Relationship between ISO 230-2/-6 Test Results and Positioning Accuracy of Machine Tools Using LaserTRACER

Abstract

:1. Introduction

- (1)

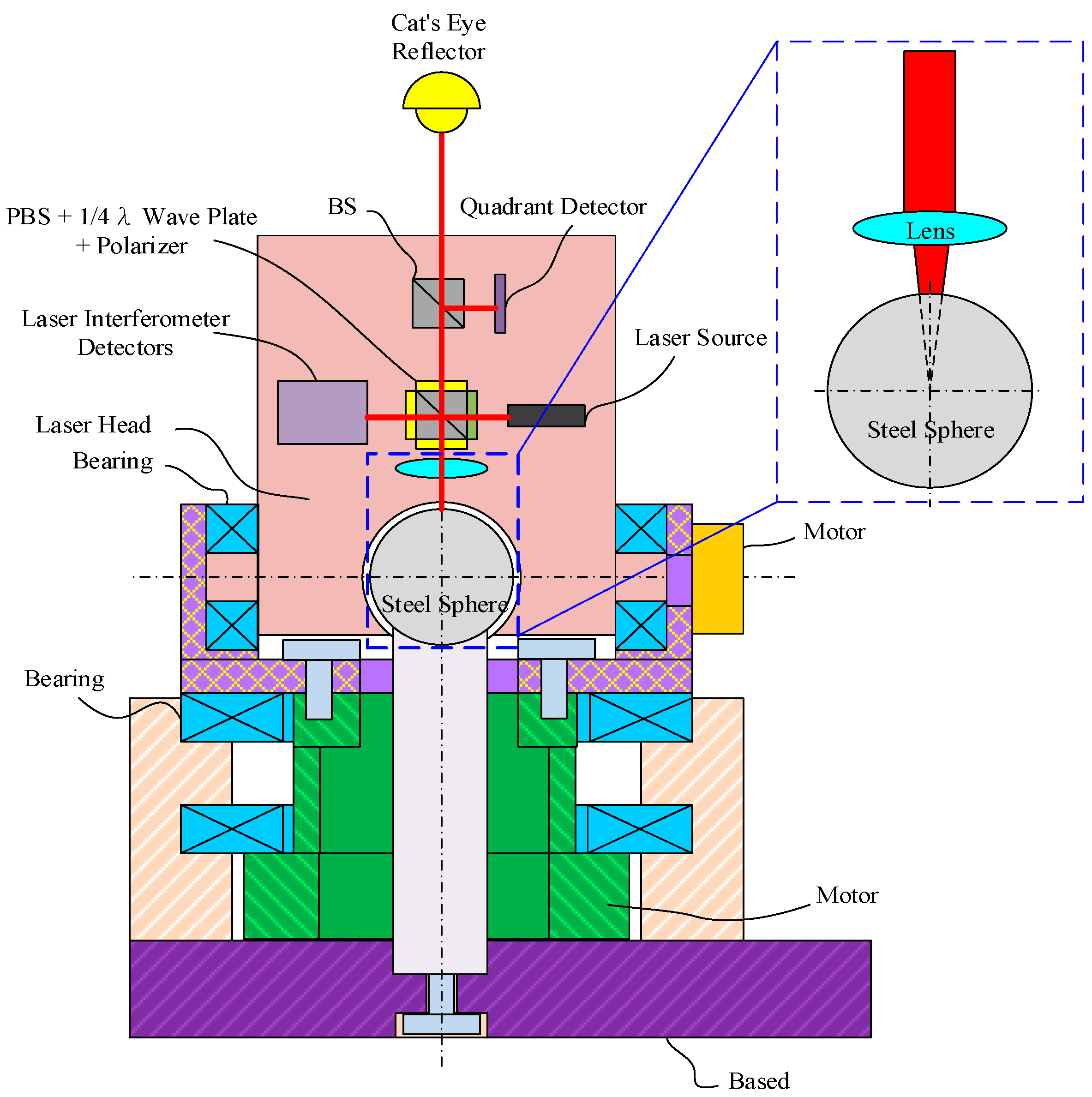

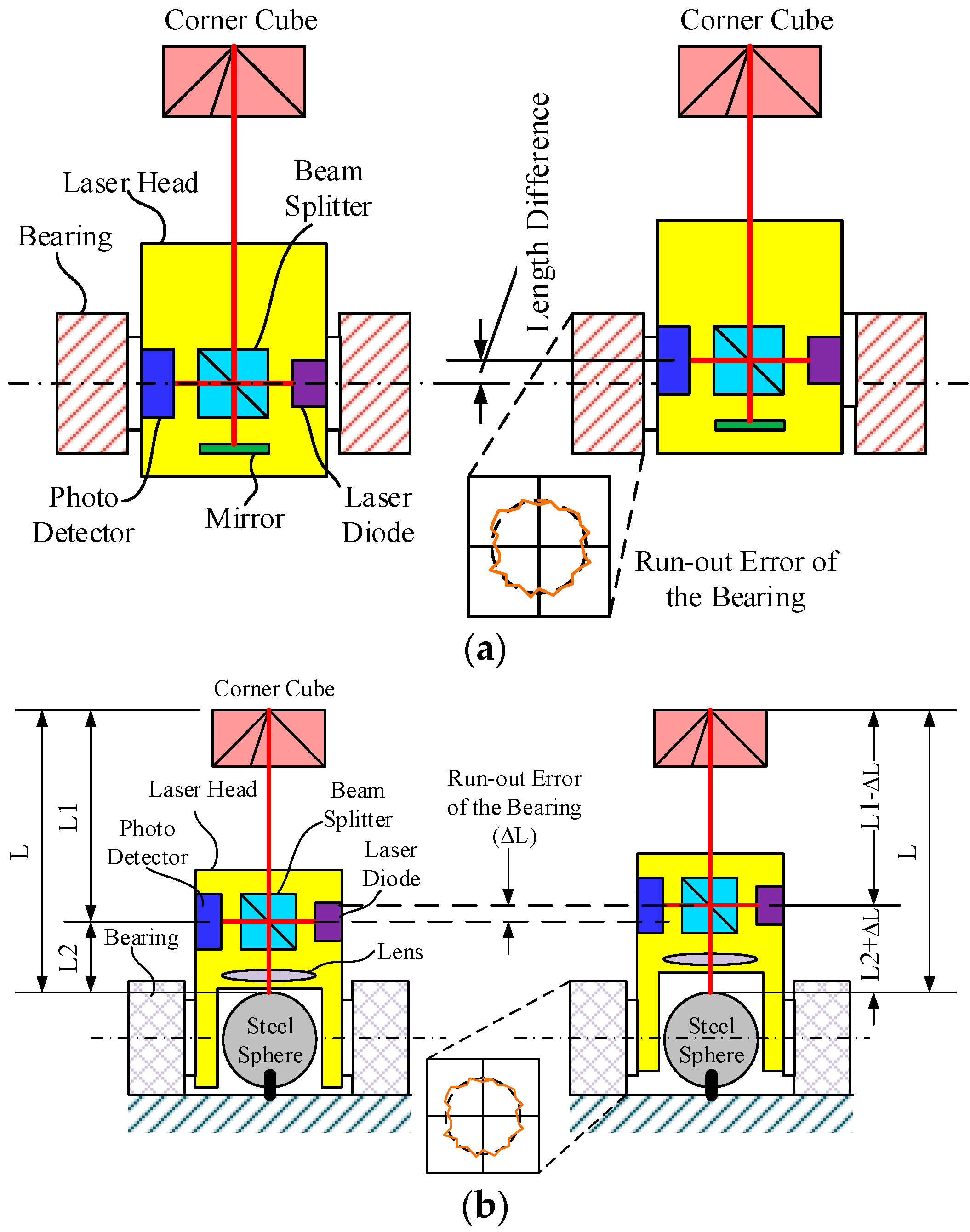

- To reduce the measurement error due to bearing run-out error and mirror offset, LaserTRACER uses a steel sphere instead [18]. As seen in Figure 2a, when the laser head is rotated, the bearing run-out error affects the length difference. When a lens and a steel sphere are used instead, the run-out error can be eliminated, as shown in Figure 2b.

- (2)

- The target spatial coordinate, which is measured by Laser Tracker, is determined by the following Equation [19]:where d represents the measured distance between the target and the Laser Trackers; α and β represent the angular position of θz and θy, respectively; and Δd, Δα and Δβ represent the deviations of d, α and β (i.e., the error sources), respectively.

- (3)

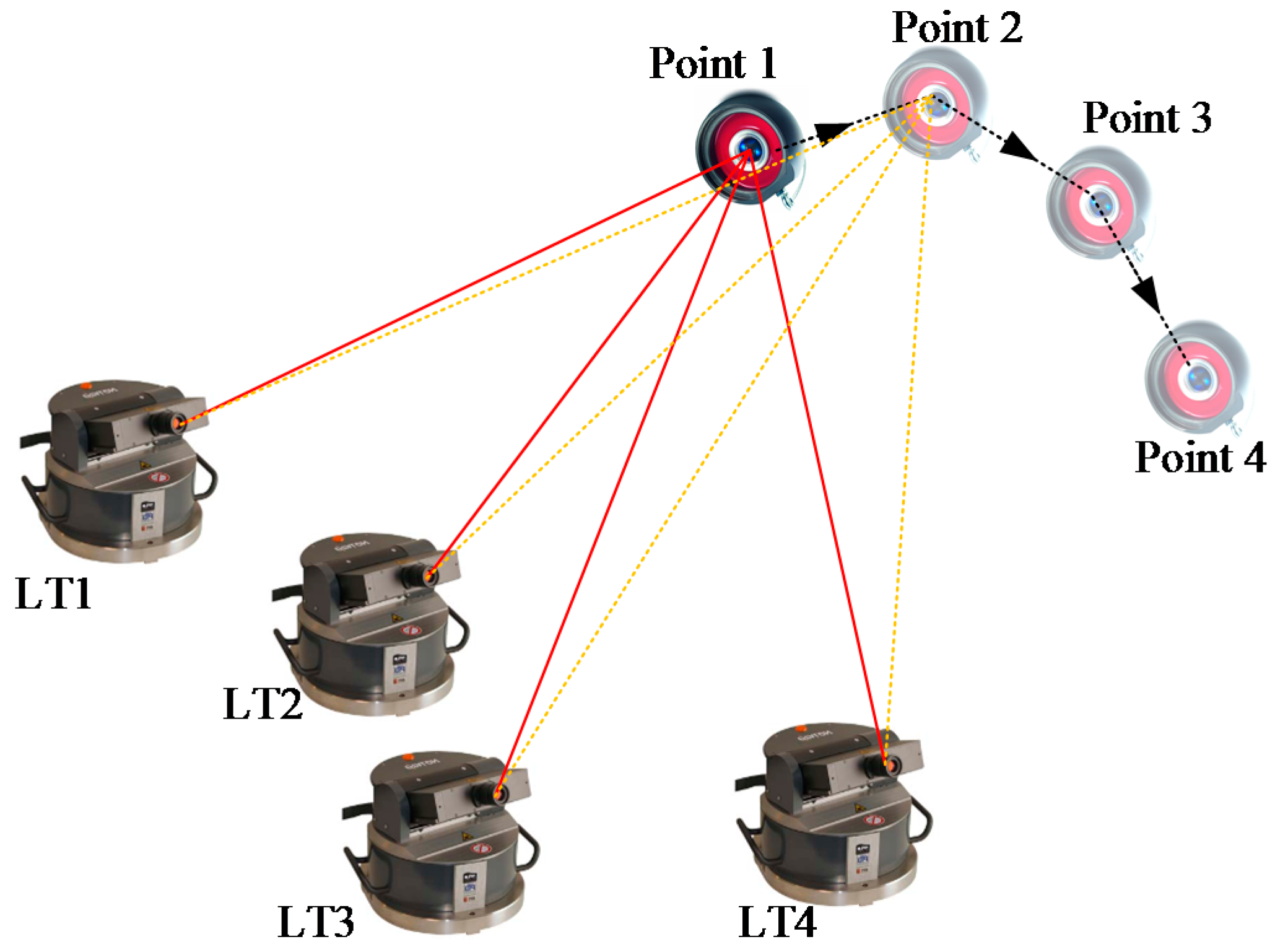

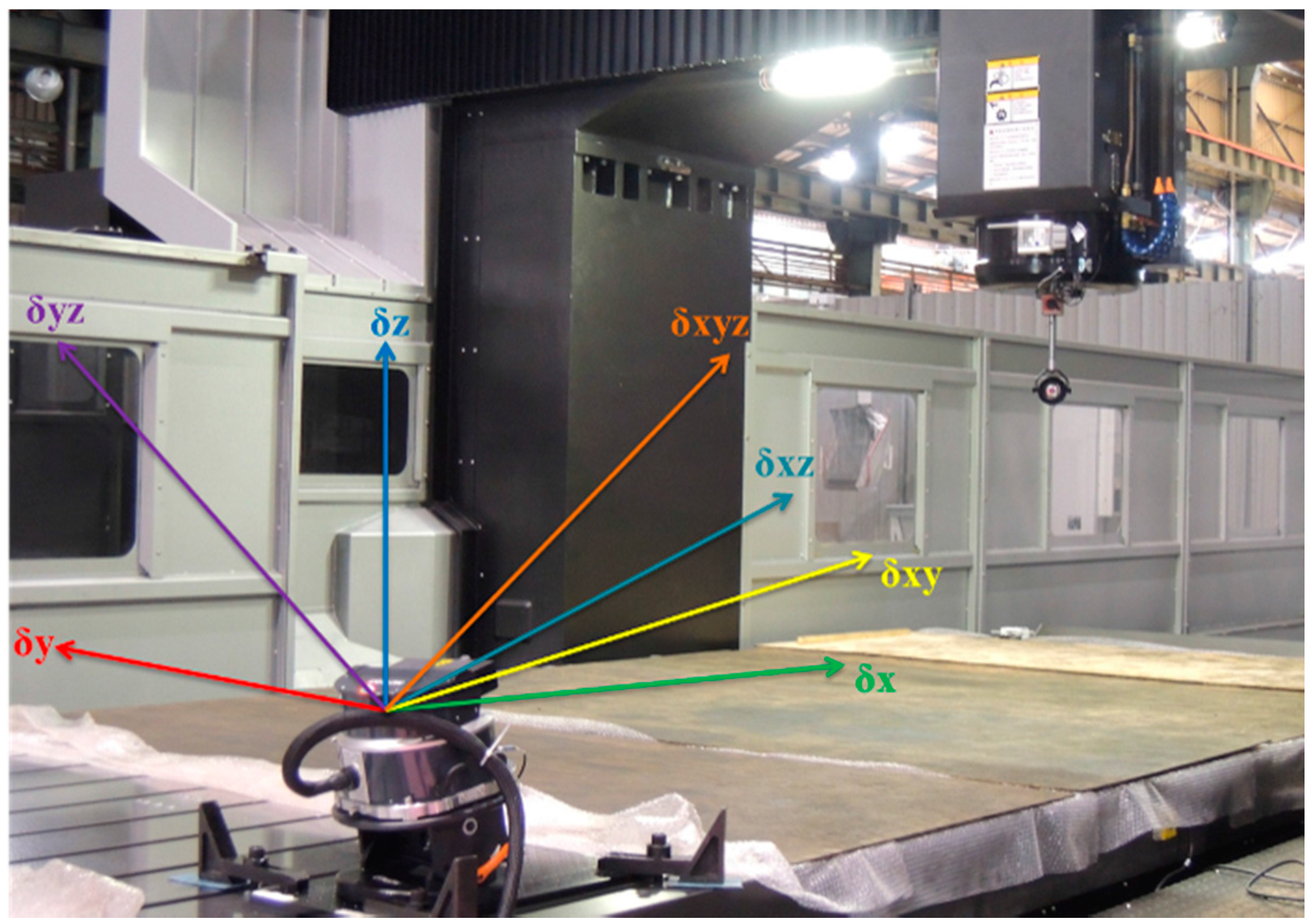

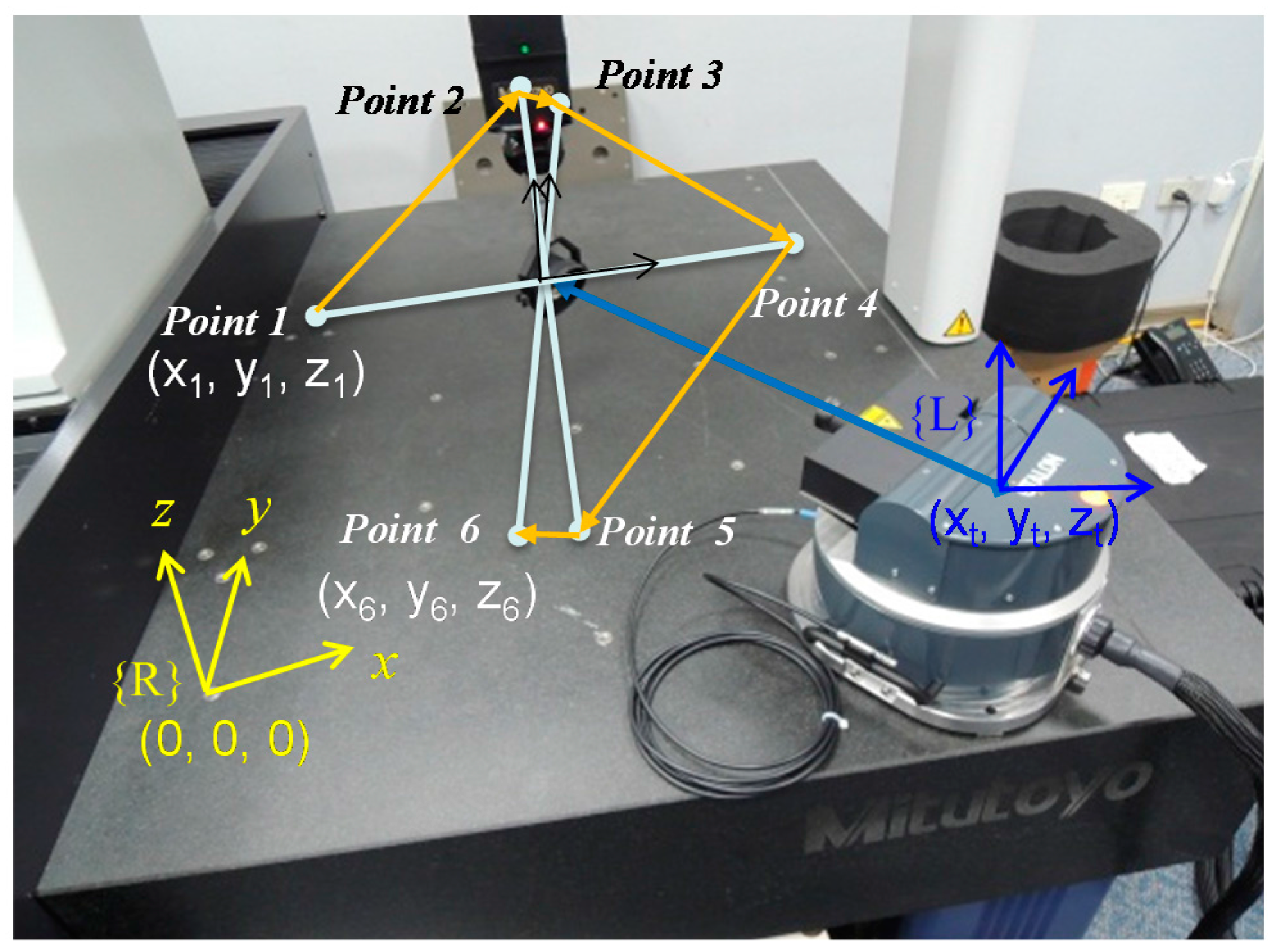

- LaserTRACER adopts multilateration for spatial coordinate measuring, as shown in Figure 3. The measurement equation is as below [12]:where is the coordinate of the i-th measurement point; is the position of the j-th LaserTRACER; is the measured length when the target stops at the i-th measurement point; is the initial distance between the target and the j-th LaserTRACER; is the scale factor for j-th LaserTRACER, which can be determined through calibration; and is the residual error.

2. Experiments

2.1. To Simulate the Error Motion

2.2. Coordinate Offset

2.3. Proportional Error

- (i)

- Assuming the target point is (100, 50, 30.2) mm and the given proportional error for z-axis is 1.01, thus, the command position will be (100, 50, 30.804) mm.

- (ii)

- Assuming the target point is (82.55, 50, 30.2) mm and the given proportional error for z-axis is 0.99 for x-axis, the command position will be on (81.725, 50, 30.2) mm.

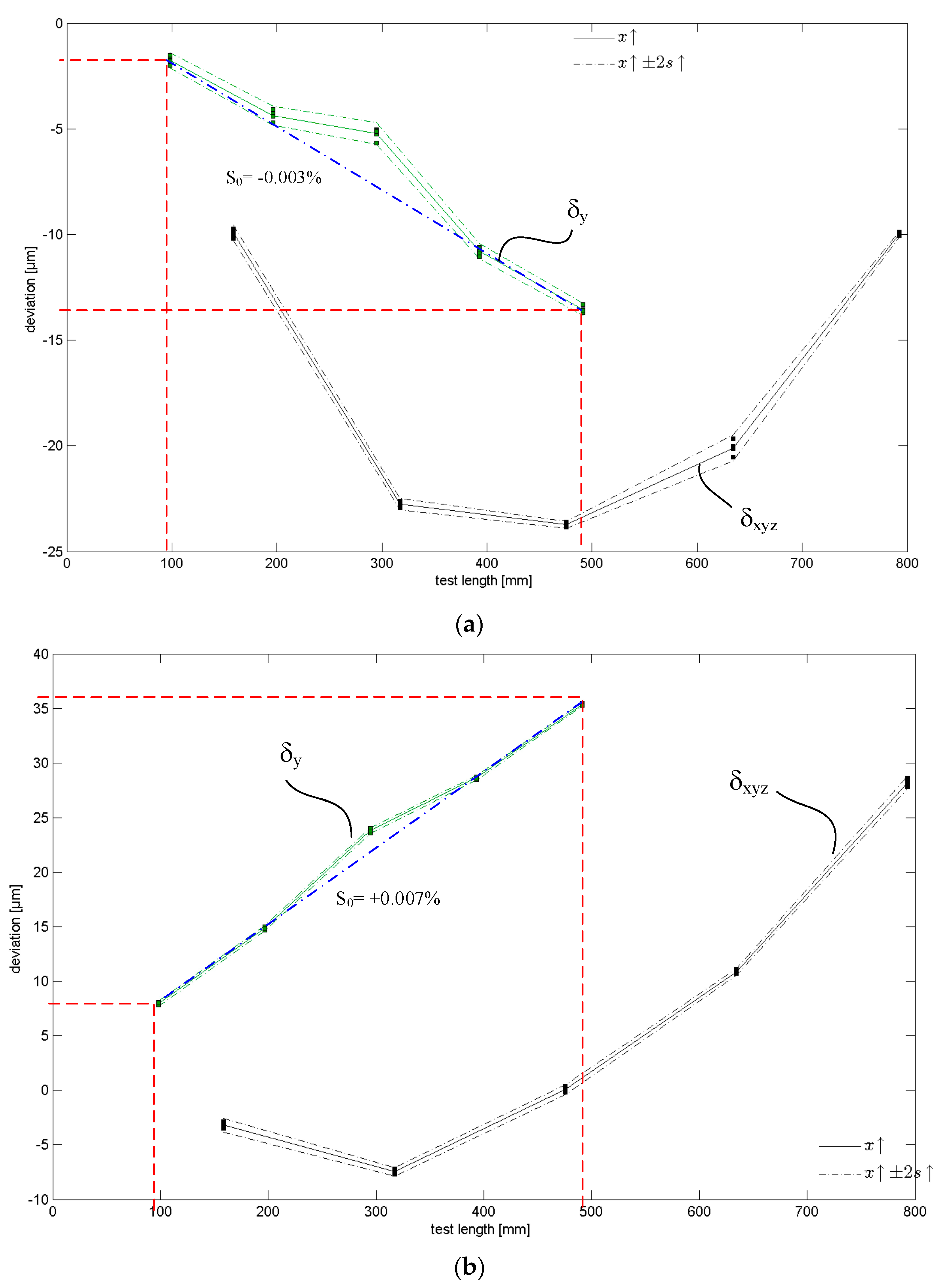

2.4. ISO 230 Test with Proportional Error

3. ISO 230-2 and ISO 230-6 Tests Using LaserTRACER

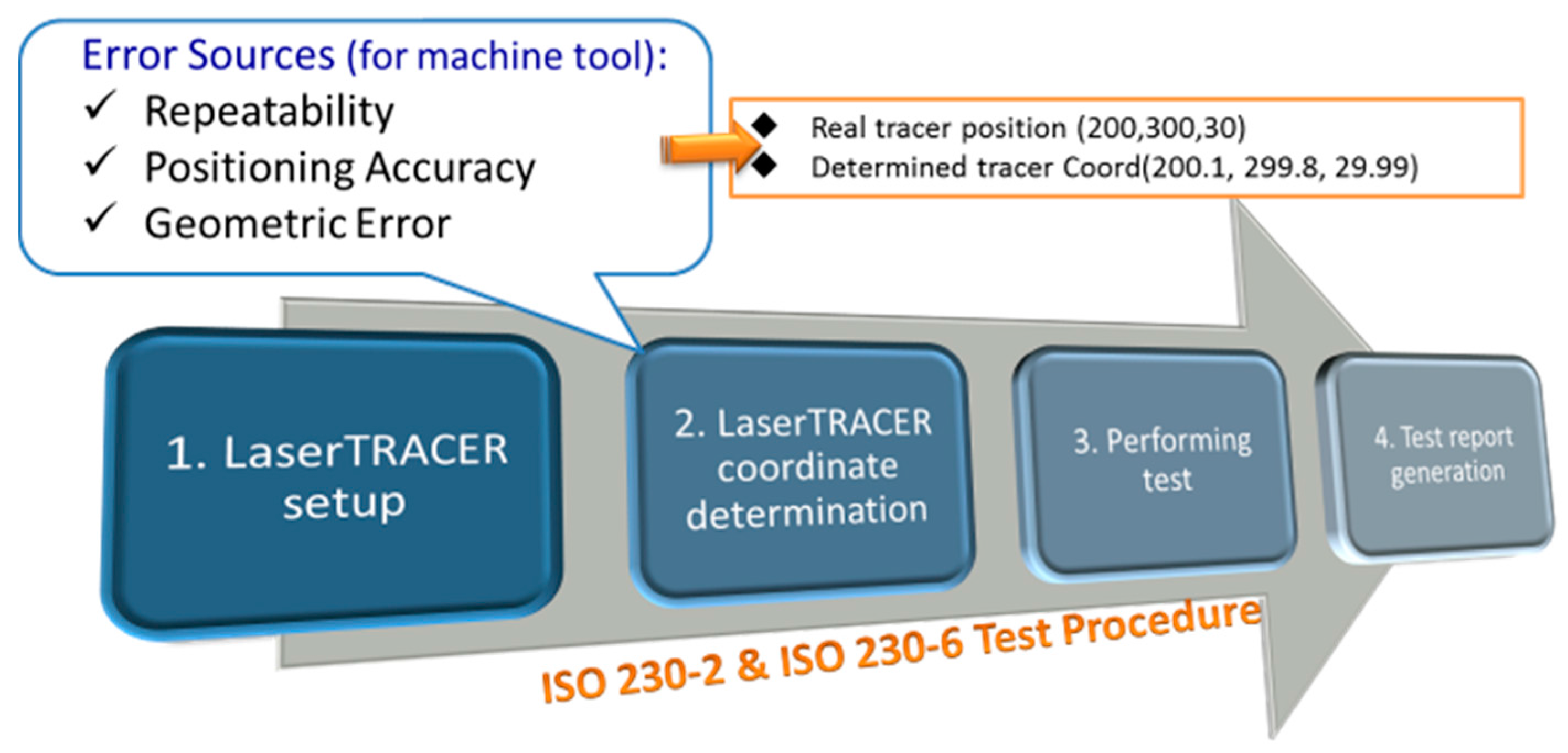

3.1. Test Procedure

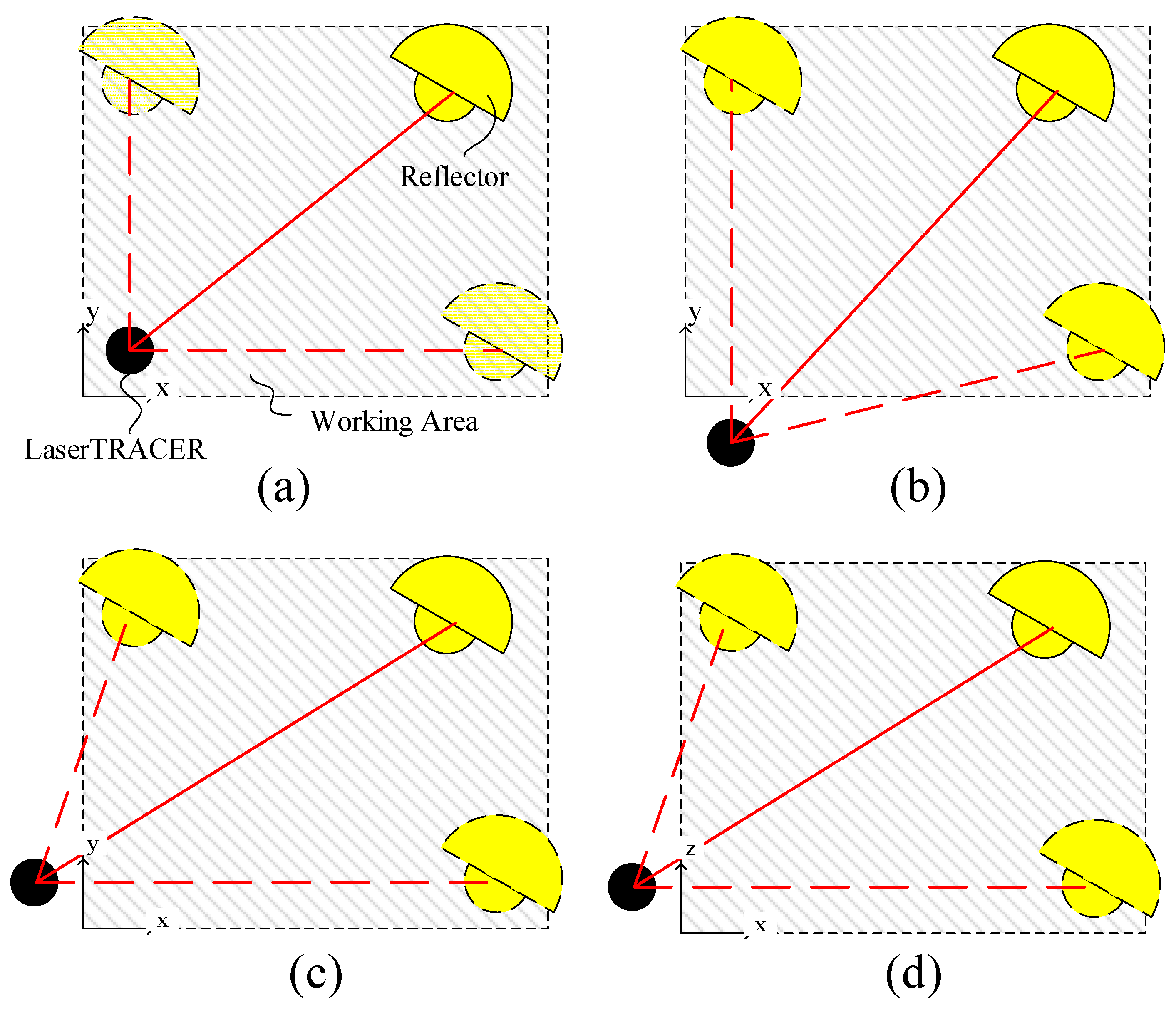

3.2. The Working Space

3.3. LaserTRACER Coordinate Determination

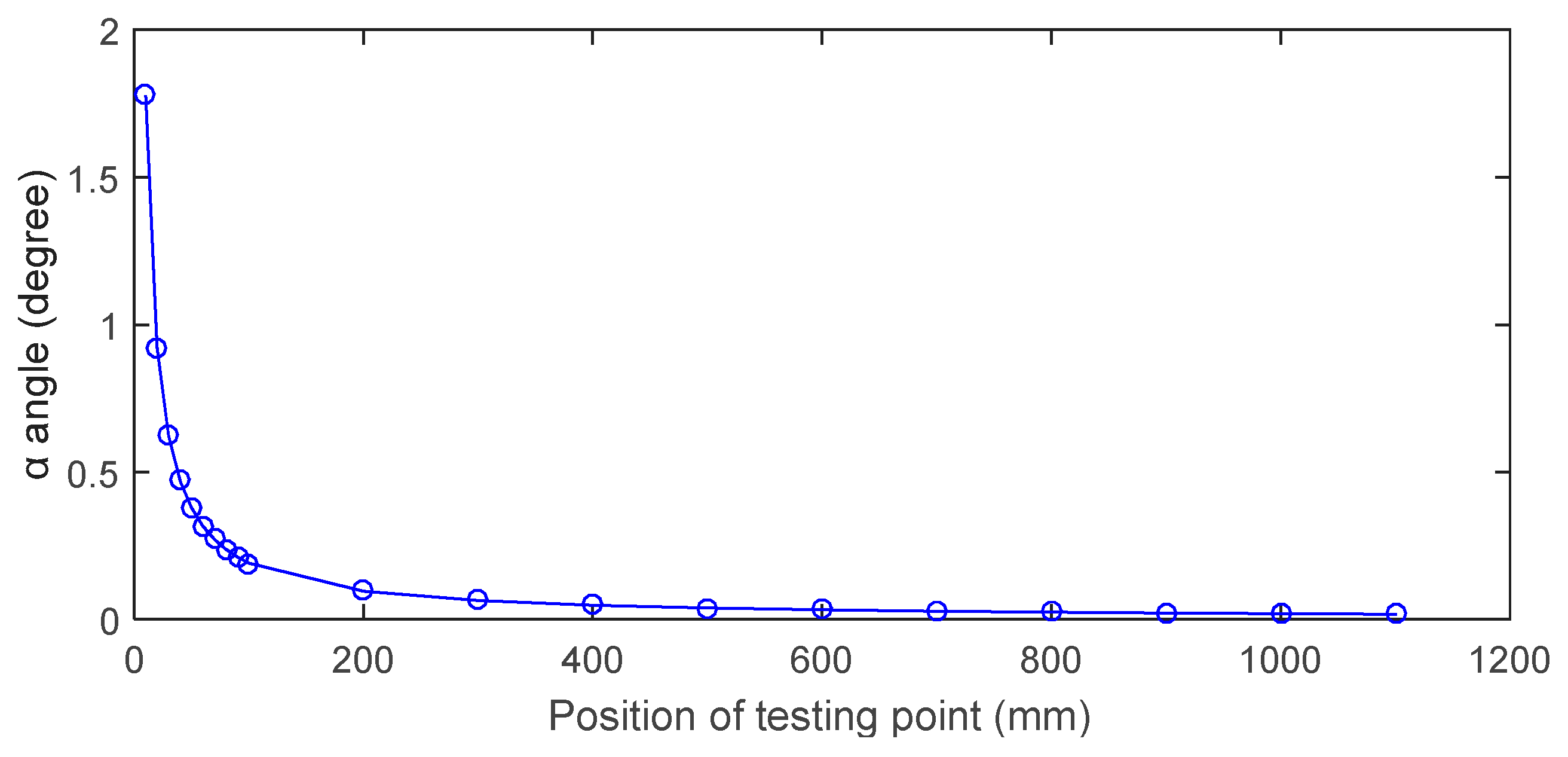

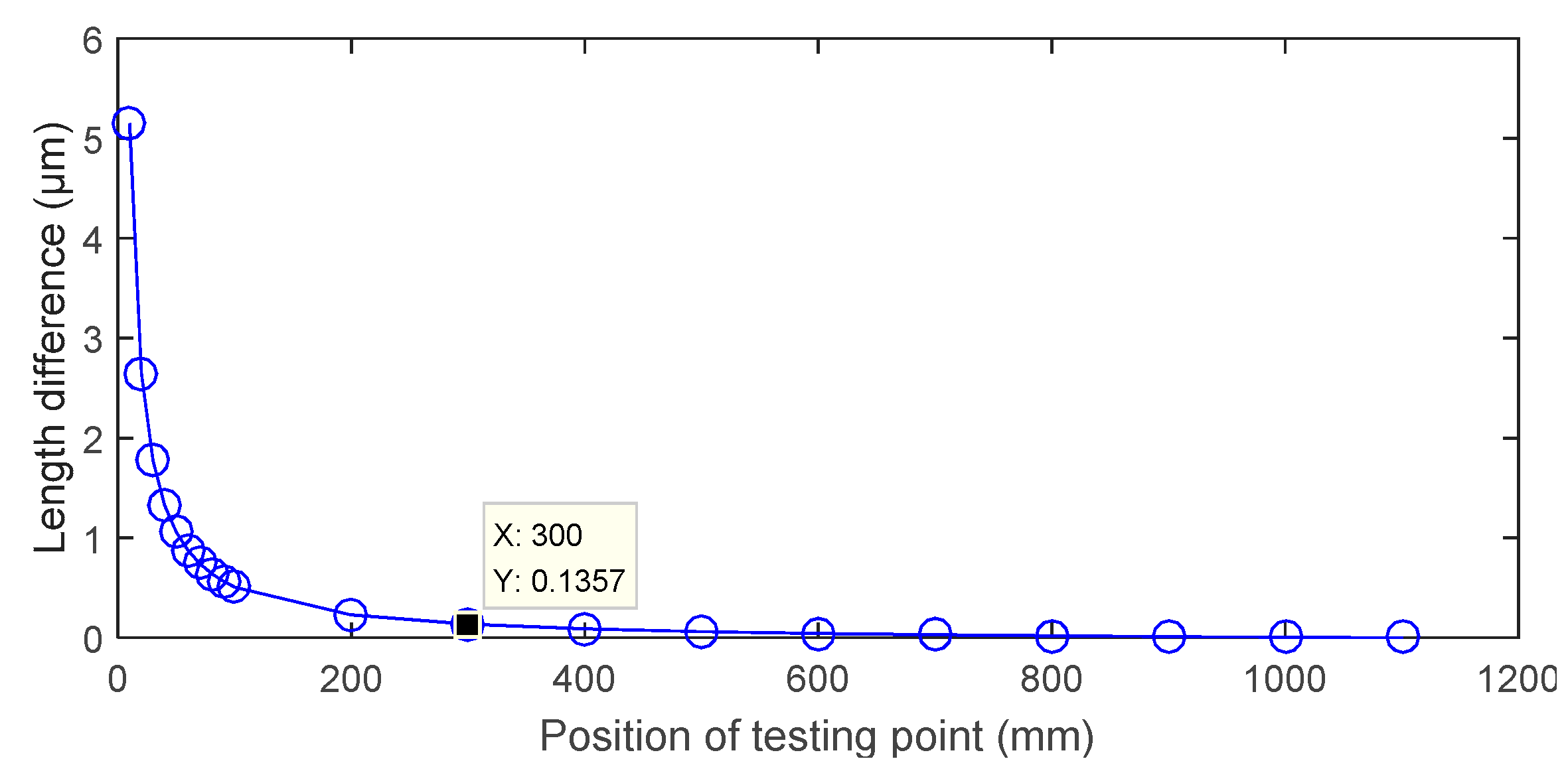

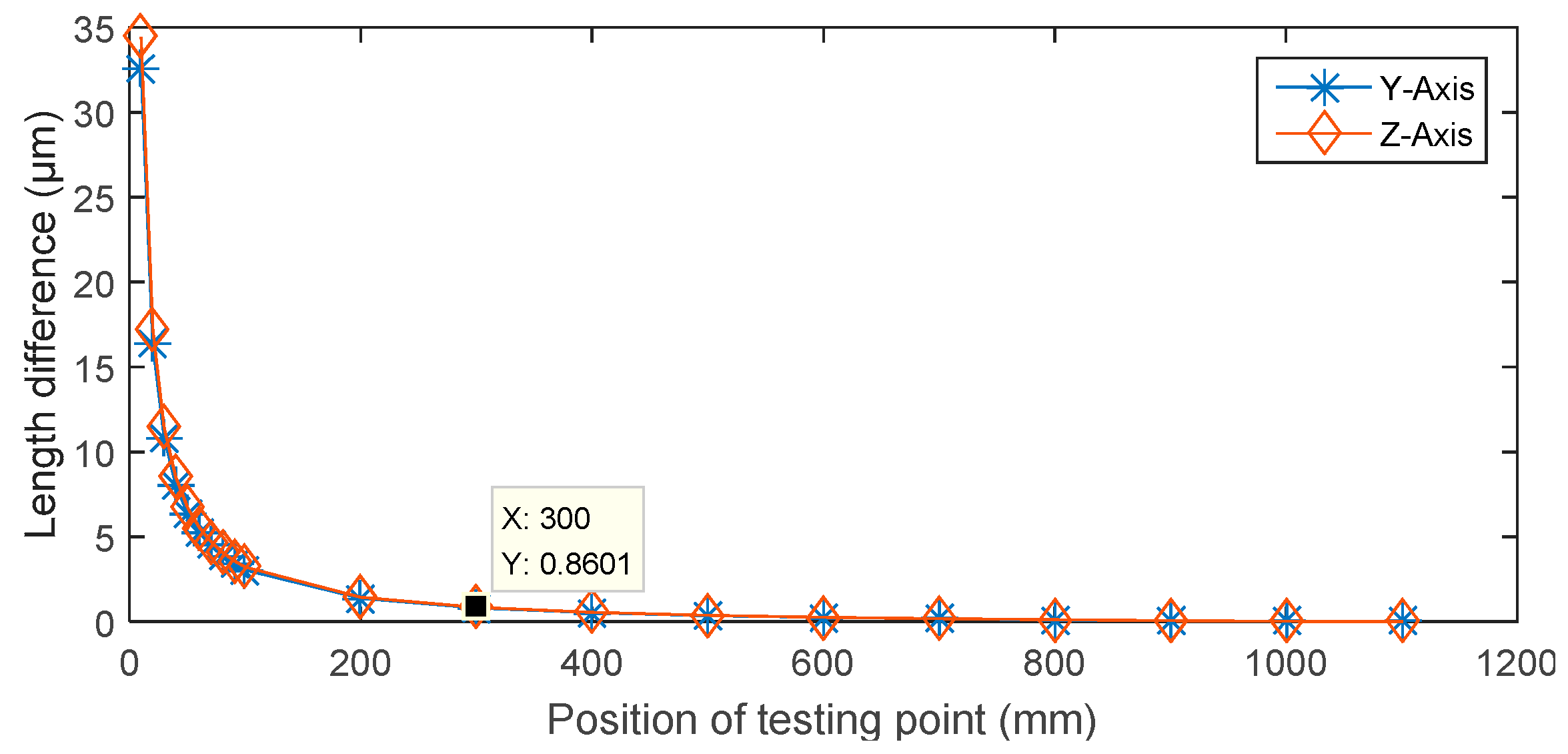

4. Effect of Positioning Accuracy

Effect of Length Difference

5. Conclusions

- (1)

- Positioning accuracy of the machine tool causes LaserTRACER coordinate determined error;

- (2)

- The coordinate determined error because of coordinate offset error exactly equals the given value;

- (3)

- The coordinate offset error does not affect the ISO 230-2 and -6 test results;

- (4)

- Although the proportional error, in an example simulation of the ball screw lead difference, causes the coordinate determined error, it does not affect the ISO 230-2 and -6 test results;

- (5)

- Positioning accuracy and repeatability can be achieved through ISO 230-2 and -6 tests using a LaserTRACER.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, G.; Ouyang, R.; Lu, B.; Hocken, R.; Veale, R.; Donmez, A. A Displacement method for machine geometry calibration. CIRP Ann. Manuf. Technol. 1988, 37, 515–518. [Google Scholar] [CrossRef]

- International Organization for Standardization. 230: Test code for machine tools. In Part 6: Determination of Positioning Accuracy on Body and Face Diagonals (Diagonal Displacement Tests); ISO: Geneva, Switzerland, 2002. [Google Scholar]

- International Organization for Standardization. 230: Test code for machine tools. In Part 2: Determination of Accuracy and Repeatability of Positioning Numerically Controlled Axes; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Liu, C.H.; Jywe, W.Y.; Hsu, C.C.; Hsu, T.H. Development of a laser-based high-precision six-degrees-of-freedom motion errors measuring system for linear stage. Rev. Sci. Instrum. 2005, 76. [Google Scholar] [CrossRef]

- Lau, K.; Hocken, R.J.; Haight, W.C. Automatic laser tracking interferometer system for robot metrology. Precis. Eng. 1986, 8, 3–8. [Google Scholar] [CrossRef]

- Muralikrishnan, B.; Phillips, S.; Sawyer, D. Laser trackers for large-scale dimensional metrology: A review. Precis. Eng. 2016, 44, 13–28. [Google Scholar] [CrossRef]

- Physikalisch-Technische Bundesanstalt. Nachführbares Interferometer Mit Mechanisch und Thermisch Entkoppeltem, Metrologischem Referenzelement (TRACER); PTB: Braunschweig, Germany, 2004. [Google Scholar]

- Hughes, E.B. Tracking System. US Patent 6147748, 14 November 2000. [Google Scholar]

- Hughes, E.B.; Wilson, A.; Peggs, G.N. Design of a high-accuracy CMM based on multi-lateration techniques. CIRP Ann. Manuf. Technol. 2000, 49, 391–394. [Google Scholar] [CrossRef]

- Bala, M.; Lee, V.; Blackburn, C.; Sawyer, D.; Phillips, S.; Ren, W.; Hughes, B. Assessing ranging errors as a function of azimuth in laser trackers and tracers. Meas. Sci. Technol. 2013, 24. [Google Scholar] [CrossRef]

- Toshiyuki, T.; Goto, M.; Kurosawa, T.; Tanimura, Y.; Koseki, Y. The first measurement of a three-dimensional coordinate by use of a laser tracking interferometer system based on trilateration. Meas. Sci. Technol. 1998, 9, 38–41. [Google Scholar]

- Wendt, K.; Franke, M.; Härtig, F. Measuring large 3D structures using four portable tracking laser interferometers. Measurement 2012, 45, 2339–2345. [Google Scholar] [CrossRef]

- Wang, J.; Guo, J.; Zhou, B.; Xiao, J. The detection of rotary axis of NC machine tool based on multi-station and time-sharing measurement. Measurement 2012, 45, 1713–1722. [Google Scholar] [CrossRef]

- Lee, H.W.; Liu, C.H.; Chu, K.T.; Tseng, H.C. Kinect who’s coming—Applying kinect to human body height measurement to improve character recognition performance. Smart Sci. 2015, 3, 117–121. [Google Scholar]

- Lee, H.W.; Chen, C.L. Applying dual-laser spot positions measurement technology on a two-dimensional tracking measurement system. Meas. Sci. Technol. 2009, 20. [Google Scholar] [CrossRef]

- Lee, H.W.; Chen, C.L.; Liu, C.H. Development of an optical three-dimensional laser tracker using dual modulated laser diodes and a signal detector. Rev. Sci. Instrum. 2011, 82. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.W.; Liu, C.H. Development of a steel ball center alignment device based on Michelson interference concept. Rev. Sci. Instrum. 2014, 85. [Google Scholar] [CrossRef] [PubMed]

- Bundesrepublik Deutschland, vertr. d.d.; Bundesministerium für Wirtschaft und Arbeit, dieses vertr. d.d.; Präsidenten der Physikalisch-Technischen Bundesanstalt. Laser Interferometer for Spacing Measurement Has Reference Sphere Positioned on Post and Base Plate Made of Thermally Invariant Material. German Patent DE202004007647, 16 September 2004. (In German)[Google Scholar]

- Ouyang, J.F.; Liu, W.L.; Yan, Y.G.; Sun, D.X. Angular error calibration of laser tracker system. Proc. SPIE Adv. Laser Technol. 2005, 6344. [Google Scholar] [CrossRef]

- Linares, J.M.; Chaves-Jacob, J.; Schwenke, H.; Longstaff, A.; Fletcher, S.; Flore, J.; Uhlmann, E.; Wintering, J. Impact of measurement procedure when error mapping and compensating a small CNC machine using a multilateration laser interferometer. Precis. Eng. 2014, 38, 578–588. [Google Scholar] [CrossRef]

- Zhang, G.; Veale, R.; Charlton, T.; Borchardt, B.; Hocken, R. Error compensation of coordinate measuring machines. CIRP Ann. Manuf. Technol. 1985, 34, 445–448. [Google Scholar] [CrossRef]

- Wang, J.; Guo, J.; Zhang, G.; Guo, B.; Wang, H. The technical method of geometric error measurement for multi-axis NC machine tool by laser tracker. Meas. Sci. Technol. 2012, 23, 45003–45013. [Google Scholar] [CrossRef]

- Schwenke, H.; Franke, M.; Hannaford, J.; Kunzmann, H. Error mapping of CMMs and machine tools by a single tracking interferometer. CIRP Ann. Manuf. Technol. 2005, 54, 475–478. [Google Scholar] [CrossRef]

- Schwenke, H.; Schmitt, R.; Jatzkowski, P.; Warmann, C. On-the-fly calibration of linear and rotary axes of machine tools and CMMs using a tracking interferometer. CIRP Ann. Manuf. Technol. 2009, 58, 477–480. [Google Scholar] [CrossRef]

- Ezedine, F.; Linares, J.M.; Sprauel, J.M.; Chaves-Jacob, J. Smart sequential multilateration measurement strategy for volumetric error compensation of an extra-small machine tool. Precis. Eng. 2016, 43, 178–186. [Google Scholar] [CrossRef]

| Mode | Working Range (m) | Angular Accuracy | Distance Accuracy | |

|---|---|---|---|---|

| ADM | IFM | |||

| Leica AT960 | 40/160 | ±15 μm + 6 μm/m | ±0.5 μm/m (AIFM) | |

| Leica AT930 | 160 | ±15 μm + 6 μm/m | ||

| Leica AT901 | 50/160 | ±15 μm + 6 μm/m | ±10 μm | ±0.4 μm + 0.3 μm/m |

| Leica AT402 | 320 | ±15 μm + 6 μm/m | ±10 μm | - |

| Leica AT401 | 320 | ±15 μm + 6 μm/m | ±10 μm | - |

| Leica LTD600 | 40 | ±25 μm | ±25 μm | ±10 μm ±0.5 μm/m |

| API Tracker3 | 30/80/> 120 | 3.5 μm/m | ±15 μm | whthin ±0.5 μm/m |

| API Radian | 40/100/> 160 | 3.5 μm/m | ±10 μm | whthin ±0.5 μm/m |

| API Omnitrac2 | 160/200 | 3.5 μm/m | ±15 μm | - |

| FARO ION | 30/40/55 | 20 μm + 5 μm/m | 16 μm + 0.8 μm/m | 4 μm + 0.8 μm/m |

| FARO Vantage | 30/60/80 | 20 μm + 5 μm/m | 16 μm + 0.8 μm/m | - |

| Etalon LaserTRACER | 0.2–20 | - | - | 0.2 μm + 0.3 μm/m (Measuring Uncertainty, k = 2) |

| Offset Value | Coordinate Difference | ||

|---|---|---|---|

| x | y | z | |

| x-axis, +1 mm | −1.00 | 0.00 | 0.00 |

| x-axis, −1 mm | 1.00 | 0.00 | 0.00 |

| y-axis, +1 mm | 0.00 | −1.00 | 0.00 |

| y-axis, −1 mm | 0.00 | 1.01 | 0.01 |

| z-axis, +1 mm | 0.00 | 0.00 | −0.99 |

| z-axis, −1 mm | 0.01 | 0.00 | 1.00 |

| x- and y-axis, +1 mm | −1.00 | −1.00 | 0.01 |

| x- and y-axis, −1 mm | 1.00 | 1.00 | 0.01 |

| x- and z-axis, +1 mm | −1.00 | 0.00 | −0.99 |

| x- and z-axis, −1 mm | 1.00 | 0.00 | 1.01 |

| y- and z-axis, +1 mm | 0.01 | −1.00 | −1.00 |

| y- and z-axis, −1 mm | 0.00 | 1.00 | 1.01 |

| Proportional Value | Coordinate Difference | ||

|---|---|---|---|

| x | y | z | |

| x-axis, 1.01 | 0.06 | −0.10 | −0.01 |

| x-axis, 0.99 | −0.06 | 0.10 | 0.02 |

| y-axis, 1.01 | 0.15 | −0.25 | −0.03 |

| y-axis, 0.99 | −0.14 | 0.24 | 0.04 |

| z-axis, 1.01 | 0.01 | −0.01 | −0.04 |

| z-axis, 0.99 | −0.02 | 0.03 | 0.40 |

| x- and y-axis, 1.01 | 0.21 | −0.35 | −0.04 |

| x- and y-axis, 0.99 | −0.20 | 0.35 | 0.05 |

| x- and z-axis, 1.01 | 0.06 | −0.11 | −0.05 |

| x- and z-axis, 0.99 | −0.06 | 0.11 | 0.06 |

| y- and z-axis, 1.01 | 0.15 | −0.25 | −0.07 |

| y- and z-axis, 0.99 | −0.14 | 0.25 | 0.08 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-W.; Chen, J.-R.; Pan, S.-P.; Liou, H.-C.; Hsu, P.-E. Relationship between ISO 230-2/-6 Test Results and Positioning Accuracy of Machine Tools Using LaserTRACER. Appl. Sci. 2016, 6, 105. https://doi.org/10.3390/app6040105

Lee H-W, Chen J-R, Pan S-P, Liou H-C, Hsu P-E. Relationship between ISO 230-2/-6 Test Results and Positioning Accuracy of Machine Tools Using LaserTRACER. Applied Sciences. 2016; 6(4):105. https://doi.org/10.3390/app6040105

Chicago/Turabian StyleLee, Hau-Wei, Jr-Rung Chen, Shan-Peng Pan, Hua-Chung Liou, and Po-Er Hsu. 2016. "Relationship between ISO 230-2/-6 Test Results and Positioning Accuracy of Machine Tools Using LaserTRACER" Applied Sciences 6, no. 4: 105. https://doi.org/10.3390/app6040105