Effects of Solution Treatment on Microstructure and High-Cycle Fatigue Properties of 7075 Aluminum Alloy

Abstract

:1. Introduction

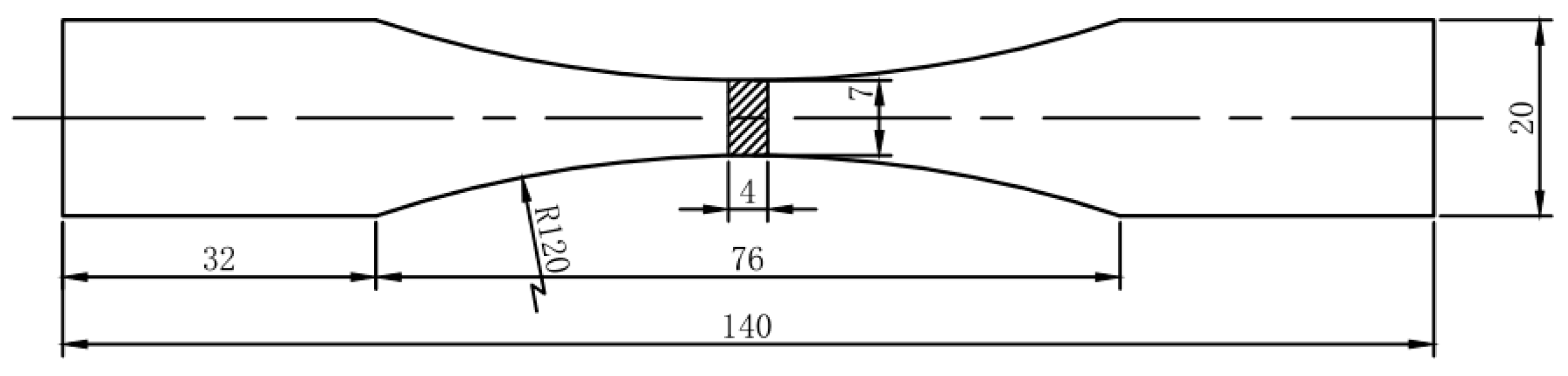

2. Material and Experiments

3. Results and Discussion

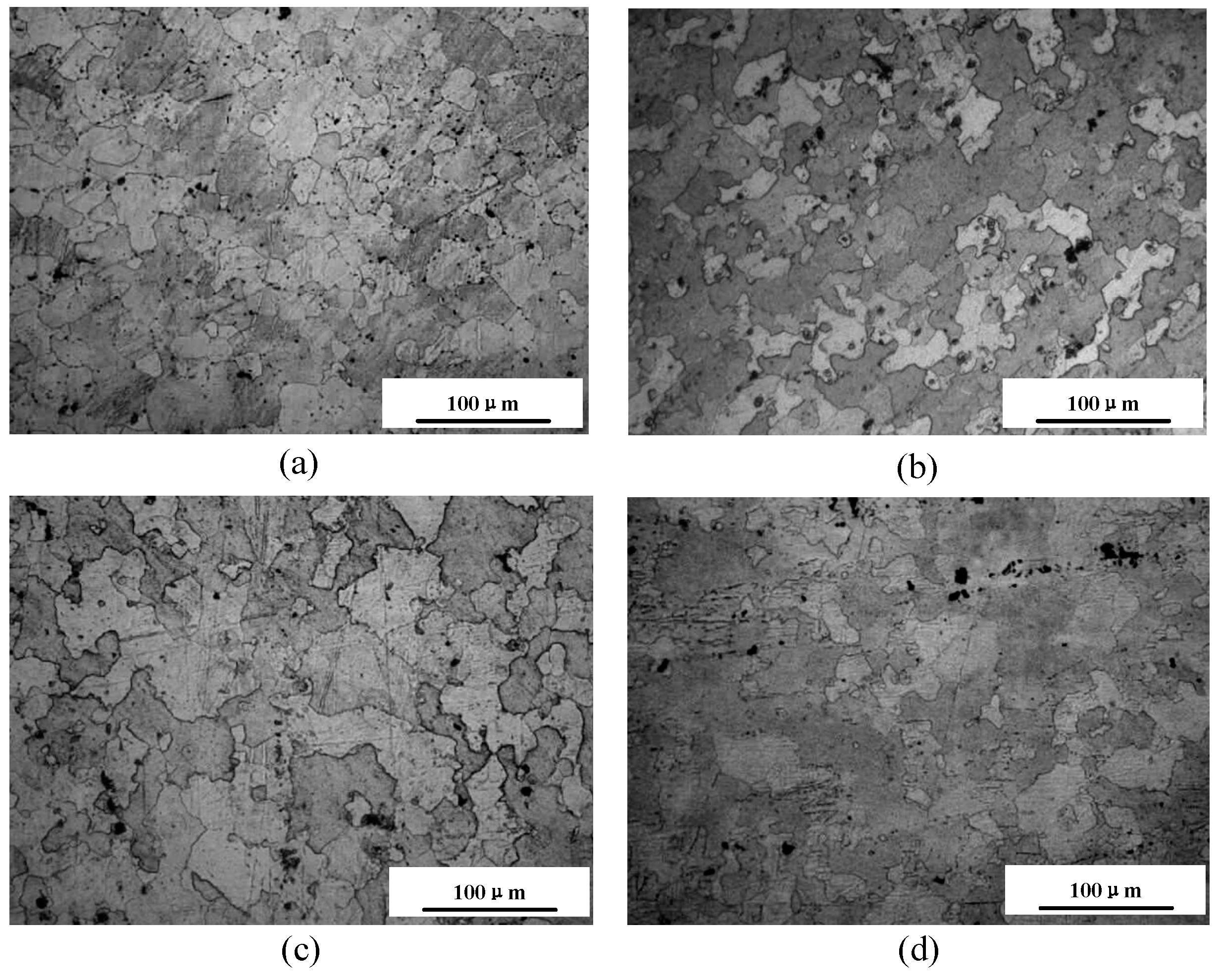

3.1. Effects of Solution Treatment on the Microstructure

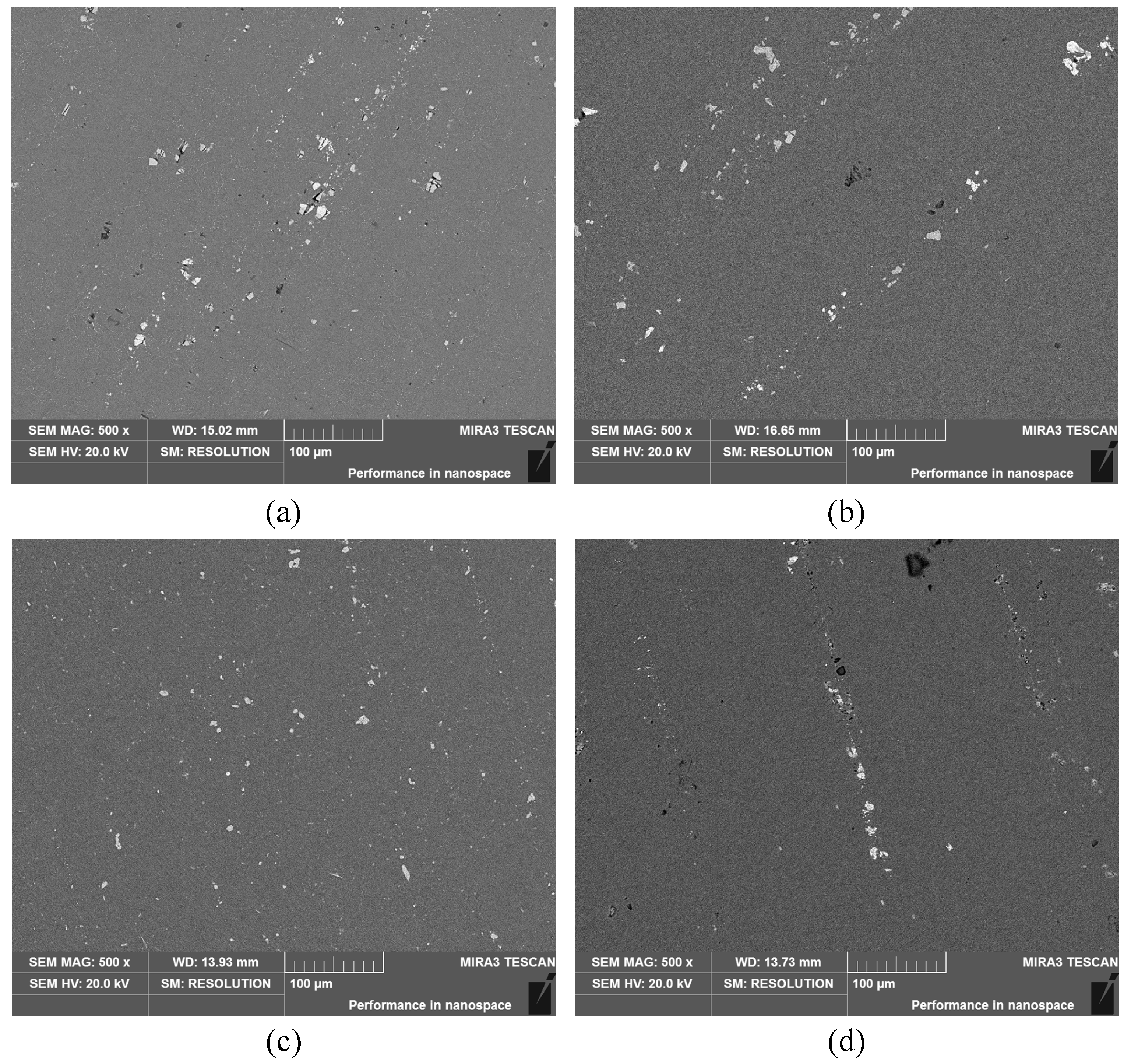

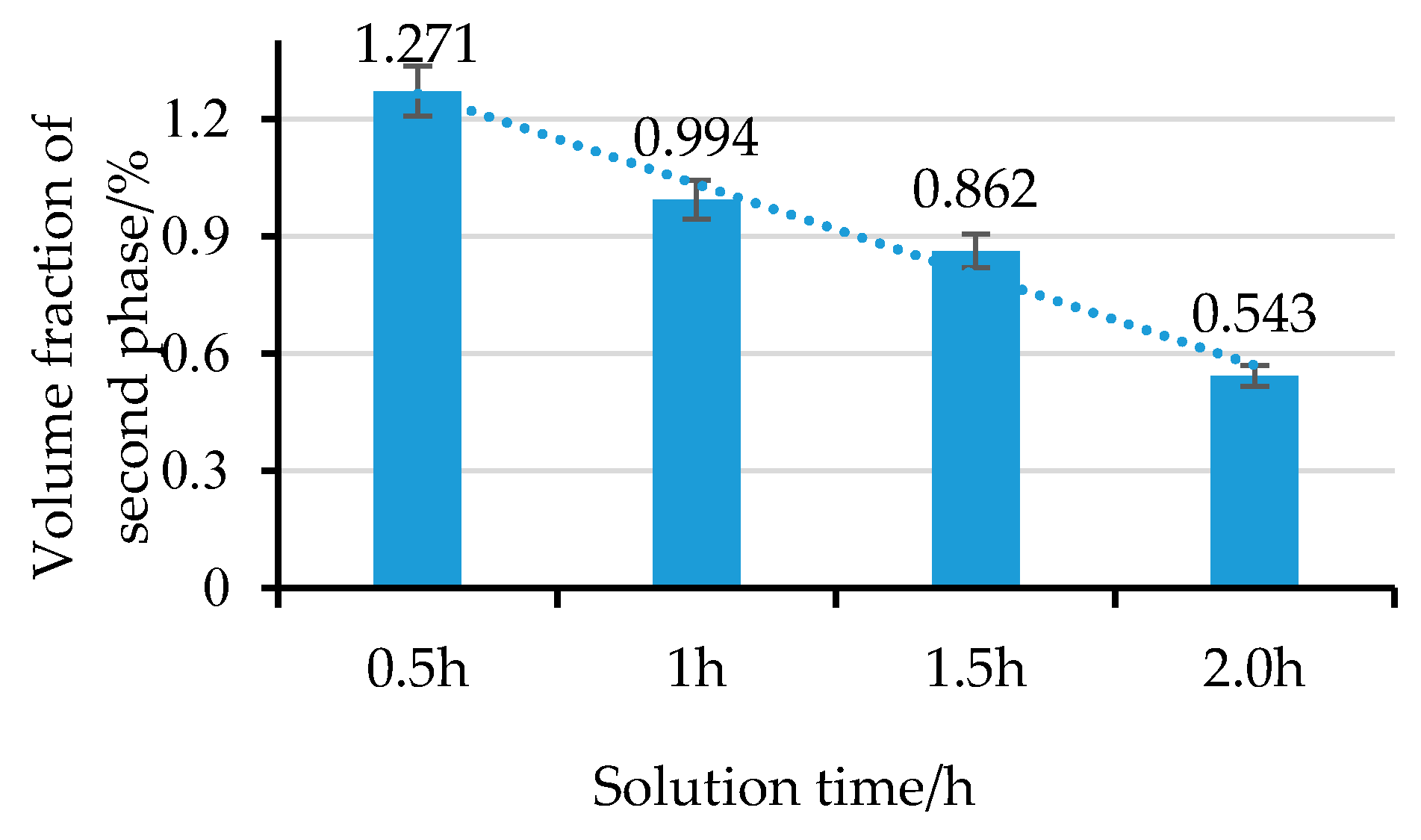

3.2. Effects of Solution Treatment on the Second Phase

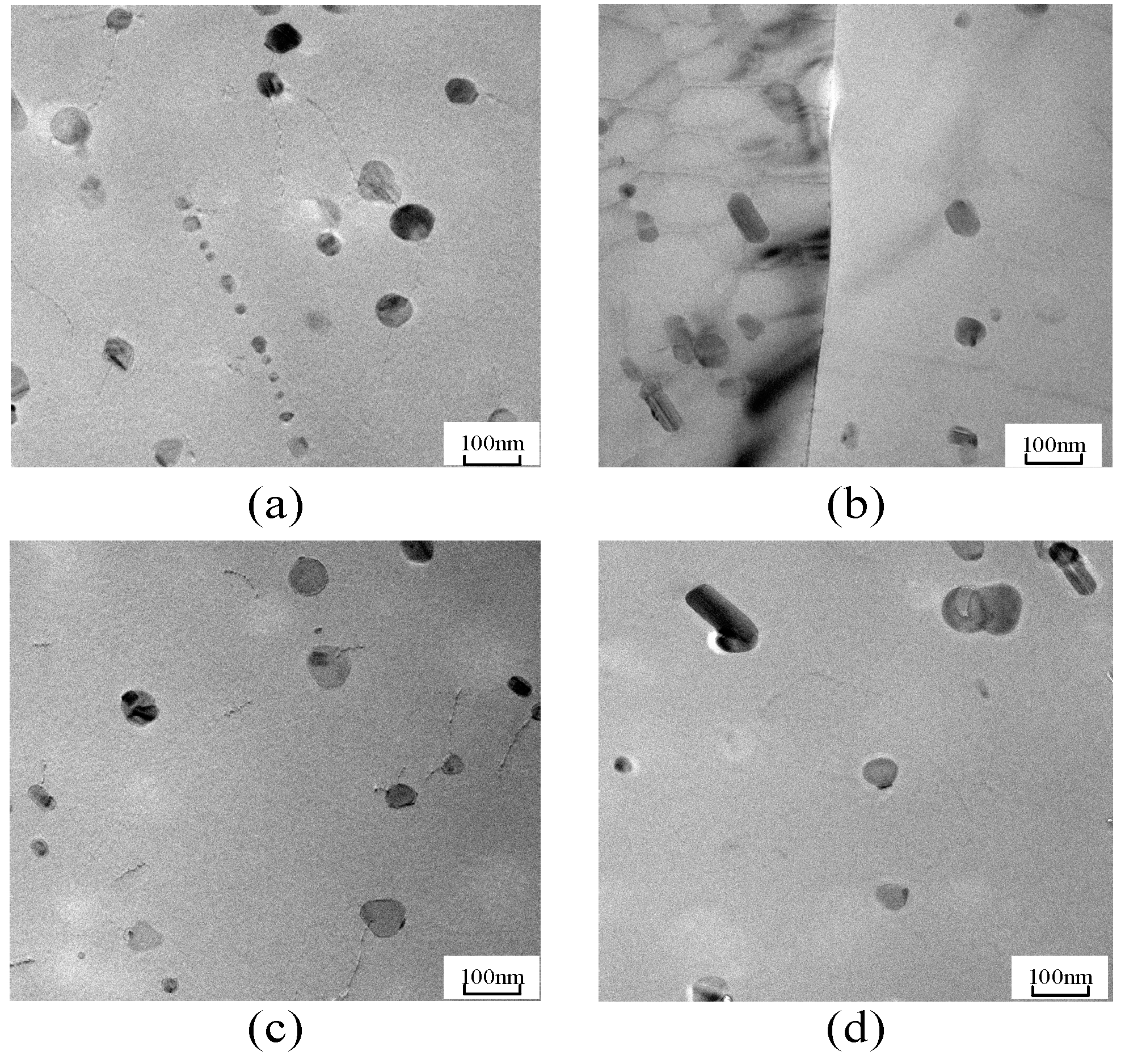

3.3. Effects of Solution Treatment on the Precipitated Phases

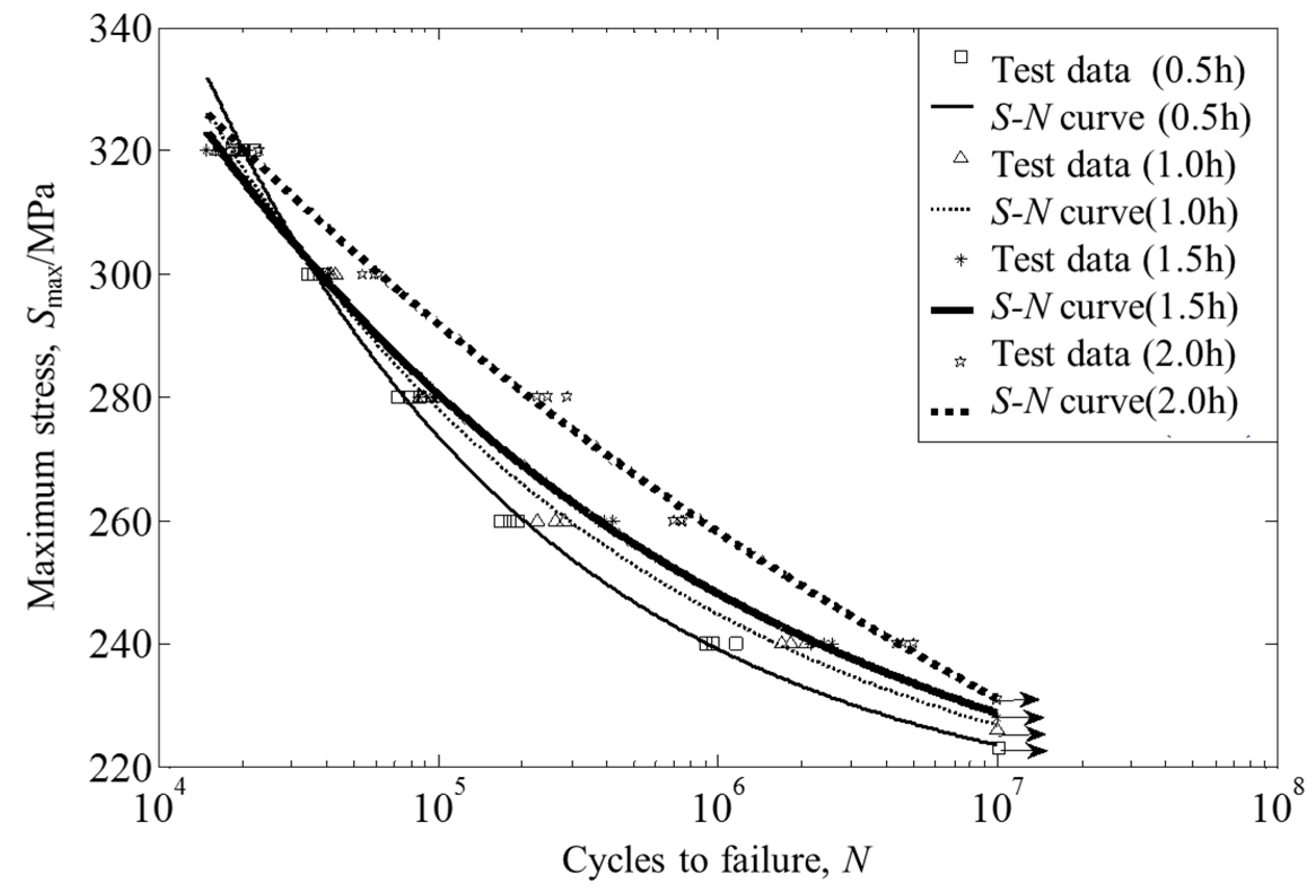

3.4. Effects of Solution Treatment on the High-Cycle Fatigue Life

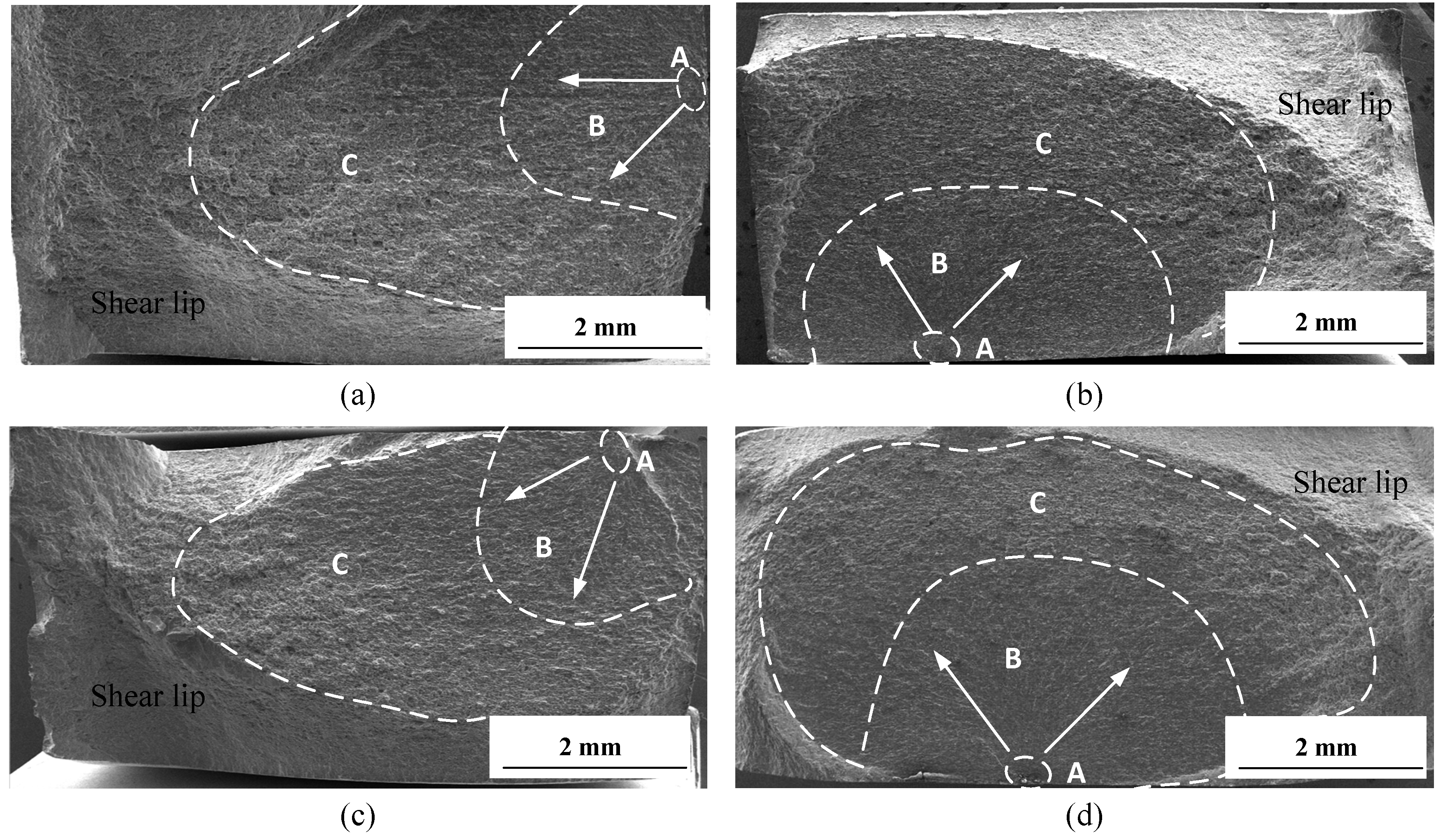

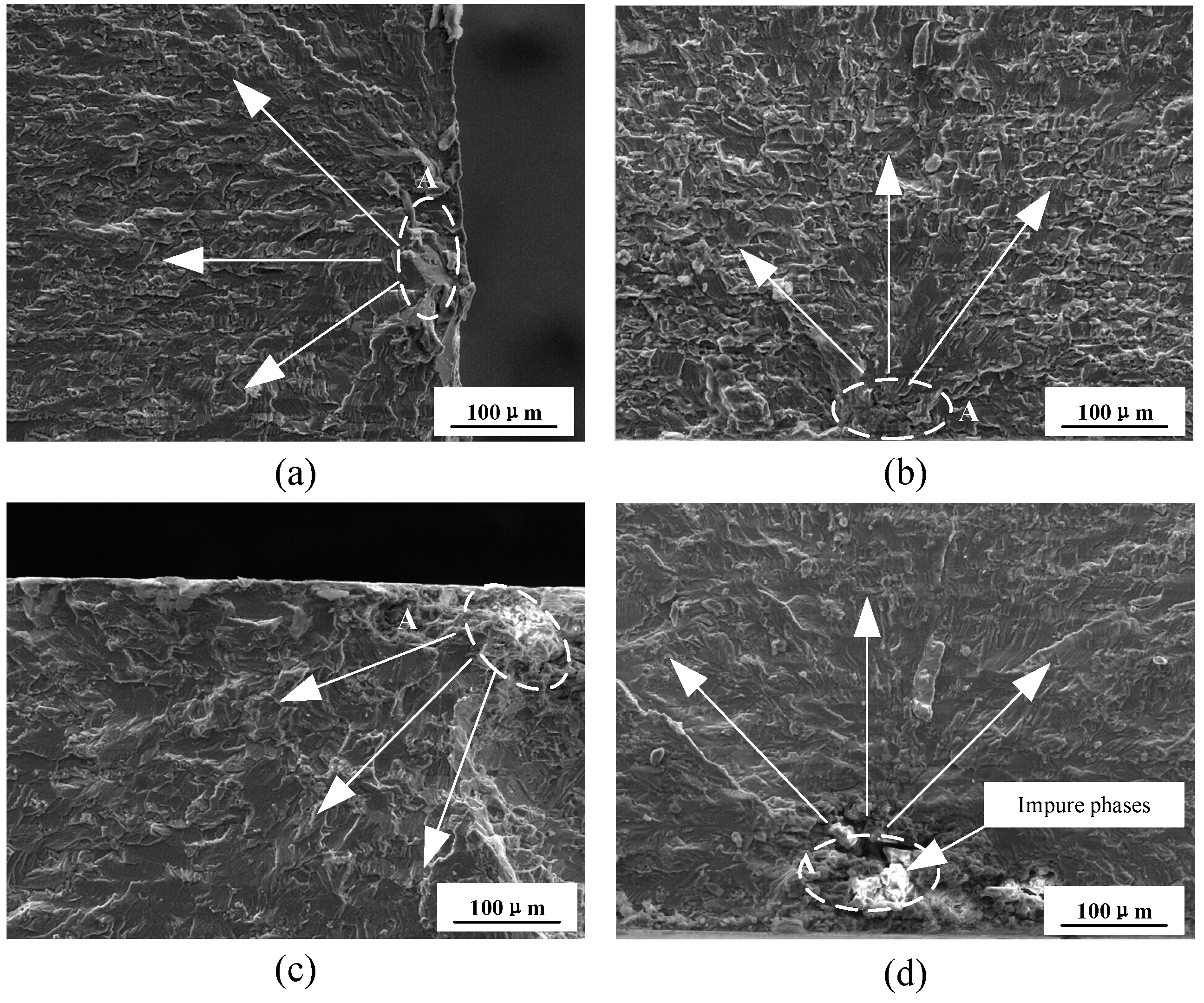

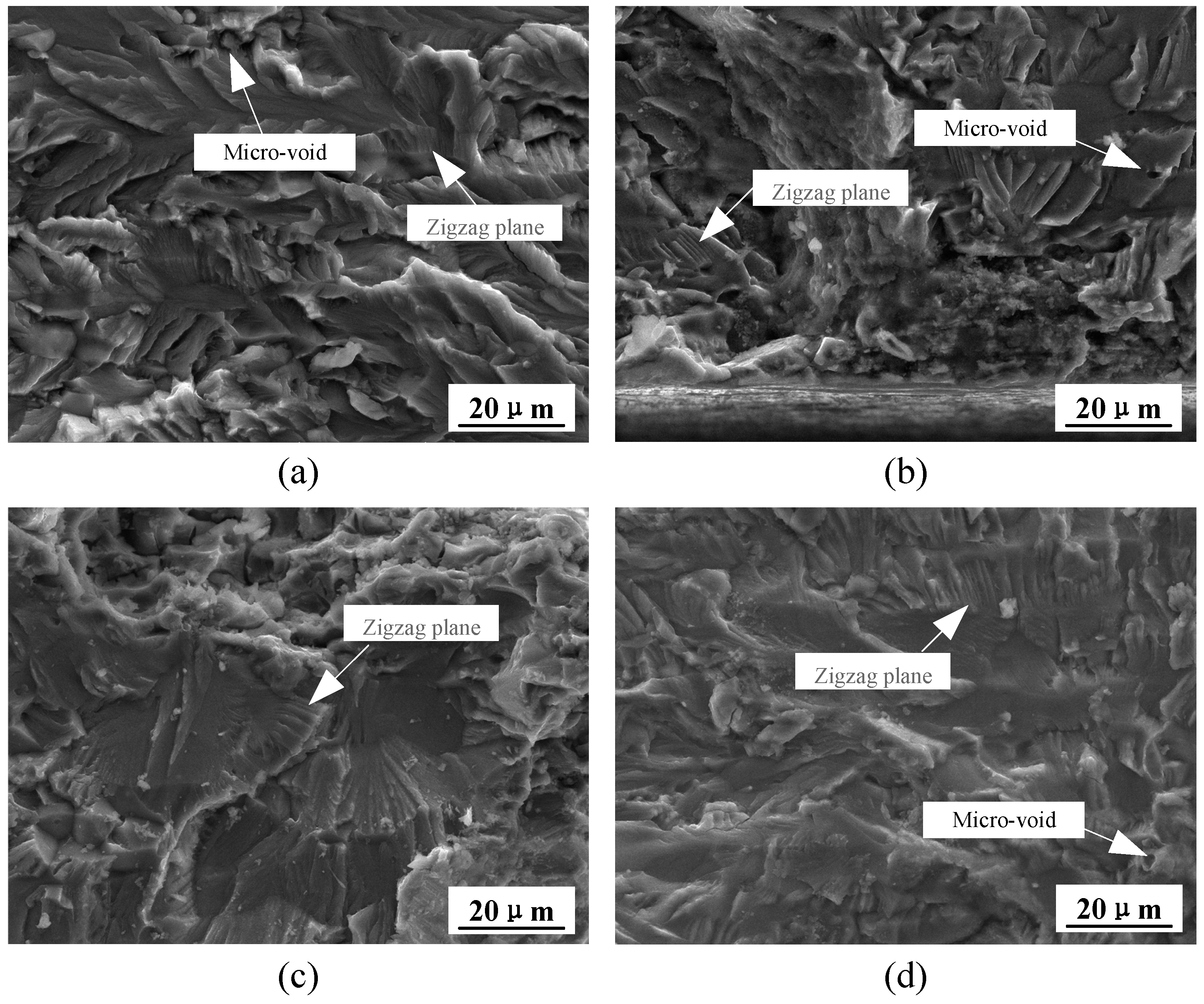

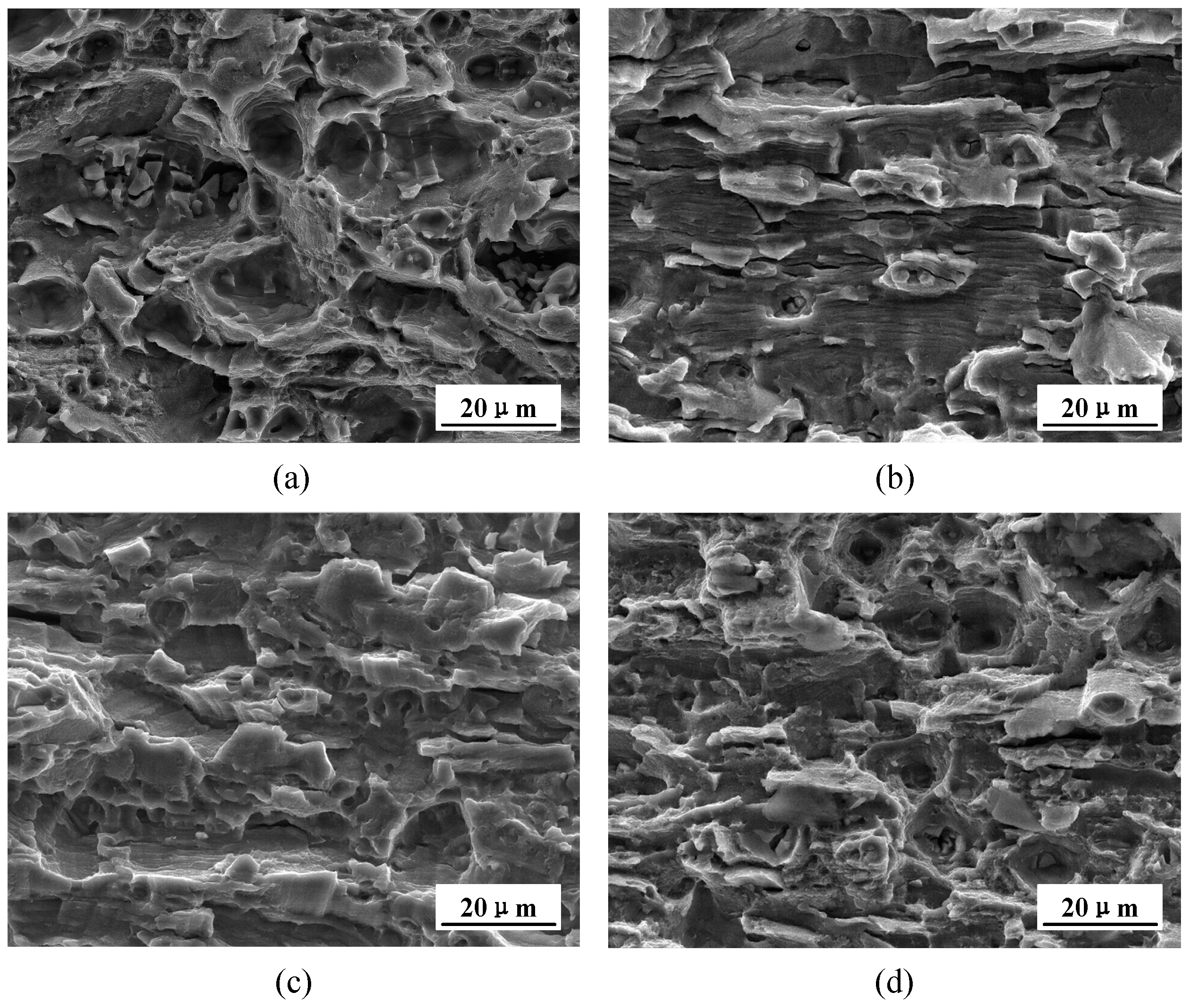

3.5. Analysis of the Morphology of High-Cycle Fatigue Fractures

4. Conclusions

- As the solution treatment time increases, different levels of recrystallization and grain growth occur in the studied alloy. The recrystallized grains merge and extend outward, flattening the crystal boundaries. When the solution treatment time is 2 h, most boundaries of adjacent grains disappear, becoming continuous rather than interrupted. Recrystallization is obvious and the average grain sizes are large.

- The large secondary phases in the Al-Zn-Mg-Cu alloy are mainly undissolved T phase, S phase, Fe-rich phase, and Si-rich phase. Appropriate extension of the solution time can promote the dissolution of the second phase particles, reduce the number and size of the second phase particles, and improve the degree of solid solution of the alloy, so that the alloy microstructure is more uniform.

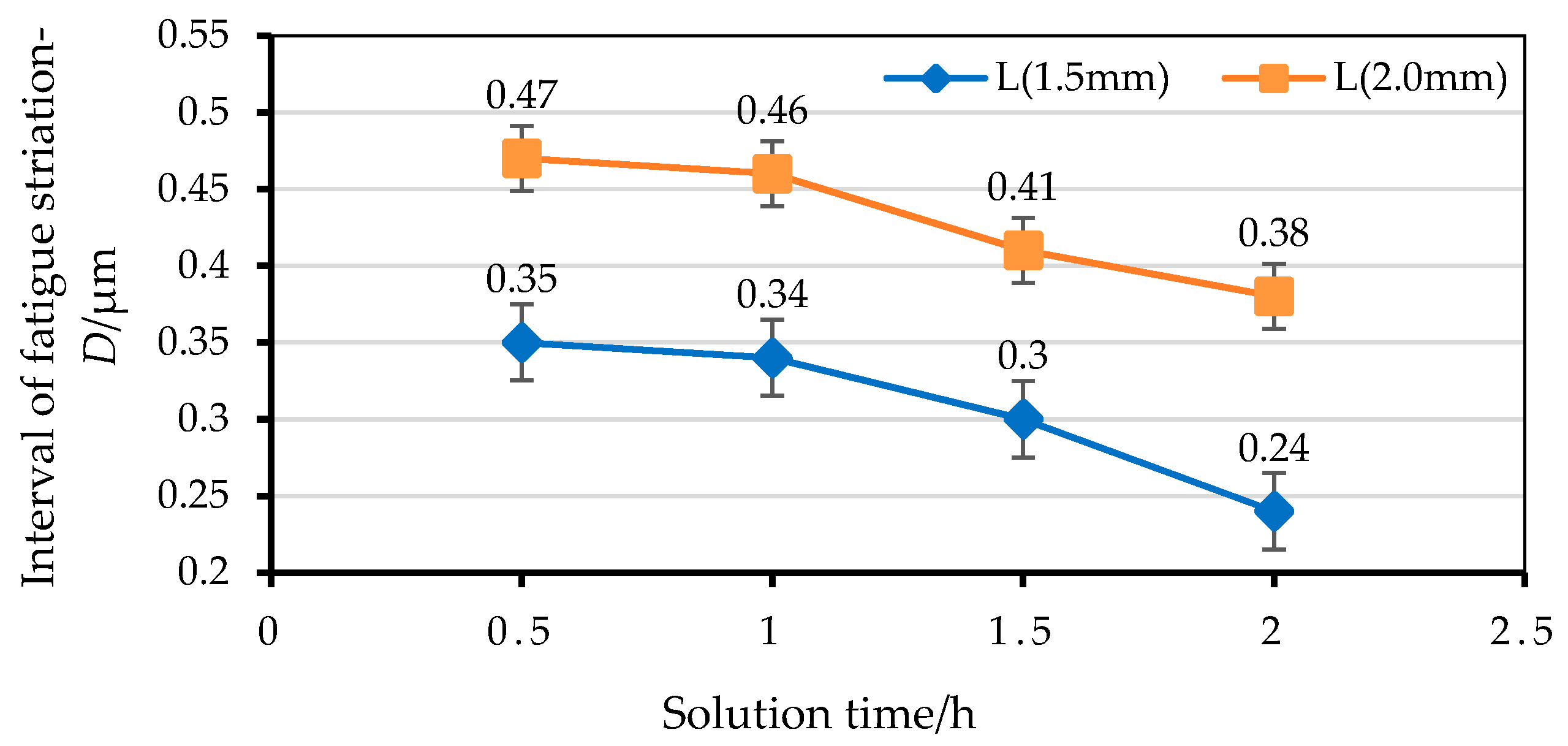

- The solution time has a significant influence on the high-cycle fatigue properties of the Al-Zn-Mg-Cu alloy, especially when the fatigue life exceeds the 105 level at low stress levels. The large second phases gradually dissolve with the increase of the solution time, which can lower the probability of crack initiation. In the second stage of crack propagation, fatigue striations and secondary cracks are obviously observed. The number of secondary cracks increases with extending the solution time, which can reduce the drive force and crack propagation growth rate, promoting the high-cycle fatigue properties of the Al-Zn-Mg-Cu alloy. The changing trend of the fatigue striation interval validated this conclusion.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Andreatta, F.; Terryn, H.; de Wit, J.H.W. Effect of solution heat treatment on galvanic coupling between intermetallics and matrix in AA7075-T6. Corros. Sci. 2003, 45, 1733–1746. [Google Scholar] [CrossRef]

- Fernandez Gutierrez, R.; Sket, F.; Maire, E.; Wilde, F.; Boller, E.; Requena, G. Effect of solution heat treatment on microstructure and damage accumulation in cast Al-Cu alloys. J. Alloys Compd. 2017, 697, 341–352. [Google Scholar] [CrossRef]

- Xiong, C.X.; Deng, Y.L.; Wan, L.; Zhang, X.M. Evolutions of microstructures and textures of 7050 Al alloy plate during solution heat treatment. Chin. J. Nonferr. Met. 2010, 20, 427–434. [Google Scholar]

- Jie, L.I.; Song, R.; Chen, X. Study on strengthening solution treatment for 7050 high strength aluminum alloy. Hot Work. Technol. 2009, 38, 125–128. [Google Scholar]

- Deng, Y.L.; Wan, L.; Zhang, Y.; Zhang, X.R. Effect of solution treatment on quenched depth of 7050-T6 aluminum alloy. Heat Treat. Met. 2009, 34, 44–47. [Google Scholar]

- Wang, H.B.; Meng, F.L.; Zhao, H.Y.; Cai, Y.H.; Zhang, J.S. Effects of solid solution treatment on microstructure and properties of cast-rolled 7050 aluminum alloy. Trans. Mater. Heat Treat. 2013, 34, 99–103. [Google Scholar]

- Zeng, Z.; Peng, B.; Zeng, S.; Jiang, H.; Ning, A. Effects of progressive solution treatment on microstructure and mechanical properties of 7055 aluminum. Spec. Cast. Nonferr. Alloys 2009, 29, 672–674. [Google Scholar]

- Chen, K.; Liu, H.; Zhang, Z.; Li, S.; Todd, R.I. The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments. J. Mater. Process. Technol. 2003, 142, 190–196. [Google Scholar] [CrossRef]

- Senkov, O.N.; Shagiev, M.R.; Senkova, S.V.; Miracle, D.B. Precipitation of Al3(Sc, Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties. Acta Mater. 2008, 56, 3723–3738. [Google Scholar] [CrossRef]

- Davies, R.K.; Randle, V.; Marshall, G.J. Continuous recrystallization related phenomena in a commercial Al-Fe-Si alloy. Acta Mater. 1998, 46, 6021–6032. [Google Scholar] [CrossRef]

- Hailin, Y.; Shouxun, J.; Zhongyun, F. Effect of heat treatment and Fe content on the microstructure and mechanical properties of die-cast Al-Si-Cu alloys. Mater. Des. 2015, 85, 823–832. [Google Scholar]

- Nayak, I.K.; Rao, S.V.R.; Kapoor, K. Effect of heat treatment and surface condition on inter-granular corrosion of alloy 800. Mater. Perform. Charact. 2016, 5, 239–252. [Google Scholar] [CrossRef]

- Lazaro, J.; Solorzano, E.; Escudero, J.; de Saja, J.A.; Rodriguez-Perez, M.A. Applicability of solid solution heat treatments to aluminum foams. Metals 2012, 2, 508–528. [Google Scholar] [CrossRef]

- Gang, L.; Jun, S.; Ce-Wen, N.; Kang-Hua, C. Experiment and multiscale modeling of the coupled influence of constituents and precipitates on the ductile fracture of heat-treatable aluminum alloys. Acta Mater. 2005, 53, 3459–3468. [Google Scholar]

- Song, F.X.; Zhang, X.M.; Liu, S.D.; Bai, T.; Han, N.M.; Tan, J.B. Effects of solution heat treatment on microstructure and corrosion properties of 7050 Al alloy. J. Aeronaut. Mater. 2013, 33, 14–21. [Google Scholar]

- Yan, L.; Du, F.S.; Dai, S.L.; Yang, S.J. Effect of microstructures on fatigue crack propagation in 2E12 aluminum alloy. Chin. J. Nonferr. Met. 2010, 20, 1275–1281. [Google Scholar]

- Fan, X.; Jiang, D.; Zhong, L.; Wang, T.; Ren, S. Influence of microstructure on the crack propagation and corrosion resistance of Al-Zn-Mg-Cu alloy 7150. Mater. Charact. 2007, 58, 24–28. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, J.; Jiang, Y. A study of fatigue crack growth of 7075-T651 aluminum alloy. Int. J. Fatigue 2008, 30, 1169–1180. [Google Scholar] [CrossRef]

- Rong, L.; Yingping, J.; Shijie, W.; Shuzhen, L. Effect of microstructure on fracture toughness and fatigue crack growth behavior of Ti17 alloy. Metals 2016, 6, 186. [Google Scholar] [CrossRef]

- Okazaki, Y. Comparison of fatigue properties and fatigue crack growth rates of various implantable metals. Materials 2012, 5, 2981–3005. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; López de Lacalle, L.N.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Avilés, R.; Albizuri, J.; Rodríguez, A.; López de Lacalle, L.N. Influence of low-plasticity ball burnishing on the high-cycle fatigue strength of medium carbon aisi 1045 steel. Int. J. Fatigue 2013, 55, 230–244. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Taylor, D. Multiaxial fatigue resistance of shot peened high-strength aluminum alloys. Int. J. Fatigue 2014, 61, 271–282. [Google Scholar] [CrossRef]

- Han, J.; Dai, Q.-X.; Zhao, Y.-T.; Li, G.-R. Study on fatigue performance of 7075-T651 aluminum alloys. J. Aeronaut. Mater. 2010, 30, 92–96. [Google Scholar]

- Trško, L.; Guagliano, M.; Bokůvka, O.; Nový, F. Fatigue life of AW 7075 aluminium alloy after severe shot peening treatment with different intensities. Procedia Eng. 2014, 74, 246–252. [Google Scholar] [CrossRef]

- Oskouei, R.H.; Ibrahim, R.N. The effect of a heat treatment on improving the fatigue properties of aluminium alloy 7075-T6 coated with TiN by PVD. Procedia Eng. 2011, 10, 1936–1942. [Google Scholar] [CrossRef]

- Dowling, N.E.; Calhoun, C.A.; Arcari, A. Mean stress effects in stress-life fatigue and the walker equation. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 163–179. [Google Scholar] [CrossRef]

- Le Jolu, T.; Morgeneyer, T.F.; Denquin, A.; Gourgues-Lorenzon, A.F. Fatigue lifetime and tearing resistance of AA2198 Al-Cu-Li alloy friction stir welds: Effect of defects. Int. J. Fatigue 2015, 70, 463–472. [Google Scholar] [CrossRef]

| Zn | Mg | Cu | Cr | Fe | Si | Mn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 5.71 | 2.45 | 1.5 | 0.18 | 0.17 | 0.06 | 0.034 | 0.019 | Bal. |

| Spec No. | Smax (MPa) | Fatigue Life—N (Cycles) | |||

|---|---|---|---|---|---|

| Case 1 (480 °C/0.5 h) | Case 2 (480 °C/1 h) | Case 3 (480 °C/1.5 h) | Case 4 (480 °C/2 h) | ||

| 1# | 320 | 20,210 | 16,151 | 20,790 | 19,245 |

| 2# | 18,410 | 18,050 | 15,990 | 20,095 | |

| 3# | 22,141 | 19,151 | 14,790 | 22,945 | |

| 4# | 300 | 34,157 | 41,151 | 37,956 | 59,410 |

| 5# | 36,141 | 40,040 | 38,990 | 61,945 | |

| 6# | 39,520 | 42,642 | 40,247 | 53,921 | |

| 7# | 280 | 80,241 | 95,356 | 99,036 | 246,569 |

| 8# | 71,451 | 86,547 | 95,701 | 226,569 | |

| 9# | 86,584 | 88,470 | 84,943 | 291,016 | |

| 10# | 260 | 193,039 | 261,477 | 372,882 | 699,403 |

| 11# | 168,320 | 284,757 | 392,414 | 738,941 | |

| 12# | 181,241 | 224,646 | 420,440 | 751,814 | |

| 13# | 240 | 966,022 | 2,059,221 | 2,394,939 | 4,353,010 |

| 14# | 904,514 | 1,824,641 | 2,560,780 | 4,568,122 | |

| 15# | 1,155,842 | 1,700,578 | 2,149,401 | 5,004,514 | |

| Solution Time/h | Fitting Parameters | Fitting Formula | ||

|---|---|---|---|---|

| a | b | A | ||

| 0.5 | 10.22 | −2.90 | 210.7 | |

| 1.0 | 11.99 | −3.75 | 205.4 | |

| 1.5 | 13.64 | −4.53 | 199.4 | |

| 2.0 | 28.35 | 10.46 | 121.1 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Liu, Y.; Ma, L.; Yi, J. Effects of Solution Treatment on Microstructure and High-Cycle Fatigue Properties of 7075 Aluminum Alloy. Metals 2017, 7, 193. https://doi.org/10.3390/met7060193

Liu C, Liu Y, Ma L, Yi J. Effects of Solution Treatment on Microstructure and High-Cycle Fatigue Properties of 7075 Aluminum Alloy. Metals. 2017; 7(6):193. https://doi.org/10.3390/met7060193

Chicago/Turabian StyleLiu, Chi, Yilun Liu, Liyong Ma, and Jiuhuo Yi. 2017. "Effects of Solution Treatment on Microstructure and High-Cycle Fatigue Properties of 7075 Aluminum Alloy" Metals 7, no. 6: 193. https://doi.org/10.3390/met7060193