVOF-sprayed Ni-based alloy, while the Fe-Ni-Cr-B-C sample had somewhat poorer cohesion. Furthermore, Fe-based coatings possess lower bond strength compared to the reference coatings, as evaluated by tensile testing according to the standard EN582. Bond strength is reported to be about 30 MPa.

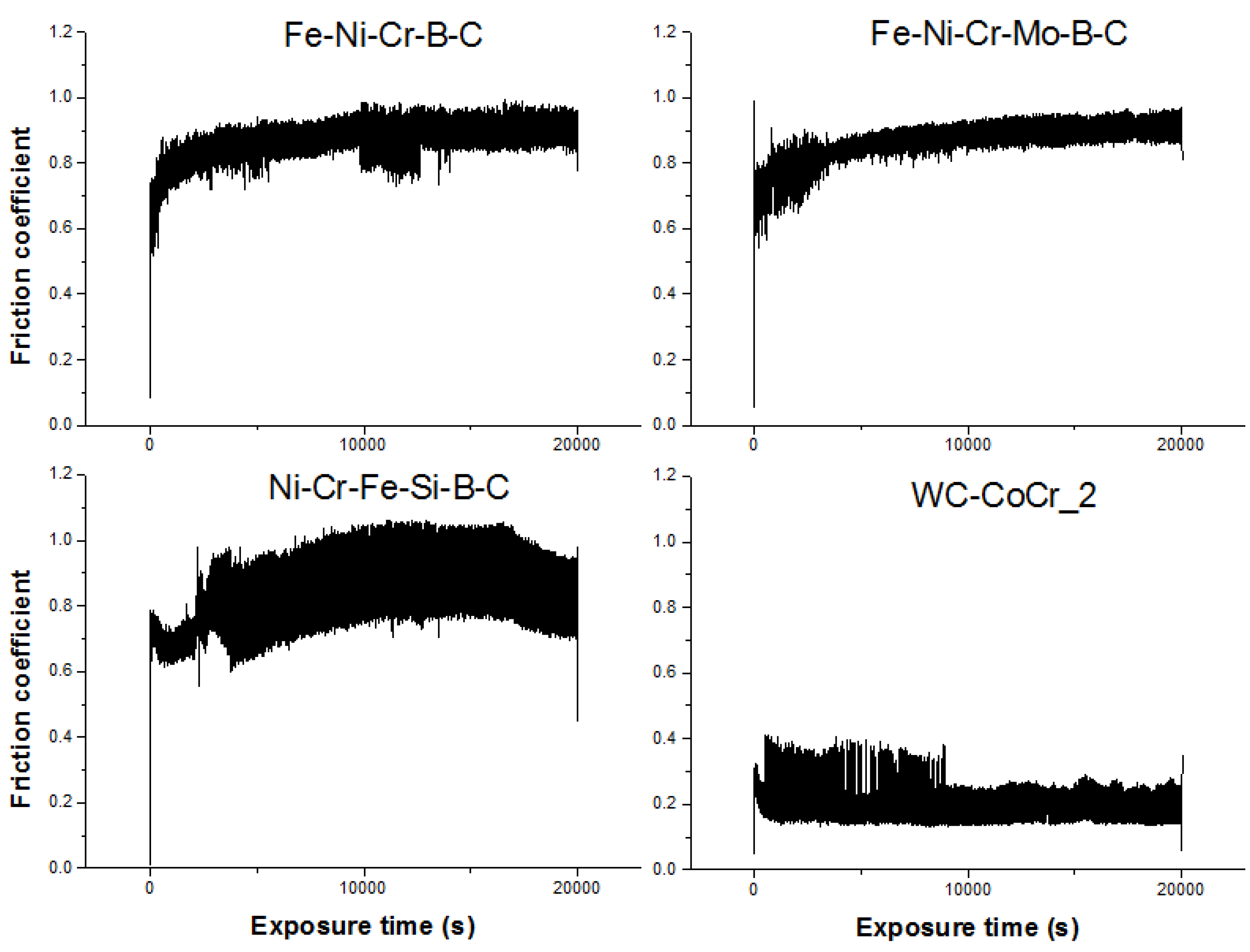

- Although the dry sliding wear resistance of HVOF-sprayed Fe-based metal alloy coatings could not compare with that of a cermet material (WC-CoCr), their sliding wear rate was reported to be lower than that of conventional HVOF-sprayed Ni-based metal alloy coatings. Fe-based coatings are found to possess a lower and more stable friction coefficient and more specifically the formation of a Mo-containing oxide scale during sliding wear is effective in reducing adhesion to the counterbody, decreasing friction and lessening the fluctuation of the friction coefficient.

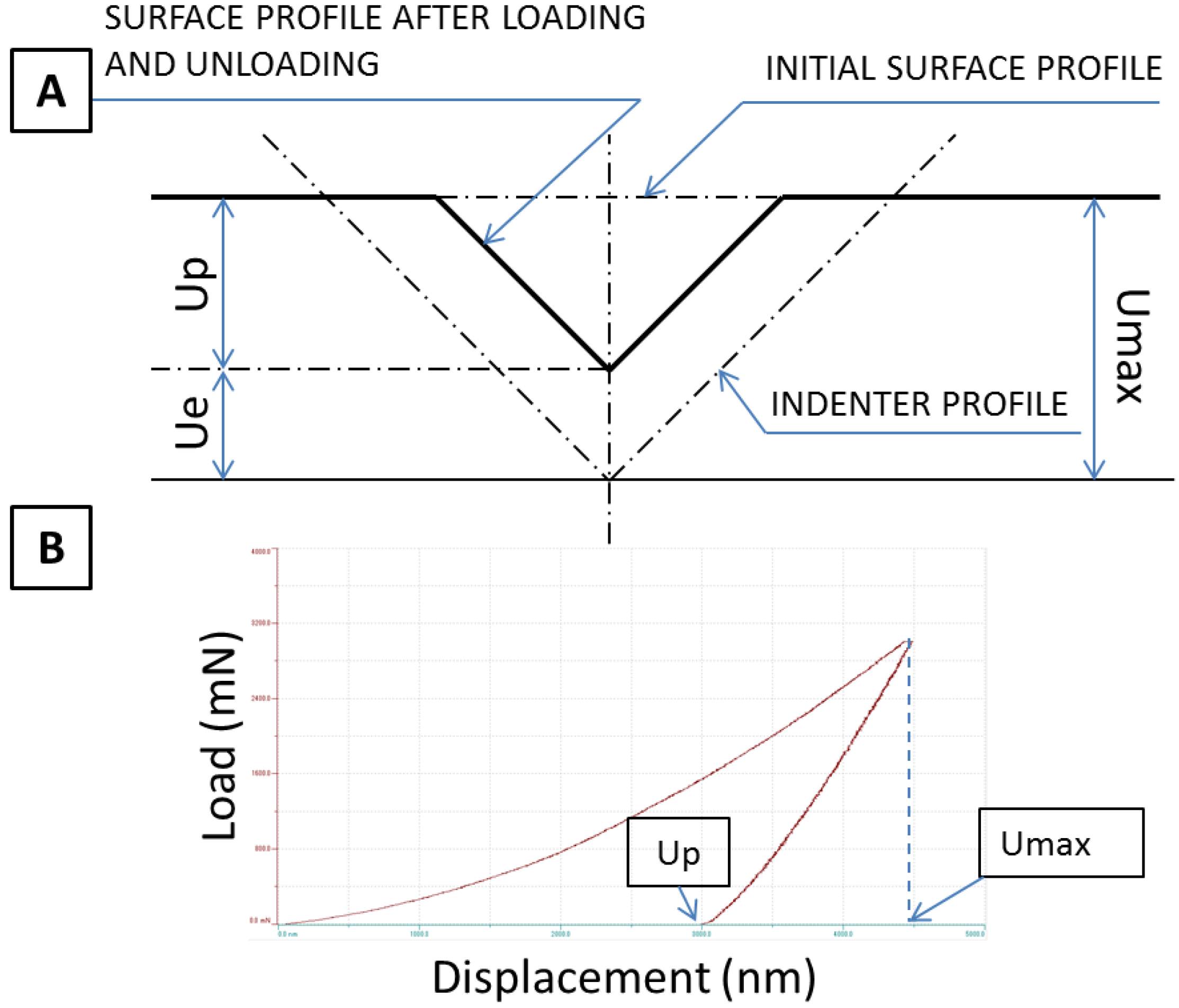

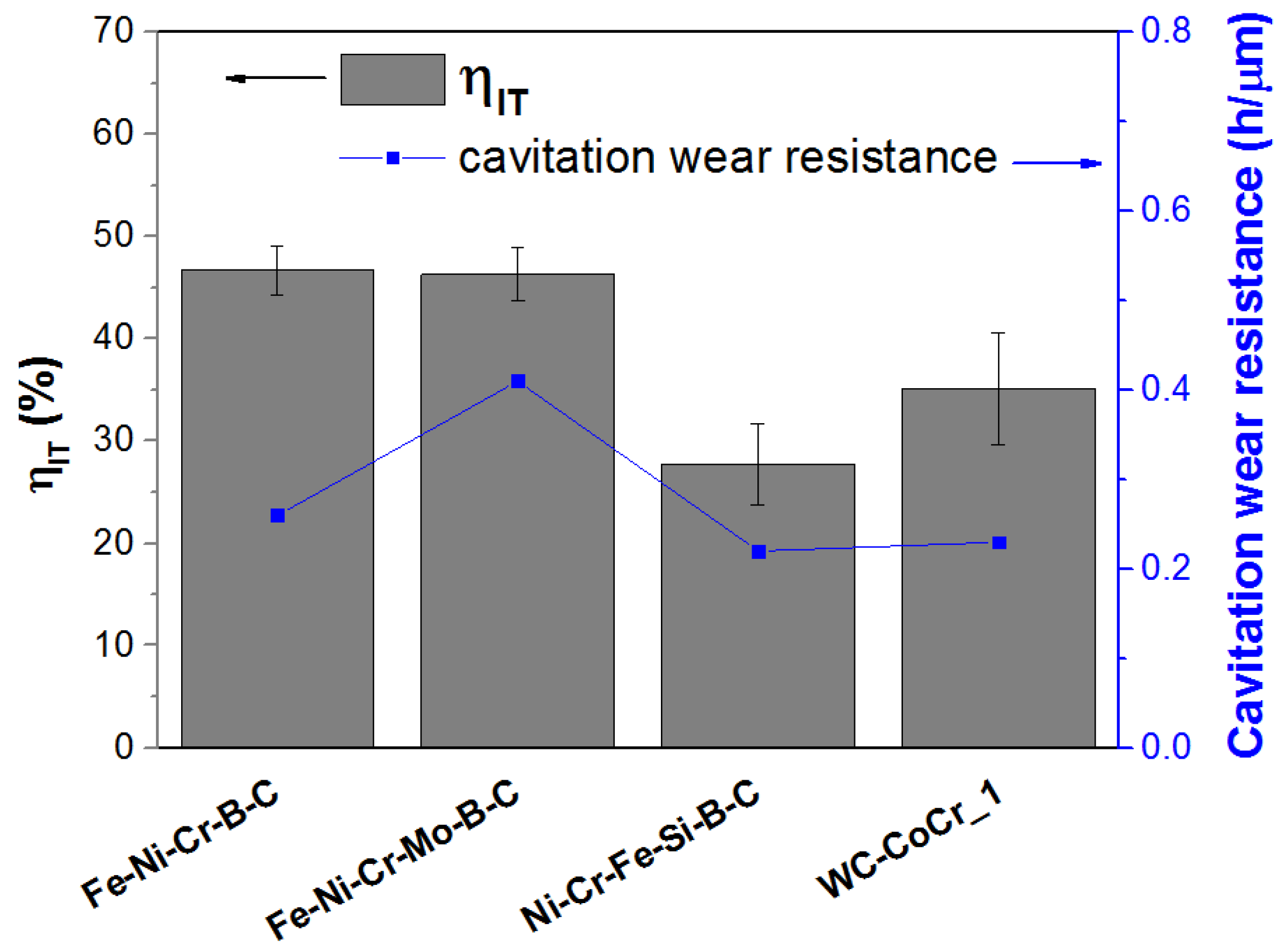

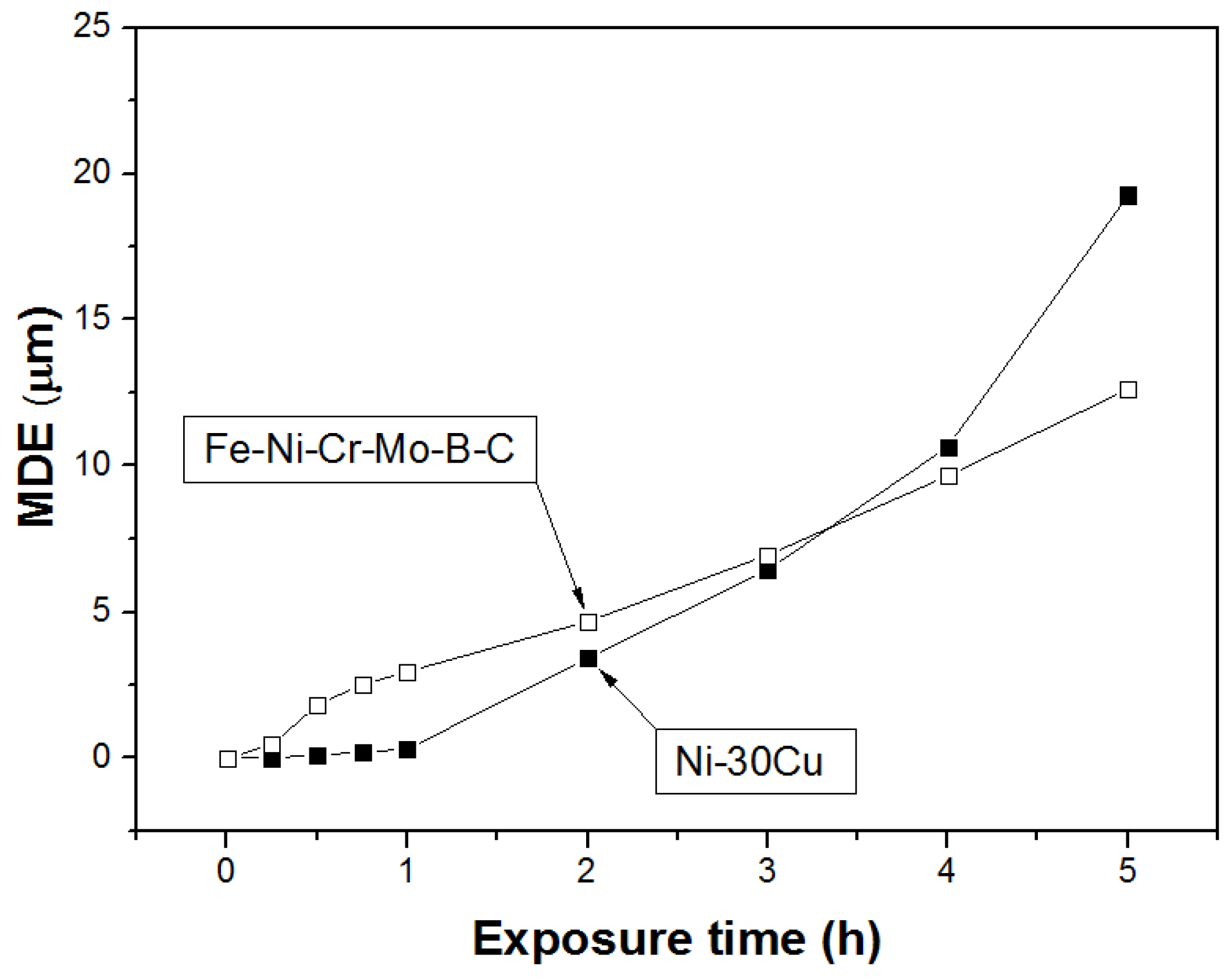

- HVOF-sprayed Fe-based coatings, but most specifically the novel composition (Fe-Ni-Cr-Mo-B-C), presented superior cavitation wear resistance in comparison to those of Ni- and WC-based conventional coatings. Its high surface elasticity, as determined by depth sensing indentation tests, coupled to its good interparticle cohesion, indicated by the relatively low difference between micro- and nano-hardness values, were found to play a fundamental role in the energy dissipation mechanism during bubble impact.

- Abrasion wear resistance of the cermet reference (WC-CoCr) is noticeably higher than that of Fe-based coatings due to higher hardness, which prevents the abrasive sand from penetrating into the coating and from ploughing out a groove by plastic deformation. However, Fe-based coatings showed lower abrasion wear rate compared to a Ni-based reference coating.

Acknowledgments

Conflicts of Interest

References

- Mellor, G.B. Surface Coatings for Protection against Wear; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International: Materials Park, OH, USA, 2004; pp. 171–213. [Google Scholar]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons: Chichester, UK, 2008. [Google Scholar]

- Berger, L.M. Hardmetal as thermal spray coatings. Powder Metall. 2007, 50, 205–214. [Google Scholar] [CrossRef]

- Montavon, G. Safety Issues and Risks Related to Thermal Spray Process, ETSA Summer School Tampere University of Technology, Tampere, Finland, 13–14 June 2012.

- Cobalt–Tungsten Carbide: Powders and Hard Metals; 12th Report on Carcinogens; U.S. Department of Health and Human Services: Washington, DC, USA, 10 June 2011.

- Yuping, W.; Pinghua, L.; Chenglin, C.; Zehua, W.; Ming, C.; Junhua, H. Cavitation erosion characteristics of a Fe–Cr–Si–B–Mn coating fabricated by high velocity oxy-fuel (HVOF) thermal spray. Mater. Lett. 2007, 61, 1867–1872. [Google Scholar] [CrossRef]

- Schwetzke, R.; Kreye, H. Cavitation Erosion of HVOF Coatings; ASM International: Material Park, OH, USA, 1996. [Google Scholar]

- Pukasiewicz, A.G.M.; Capra, A.R.; Paredes, R.S.C. Cavitation Erosion Mechanism in Fe-Mn-Cr-Si-Ni Arc Thermally Sprayed Coatings. In Proceedings of the International Thermal Spray Conference 2011, Hamburg, Germany, 27–29 September 2011.

- Bolelli, G.; Bonferroni, B.; Laurila, J.; Lusvarghi, L.; Milanti, A.; Niemi, K.; Vuoristo, P. Micromechanical properties and sliding wear behaviour of HVOF-sprayed Fe-based alloy coatings. Wear 2012, 276–277, 29–47. [Google Scholar] [CrossRef]

- Cherigui, M.; Feraoun, H.I.; Feninehe, N.E.; Aourag, H.; Coddet, C. Structure of amorphous iron-based coatings processed by HVOF and APS thermally spraying. Mater. Chem. Phys. 2004, 85, 113–119. [Google Scholar] [CrossRef]

- Guo, R.Q.; Zhang, C.; Chen, Q.; Yang, Y.; Li, N.; Liu, L. Study of structure and corrosion resistance of Fe-based amorphous coatings prepared by HVAF and HVOF. Corros. Sci. 2011, 53, 2351–2356. [Google Scholar] [CrossRef]

- Kumar, S.; Kim, J.; Kim, H.; Lee, C. Phase dependence of Fe-based bulk metallic glasses on properties of thermal spray coatings. J. Alloys Compd. 2009, 475, L9–L12. [Google Scholar] [CrossRef]

- Chokethawai, K.; McCartney, D.G.; Shipway, P.H. Microstructure evolution and thermal stability of an Fe-based amorphous alloy powder and thermally sprayed coatings. J. Alloys Compd. 2009, 480, 351–359. [Google Scholar] [CrossRef]

- Shina, J.H.; Wang, Q.M.; Kima, K.H. Microstructural evolution and tribological behavior of Mo–Cu–N coatings as a function of Cu content. Mater. Chem. Phys. 2011, 130, 870–879. [Google Scholar] [CrossRef]

- Tiana, B.; Yuea, W.; Fua, Z.; Gu, Y.; Wang, C.; Liu, J. Surface properties of Mo-implanted PVD TiN coatings using MEVVA source. Appl. Surf. Sci. 2013, 280, 482–488. [Google Scholar] [CrossRef]

- Woydt, M.; Skopp, A.; Dörfel, I.; Witk, K. Wear engineering oxides/anti-wear oxides. Wear 1998, 218, 84–95. [Google Scholar] [CrossRef]

- Nohava, J.; Bonferroni, B.; Bolelli, G.; Lusvarghi, L. Interesting aspects of indentation and scratch methods for characterization of thermally-sprayed coatings. Surf. Coat. Technol. 2010, 205, 1127–1131. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surface. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- ISO 14577-1:2002(en): Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters; International Organization for Standardization: Geneva, Switzerland, 2002.

- EN 582:1993: Thermal Spraying. Determination of Tensile Adhesive Strength; European Committee for Standardization: Brussels, Belgium, 1993.

- ASTM G65-04(2010): Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM G32-10: Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Jin, H.W.; Rhyim, Y.M.; Hong, S.G.; Park, C.G. Microstructural evolution of the rapidly quenched Fe–Cr–B alloy thermal spray coatings. Mater. Sci. Eng. A 2001, 304–306, 1069–1074. [Google Scholar]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Inoue, A. Glass-forming ability of alloys. J. Non-Cryst. Solids 1993, 156–158, 473–480. [Google Scholar] [CrossRef]

- Leffler, B. STAINLESS—Stainless Steels and Their Properties, 2nd ed.; Avesta Sheffield AB Research Foundation, Avesta Sheffield Ltd: Sheffield, UK, 1998. [Google Scholar]

- Richer, P.; Yandouzi, M.; Beauvais, L.; Jodoin, B. Oxidation behaviour of CoNiCrAlY bond coats produced by plasma, HVOF and cold gas dynamic spraying. Surf. Coat. Technol. 2010, 204, 3962–3974. [Google Scholar] [CrossRef]

- Margadant, N.; Neuenschwander, J.; Stauss, S.; Kaps, H.; Kulkarni, A.; Matejicek, J.; Rössler, G. Impact of probing volume from different mechanical measurement methods on elastic properties of thermally sprayed Ni-based coatings on a mesoscopic scale. Surf. Coat. Technol. 2006, 200, 2805–2820. [Google Scholar] [CrossRef]

- Bolelli, G.; Rauch, J.; Cannillo, V.; Killinger, A.; Lusvarghi, L.; Gadow, R. Microstructural and tribological investigation of High-Velocity Suspension Flame Sprayed (HVSFS) Al2O3 coatings. J. Therm. Spray Technol. 2009, 18, 35–49. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, L.; Chan, K.C.; Chen, Q.; Tang, C.Y. Wear behavior of HVOF-sprayed Fe-based amorphous coatings. Intermetallics 2012, 29, 80–85. [Google Scholar] [CrossRef]

- Shebanova, O.N.; Lazor, P. Raman spectroscopic study of magnetite (FeFe2O4): A new assignment for the vibrational spectrum. J. Solid State Chem. 2003, 174, 424–430. [Google Scholar] [CrossRef]

- Varshney, D.; Yogi, A. Structural and transport properties of stoichiometric and Cu2+-doped magnetite: Fe3−xCuxO4. Mater. Chem. Phys. 2010, 123, 434–438. [Google Scholar] [CrossRef]

- Varshney, D.; Yogi, A. Structural and transport properties of stoichiometric Mn2+-doped magnetite: Fe3−xMnxO4. Mater. Chem. Phys. 2011, 128, 489–494. [Google Scholar] [CrossRef]

- Uozato, S.; Nakata, K.; Ushio, M. Evaluation of ferrous powder thermal spray coatings on diesel engine cylinder bores. Surf. Coat. Technol. 2005, 200, 2580–2586. [Google Scholar] [CrossRef]

- Rabiei, A.; Mumm, D.R.; Hutchinson, J.W.; Schweinfest, R.; Rühle, M.; Evans, A.G. Microstructure, deformation and cracking characteristics of thermal spray ferrous coatings. Mater. Sci. Eng. A 1999, 269, 152–165. [Google Scholar] [CrossRef]

- Vetter, J.; Barbezat, G.; Crummenauer, J.; Avissar, J. Surface treatment selections for automotive applications. Surf. Coat. Technol. 2005, 200, 1962–1968. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A. Coating Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering, 2nd ed.; Elsevier: Oxford, UK, 2009. [Google Scholar]

- Saikko, V.; Pfaff, H.G. Low wear and friction in alumina/alumina total hip joints: A hip simulator study. Acta Orthop. Scand. 1998, 69, 443–448. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Ohashi, M.; Ikeuchi, K. Start up and steady state friction of alumina against alumina. Wear 1997, 210, 112–119. [Google Scholar] [CrossRef]

- Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Wear and Corrosion Resistance of High-Velocity Oxygen-Fuel Sprayed Iron-Based Composite Coatings. In Proceedings of ASME 2013 International Mechanical Engineering Congress & Exposition, San Diego, CA, USA, 15–21 November 2013.

- Valarezo, A.; Sampath, S. An integrated assessment of process-microstructure-property relationships for thermal-sprayed NiCr coatings. J. Therm. Spray Technol. 2011, 20, 1244–1258. [Google Scholar] [CrossRef]

- Barletta, M.; Bolelli, G.; Bonferroni, B.; Lusvarghi, L. Wear and corrosion behavior of HVOF-sprayed WC-CoCr coatings on Al alloys. J. Therm. Spray Technol. 2010, 19, 358–367. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings. Coatings 2014, 4, 98-120. https://doi.org/10.3390/coatings4010098

Milanti A, Koivuluoto H, Vuoristo P, Bolelli G, Bozza F, Lusvarghi L. Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings. Coatings. 2014; 4(1):98-120. https://doi.org/10.3390/coatings4010098

Chicago/Turabian StyleMilanti, Andrea, Heli Koivuluoto, Petri Vuoristo, Giovanni Bolelli, Francesco Bozza, and Luca Lusvarghi. 2014. "Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings" Coatings 4, no. 1: 98-120. https://doi.org/10.3390/coatings4010098

APA StyleMilanti, A., Koivuluoto, H., Vuoristo, P., Bolelli, G., Bozza, F., & Lusvarghi, L. (2014). Microstructural Characteristics and Tribological Behavior of HVOF-Sprayed Novel Fe-Based Alloy Coatings. Coatings, 4(1), 98-120. https://doi.org/10.3390/coatings4010098