Analysis of Thermo-Elastic Fracture Problem during Aluminium Alloy MIG Welding Using the Extended Finite Element Method

Abstract

:1. Introduction

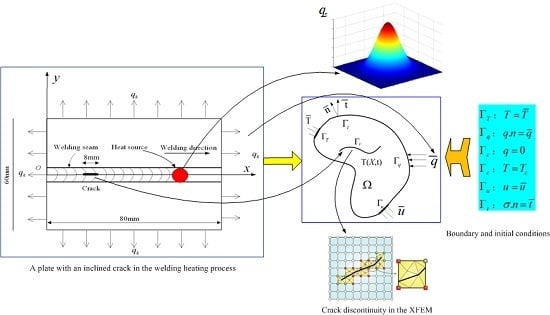

2. Problem and Equations

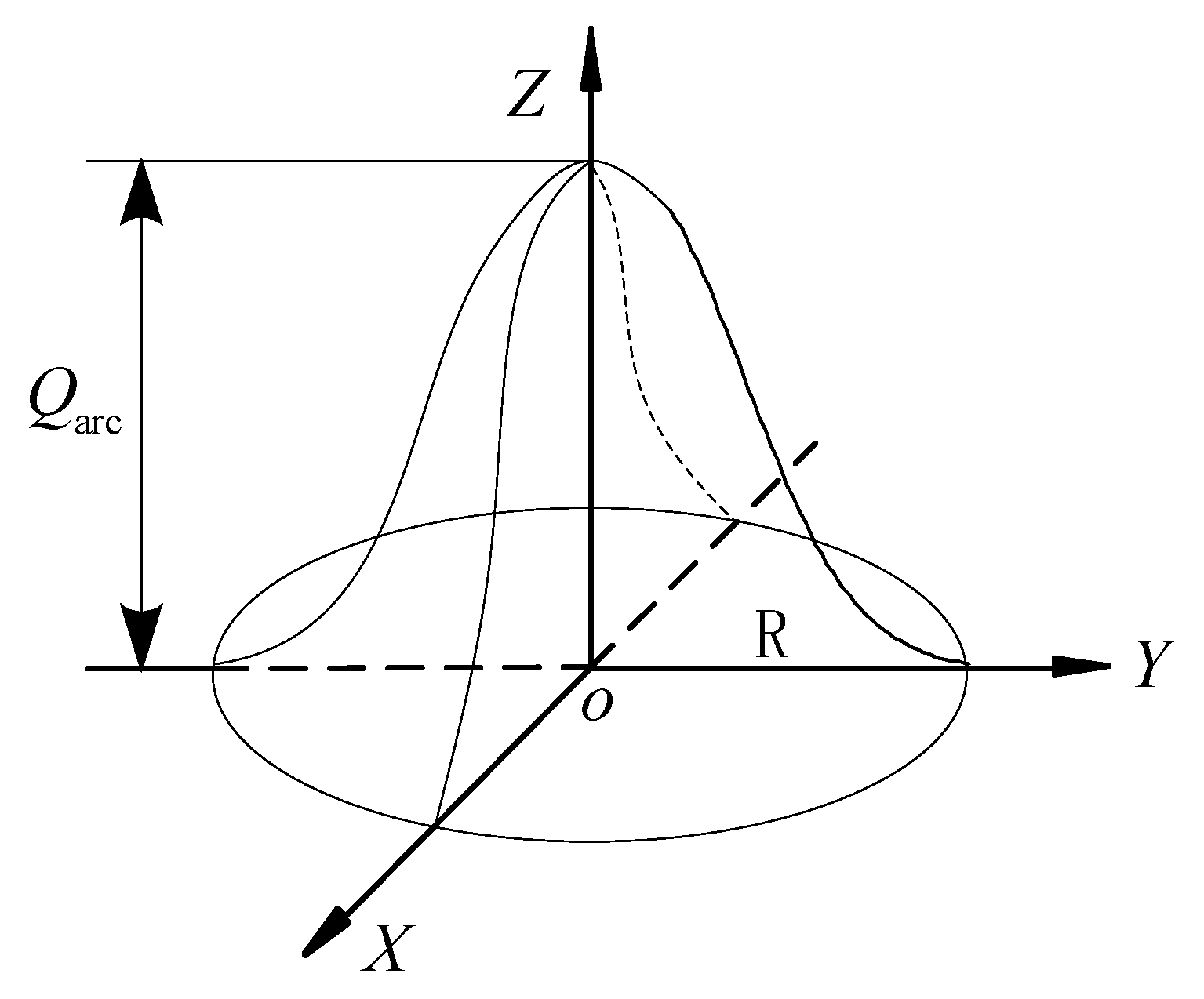

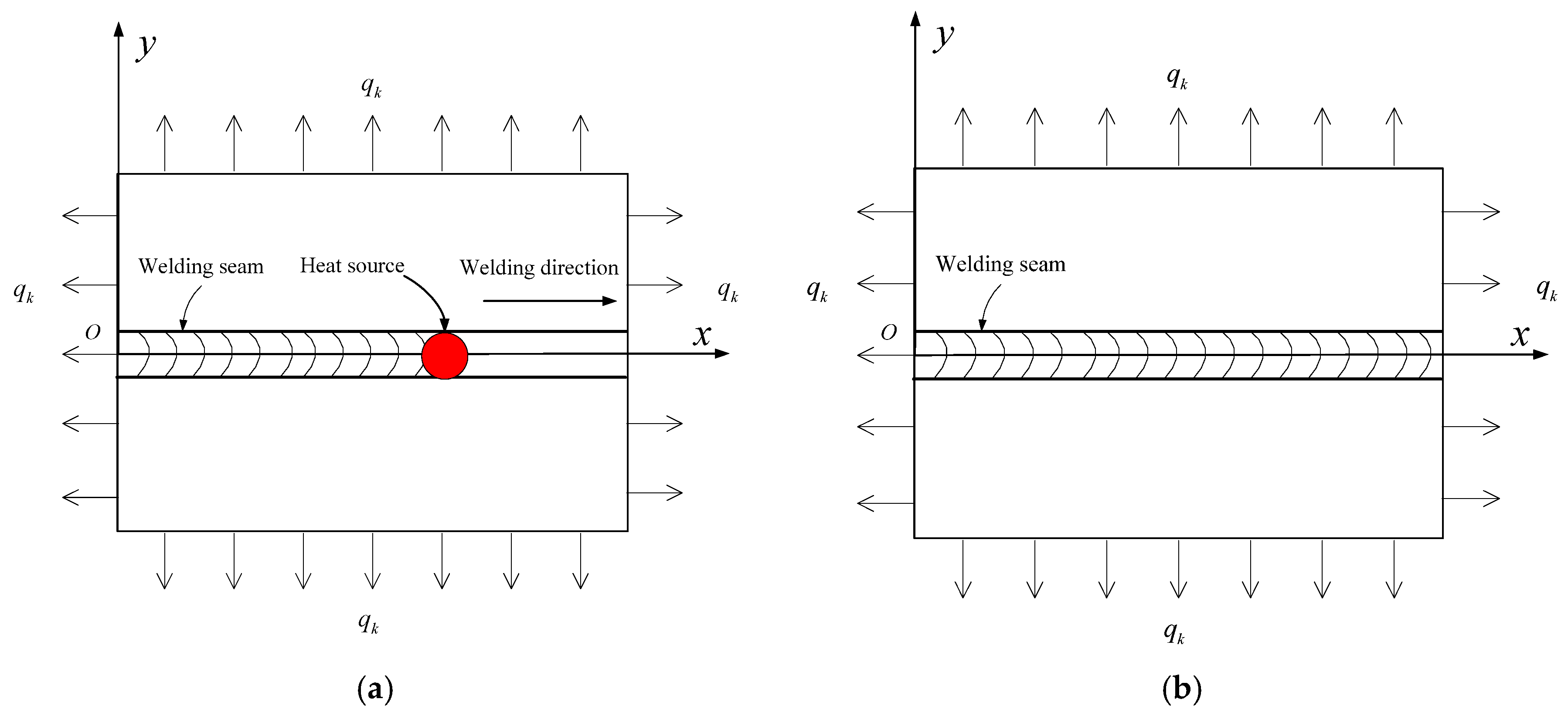

2.1. The Moving Heat Source

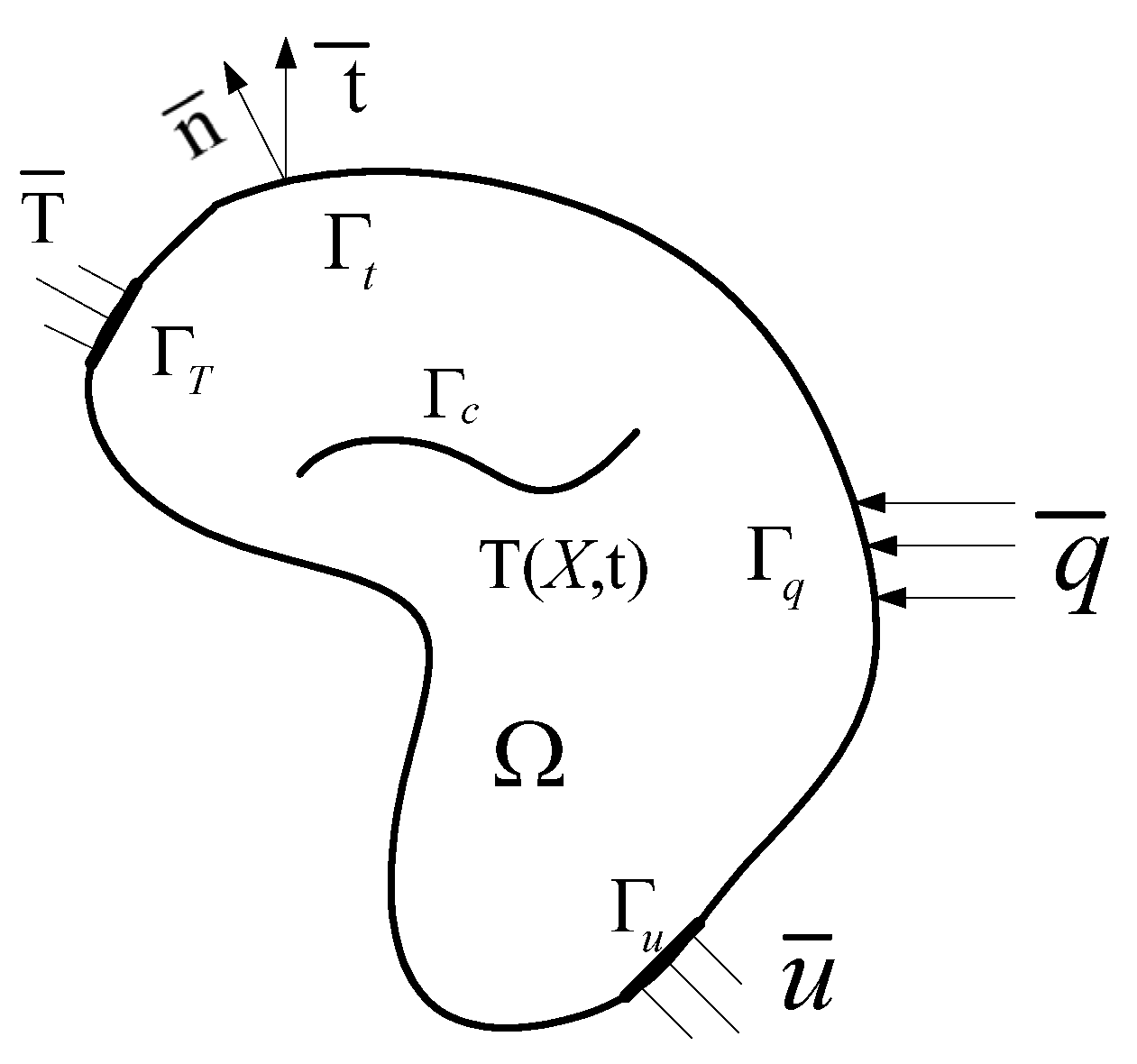

2.2. Equations

3. The XFEM Formulation of Governing Equations

3.1. Approximation of Displacement and Temperature Fields

3.2. The XFEM Spatial and Time Discretization

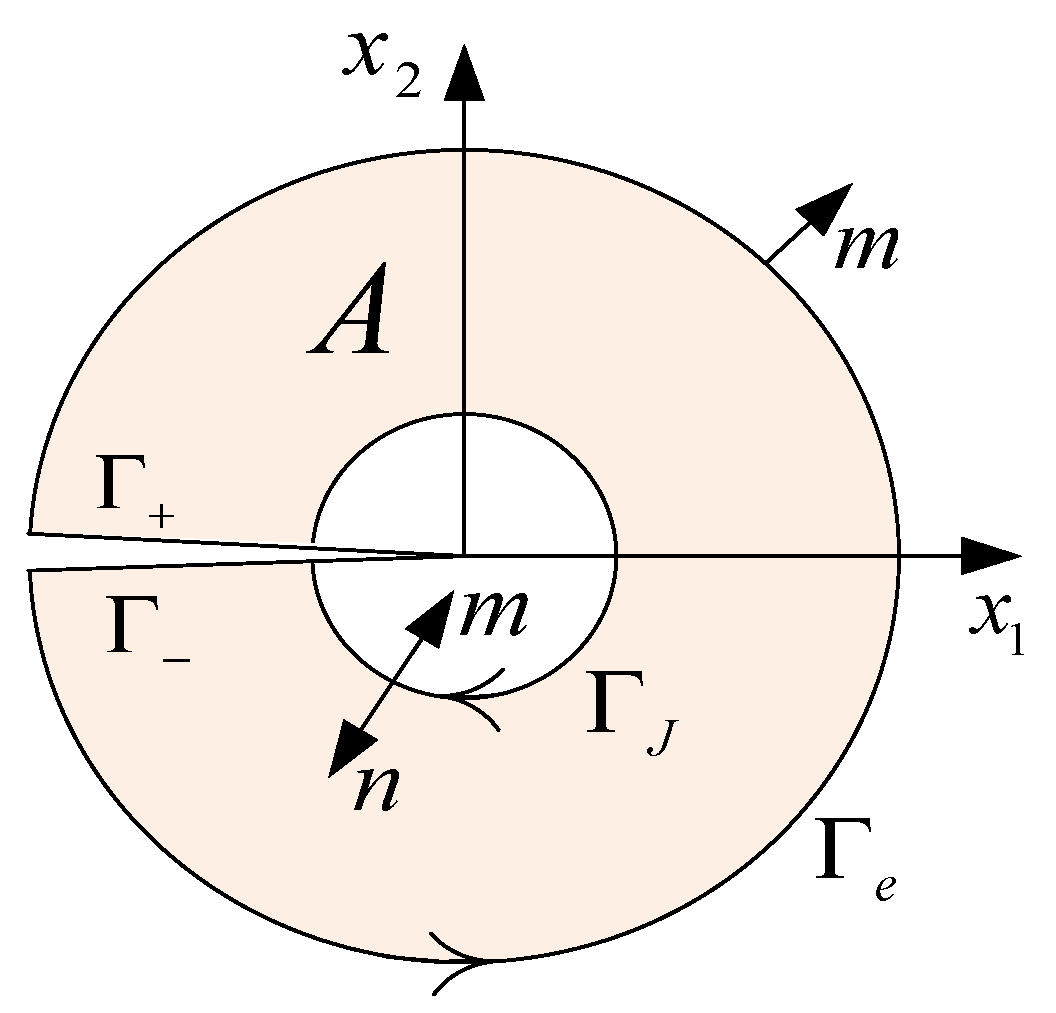

4. Stress Intensity Factors (SIFs)

5. Numerical Results and Discussion

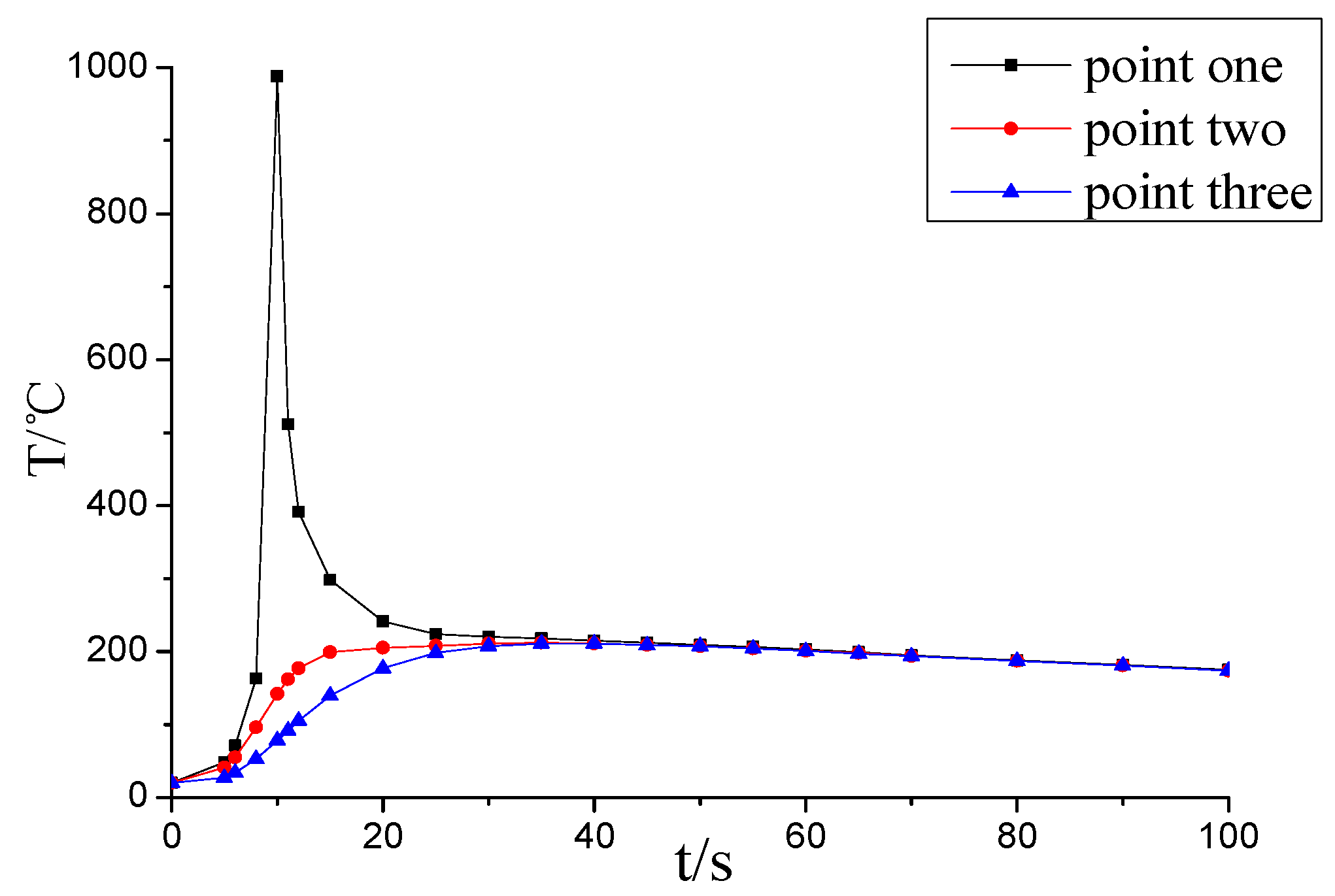

5.1. Simulation and Experimental Verification

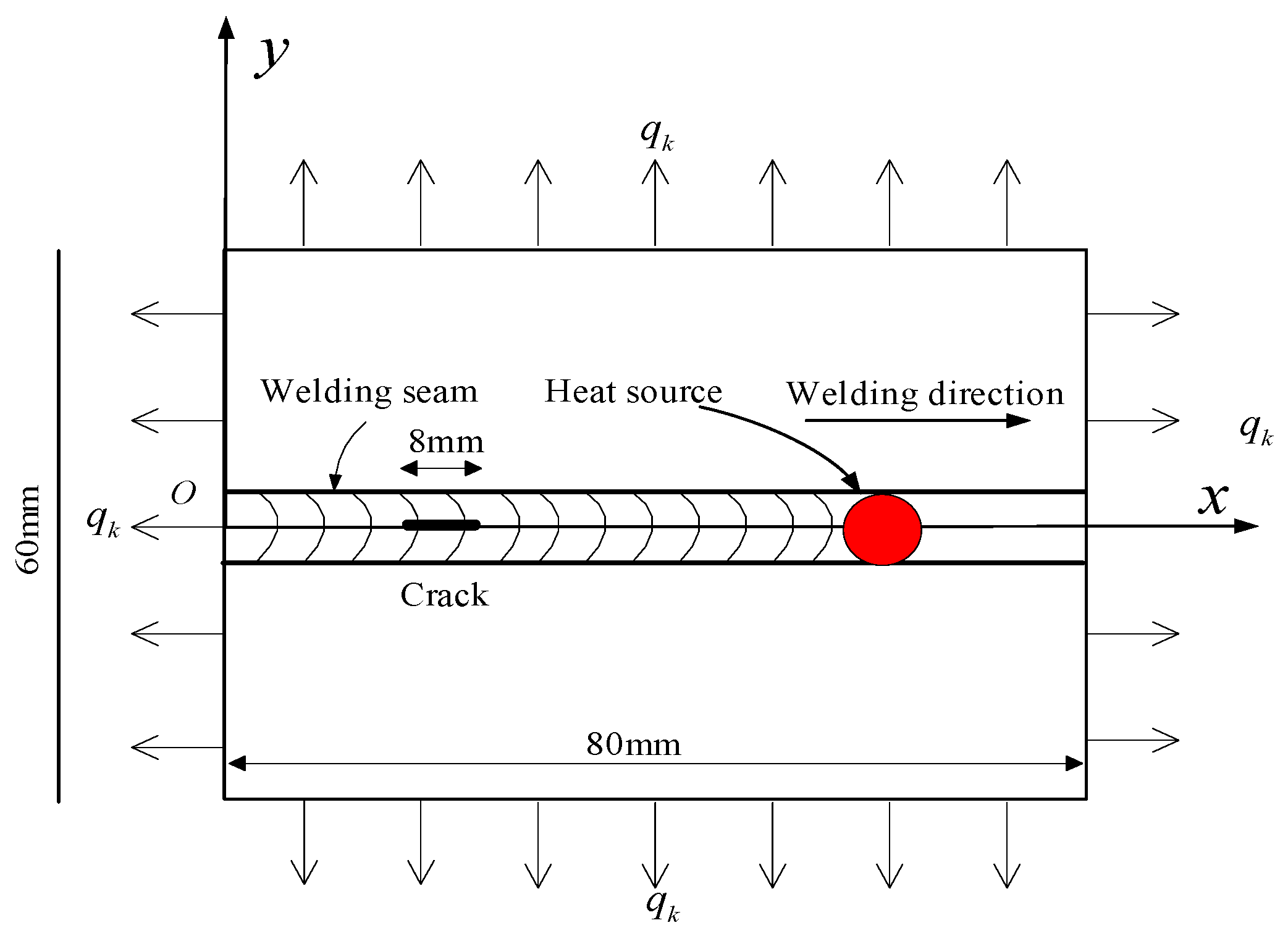

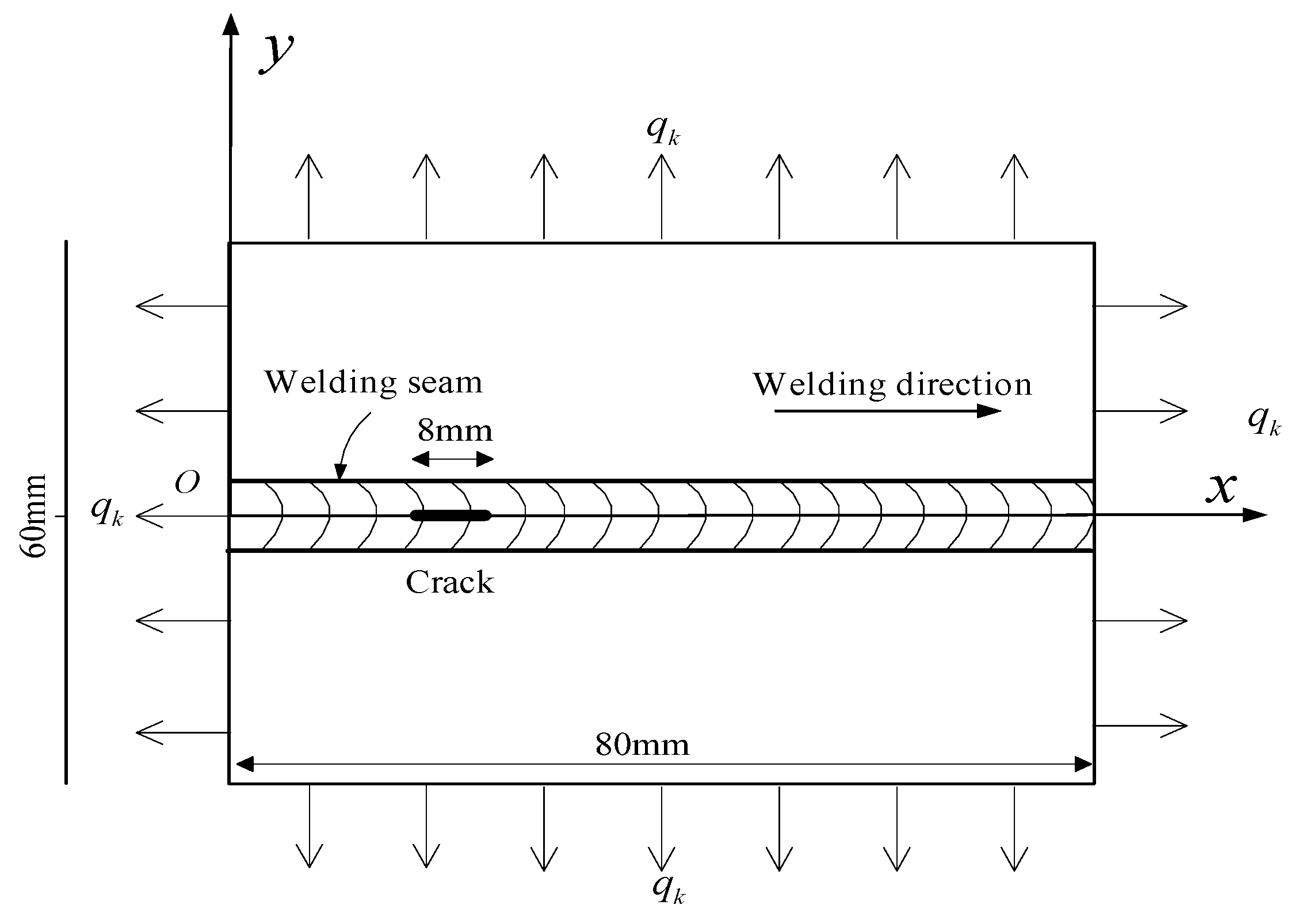

5.2. The Welding Temperature and Stress Field of Aluminum Alloy Plate with an Isothermal Crack

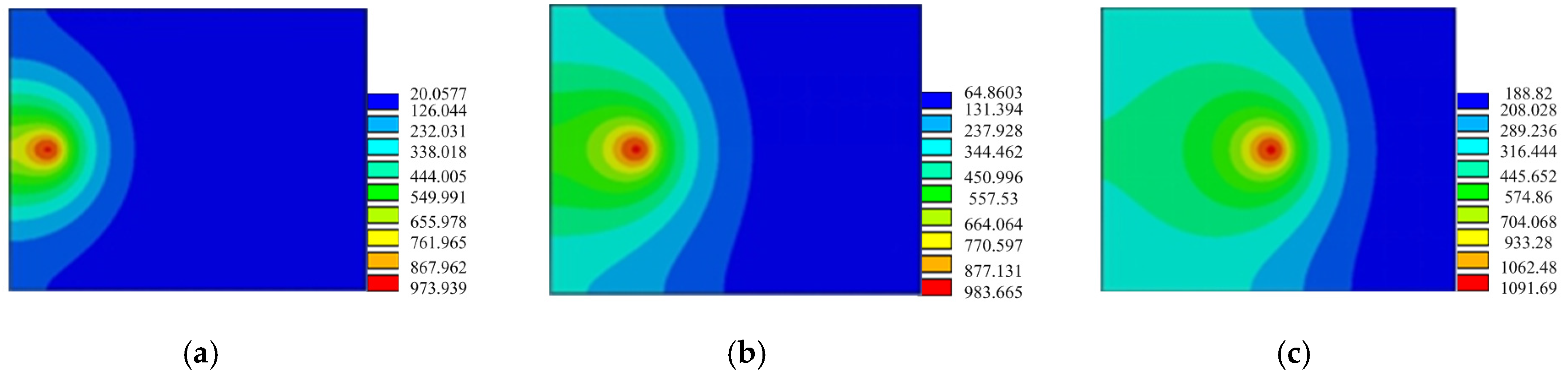

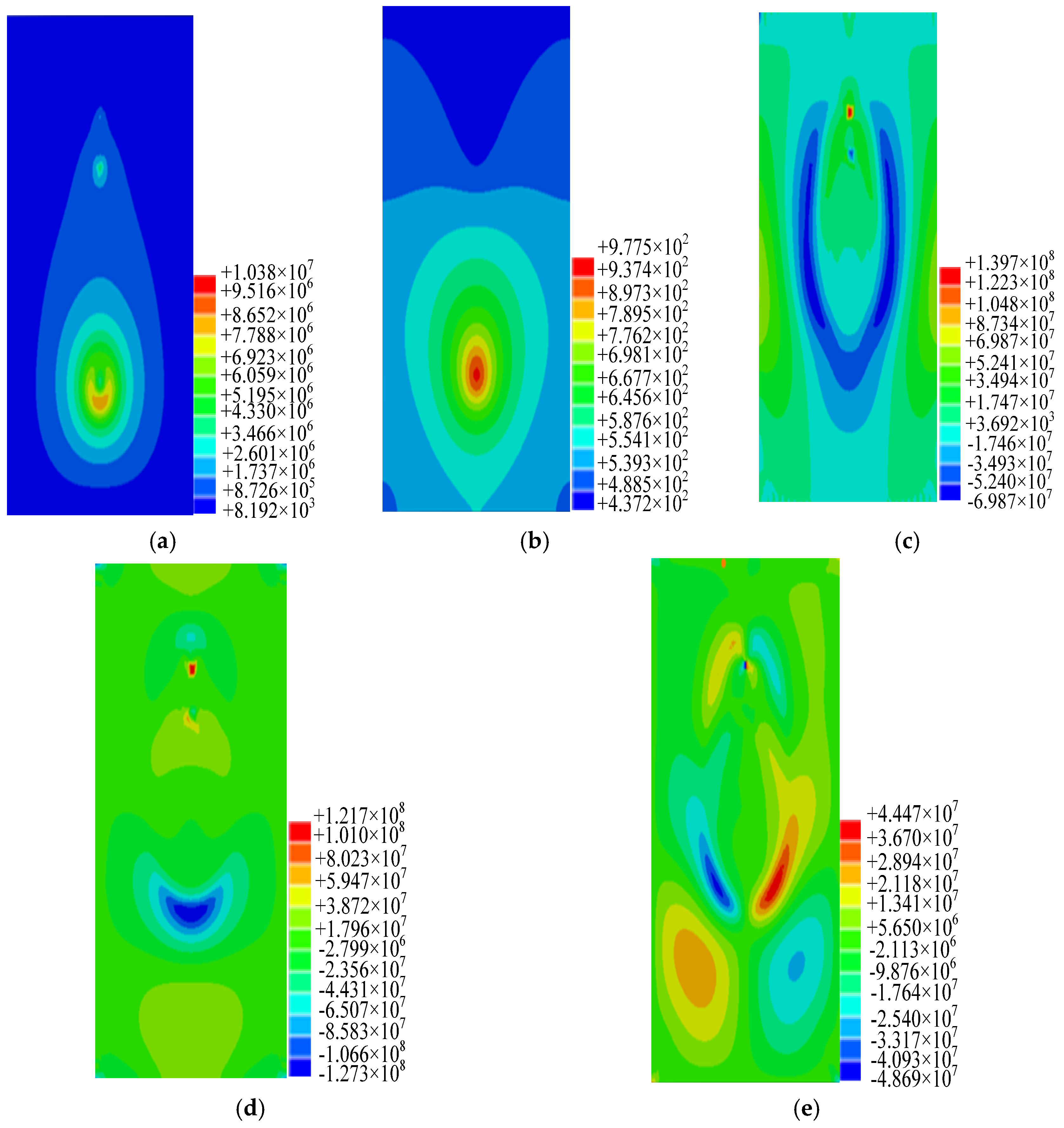

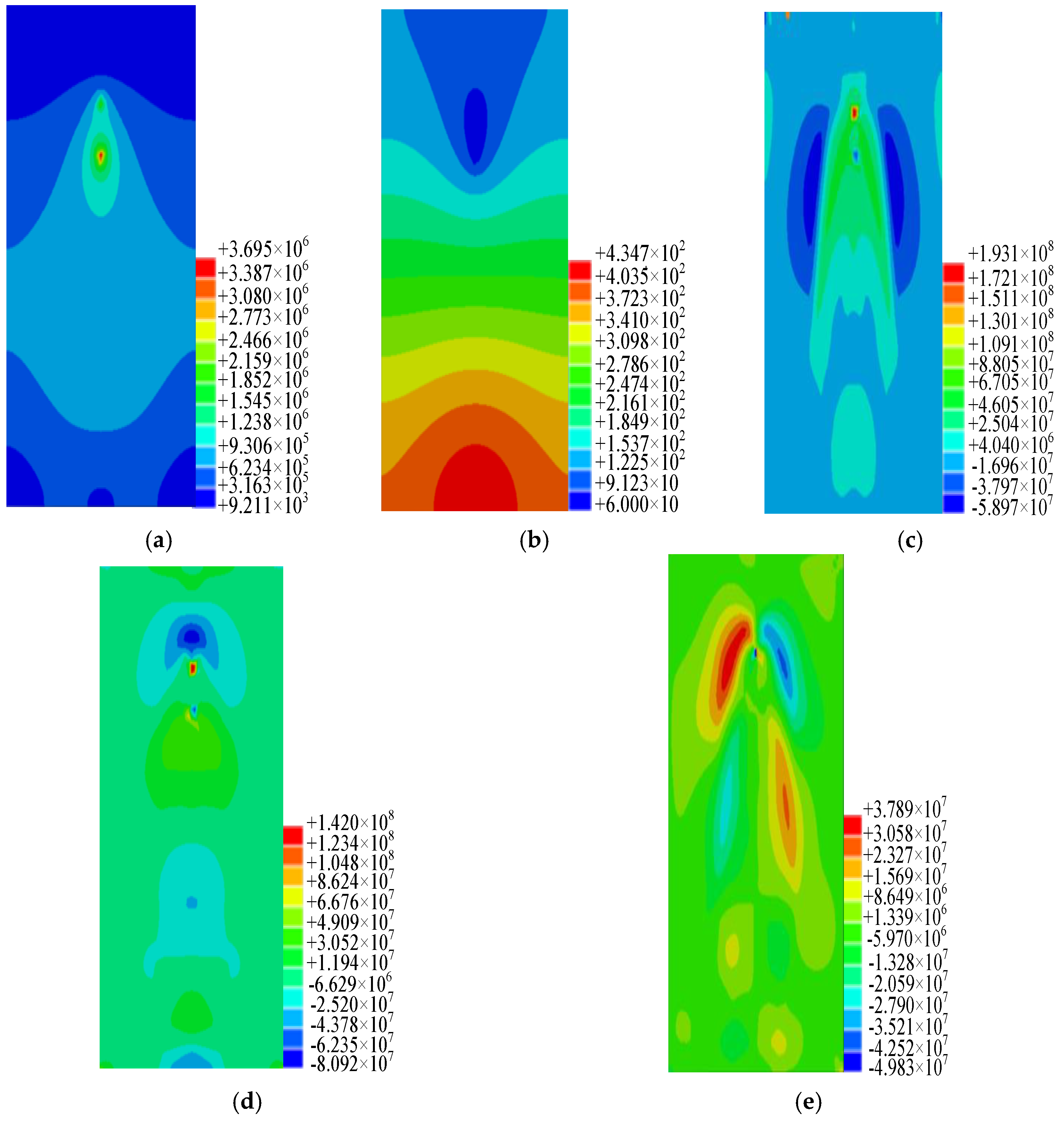

5.2.1. The Welding Temperature and Stress Field Distribution

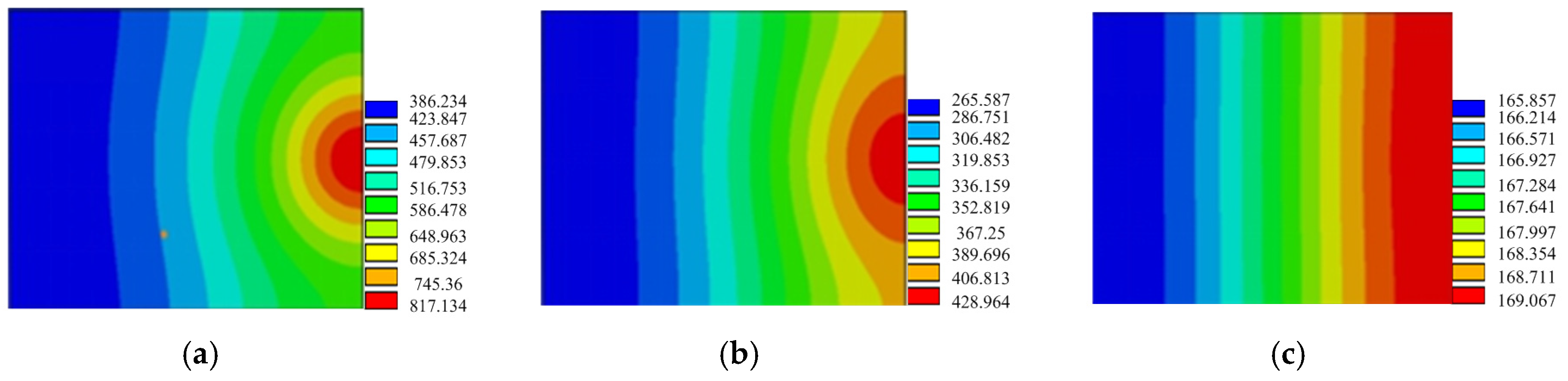

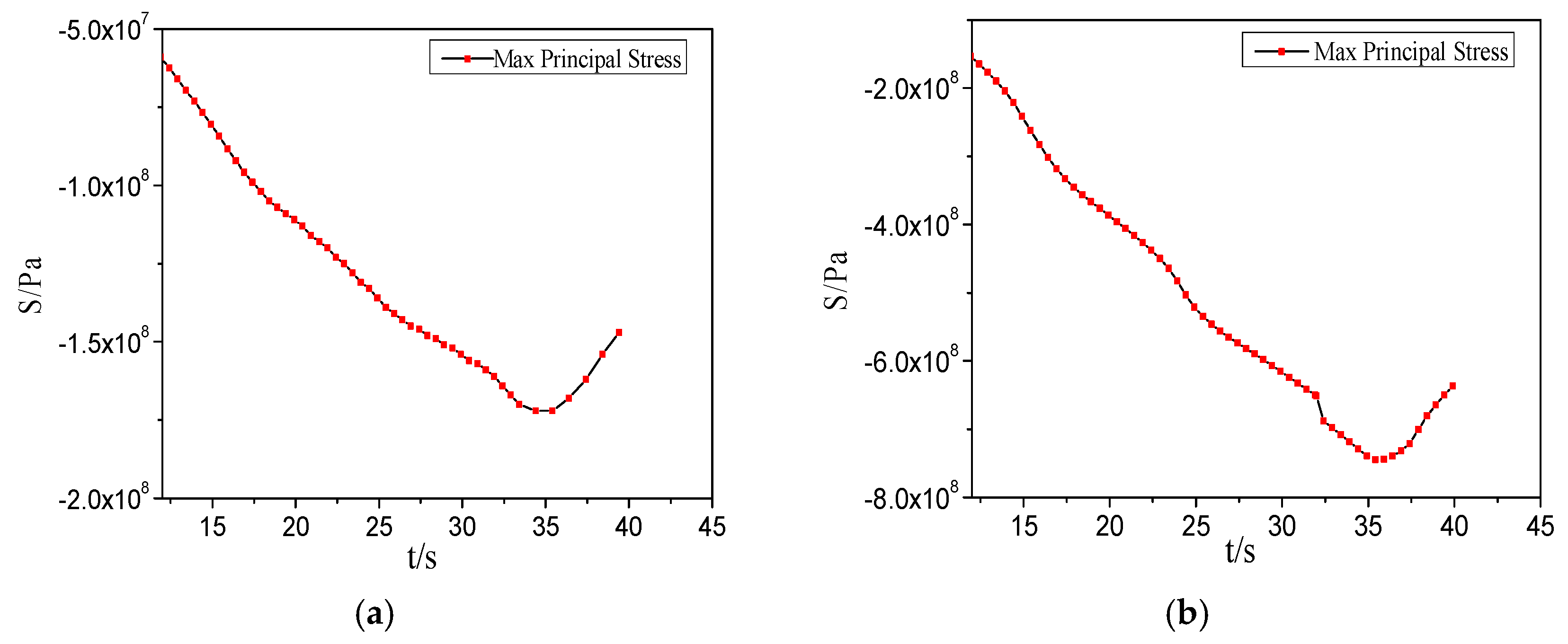

5.2.2. Stress and Strain Field near the Crack in the Welding Heating and Cooling Processes

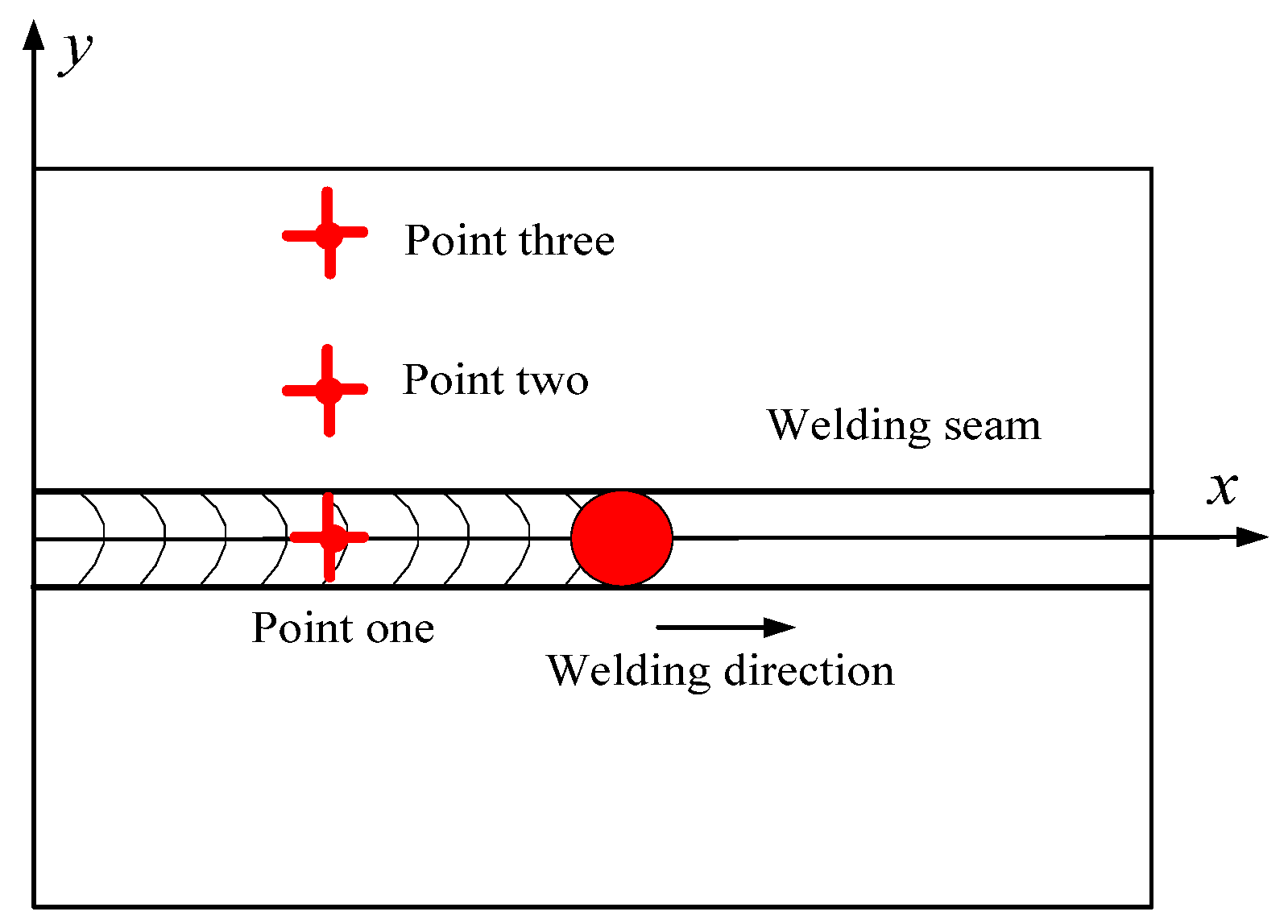

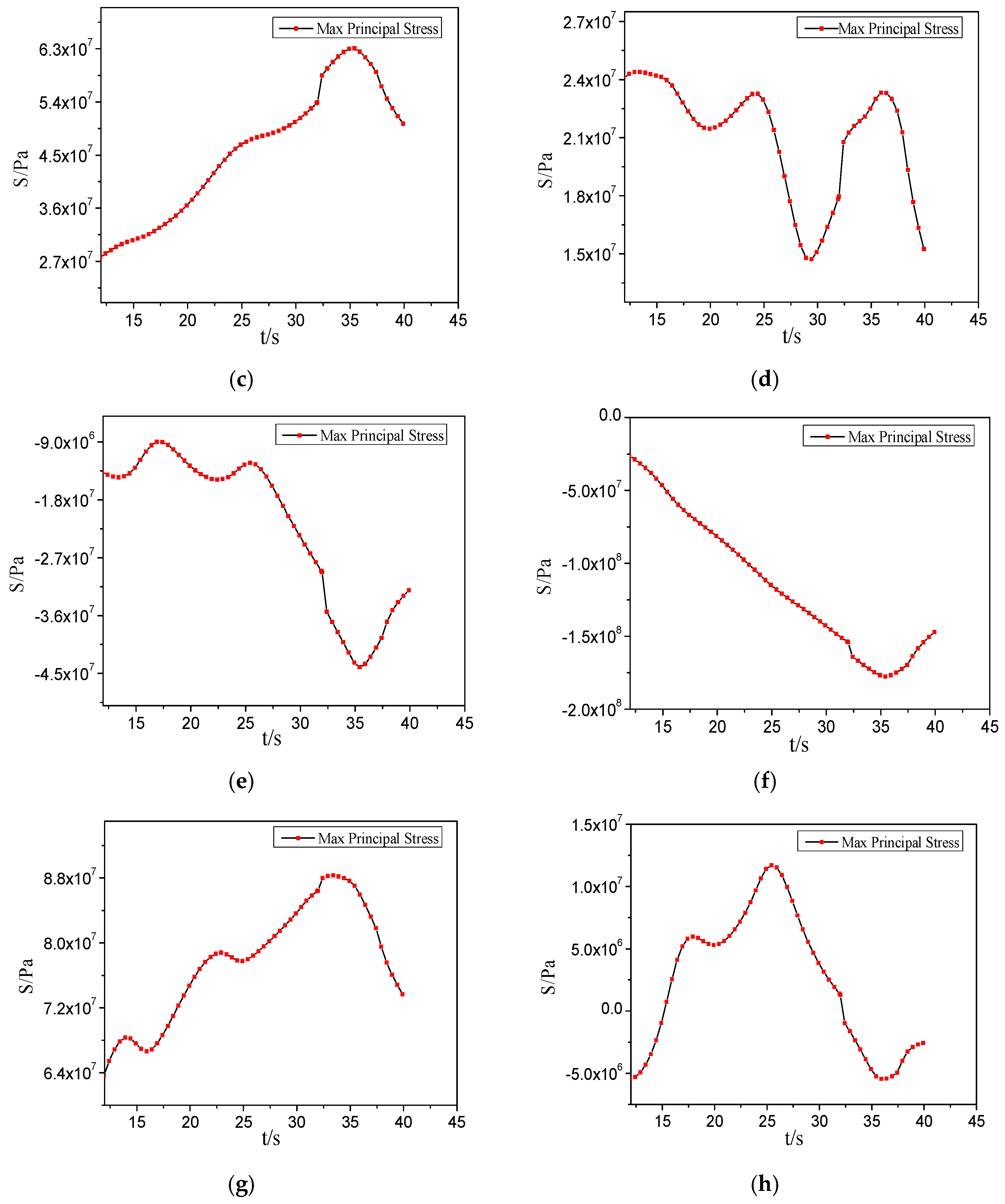

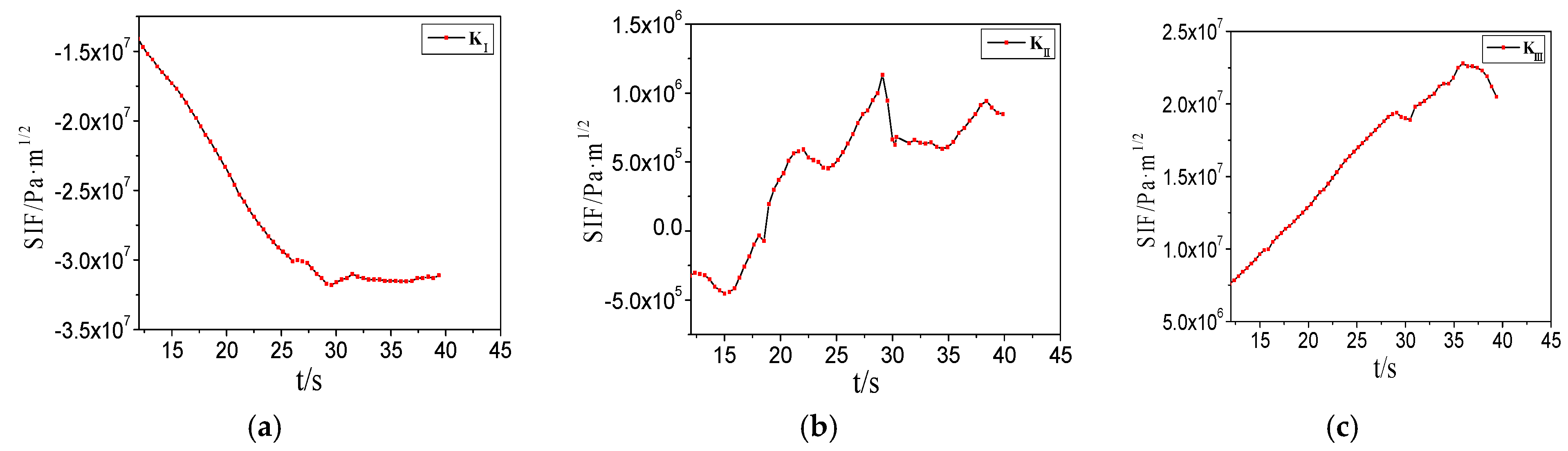

5.3. Calculation and Analysis of SIFs

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, T.Q.; Wu, C.S. Numerical simulation of plasma arc welding with keyhole-dependent heat source and arc pressure distribution. Int. J. Adv. Manuf. Technol. 2015, 78, 593–602. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, D.P.; Li, S. Numerical simulation of welding residual stress considering phase transformation effects. Adv. Mater. Res. 2011, 295–297, 1905–1910. [Google Scholar] [CrossRef]

- He, K.; Chen, J.; Xiao, S. Numerical simulation for shaping feature of molten pool in twin-arc submerged arc welding. Open J. Appl. Sci. 2012, 2, 47–53. [Google Scholar] [CrossRef]

- Yaghi, A.H.; Hyde, T.H.; Becker, A.A.; Sun, W. Finite element simulation of welding and residual stresses in a P91 steel pipe incorporating solid-state phase transformation and post-weld heat treatment. J. Strain Anal. Eng. Des. 2008, 43, 275–293. [Google Scholar] [CrossRef]

- Das, I.R.; Bhattacharjee, K.S.; Rao, S. Welding heat transfer analysis using Element Free Galerkin method. Adv. Mater. Res. 2011, 410, 298–301. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. A FEM model to study the fiber laser welding of Ti6Al4V thin sheets. Int. J. Adv. Manuf. Technol. 2016, 86, 1339–1346. [Google Scholar] [CrossRef]

- Sheikhi, M.; Ghaini, F.M.; Assadi, H. Solidification crack initiation and propagation in pulsed laser welding of wrought heat treatable aluminum alloy. Sci. Technol. Weld. Join. 2014, 19, 250–254. [Google Scholar] [CrossRef]

- He, K.F.; Zhang, Z.J.; Tan, Z.; Cheng, Y. Thermodynamic characteristics analysis of aluminium welding process. Mater. Res. Innov. 2015, 19, 89–93. [Google Scholar] [CrossRef]

- Duflot, M. The extended finite element method in thermoelastic fracture mechanics. Int. J. Numer. Methods Eng. 2008, 74, 827–847. [Google Scholar] [CrossRef]

- Zamani, A.; Eslami, M.R. Implementation of the extended finite element method for dynamic thermoelastic fracture initiation. Int. J. Solids Struct. 2010, 47, 1392–1404. [Google Scholar] [CrossRef]

- Bouhala, L.; Makradi, A.; Belouettar, S. Thermal and thermo-mechanical influence on crack propagation using an extended mesh free method. Eng. Fract. Mech. 2012, 88, 35–48. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Bayesteh, H.; Mohammadi, S. Thermo-mechanical XFEM crack propagation analysis of functionally graded materials. Mater. Sci. Eng. A 2013, 561, 285–302. [Google Scholar] [CrossRef]

- Piekarska, W.; Kubiak, M.; Saternus, Z. Application of Abaqus to analysis of the temperature field in elements heated by moving heat sources. Arch. Foundry Eng. 2010, 10, 177–182. [Google Scholar]

- Khoei, A.R. Extended Finite Element Method: Theory and Applications; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2015; pp. 1–565. [Google Scholar]

- Gravouil, A.; Moës, N.; Belytschko, T. Non-planar 3D crack growth by the extended finite element and level sets-Part II: Level set update. Int. J. Numer. Methods Eng. 2002, 53, 2569–2586. [Google Scholar] [CrossRef]

- Liu, Z.; Oswaldb, J.; Belytschkoa, T. XFEM modeling of ultrasonic wave propagation in polymer matrix particulate fibrous composites. Wave Motion 2013, 50, 389–401. [Google Scholar] [CrossRef]

- Moran, B.; Shih, C.F. A general treatment of crack tip contour integrals. Int. J. Fract. 1987, 35, 295–310. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G. Analysis and comparison of friction stir welding and laser assisted friction stir welding of aluminum alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef]

| T (°C) | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|---|---|---|---|

| λ (W/m·°C) | 233 | 232 | 230 | 228 | 224 | 221 | 217 | 213 | 209 |

| ρ (Kg/m3) | 2780 | 2762 | 2746 | 2720 | 2698 | 2676 | 2536 | 2484 | 2310 |

| c (J/Kg·°C) | 875 | 921 | 1047 | 1130 | 1180 | 1238 | 1292 | 1436 | 1476 |

| α (°C−1) | 21.4 | 22.7 | 23.8 | 24.9 | 25.7 | 26.6 | 27.4 | 28.4 | 29.3 |

| E (GPa) | 70 | 65 | 49.4 | 38.9 | 28.5 | 18.2 | 7.8 | - | - |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, K.; Yang, Q.; Xiao, D.; Li, X. Analysis of Thermo-Elastic Fracture Problem during Aluminium Alloy MIG Welding Using the Extended Finite Element Method. Appl. Sci. 2017, 7, 69. https://doi.org/10.3390/app7010069

He K, Yang Q, Xiao D, Li X. Analysis of Thermo-Elastic Fracture Problem during Aluminium Alloy MIG Welding Using the Extended Finite Element Method. Applied Sciences. 2017; 7(1):69. https://doi.org/10.3390/app7010069

Chicago/Turabian StyleHe, Kuanfang, Qing Yang, Dongming Xiao, and Xuejun Li. 2017. "Analysis of Thermo-Elastic Fracture Problem during Aluminium Alloy MIG Welding Using the Extended Finite Element Method" Applied Sciences 7, no. 1: 69. https://doi.org/10.3390/app7010069

APA StyleHe, K., Yang, Q., Xiao, D., & Li, X. (2017). Analysis of Thermo-Elastic Fracture Problem during Aluminium Alloy MIG Welding Using the Extended Finite Element Method. Applied Sciences, 7(1), 69. https://doi.org/10.3390/app7010069