Substructural Alignment during ECAE Processing of an Al-0.1Mg Aluminium Alloy

Abstract

:1. Introduction

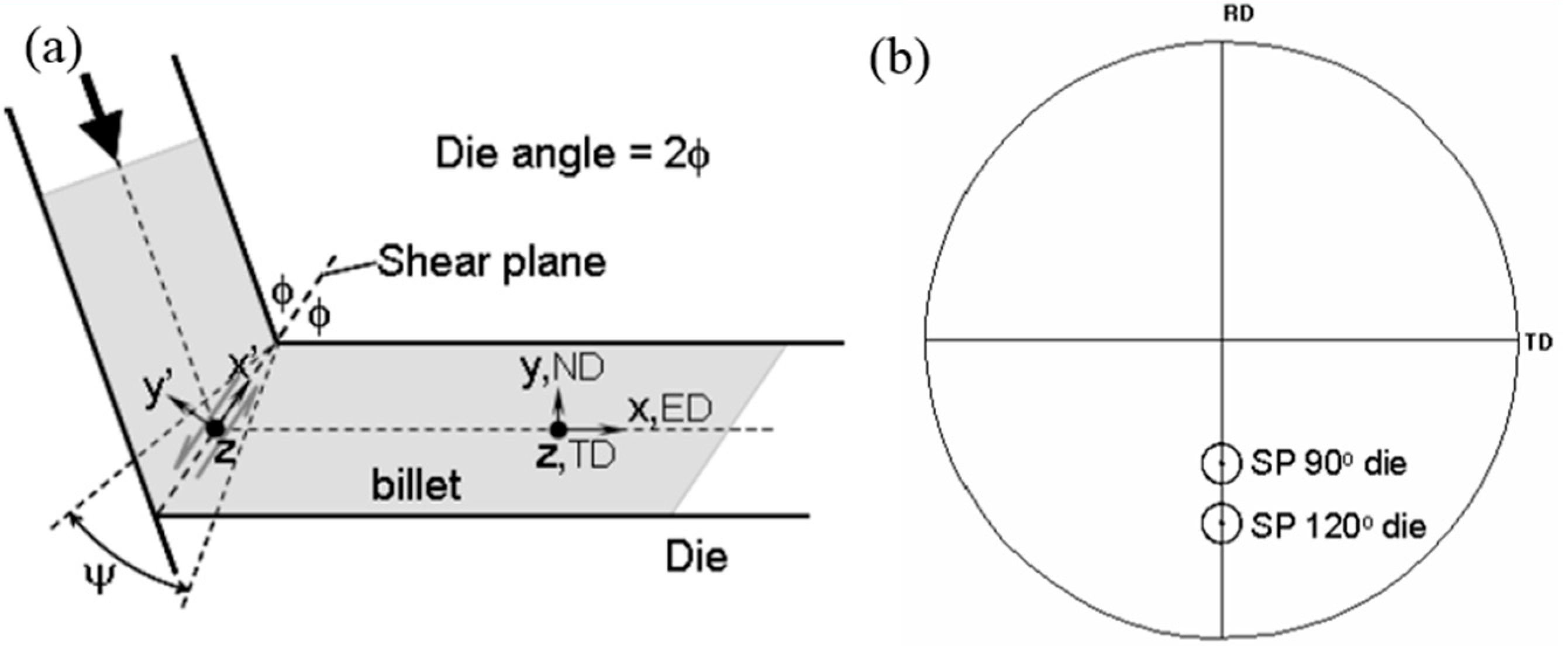

2. Materials and Methods

3. Results

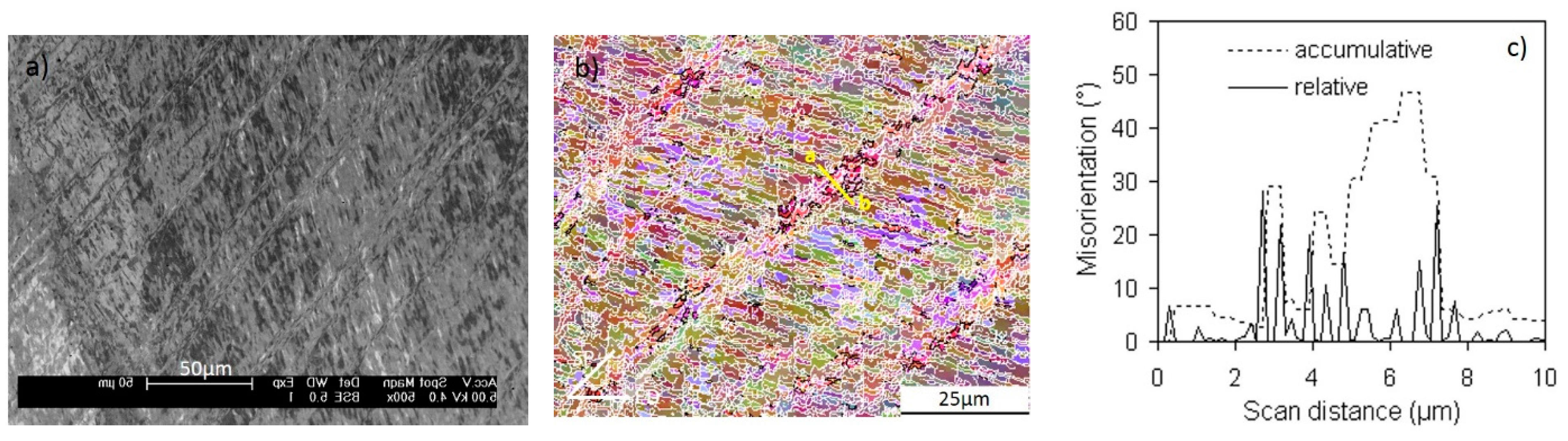

3.1. Cell Bands Alignment in the 1st Pass

3.2. Structural Evolution in the 2nd Pass

3.3. Lamellar Fibre Structure in the 3rd Pass

4. Discussion

4.1. General Features of Deformation Structure

4.2. Substructural Alignment

4.3. The Development of the Preferred Orientations and Their Effect on Deformation

4.4. Comparison with Torsion and Rolling

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Segal, V.M.; Reznikov, V.I.; Drobyshevskiy, A.E.; Kopylov, V.I. Simple shear in equal channel angular extrusion. Russian Metallurgy. Engl. Transl. 1981, 1, 99–107. [Google Scholar]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Gholinia, A.; Prangnell, P.B.; Markushev, M.V. The effect of strain path on the development of deformation structures in severely deformed aluminium alloys processed by ECAE. Acta Mater. 2000, 48, 1115–1130. [Google Scholar] [CrossRef]

- Casati, R.; Fabrizi, A.; Tuissi, A.; Xia, K.; Vedani, M. ECAP consolidation of Al matrix composites reinforced with in-situ γ-Al2O3 nanoparticles. Mater. Sci. Eng. A 2015, 648, 113–122. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Segal, V.M. Equal Channel angular extrusion: From macromechanics to structure formation. Mater. Sci. Eng. A 1999, 271, 322–333. [Google Scholar] [CrossRef]

- Segal, V.M. Engineering and commercialization of equal channel angular extrusion (ECAE). Mater. Sci. Eng. A 2004, 386, 269–276. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Bowen, J.R.; Apps, P.J. Ultrfine grain structures in aluminium alloys by severe deformation processing. Mater. Sci. Eng. A 2004, 375–377, 178–185. [Google Scholar] [CrossRef]

- Huang, Y.; Prangnell, P.B. Orientation splitting and its contribution to grain refinement during equal channel angular extrusion. J. Mater. Sci. 2008, 43, 7273–7279. [Google Scholar] [CrossRef]

- Zhang, D.; Li, S. Orientation dependencies of mechanical response, microstructure and texture evolution of AZ31 magnesium alloy processed by equal channel angular extrusion. Mater. Sci. Eng. A 2011, 528, 4982–4987. [Google Scholar] [CrossRef]

- Sitdikov, O.; Avtokratova, E.; Sakai, T. Microstructural and texture changes during equal channel angular pressing of an Al-Mg-Sc alloy. J. Alloy. Comp. 2015, 648, 195–204. [Google Scholar] [CrossRef]

- Fukuda, Y.; Oh-ishi, K.; Furukawa, M.; Horita, Z.; Langdon, T.G. Influence of crystal orientation on ECAP of aluminium single crystals. Mater. Sci. Eng. A 2006, 420, 79–86. [Google Scholar] [CrossRef]

- Winther, G. Slip patterns and preferred dislocation boundary planes. Acta Mater. 2003, 51, 417–429. [Google Scholar] [CrossRef]

- Hurley, P.; Humphreys, F.J.; Bate, P. An objective study of substructural boundary aliognment in aluminium. Acta Mater. 2003, 51, 4737–4750. [Google Scholar] [CrossRef]

- Winther, G.; Juul Jensen, D.; Hansen, N. Dense dislocation walls and microbands aligned with slip planes—Theoretical considerations. Acta Mater. 1997, 45, 5059–5068. [Google Scholar] [CrossRef]

- Haldar, A.; Huang, X.; Leffers, T.; Hansen, N.; Ray, R.K. Grai orientation dependence of microstructures in a warm rolled IF steel. Acta Mater. 2004, 52, 5405–5418. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Bate, P. Measuring the alignment of low angle boundaries formed during deformation. Acta Mater. 2006, 54, 817–829. [Google Scholar] [CrossRef]

- Ferrasse, F.; Segal, V.M.; Hartwig, T.K.; Goforth, R.E. Microstructure and properties of copper and aluminium alloy 3003 heaviely worked by equal angular extrusion. Metall. Mater. Trans. A 1997, 28, 1047–1057. [Google Scholar] [CrossRef]

- Apps, P.J.; Bowen, J.R.; Prangnell, P.B. The effect of coarse second-phase particles on the rate of grain refinement during severe deformation processing. Acta Mater. 2003, 51, 2811–2822. [Google Scholar] [CrossRef]

- Etter, A.L.; Baudin, T.; Rey, C.; Penelle, R. Microstructural and texture characterization of copper processed by ECAE. Mater. Char. 2006, 56, 19–25. [Google Scholar] [CrossRef]

- Prangnell, P.B.; Huang, Y.; Berta, M.; Apps, P.J. Mechanisms of formation of submicron grain structures by severe deformation. Mater. Sci. Forum 2007, 550, 159–168. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Q: Dislocations structures—How far from equilibrium? A: Very close indeed. Mater. Sci. Eng. A 2001, 315, 211–216. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Annealing Phenomena, 2nd ed.; Pergamon Press: Oxford, UK, 2004; pp. 28–35. [Google Scholar]

- Longdon, T.G. The principles of grain refinement in equal channel angular extrusion. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Oh-ishi, K.; Raab, G.I.; McNelley, I.R. Influence of ECAP processing parameters on texture and microstructure of commercially pure aluminium. Mater. Sci. Eng. A 2006, 441, 245–252. [Google Scholar] [CrossRef]

- Kliauga, A.M.; Bolmaro, R.E.; Ferrante, M. The evolution of texture in an equal channel pressed aluminium AA1050. Mater. Sci. Eng. A 2015, 623, 22–31. [Google Scholar] [CrossRef]

- Li, S.; Gazder, A.; Beyerlein, I.J.; Davies, C.H.J.; Pereloma, E.V. Microstructure and texture evolution during equal channel angular extrusion of interstitial free steel—Effects of die angle and processing route. Acta Mater. 2007, 55, 1017–1032. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Lebensohn, R.A.; Tomé, C.N. Modelling texture and microstructure in the equal channel angular extrusion process. Mater. Sci. Eng. A 2003, 345, 122–138. [Google Scholar] [CrossRef]

- Signorelli, J.W.; Turner, P.A.; Sordi, V.; Ferrante, M.; Vieira, E.A.; Bolmaro, R.E. Computational simulation of texture and microstructure evolution in Al alloys deformed by ECAE. Scr. Mater. 2006, 55, 1099. [Google Scholar] [CrossRef]

- Pithan, C.; Hashimoto, T.; Kawazoe, M.; Nagahora, J.; Higashi, K. Microstructure and texture evolution in ECAE processed A5056. Mater. Sci. Eng. A 2000, 280, 62–68. [Google Scholar] [CrossRef]

- Gholinia, A.; Bate, P.; Prangnell, P.B. Modelling texture development during equal channel angular extrusion of aluminium. Acta Mater. 2002, 50, 2121–2136. [Google Scholar] [CrossRef]

- Canova, G.R.; Kocks, U.F.; Jonas, J.J. Theory of torsion texture dev elopement. Acta Metal. 1984, 32, 211–226. [Google Scholar] [CrossRef]

- Hurley, P.J.; Humphreys, F.J. Modelling the recrystallization in single phase aluminium. Acta Mater. 2003, 51, 3779–3793. [Google Scholar] [CrossRef]

| Notation | Orientations {hkl}<uvw> | Slip Systems in SSRS | Schmid Factor | Structural Features | ||

|---|---|---|---|---|---|---|

| ECAERS | SSRS | Plane/θSP *1 | Direction/θSD *2 | |||

| A1 | (521)[01-2] (52-1)[012] | (111)[-110] (11-1)[-110] | (111)/0 (111)/0 | [-110]/0 [-110]/0 | 1 | CBs, SBs |

| A2 | (81-1)[1-44] | (111)[-1-12] | (111)/0 | [-101]/+35.26 [0-11]/−35.26 | 0.82 | CBs, 1DBs, SBs |

| B1 | (122)[-411] | (100)[01-1] | (11-1)/57.4 (1-11)/−57.4 | [011]/0 [011]/0 | ~0.56 | CBs, 2DBs |

| B2 | (341)[-527] (3-14)[57-2] | (112)[1-10] (121)[10-1] | (111)/+19.42 (111)/−19.42 | [1-10]/0 [10-1]/0 | ~0.94 | SBs, fibre |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y. Substructural Alignment during ECAE Processing of an Al-0.1Mg Aluminium Alloy. Metals 2016, 6, 158. https://doi.org/10.3390/met6070158

Huang Y. Substructural Alignment during ECAE Processing of an Al-0.1Mg Aluminium Alloy. Metals. 2016; 6(7):158. https://doi.org/10.3390/met6070158

Chicago/Turabian StyleHuang, Yan. 2016. "Substructural Alignment during ECAE Processing of an Al-0.1Mg Aluminium Alloy" Metals 6, no. 7: 158. https://doi.org/10.3390/met6070158

APA StyleHuang, Y. (2016). Substructural Alignment during ECAE Processing of an Al-0.1Mg Aluminium Alloy. Metals, 6(7), 158. https://doi.org/10.3390/met6070158