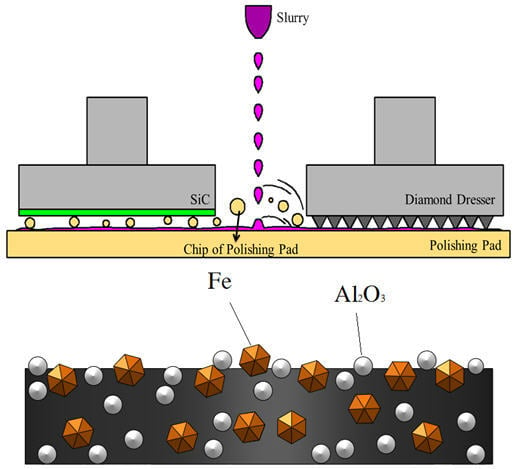

Investigation of Polishing Pads Impregnated with Fe and Al2O3 Particles for Single-Crystal Silicon Carbide Wafers

Abstract

:1. Introduction

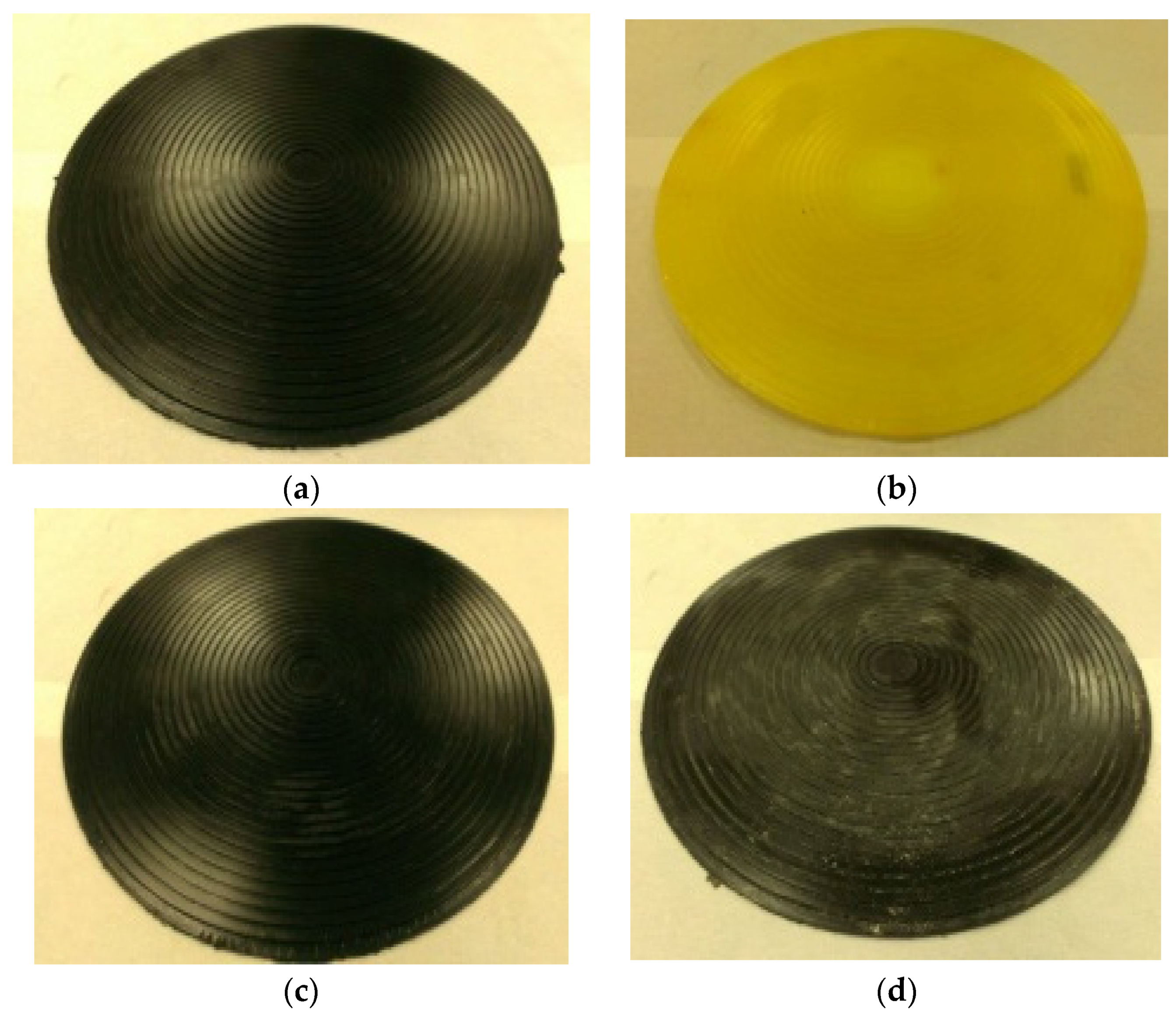

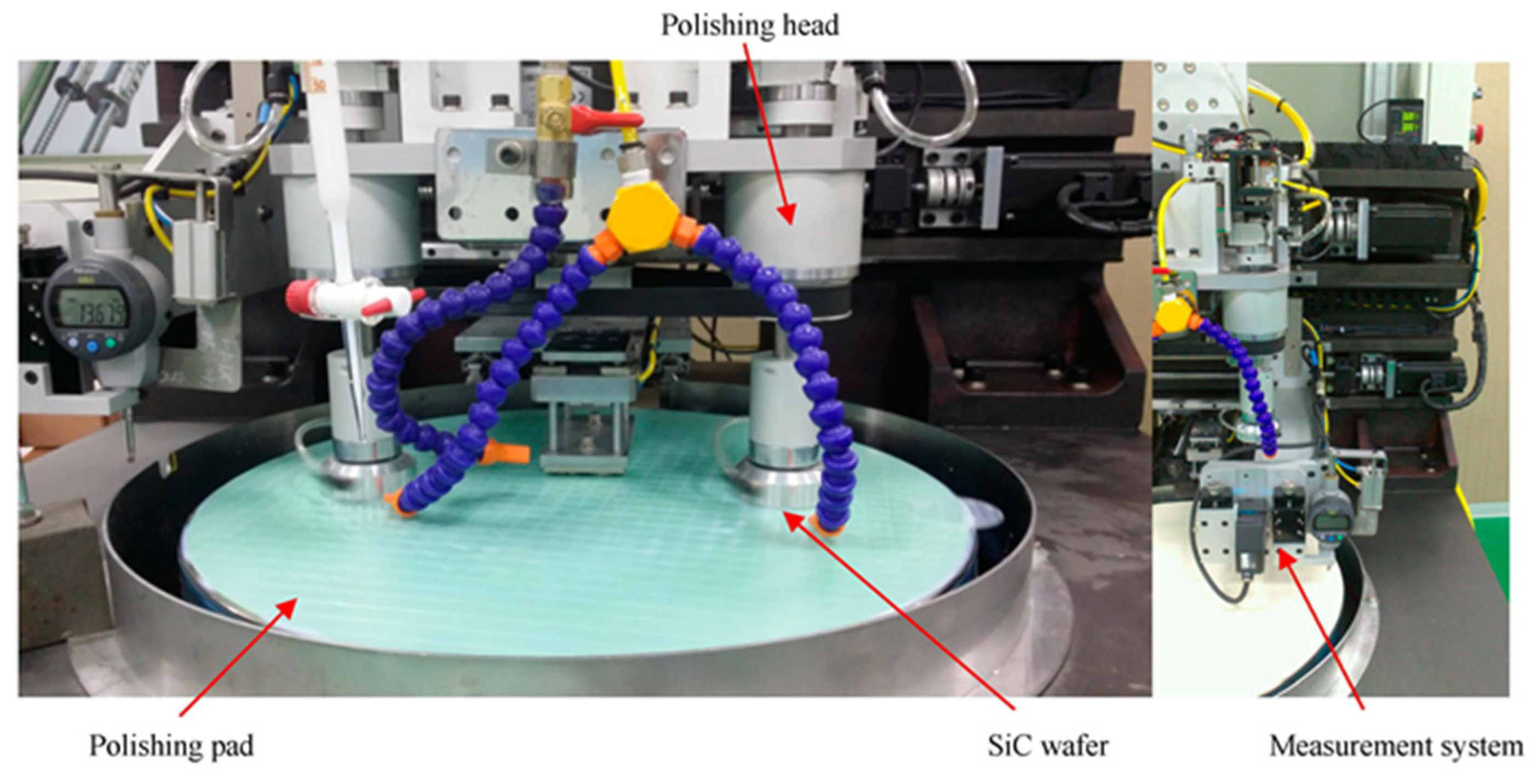

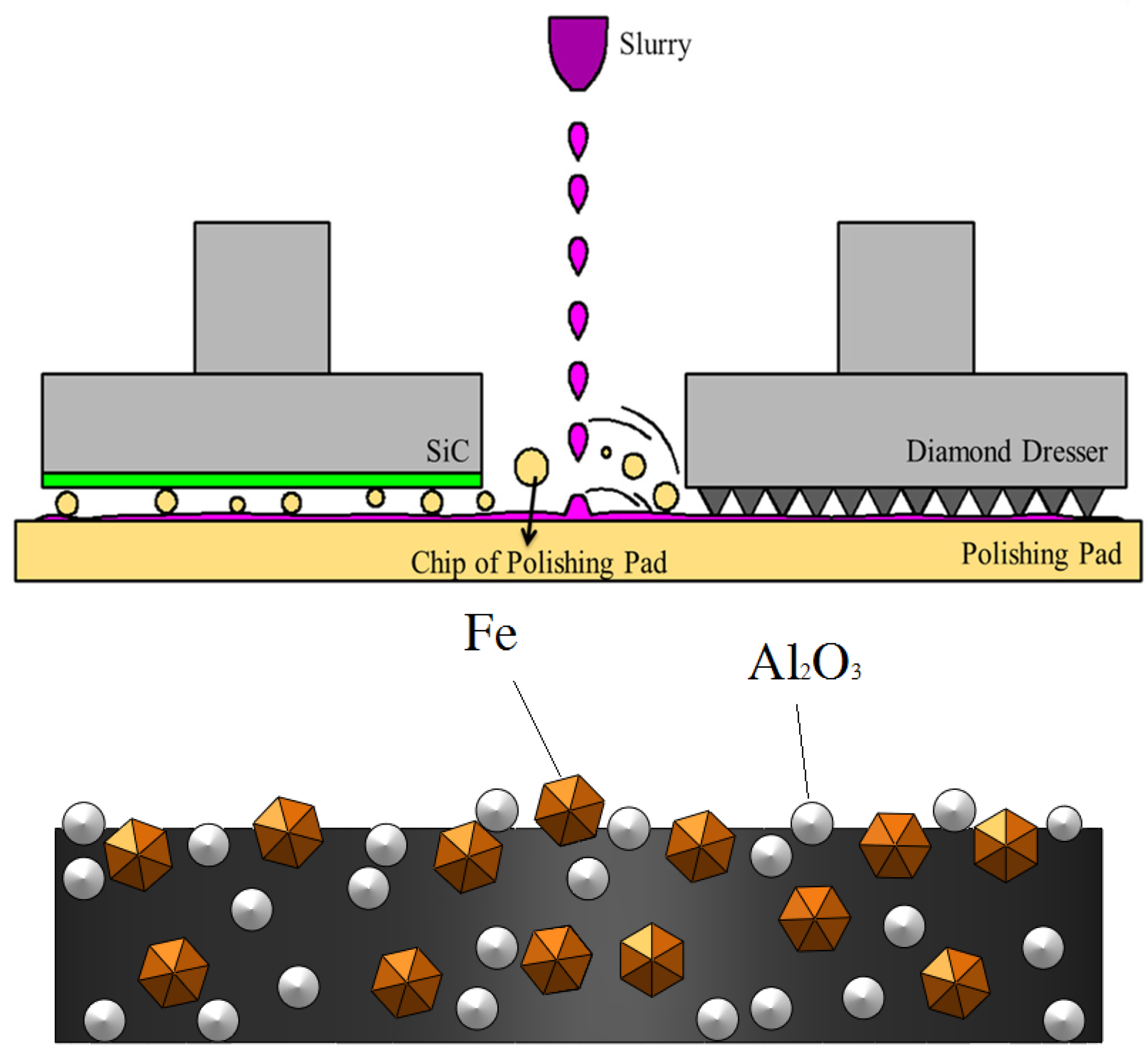

2. Experimental Section

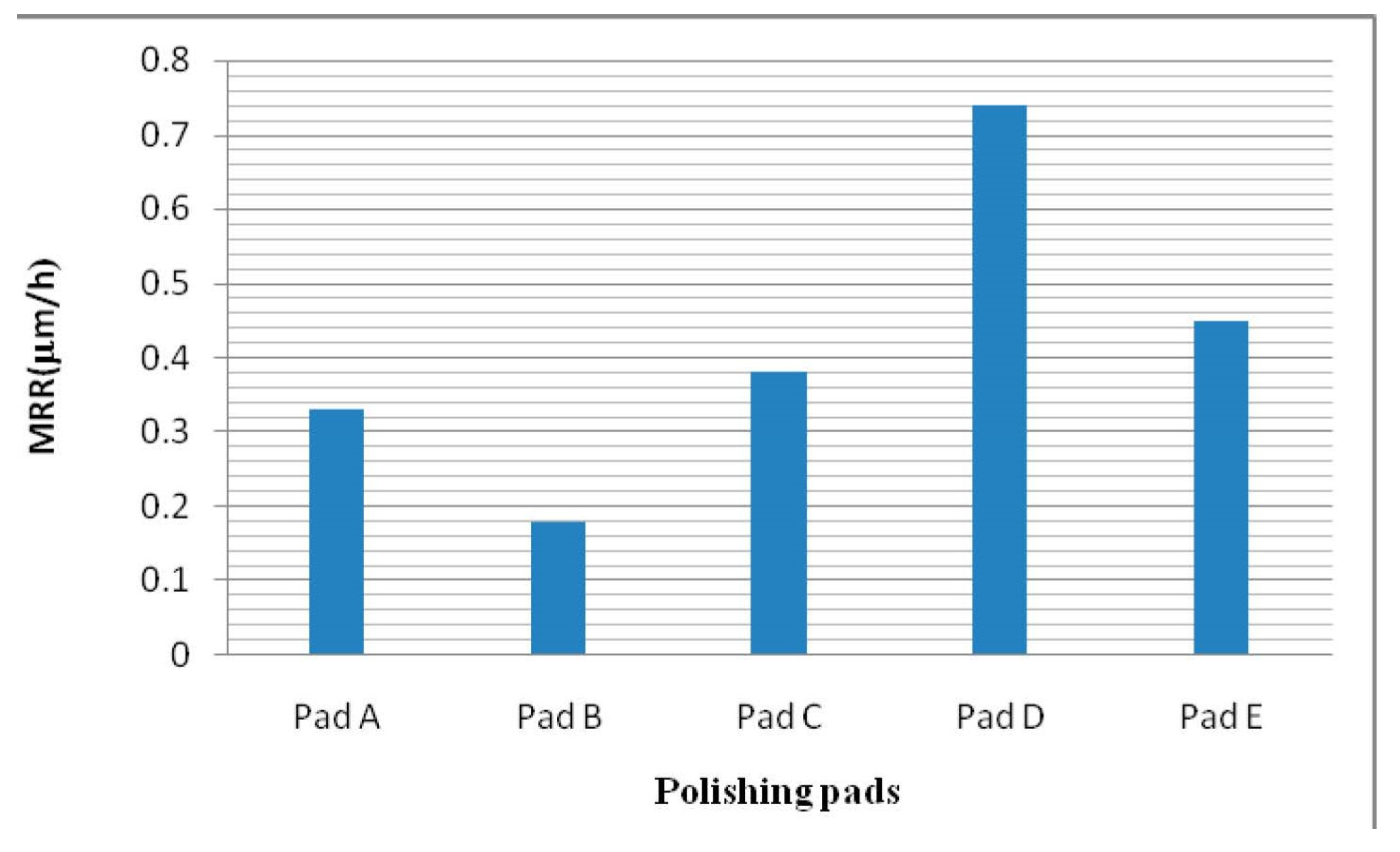

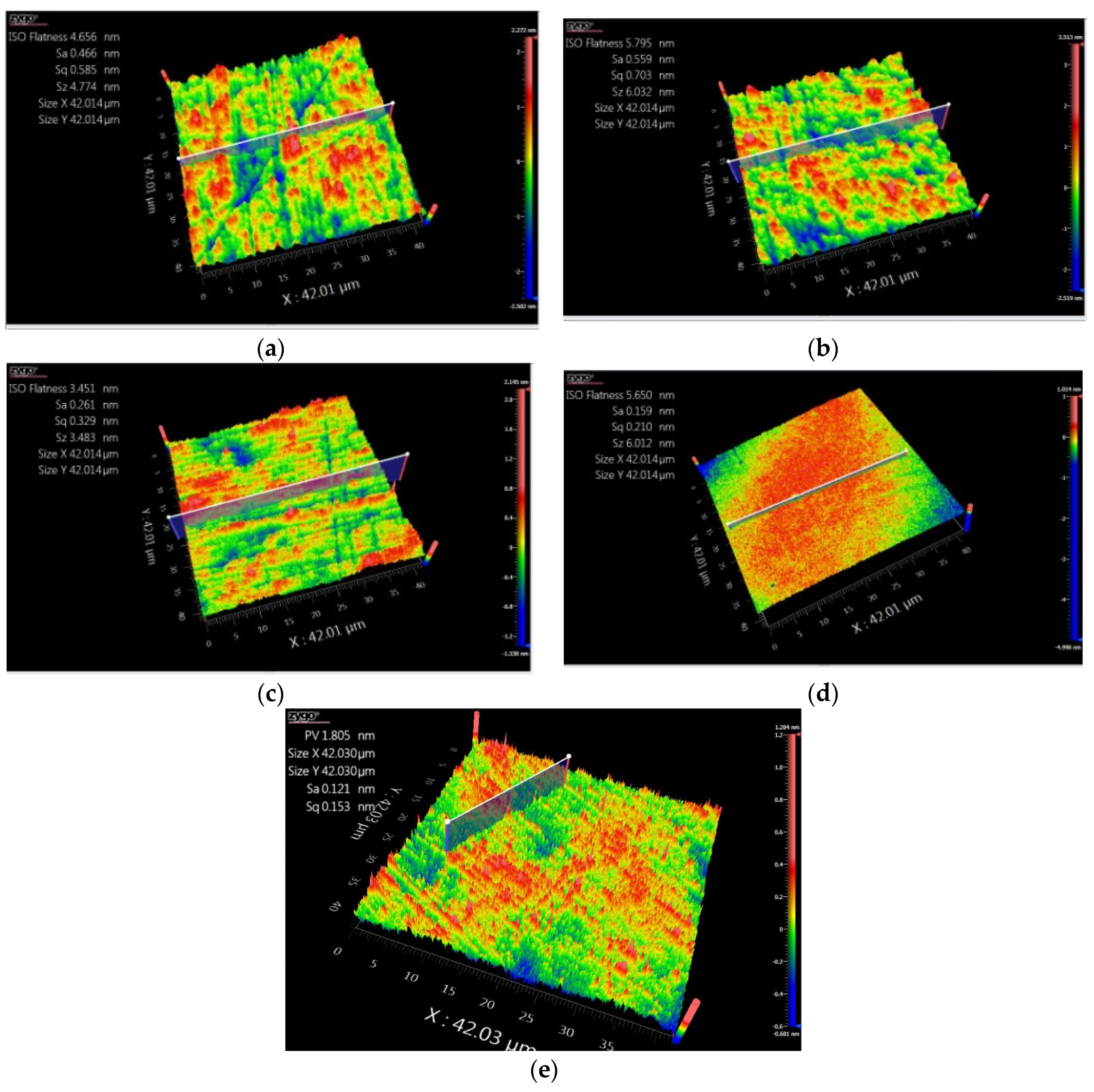

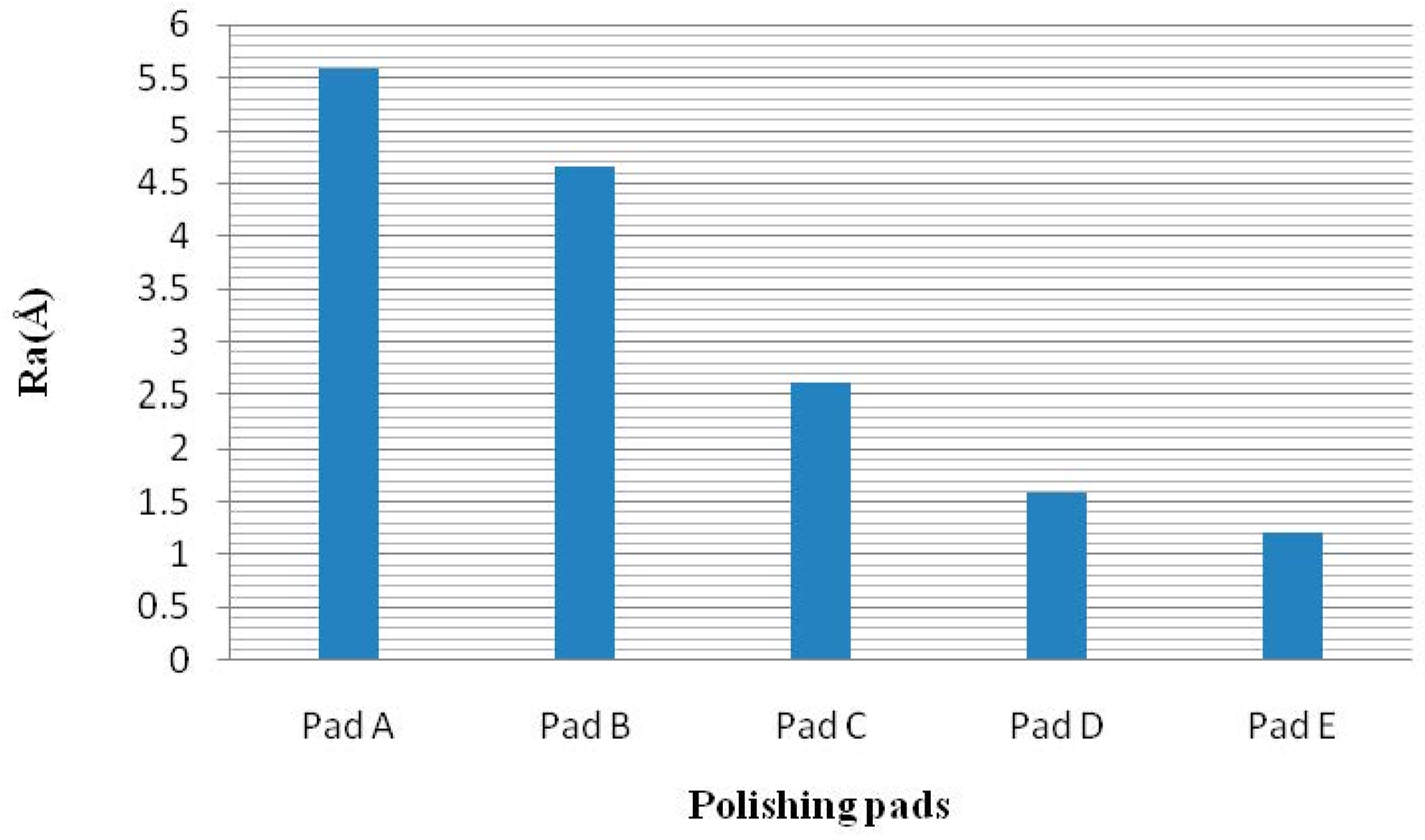

3. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huo, F.W.; Guo, D.M.; Kang, R.K.; Feng, G. Nanogrinding of SiC wafers with high flatness and low subsurface damage. Trans. Nonferrous Met. Soc. China 2012, 22, 3027–3033. [Google Scholar] [CrossRef]

- Shi, X; Pan, G.; Zhou, Y.; Zou, C.; Gong, H. Extended study of the atomic step-terrace structure on hexagonal SiC (0001) by chemical mechanical planarization. Appl. Surf. Sci. 2013, 284, 195–206. [Google Scholar]

- Kikuchi, M.; Takahashi, Y.; Suga, T.; Suzuki, S.; Bando, Y. Mechanical chemical polishing of silicon carbide single crystal with chromium (III) oxide abrasive. J. Am. Ceram. Soc. 1992, 75, 189–194. [Google Scholar] [CrossRef]

- Zhou, L.; Audurier, V.; Pirouz, P.; Powell, J.A. Chemomechanical polishing of silicon carbide. J. Electrochem. Soc. 1997, 144, L161–L163. [Google Scholar] [CrossRef]

- Neslen, C.L.; Mitchel, W.C.; Hengehold, R.L. Effects of process parameter variations on the removal rate in chemical mechanical polishing of 4H-SiC. J. Electron. Mater. 2001, 30, 1271–1275. [Google Scholar] [CrossRef]

- Zhu, Z.; Muratov, V.; Fischer, M. Tribochemical polishing of silicon carbide in oxidant solution. Wear 1999, 225–229, 848–856. [Google Scholar] [CrossRef]

- Kuo, P.; Currier, I. Augmented CMP techniques for silicon carbide. Mater. Sci. Forum 2006, 527–529, 1099–1102. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, D.I.; An, J.H.; Lee, H.J.; Kim, K.H.; Jeong, H. Hybrid polishing mechanism of single crystal SiC using mixed abrasive slurry. CIRP. Ann.-Manuf. Technol. 2010, 59, 333–336. [Google Scholar] [CrossRef]

- Yamamura, K.; Takiguchi, T.; Ueda, M.; Deng, H.; Hattori, A.N.; Zettsu, N. Plasma assisted polishing of single crystal SiC for obtaining atomically flat strain-free surface. CIRP Ann.-Manuf. Technol. 2011, 60, 571–574. [Google Scholar] [CrossRef]

- Kubota, A.; Yoshimura, M.; Fukuyama, S.; Iwamoto, C.; Touge, M. Planarization of C-face 4H-SiC substrate using Fe particles and hydrogen peroxide solution. Precis. Eng. 2012, 36, 137–140. [Google Scholar] [CrossRef]

- Lagudu, U.R.K.; Isono, S.; Krishnan, S.; Babu, S.V. Role of ionic strength in chemical mechanical polishing of silicon carbide using silica slurries. Eng. Asp. 2014, 445, 119–127. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-regime grinding: A new technology for machining brittle materials. J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

| Polish Pad | Content | Slurry |

|---|---|---|

| Pad-A | 1% Fe | H2O2 (20%) + HCL (pH ~ 4.0) |

| Pad-B | 1% Al2O3 | |

| Pad-C | 1% Fe + 1% Al2O3 | |

| Pad-D | 1% Fe + 3% Al2O3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, J.-K.; Huang, C.-Y.; Tsai, M.-Y.; Tsai, C.-C. Investigation of Polishing Pads Impregnated with Fe and Al2O3 Particles for Single-Crystal Silicon Carbide Wafers. Appl. Sci. 2016, 6, 89. https://doi.org/10.3390/app6030089

Ho J-K, Huang C-Y, Tsai M-Y, Tsai C-C. Investigation of Polishing Pads Impregnated with Fe and Al2O3 Particles for Single-Crystal Silicon Carbide Wafers. Applied Sciences. 2016; 6(3):89. https://doi.org/10.3390/app6030089

Chicago/Turabian StyleHo, Jihng-Kuo, Chih-Yung Huang, Ming-Yi Tsai, and Che-Cheng Tsai. 2016. "Investigation of Polishing Pads Impregnated with Fe and Al2O3 Particles for Single-Crystal Silicon Carbide Wafers" Applied Sciences 6, no. 3: 89. https://doi.org/10.3390/app6030089