Research on the Grain Boundary Liquation Mechanism in Heat Affected Zones of Laser Forming Repaired K465 Nickel-Based Superalloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

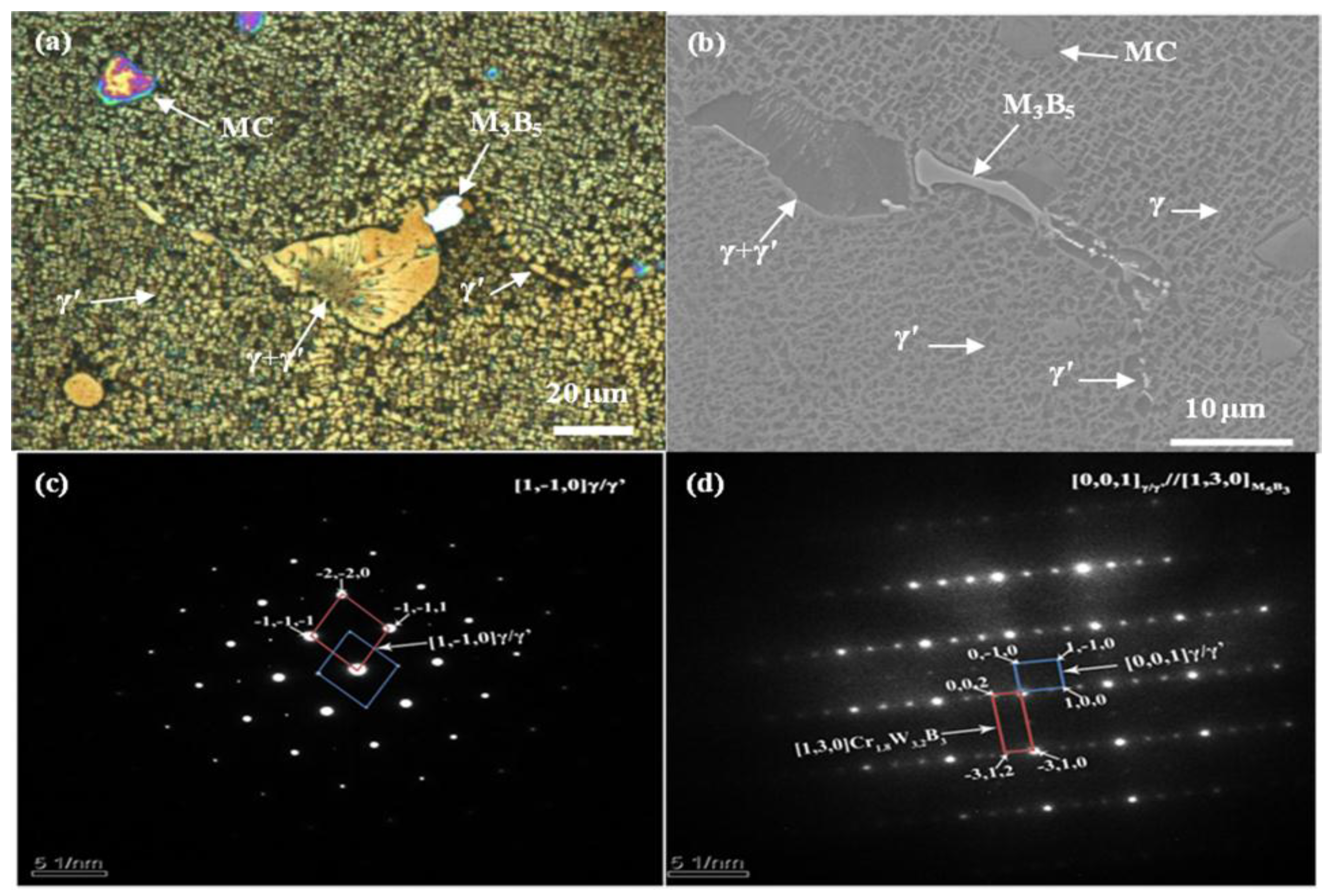

3.1. Main Phases of K465 Nickel-Based Cast Superalloy Substrate

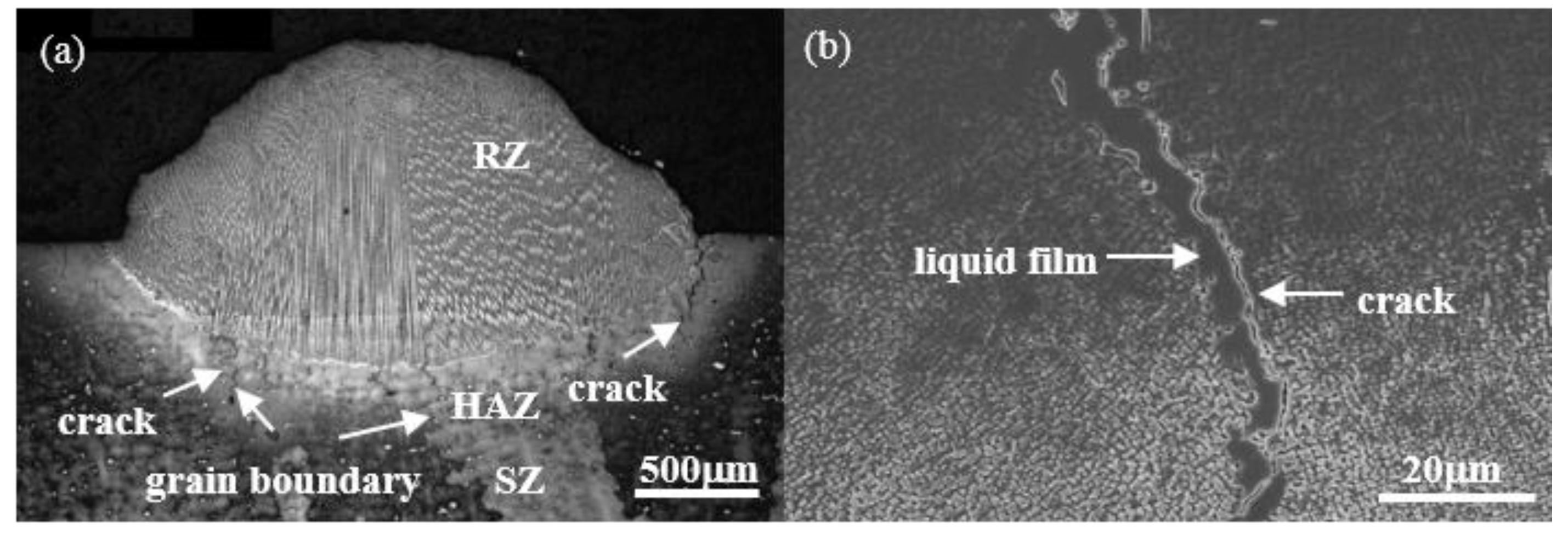

3.2. Liquation Cracking Characteristics

4. Discussion

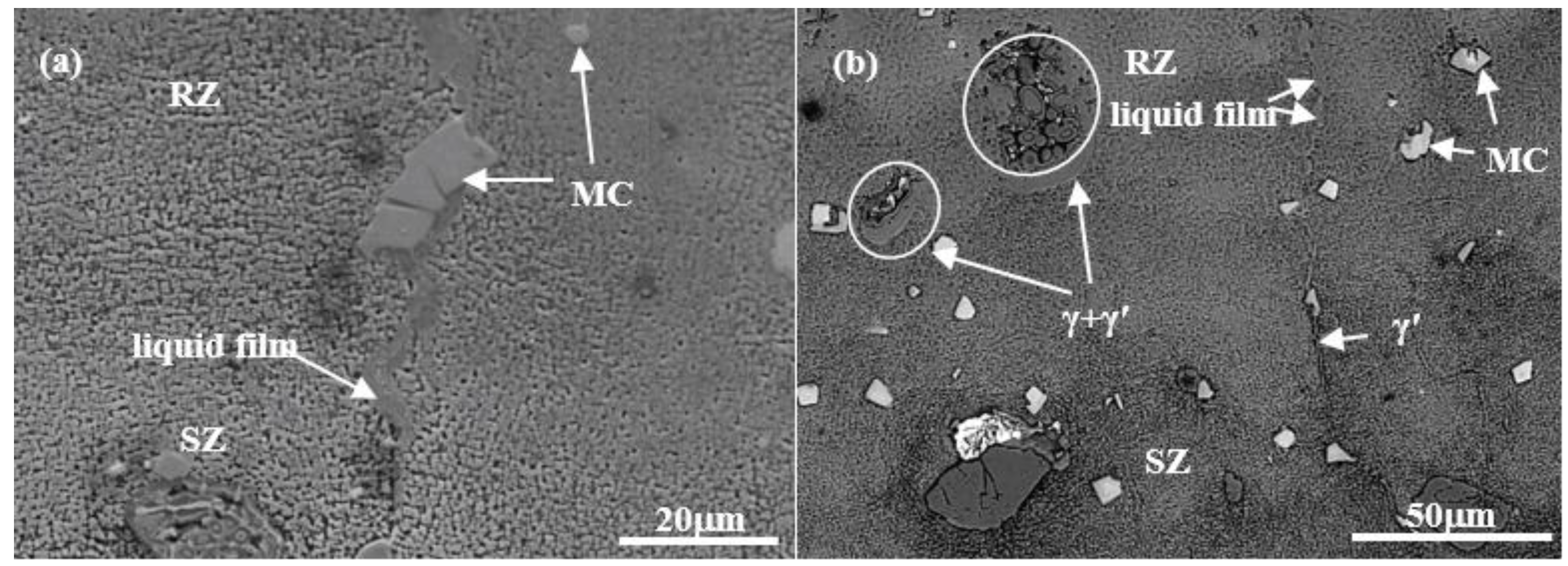

4.1. Grain Boundary Liquation Mechanism in HAZ

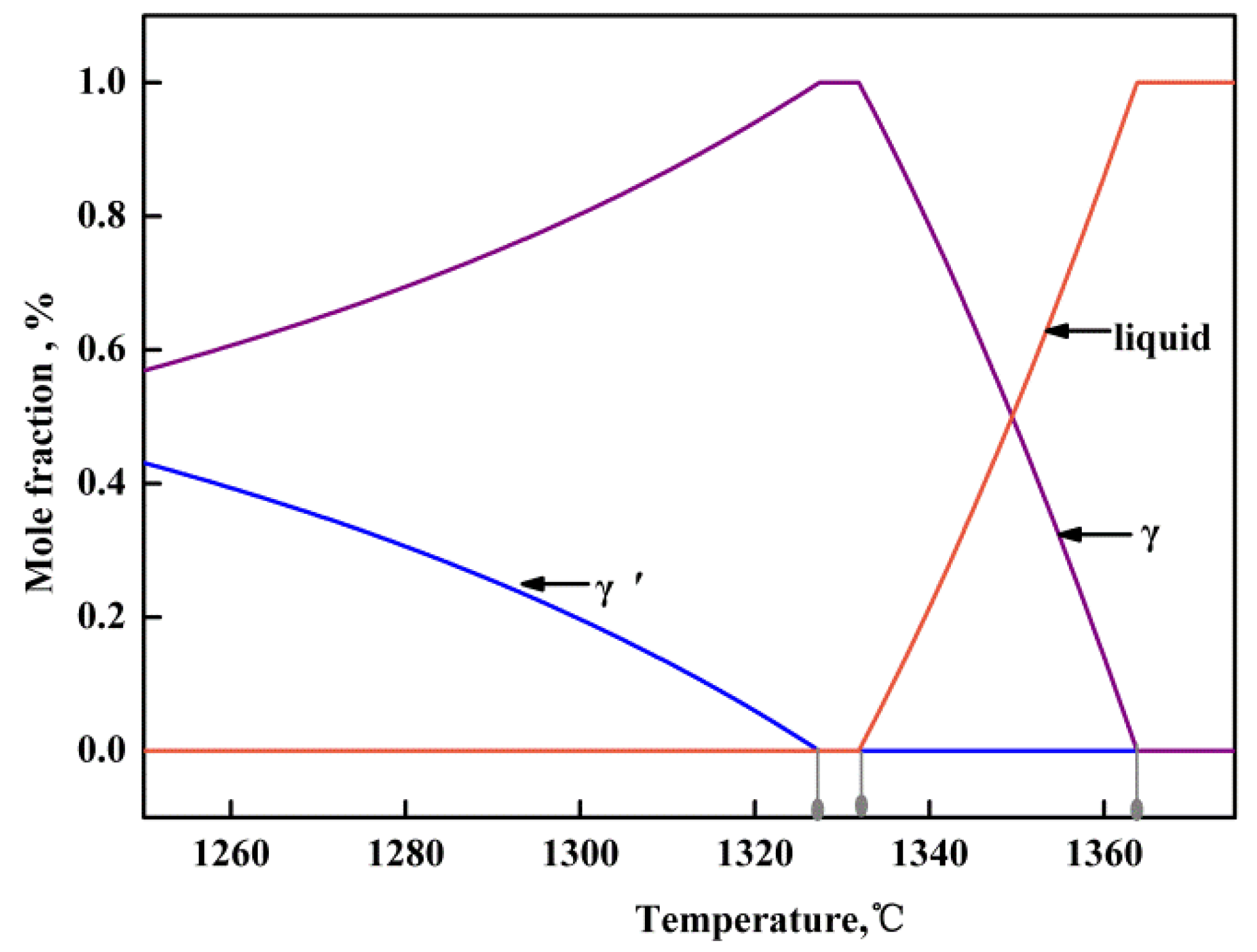

4.2. Transition Characteristics of the Intragranular γ′ Phase

4.3. The Influence of Borides on Grain Boundary Liquation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| LFR | Laser Forming Repairing |

| LFRed | Laser Forming Repaired |

| SZ | Substrate Zone |

| HAZ | Heat Affected Zone |

| RZ | Repaired Zone |

References

- Yang, J.X.; Zheng, Q.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Formation of μ Phase During Thermal Exposure and Its Effect on The Properties of K465 Superalloy. Scr. Mater. 2006, 55, 331–334. [Google Scholar] [CrossRef]

- Yang, J.X.; Zheng, Q.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Relative Stability of Carbides and Their Effects on The Properties of K465 Superalloy. Mater. Sci. Eng. A 2006, 429, 341–347. [Google Scholar] [CrossRef]

- Yaso, M.; Morito, S.; Ohba, T.; Kubota, K. Microstructure of Martensite in Fe–C–Cr Steel. Mater. Sci. Eng. A 2008, 481, 770–773. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Microstructure and Phase Evolution in Laser Rapid Forming of a Functionally Graded Ti–Rene88DT Alloy. Acta Mater. 2006, 54, 1901–1915. [Google Scholar] [CrossRef]

- Gaumann, M.; Henry, S.; Cleton, F.; Wegniere, J.D.; Kurz, W. Epitaxial Laser Metal Forming: Analysis of Microstructure Formation. Mater. Sci. Eng. A 1999, 271, 232–241. [Google Scholar] [CrossRef]

- Liu, F.C.; Lin, X.; Huang, C.P.; Song, M.H.; Yang, G.L.; Chen, J.; Huang, W.D. The Effect of Laser Scanning Path on Microstructures and Mechanical Properties of Laser Solid Formed Nickel-base Superalloy Inconel 718. J. Alloy. Compd. 2011, 205, 4505–4509. [Google Scholar] [CrossRef]

- Lin, X.; Yang, H.O.; Chen, J.; Huang, W.D. Microstructure Evolution of 316L Stainless Steel During Laser Rapid Forming. Acta Metall. Sin. 2006, 42, 361–368. [Google Scholar]

- Henderson, M.B.; Arrell, D.; Larsson, R.; Heobel, M.; Marchant, G. Nickel Based Superalloy Welding Practices for Industrial Gas Turbine Applications. Sci. Technol. Weld. Join. 2004, 9, 13–21. [Google Scholar] [CrossRef]

- Montazeri, M.; Ghaini, F.M. The Liquation Cracking Behavior of IN738LC Superalloy During Low Power Nd:YAG Pulsed Laser Welding. Mater. Charact. 2012, 67, 65–73. [Google Scholar] [CrossRef]

- Richards, N.L.; Nakkalil, R.; Chaturvedi, M.C. The Influence of Electron-Beam Welding Parameters on Heat-Affected-Zone Microfissuring in INCOLOY 903. Metall. Mater. Trans. A 1994, 25, 1733–1745. [Google Scholar] [CrossRef]

- Ojo, O.A. Intergranular Liquation Cracking in Heat Affected Zone of A Welded Nickel Based Superalloy in As Cast Condition. Mater. Sci. Technol. 2007, 23, 1149–1155. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Contribution of Constitutional Liquation of Gamma Prime Precipitate to Weld HAZ Cracking of Cast Inconel 738 Superalloy. Scr. Mater. 2004, 50, 641–646. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Microstructural Study of Weld Fusion Zone of TIG Welded IN738LC Nickel-based Superalloy. Scr. Mater. 2004, 51, 683–688. [Google Scholar] [CrossRef]

- Ojo, O.A.; Chaturvedi, M.C. On The Role of Liquated γ′ Precipitates in Weld Heat Affected Zone Microfissuring of a Nickel-based Superalloy. Mater. Sci. Eng. A 2005, 403, 77–86. [Google Scholar] [CrossRef]

- Tancret, F. Thermo-Calc and Dictra Simulation of Constitutional Liquation of Gamma Prime (γ′) During Welding of Ni Base Superalloys. Comput. Mater. Sci. 2007, 41, 13–19. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Zhu, B.D. The Study on The Laser Cladding Process and Cracking of Cast Ni-Based Superalloy K3. J. Mater. Eng. 1996, 1, 32–35. [Google Scholar]

- Li, X.L.; Liu, J.W.; Zhong, M.L. Research on Laser Cladding Superalloy K403. Appl. Laser 2002, 22, 283–286. [Google Scholar]

- Huang, X.; Chaturvedi, M.C.; Richards, N.L.; Jackman, J. The Effect of Grain Boundary Segregation of Boron in Cast Alloy 718 HAZ Microfissuring—A SIMS Analysis. Acta Mater. 1997, 45 1997, 45, 3095–3107. [Google Scholar] [CrossRef]

- Qian, M.; Lippold, J.C. The Effect of Annealing Twin-generated Special Grain Boundaries on HAZ Liquation Cracking of Nickel-base Superalloys. Acta Mater. 2003, 51, 3351–3361. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M. Phase Formation and Microstructure Evolution in Laser Rapid Forming of Graded SS316L/Rene88DT Alloy. Mater. Sci. Eng. A 2005, 402, 294–306. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The Kinetics of Precipitation From Supersaturated Solid Solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Seo, S.M.; Kim, Y.S.; Lee, J.H.; Jo, C.Y.; Miyahara, H.; Ogi, K. Eta Phase and Boride Formation in Directionally Solidified Ni-Base Superalloy IN792 + Hf. Metall. Mater. Trans. A 2007, 38, 883–893. [Google Scholar] [CrossRef]

- Zheng, Y.R.; Zhang, D.T. Color Metallographic Investigation of Superalloys and Steels; National Defence Industry Press: Beijing, China, 1999; pp. 5–10. [Google Scholar]

- Osoba, L.O.; Ding, R.G.; Ojo, O.A. Improved Resistance to Laser Weld Heat-affected Zone Microfissuring in a Newly Developed Superalloy HAYNES 282. Metall. Mater. Trans. 2012, 43, 4281–4295. [Google Scholar] [CrossRef]

- Wang, X.P.; Zheng, Y.R.; Xiao, C.B.; Wang, B.L.; Han, Y.F. Study of Effect of Boron Content on Solidification Process of IC6 Alloys. J. Aeronaut. Mater. 2000, 20, 21–27. [Google Scholar]

| Laser Power (W) | Scan Speed (mm/s) | Spot Diameter (mm) | Powder Feeding Rate (g/min) | Preheating Temperature (°C) | Increment of Z (mm) |

|---|---|---|---|---|---|

| 1000 | 100 | 3 | 10 | 400 | 0.3 |

| Phases | Element | |||||||

|---|---|---|---|---|---|---|---|---|

| Ni | Co | Cr | Mo | Nb | Al | Ti | W | |

| γ′agb | 70.5 ± 0.4 | 8.39 ± 0.4 | 4.33 ± 0.2 | 0.57 ± 0.1 | 1.26 ± 0.2 | 8.29 ± 0.1 | 4.41 ± 0.4 | 2.26 ± 0.9 |

| γ′i | 69.1 ± 0.5 | 9.23 ± 0.4 | 5.72 ± 0.8 | 0.80 ± 0.1 | 0.94 ± 0.1 | 7.26 ± 0.7 | 3.22 ± 0.4 | 3.75 ± 0.9 |

| γi | 61.5 ± 1.2 | 12.3 ± 0.6 | 11.9 ± 0.6 | 1.67 ± 0.1 | 0.57 ± 0.1 | 5.56 ± 0.1 | 2.16 ± 0.2 | 4.42 ± 0.3 |

| Group | Element | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ni | Co | Cr | Mo | Nb | Al | Ti | W | ||

| a | 70.50 | 8.39 | 4.33 | 0.57 | 1.26 | 8.29 | 4.41 | 2.26 | |

| b | 68.70 | 9.04 | 5.89 | 0.76 | 1.14 | 7.82 | 4.03 | 2.62 | |

| c | 64.52 | 10.99 | 9.35 | 1.30 | 0.80 | 6.46 | 2.91 | 3.67 | |

| d | 61.50 | 12.3 | 11.9 | 1.67 | 0.57 | 5.56 | 2.16 | 4.42 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Lin, X.; Wang, X.; Yang, H.; Song, M.; Huang, W. Research on the Grain Boundary Liquation Mechanism in Heat Affected Zones of Laser Forming Repaired K465 Nickel-Based Superalloy. Metals 2016, 6, 64. https://doi.org/10.3390/met6030064

Li Q, Lin X, Wang X, Yang H, Song M, Huang W. Research on the Grain Boundary Liquation Mechanism in Heat Affected Zones of Laser Forming Repaired K465 Nickel-Based Superalloy. Metals. 2016; 6(3):64. https://doi.org/10.3390/met6030064

Chicago/Turabian StyleLi, Qiuge, Xin Lin, Xinghua Wang, Haiou Yang, Menghua Song, and Weidong Huang. 2016. "Research on the Grain Boundary Liquation Mechanism in Heat Affected Zones of Laser Forming Repaired K465 Nickel-Based Superalloy" Metals 6, no. 3: 64. https://doi.org/10.3390/met6030064