A Study on Cutting Force of Machining In Situ TiB2 Particle-Reinforced 7050Al Alloy Matrix Composites

Abstract

:1. Introduction

2. Materials and Methods

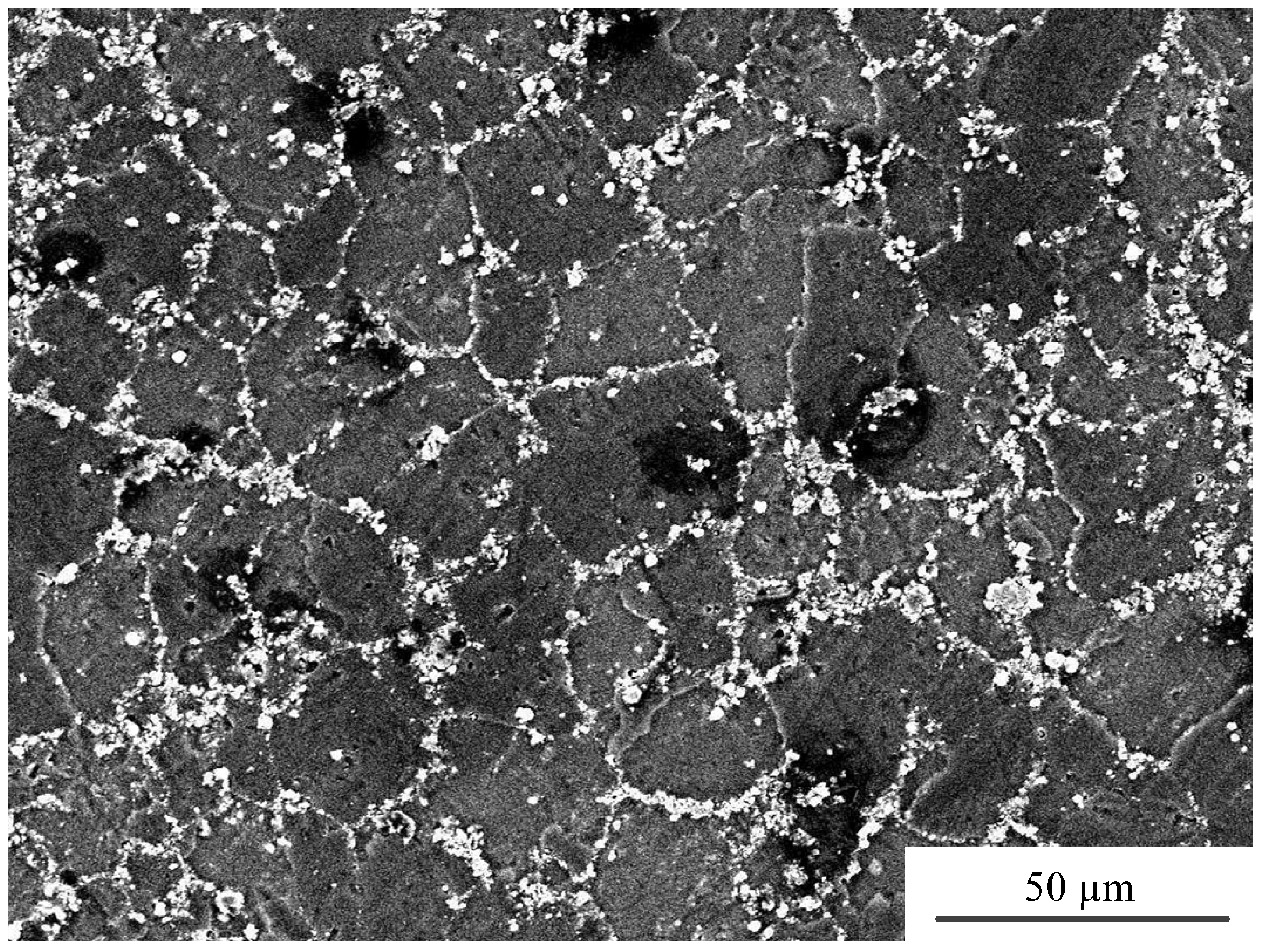

2.1. Tool and Workpiece Material

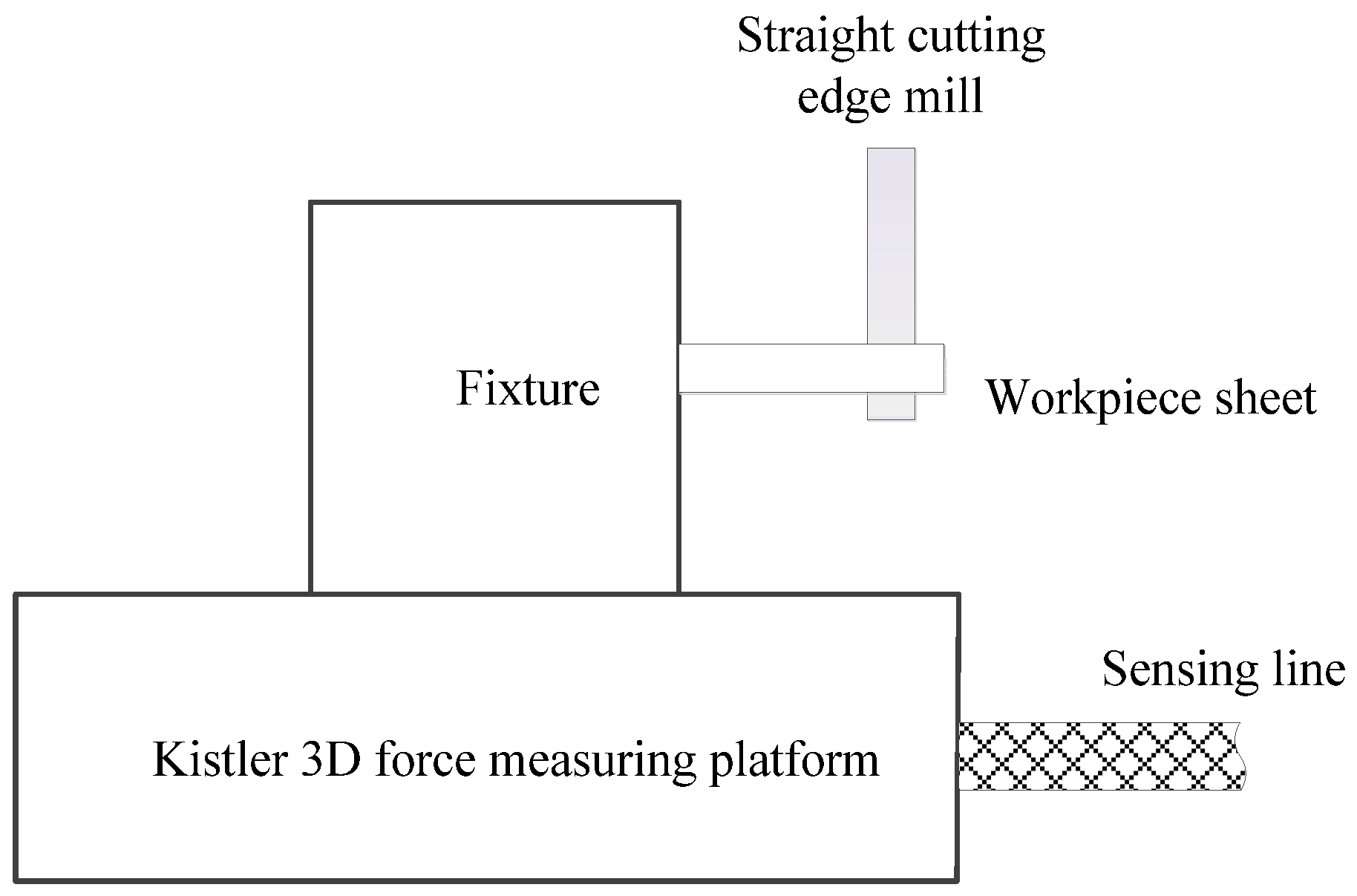

2.2. Experiment Design

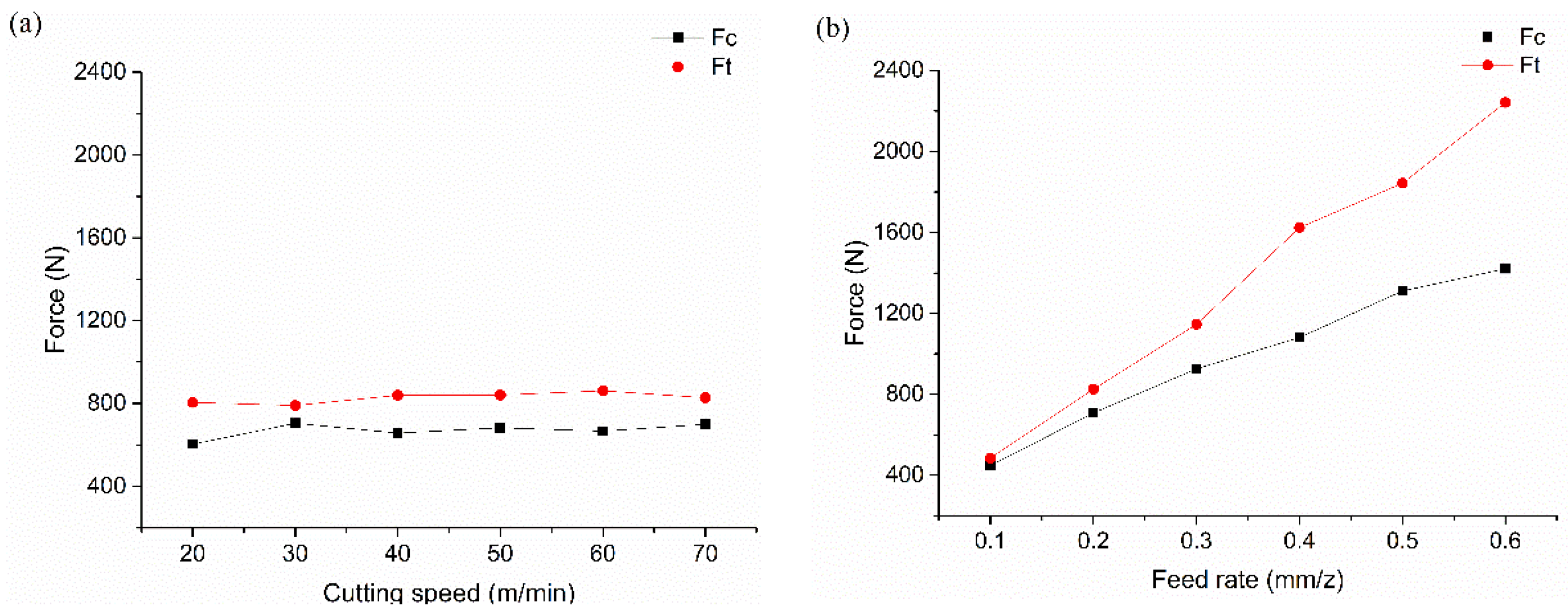

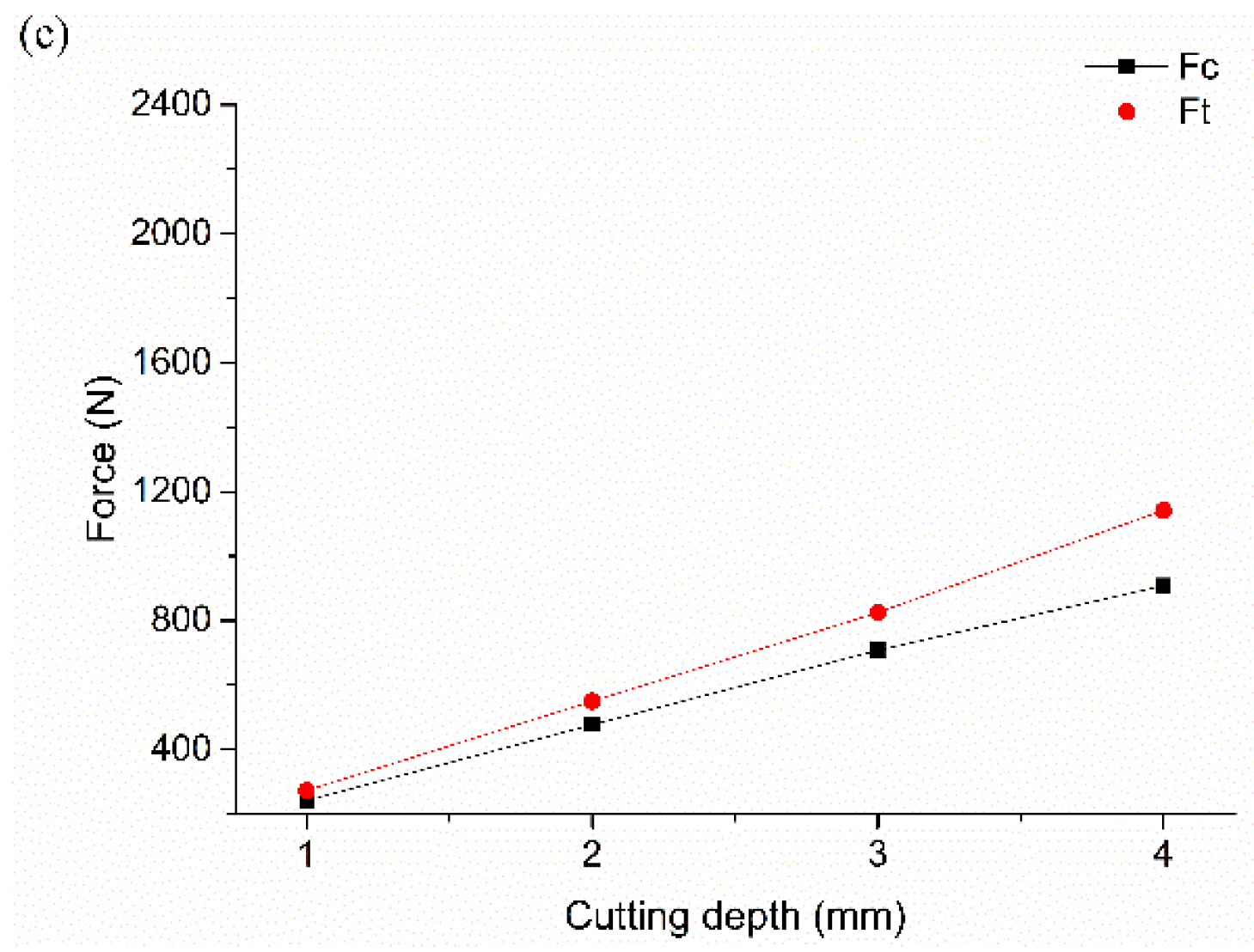

3. Effect of Cutting Parameters

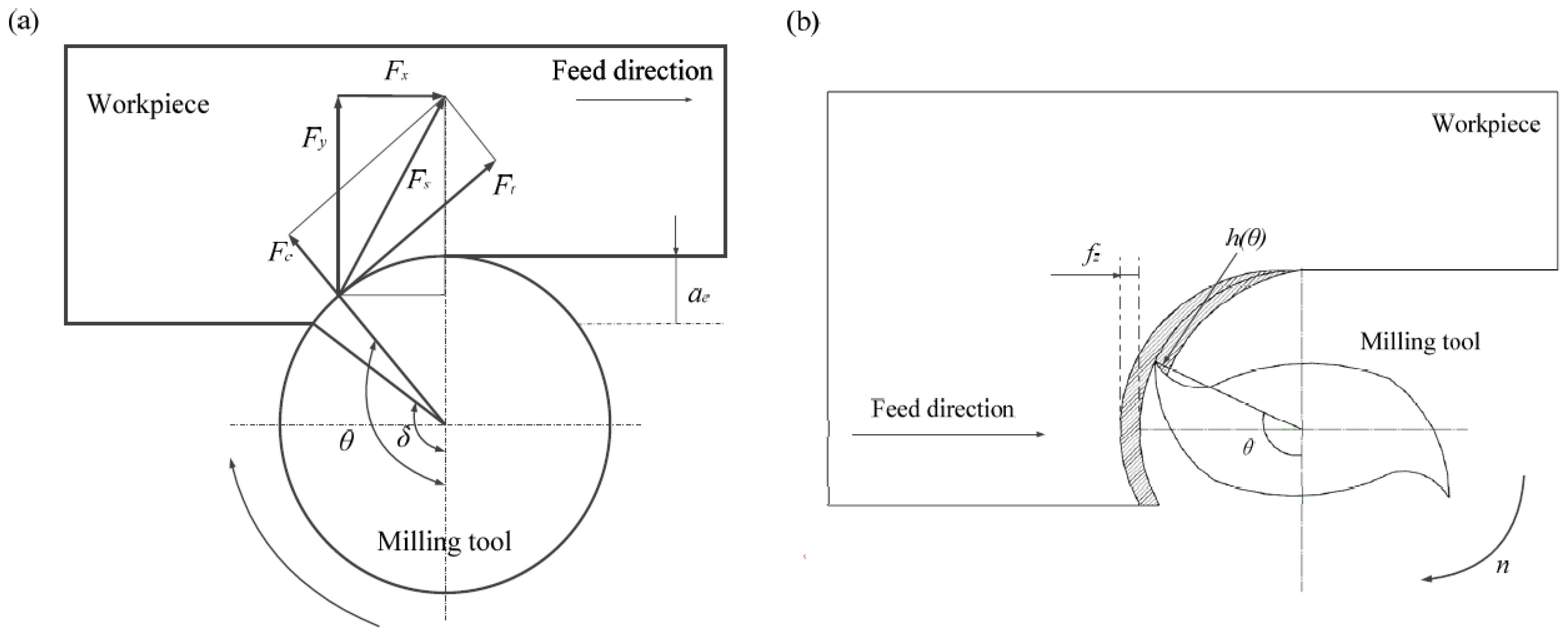

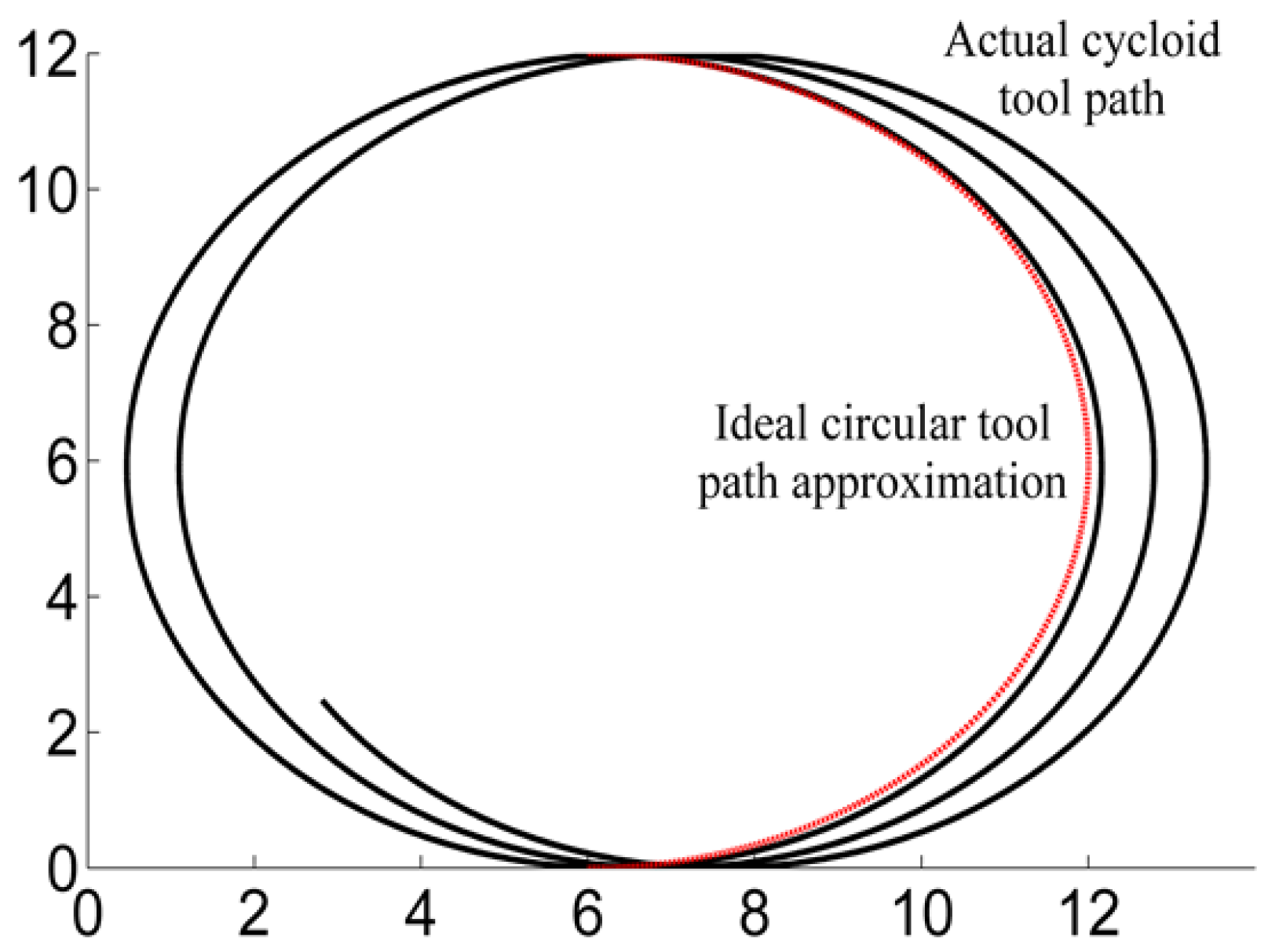

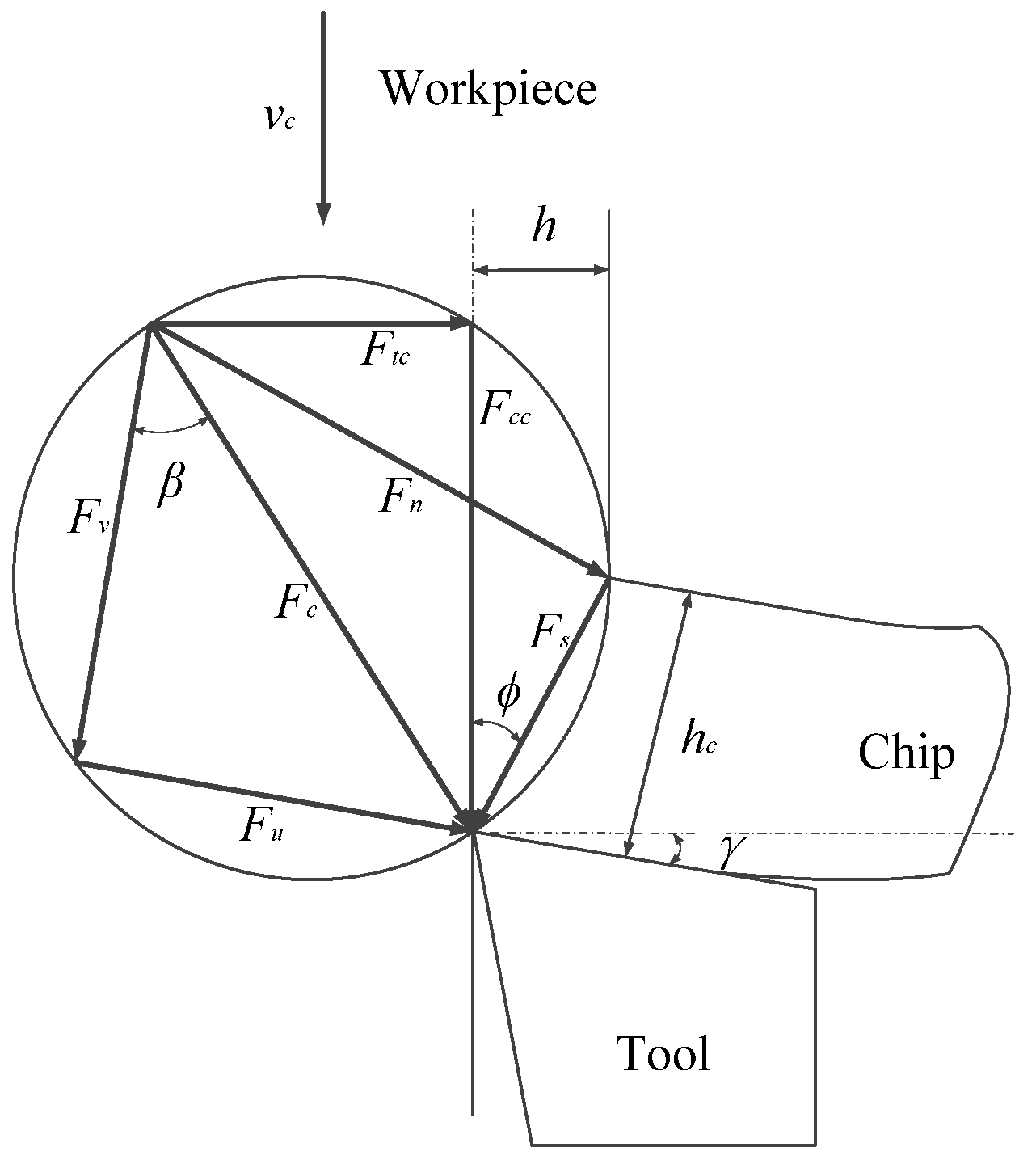

4. Modeling of Machining Forces

4.1. Computing Shear Angle, Mean Friction Angle, and Shear Stress

4.2. Chip Formation and Ploughing Forces

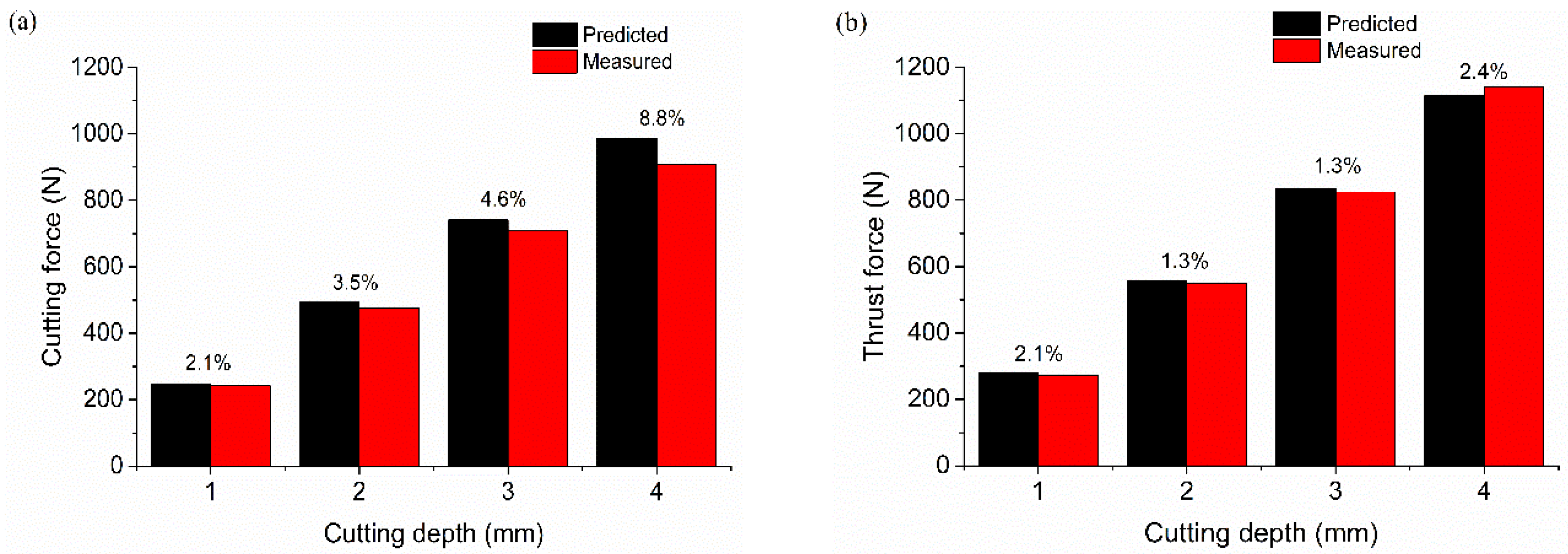

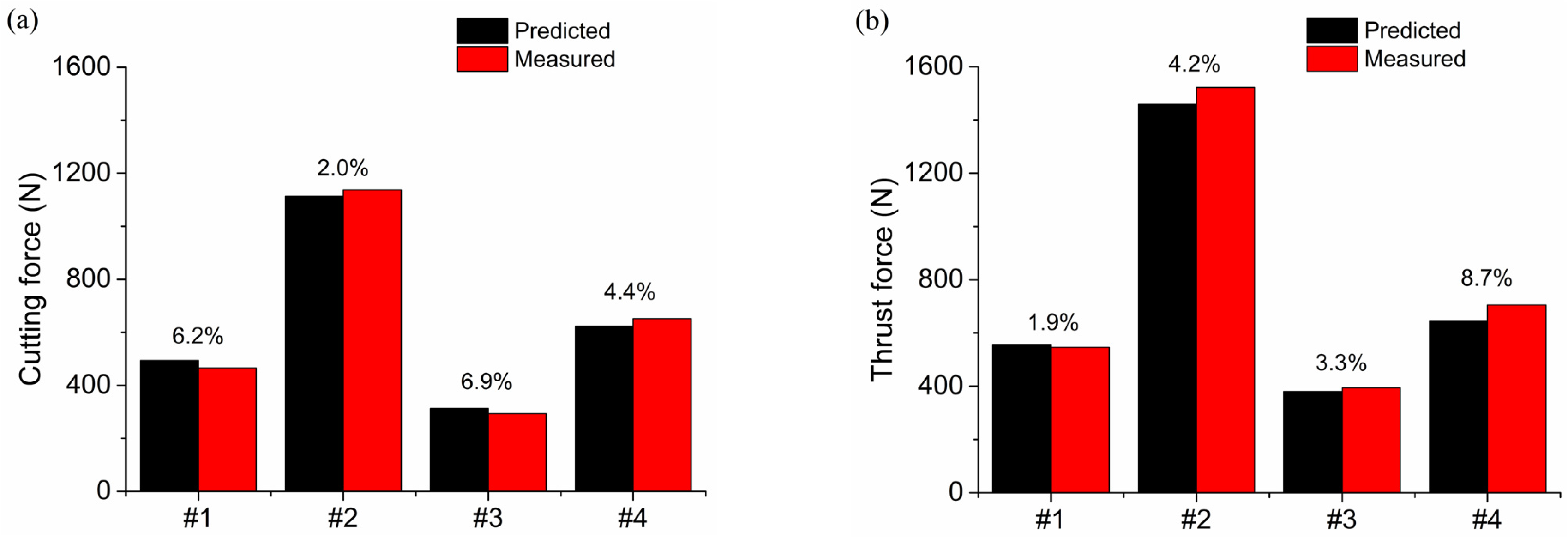

5. Verification and Results

6. Conclusions

- With the in situ synthesis method, the in situ TiB2/Al composite was treated as an equivalent homogenous material. The cutting force was considered to consist of chip formation and ploughing forces, which were calculated based on the single shear plane method and the slip line field theory, respectively. Additionally, comparison tests showed an excellent and acceptable agreement between the predicted forces and the experimental ones.

- On the contrary of cutting ex situ SiCp/Al MMCs, it was found that, at varying feed rates instead of cutting speeds, the linear relationship between the shear angle φ and (β − γ) seems to be still suitable for cutting in situ TiB2/7050Al composites:

- It seems that the influence of cutting parameters on normal stress is higher than that on shear stress. Similarly with ex situ SiC/Al MMCs, the normal stress of cutting in situ TiB2/Al composites increases with an increase in the cutting speed. Differently, the normal stress also increases as the feed rate increases, which is opposite to ex situ SiC/Al MMCs. However, the shear stress seems to fluctuate slightly around 300 MPa under different cutting parameters.

- Among all of the cutting parameters, feed rate plays an important role in the cutting forces, shear angle, mean friction angle, shear stress, and normal stress, instead of the cutting speed, which is found to have a dominant influence on measured forces Fcc, Fct, and shear angle φ in cutting ex situ SiC/Al composites. The relationship between the feed rate and shear angle, mean friction angle, and shear stress is given below:

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | Cross-sectional area of the cut (mm2) |

| B, C | Constants in Equation (14) |

| D | Cutter diameter (mm) |

| vc | Cutting speed (m/min) |

| fz | Feed rate (mm/z) |

| ap | Cutting depth (mm) |

| ae | Cutting width (mm) |

| h | Uncut chip thickness (mm) |

| hc | Chip thickness (mm) |

| hmax | Maximum uncut chip thickness (mm) |

| Rc | Chip compression ratio |

| δ | Immersion angle at maximum uncut chip Thickness (deg) |

| θ | Instantaneous angle of immersion (deg) |

| φ | Shear angle (deg) |

| β | Mean friction angle (deg) |

| γ | Rank angle (deg) |

| rn | Cutting edge radius (mm) |

| Fx, Fy | Cutting forces measured by force measuring platform |

| Fc | Total force in the cutting direction (N) |

| Fcc | Cutting force for chip formation (N) |

| Fcp | Cutting force for ploughing (N) |

| Ft | Total force in thrust direction (N) |

| Ftc | Thrust force for chip formation (N) |

| Ftp | Thrust force for ploughing (N) |

| Fs | Shear force on the shear plane (N) |

| Fn | Normal force on the shear plane (N) |

| Fu | Friction force on the rank face (N) |

| Fv | Normal force on the rank face (N) |

| l | Active cutting edge length (mm) |

| τs | Shear stress of MMCs (MPa) |

| τm | Shear stress of matrix material (MPa) |

References

- Rana, R.S.; Purohit, R.; Das, S. Review of recent studies in Al matrix composites. Int. J. Sci. Eng. Res. 2012, 3, 1–16. [Google Scholar]

- Das, D.K.; Mishra, P.C.; Singh, S.; Thakur, R.K. Tool wear in turning ceramic reinforced aluminum matrix composites—A review. J. Compos. Mater. 2015, 49, 2949–2961. [Google Scholar]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal-matrix composites: Part I: Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Lin, J.T.; Bhattacharyya, D.; Lane, C. Machinability of a silicon-carbide reinforced aluminum metal-matrix composite. Wear 1995, 181, 883–888. [Google Scholar] [CrossRef]

- Przestacki, D. Conventional and laser assisted machining of composite A359/20SiCp. Procedia CIRP 2014, 14, 229–233. [Google Scholar] [CrossRef]

- Przestacki, D.; Jankowiak, M. Surface roughness analysis after laser assisted machining of hard to cut materials. J. Phys. Conf. Ser. 2014, 483, 012019. [Google Scholar] [CrossRef]

- Przestacki, D.; Szymanski, P.; Wojciechowski, S. Formation of surface layer in metal matrix composite A359/20SiCP during laser assisted turning. Compos. Part A Appl. Sci. Manuf. 2016, 91, 370–379. [Google Scholar] [CrossRef]

- Jenarthanan, M.; Prakash, A.R.; Jeyapaul, R. Modeling and analysis of process parameters on metal removal rate (MRR) in machining of aluminium titanium diboride (Al-TiB2) composite. Multidiscip. Model. Mater. Struct. 2015, 11, 372–385. [Google Scholar] [CrossRef]

- Krishnamurthy, K.; Venkatesh, J. Study on machining parameters of TiB2 reinforced aluminum 6063 composites. Int. J. Sci. Res. Publ. 2013, 3, 130–137. [Google Scholar]

- Mahamani, A. Machinability study of Al-5Cu-TiB2 in-situ metal matrix composites fabricated by flux-assisted synthesis. J. Miner. Mater. Charact. Eng. 2011, 10, 1243–1254. [Google Scholar]

- Anandakrishnan, V.; Mahamani, A. Investigations of flank wear, cutting force, and surface roughness in the machining of Al-6061-TiB2 in situ metal matrix composites produced by flux-assisted synthesis. Int. J. Adv. Manuf. Technol. 2011, 55, 65–73. [Google Scholar] [CrossRef]

- Xiong, Y.F.; Wang, W.H.; Jiang, R.S.; Lin, K.Y.; Song, G.D. Tool wear mechanisms for milling in situ TiB2 particle-reinforced Al matrix composites. Int. J. Adv. Manuf. Technol. 2016, 86, 3517–3526. [Google Scholar] [CrossRef]

- Xiong, Y.F.; Wang, W.H.; Jiang, R.S.; Lin, K.Y.; Song, G.D. Surface integrity of milling in-situ TiB2 particle reinforced Al matrix composites. Int. J. Refract. Met. Hard Mater. 2016, 54, 407–416. [Google Scholar] [CrossRef]

- Jiang, R.S.; Wang, W.H.; Song, G.D.; Wang, Z.Q. Experimental investigation on machinability of in situ formed TiB2 particles reinforced Al MMCs. J. Manuf. Process. 2016, 23, 249–257. [Google Scholar]

- Ge, Y.F.; Xu, J.H.; Yang, H.; Luo, S.B.; Fu, Y.C. Workpiece surface quality when ultra-precision turning of SiCp/Al composites. J. Mater. Process. Technol. 2008, 203, 166–175. [Google Scholar] [CrossRef]

- Reddy, N.S.K.; Kwang-Sup, S.; Yang, M. Experimental study of surface integrity during end milling of Al/SiC particulate metal-matrix composites. J. Mater. Process. Technol. 2008, 201, 574–579. [Google Scholar] [CrossRef]

- Wang, T.; Xie, L.J.; Wang, X.B.; Jiao, L.; Shen, J.W.; Xu, H.; Nie, F.M. Surface integrity of high speed milling of Al/SiC/65p aluminum matrix composites. Procedia CIRP 2013, 8, 475–480. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Kannan, S.; Balazinski, M. An energy based analytical force model for orthogonal cutting of metal matrix composites. CIRP Ann. Manuf. Technol. 2004, 53, 91–94. [Google Scholar] [CrossRef]

- Merchant, M.E. Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J. Appl. Phys. 1945, 16, 267–275. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.C.; Arsecularatne, J.A. Prediction of cutting forces in machining of metal matrix composites. Int. J. Mach. Tools Manuf. 2006, 46, 1795–1803. [Google Scholar] [CrossRef]

- Davim, J.P.; Silva, J.; Baptista, A.M. Experimental cutting model of metal matrix composites (MMCs). J. Mater. Process. Technol. 2007, 183, 358–362. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal matrix composites: Part II: Workpiece surface integrity. J. Mater. Process. Technol. 1998, 83, 277–285. [Google Scholar] [CrossRef]

- Hung, N.P.; Boey, F.Y.C.; Khor, K.A.; Phua, Y.S.; Lee, H.F. Machinability of aluminum alloys reinforced with silicon carbide particulates. J. Mater. Process. Technol. 1996, 56, 966–977. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, L.C. Single-point scratching of 6061 Al alloy reinforced by different ceramic particles. Appl. Compos. Mater. 1994, 1, 431–447. [Google Scholar] [CrossRef]

- Dabade, U.A.; Dapkekar, D.; Joshi, S.S. Modeling of chip-tool interface friction to predict cutting forces in machining of Al/SiCp composites. Int. J. Mach. Tools Manuf. 2009, 49, 690–700. [Google Scholar] [CrossRef]

- Sikder, S.; Kishawy, H.A. Analytical model for force prediction when machining metal matrix composite. Int. J. Mech. Sci. 2012, 59, 95–103. [Google Scholar] [CrossRef]

- Wang, M.L.; Chen, Z.; Chen, D.; Wu, Y.; Li, X.F.; Ma, N.H.; Wang, H.W. The constitutive model and processing map for in-situ 5wt% TiB2 reinforced 7050 Al alloy matrix composite. Key Eng. Mater. 2014, 575, 11–19. [Google Scholar] [CrossRef]

- Pramanik, A.; Zhang, L.C.; Arsecularatne, J.A. Machining of metal matrix composites: Effect of ceramic particles on residual stress, surface roughness and chip formation. Int. J. Mach. Tools Manuf. 2008, 48, 1613–1625. [Google Scholar] [CrossRef]

- Dandekar, C.R.; Shin, Y.C. Modeling of machining of composite materials: A review. Int. J. Mach. Tools Manuf. 2012, 57, 102–121. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal Cutting, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Waldorf, D.J. A simplified model for ploughing forces in turning. J. Manuf. Process. 2006, 8, 76–82. [Google Scholar] [CrossRef]

| Elements | Zn | Zr | Mg | Cu | Al |

|---|---|---|---|---|---|

| Composition (wt %) | 6.3 | 0.11 | 2.3 | 2.2 | Balanced |

| Particle | Size | Volume |

|---|---|---|

| TiB2 | 50–200 nm | 6% |

| Factors | Notation | Level | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| Cutting speed (m/min) | vc | 20 | 30 | 40 | 50 | 60 | 70 |

| Feed rate (mm/z) | fz | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

| Cutting depth (mm) | ap | 1 | 2 | 3 | 4 | ||

| Cutting width (mm) | ae | 8 | |||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Wang, W.; Jiang, R.; Lin, K. A Study on Cutting Force of Machining In Situ TiB2 Particle-Reinforced 7050Al Alloy Matrix Composites. Metals 2017, 7, 197. https://doi.org/10.3390/met7060197

Xiong Y, Wang W, Jiang R, Lin K. A Study on Cutting Force of Machining In Situ TiB2 Particle-Reinforced 7050Al Alloy Matrix Composites. Metals. 2017; 7(6):197. https://doi.org/10.3390/met7060197

Chicago/Turabian StyleXiong, Yifeng, Wenhu Wang, Ruisong Jiang, and Kunyang Lin. 2017. "A Study on Cutting Force of Machining In Situ TiB2 Particle-Reinforced 7050Al Alloy Matrix Composites" Metals 7, no. 6: 197. https://doi.org/10.3390/met7060197

APA StyleXiong, Y., Wang, W., Jiang, R., & Lin, K. (2017). A Study on Cutting Force of Machining In Situ TiB2 Particle-Reinforced 7050Al Alloy Matrix Composites. Metals, 7(6), 197. https://doi.org/10.3390/met7060197