Recovery of Vanadium from H2SO4-HF Acidic Leaching Solution of Black Shale by Solvent Extraction and Precipitation

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Reagents

2.2. Experimental Procedure

2.2.1. Solvent Extraction

2.2.2. Oxidation and Precipitation

2.2.3. Calcination

3. Results and Discussion

3.1. Ferric Ion Reduction

3.2. Solvent Extraction and Stripping of Vanadium (IV)

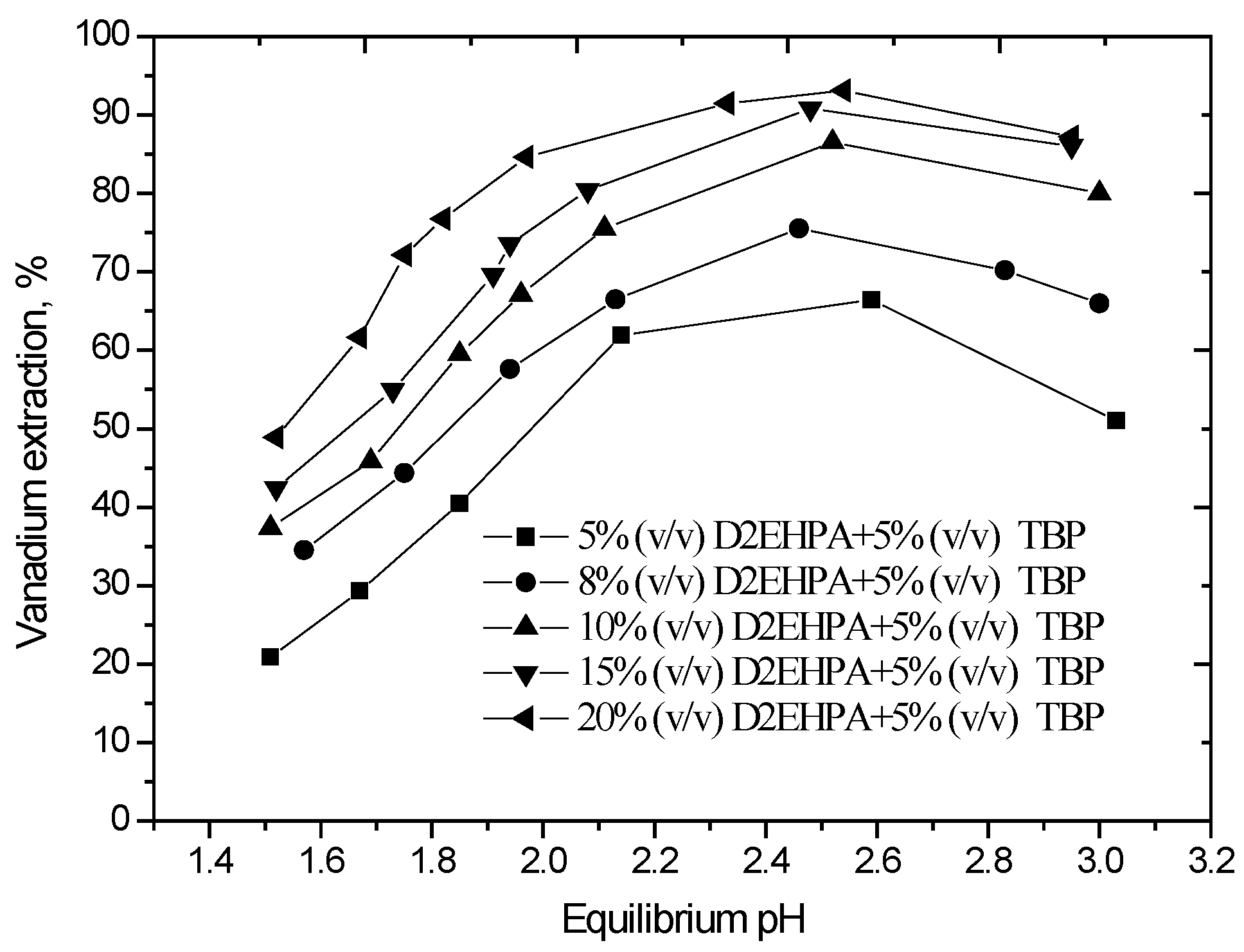

3.2.1. Effect of pH and Extractant Concentration

3.2.2. Effect of Fluoride Ion Concentration

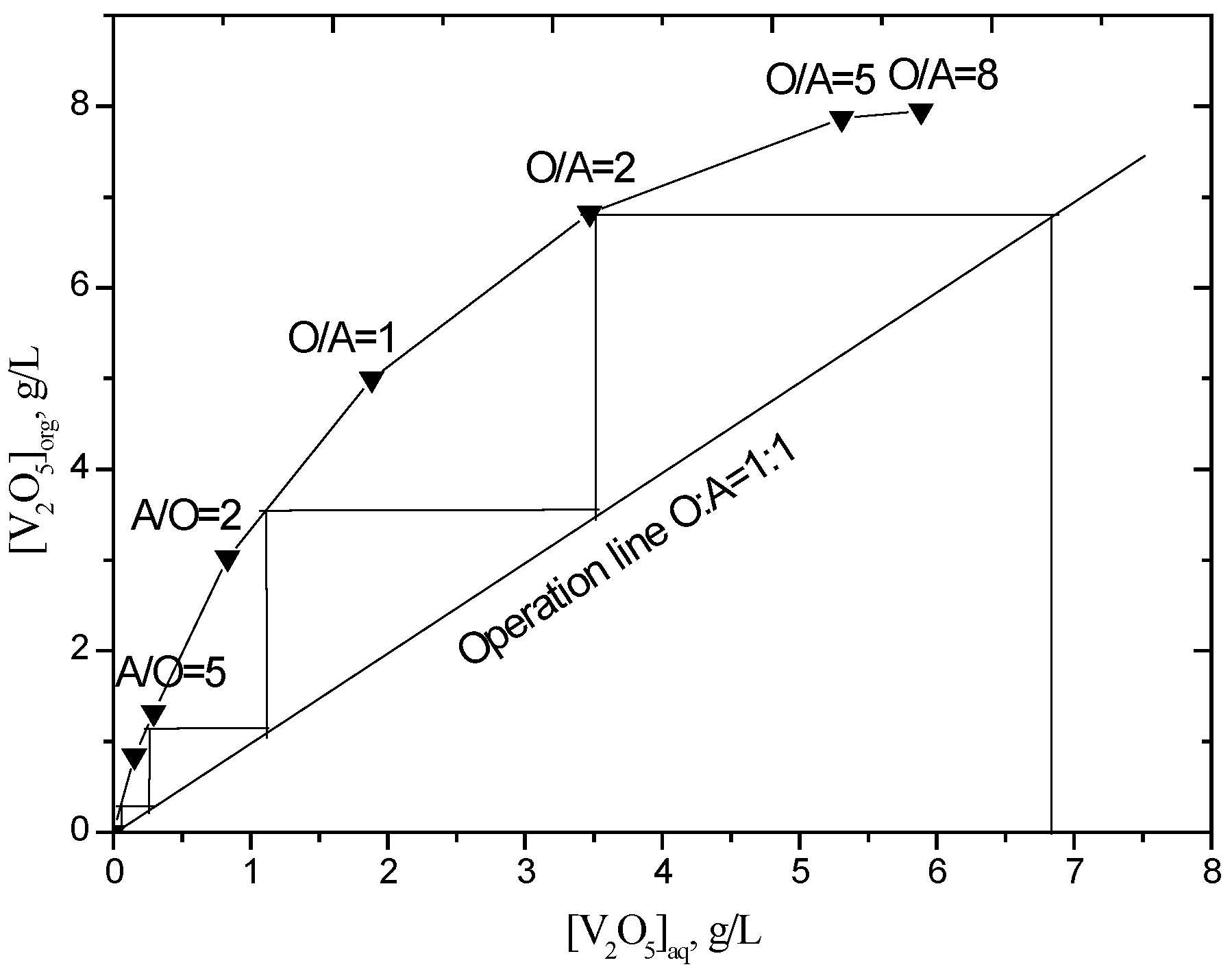

3.2.3. McCabe-Thiele Plot for Vanadium (IV) Extraction

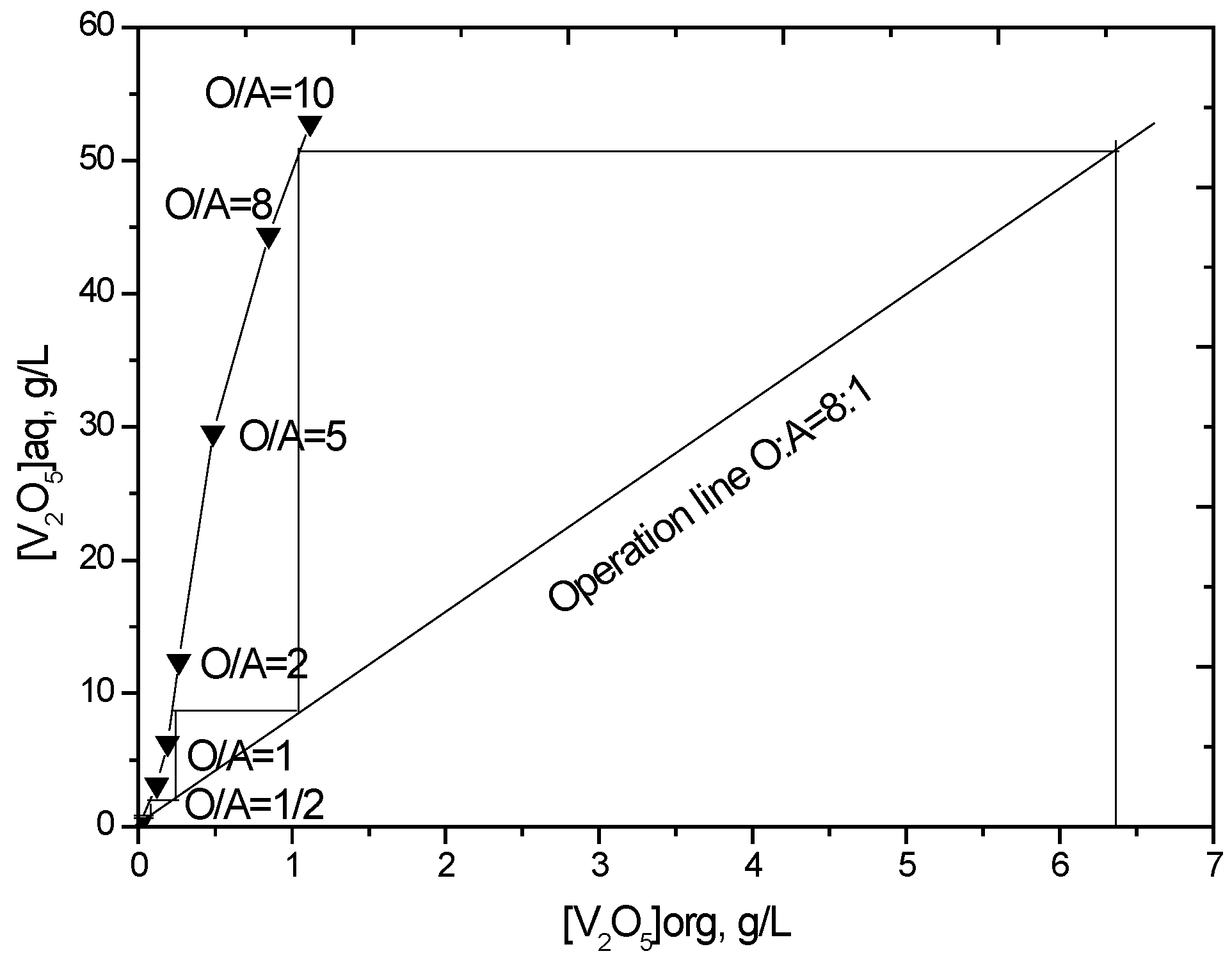

3.2.4. Stripping of Vanadium (IV)

3.2.5. Stripping Isotherm for Vanadium (IV)

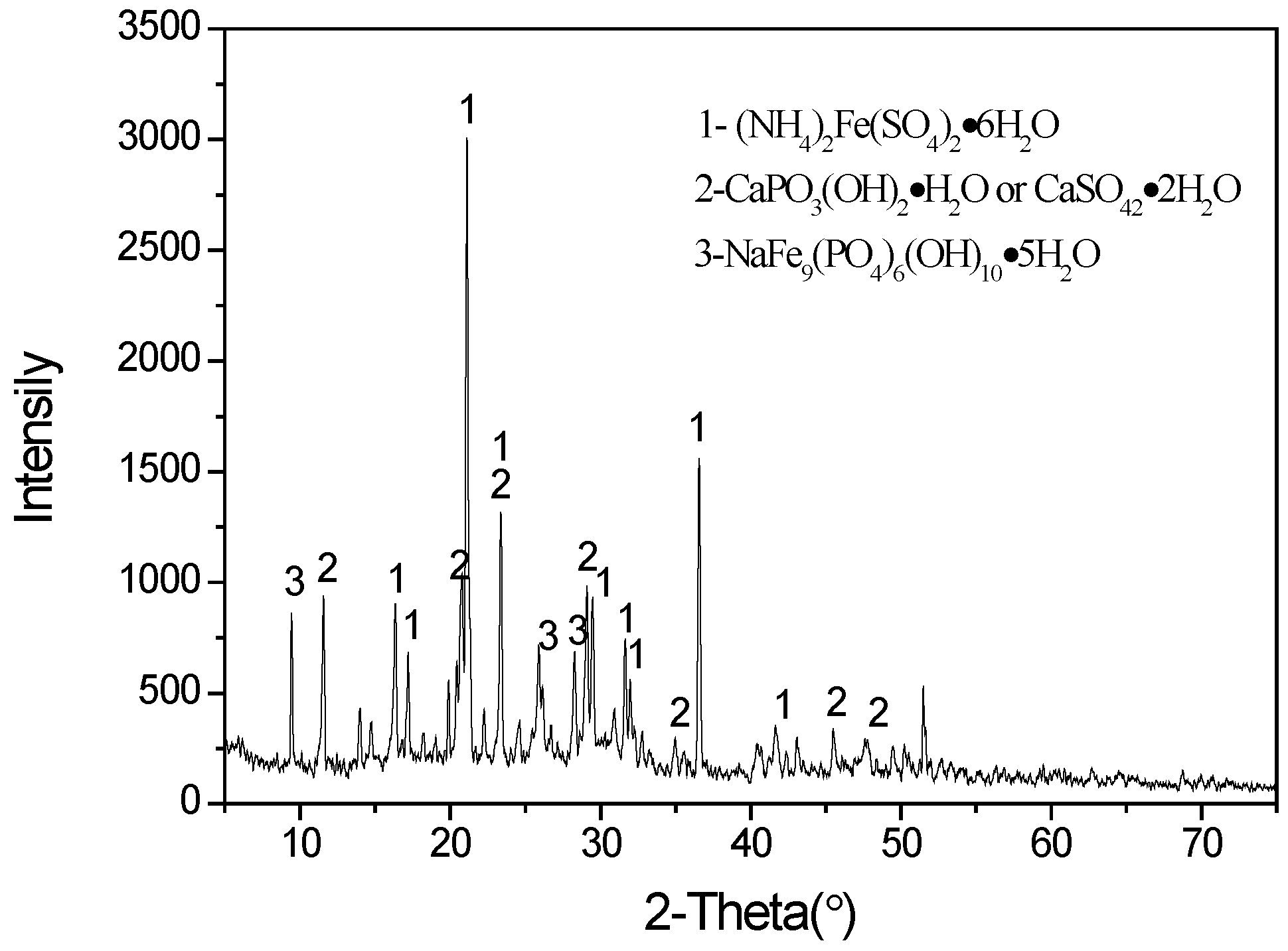

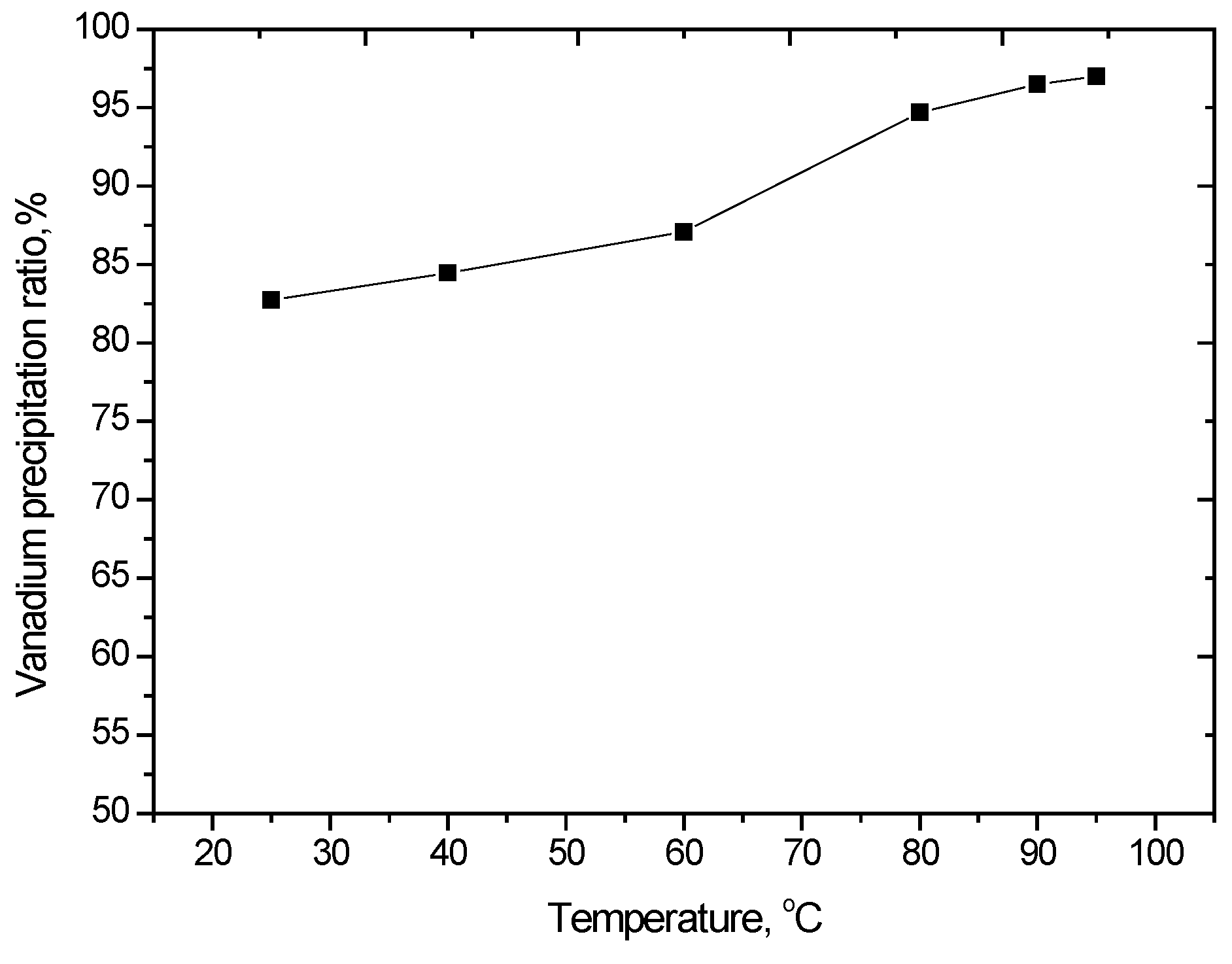

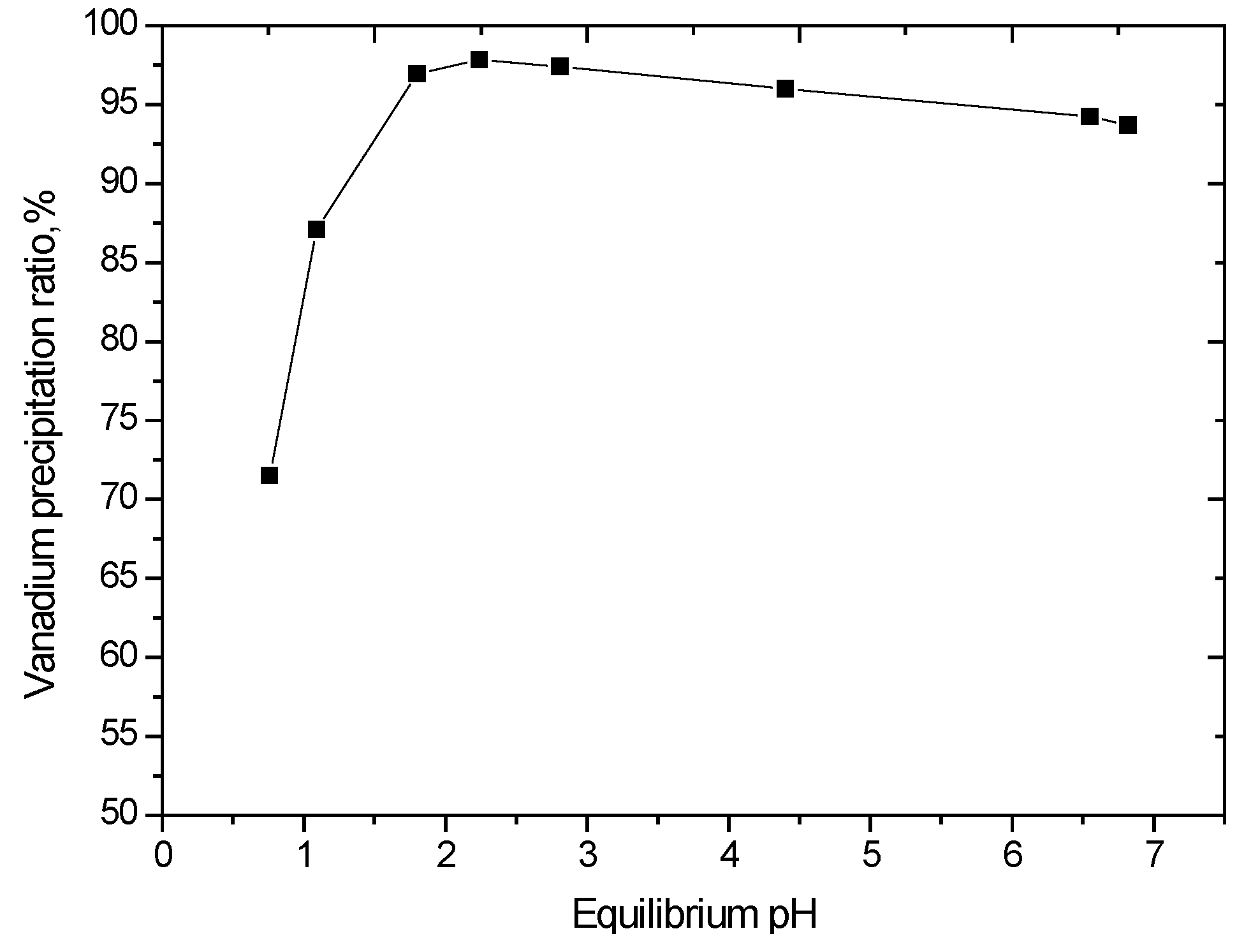

3.3. Oxidation and Precipitation

3.3.1. Oxidation

3.3.2. Precipitation

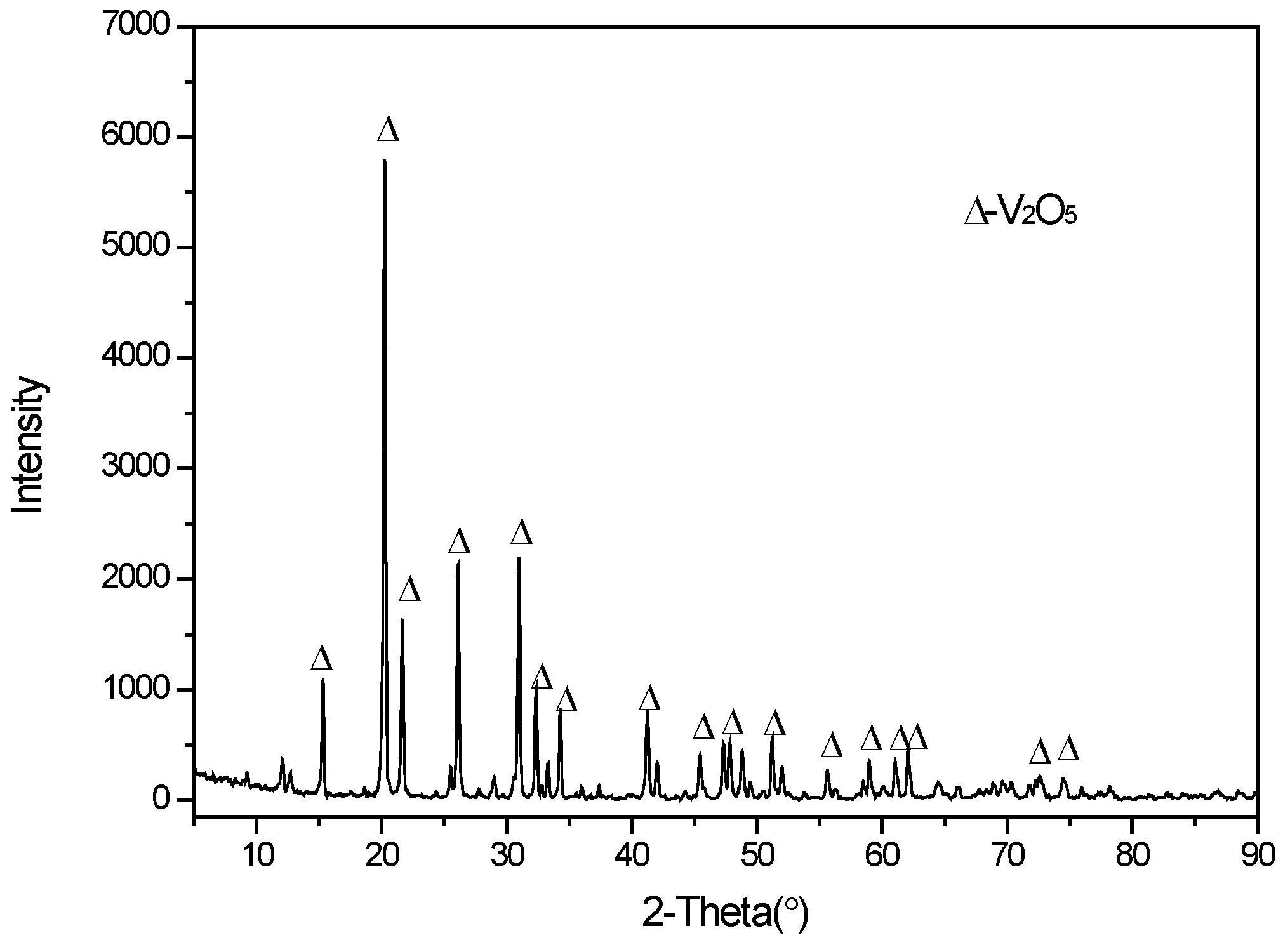

3.4. Calcination

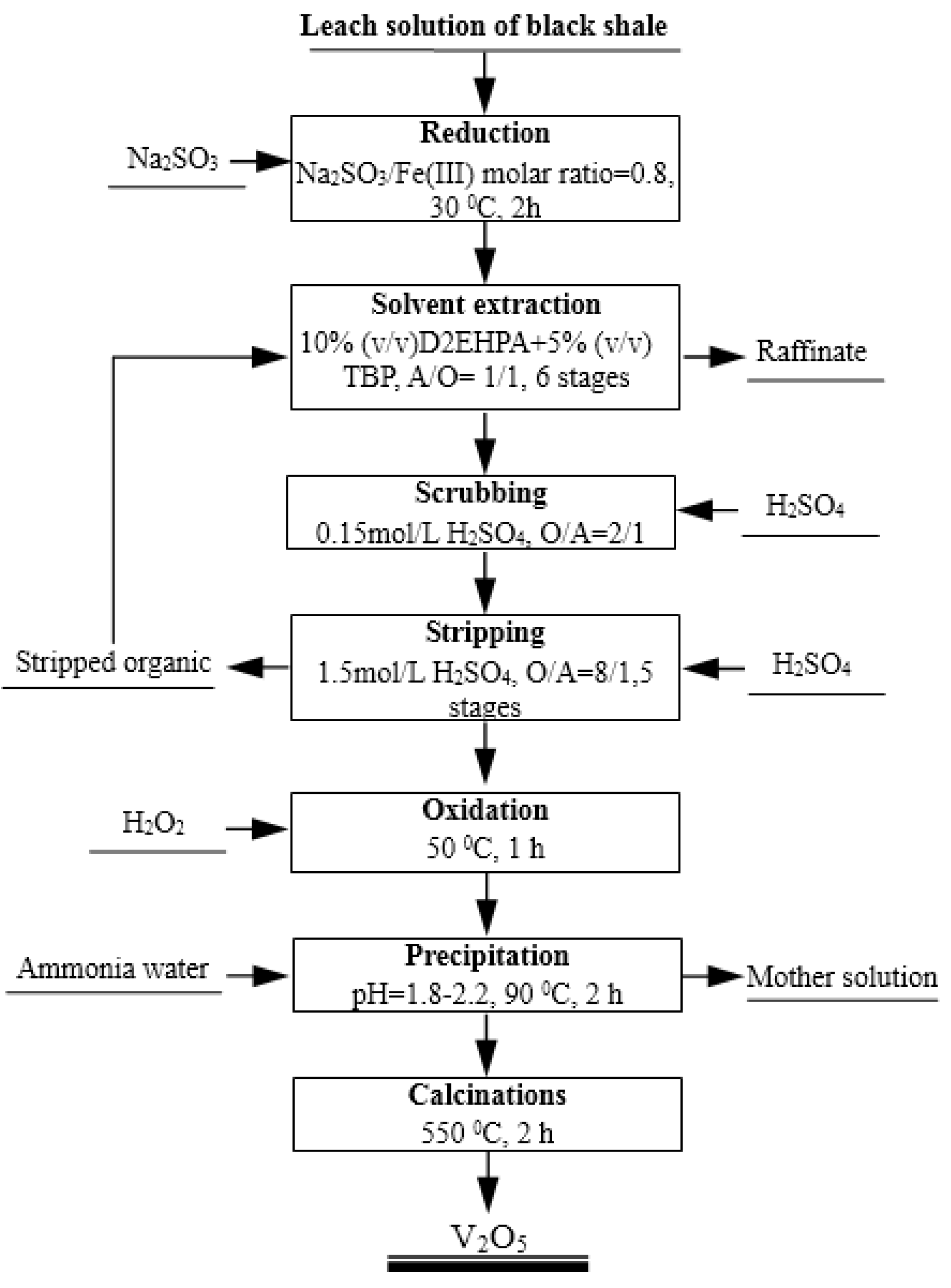

3.5. Development of a Process Flow Sheet to Recover Vanadium

4. Conclusions

- (1)

- A vanadium extraction efficiency of 96.7% was achieved using 10% (v/v) D2EHPA with 5% (v/v) TBP in sulfonated kerosene in six stages of counter-current extraction at an equilibrium pH of 2.5 and an O/A phase ratio of 1/1. Fluoride ions in the leaching solution had almost no effect on vanadium (IV) extraction.

- (2)

- 99.7% of the loaded vanadium was stripped from the organic phase by 1.5 mol/L H2SO4 in five counter-current stages at an O/A phase ratio of 8/1.

- (3)

- 98% of vanadium was precipitated as ammonium polyvanadate by oxidation and precipitation. Following calcination of the dried ammonium polyvanadate at 550 °C for 2 h, a high purity 99.52% V2O5 product was obtained.

- (4)

- A flow sheet for the extraction and recovery of vanadium from a H2SO4-HF mixed leach solution by solvent extraction and precipitation is proposed.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bin, Z. Progress of the research on extraction of vanadium pentoxide from stone coal and the market of V2O5. Hunan Nonferr. Met. 2006, 22, 16–20. (In Chinese) [Google Scholar]

- Cai, J. Development of vanadium extraction from stone coal. Rare Met. Cem. Carbides 2001, 144, 42–49. (In Chinese) [Google Scholar]

- Xu, L.; Lehmann, B.; Mao, J.; Nägler, T.F.; Neubert, N. Mo isotope and trace element patterns of lower Cambrian black shales in south China: Multi-proxy constrains on the paleoenvironment. Chem. Geol. 2012, 318–319, 45–59. [Google Scholar] [CrossRef]

- Pan, J.Y.; Ma, D.S.; Cao, S.L. Trace element geochemistry of the lower Cambrian black rock series from northwestern Hunan, south China. Prog. Nat. Sci. 2004, 14, 64–70. (In Chinese) [Google Scholar] [CrossRef]

- Pi, D.H.; liu, C.Q.; Zhou, G.A.; Jiang, S.Y. Trace and rare earth element geochemistry of black shale and kerogen in the early Cambrian Niutitang Formation in Guizhou province, south China: Constraints for redox environments and origin of metal enrichments. Precambr. Res. 2013, 225, 218–229. [Google Scholar] [CrossRef]

- Gupta, C.K.; Krishnamurthy, N. Extractive Metallurgy of Vanadium; Elsevier: Amsterdam, The Netherlands, 1992. [Google Scholar]

- Xu, G.Z. Guidance functions of vanadium valence and material composition in stone coal to extracting vanadium process. Coal Process. Compr. Util. 1989, 5, 5–8. (In Chinese) [Google Scholar]

- Guo, W.; Feng, Q.M.; Hu, C.P. Kinetics of vanadium oxidation during bone coal roasting in air. Rare Met. 1995, 14, 276–281. (In Chinese) [Google Scholar]

- Chen, T.; Qiu, G.; Zhu, D. Valence variation and oxidation kinetics of vanadium during vanadium-bearing stone coal roasting. Min. Metall. Eng. 2008, 28, 64–67. (In Chinese) [Google Scholar]

- Xu, G.; Ge, N.; Li, J. Valency study of vanadium in stone coal ash of Jiangxi province. J. China Univ. Geosci. 1990, 1, 122–130. (In Chinese) [Google Scholar]

- He, D.; Feng, Q.; Zhang, G.; Lu, Y. Mechanism of oxidizing roasting process of vanadium containing stone coal. Chin. J. Nonferr. Met. 2009, 19, 195–200. (In Chinese) [Google Scholar]

- Zhang, Y.M.; Bao, S.X.; Liu, T.; Chen, T.J.; Huang, J. The technology of extracting vanadium from stone coal in China: History, current status and future prospects. Hydrometallurgy 2011, 109, 116–124. [Google Scholar] [CrossRef]

- Lin, H.; Fan, B. Study on mechanism of phase transformation during roasting and extracting vanadium from Fangshankou stone coal. Chin. J. Rare Met. 2001, 25, 273–277. (In Chinese) [Google Scholar]

- Zhu, Y.; Zhang, G.; Feng, Q.; Lu, Y.; Ou, L.; Guang, S. Acid leaching of vanadium from roasted residue of stone coal. Trans. Nonferr. Met. Soc. China 2010, 20, s107–s111. [Google Scholar] [CrossRef]

- Jin, X.; Yang, C.; Zeng, G.; He, H.; Li, C.; Luo, Z.; Luo, S. Vanadium extraction technology from stone coal by oxidizing roasting-alkaline leaching method. Chin. J. Nonferr. Met. 2014, 24, 3177–3184. [Google Scholar]

- Li, M.; Wei, C.; Fan, G.; Li, C.; Deng, Z.; Li, X. Extraction of vanadium from black shale using pressure acid leaching. Hydrometallurgy 2009, 98, 308–313. [Google Scholar] [CrossRef]

- Dai, W.; Sun, S. Research on new process of vanadium extraction from stone coal by wet leaching. Hunan Nonferr. Met. 2009, 25, 22–25. (In Chinese) [Google Scholar]

- Deng, Z.; Wei, C.; Fan, G.; Li, M.; Li, C.; Li, X. Extracting vanadium from stone-coal by oxygen pressure acid leaching and solvent extraction. Trans. Nonferr. Met. Soc. China 2010, 20, s118–s122. [Google Scholar] [CrossRef]

- Li, C.; Wei, C.; Deng, Z.; Li, M.; Li, X.; Fan, G. Recovery of vanadium from black shale. Trans. Nonferr. Met. Soc. China 2010, 20, s127–s131. [Google Scholar] [CrossRef]

- Chen, X.; Lan, X.; Zhang, Q.; Ma, H.; Zhou, J. Leaching vanadium by high concentration sulfuric acid from stone coal. Trans. Nonferr. Met. Soc. China 2010, 20, s123–s126. [Google Scholar] [CrossRef]

- Li, M.; Wei, C.; Qiu, S.; Zhou, X.; Li, C.; Deng, Z. Kinetics of vanadium dissolution from black shale in pressure acid leaching. Hydrometallurgy 2010, 104, 193–200. [Google Scholar] [CrossRef]

- Li, M.; Wei, C.; Zhou, X.; Qiu, S.; Deng, Z.; Li, X. Kinetics of vanadium leaching from black shale in non-oxidative conditions. Miner. Process. Extr. Metall. Trans. Inst. Min. Metall. C 2012, 121, 40–47. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, X.; Li, C.; Li, J.; Liu, H.; We, S. Leaching of vanadium from carbonaceous shale. Hydrometallurgy 2009, 99, 97–99. [Google Scholar] [CrossRef]

- Li, M.; Wei, C.; Fan, G.; Wu, H.; Li, C.; Li, X. Acid leaching of black shale for the extraction of vanadium. Int. J. Miner. Process. 2010, 95, 62–67. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Yang, K.; Tian, X.D.; Qin, W.Q. Vanadium leaching from carbonaceous shale using fluosilicic acid. Int. J. Miner. Process. 2011, 100, 184–187. [Google Scholar] [CrossRef]

- Zeng, L.; Li, Q.; Xiao, L.; Zhang, Q. A study of the vanadium species in an acid leach solution of stone coal using ion exchange resin. Hydrometallurgy 2010, 105, 176–178. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Y.; Liu, T.; Huang, J.; Wang, Y. Comparison of ion exchange and solvent extraction in recovering vanadium from sulfuric acid leach solutions of stone coal. Hydrometallurgy 2013, 131–132, 1–7. [Google Scholar] [CrossRef]

- Tavakoli, M.R.; Dreisinger, D.B. Separation of vanadium from iron by solvent extraction using acidic and neutral organophosporus extractants. Hydrometallurgy 2014, 141, 17–23. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, G.; Wang, X.; Zhang, J. Solvent extraction of vanadium from sulfuric acid solution. Rare Met. 2009, 28, 209–211. (In Chinese) [Google Scholar] [CrossRef]

- Li, X.; Deng, Z.; Wei, C.; Li, C.; Li, M.; Fan, G.; Huang, H. Solvent extraction of vanadium from a stone coal acidic leach solution using D2EHPA/TBP: Continuous testing. Hydrometallurgy 2015, 154, 40–46. [Google Scholar] [CrossRef]

- Rakib, M.; Durand, G. Study of complex formation of vanadium (V) with sulphate ions using a solvent extraction method. Hydrometallurgy 1996, 43, 355–366. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, C.; Li, P.; Li, S. A new process of extracting vanadium from stone coal. Int. J. Miner. Metall. Mater. 2010, 17, 381–388. [Google Scholar] [CrossRef]

- Li, X.; Wei, C.; Deng, Z.; Li, M.; Li, C.; Fan, G. Selective solvent extraction of vanadium over iron from a stone coal/black shale acid leach solution by D2EHPA/TBP. Hydrometallurgy 2011, 105, 359–363. [Google Scholar] [CrossRef]

- GB/T 8704.5–2007; Ferrovanadium-Determination of Vanadium Content—The Ammonium Ferrous Sulfate Titrimetric Method and the Potentiometric Titrimetric Method, China; the People’s Republic of China ministry and Information Technology: Beijing, China, 2007.

- YB/T 5304–2011; Vanadium Peroxide; the People’s Republic of China ministry and Information Technology: Beijing, China, 2011.

- Cheng, C.Y. Purification of synthetic laterite leach solution by solvent extraction using D2EHPA. Hydrometallurgy 2000, 56, 369–386. [Google Scholar] [CrossRef]

| Component | Concentration (g/L) |

|---|---|

| V2O5 * | 6.75 |

| Fe(II) | 8.10 |

| Fe(III) | 5.30 |

| Al | 9.20 |

| As | 0.10 |

| Zn | 1.01 |

| Cu | 0.43 |

| Mg | 1.20 |

| Si | 0.50 |

| SO42− | 78.50 |

| P | 0.32 |

| F− | 15.0 |

| nR/nFe(III) | 0.2 | 0.4 | 0.6 | 0.8 | 1.0 |

|---|---|---|---|---|---|

| Percent of Fe (III) reduction, % | 67.2 | 80.8 | 94.1 | 99.8 | 99.9 |

| Percent of V (V) reduction, % | 96.5 | 99.2 | 99.8 | 100 | 100 |

| Component | V2O5 | Fe | Al | As | Zn | Cu | Mg |

|---|---|---|---|---|---|---|---|

| Concentration (g/L) | 0.222 | 13.0 | 9.0 | 0.93 | 0.93 | 0.41 | 1.15 |

| Component (%) | V2O5 | Si | Fe | P | S | As | K2O + Na2O | |

|---|---|---|---|---|---|---|---|---|

| Product | 99.52 | 0.005 | 0.08 | 0.01 | 0.007 | 0.006 | 0.15 | |

| YB/T 5304-2011 | V2O5 99 | ≥99.0 | ≤0.20 | ≤0.20 | ≤0.03 | ≤0.01 | ≤0.01 | ≤1.0 |

| V2O5 98 | ≥98.0 | ≤0.25 | ≤0.30 | ≤0.05 | ≤0.03 | ≤0.02 | ≤1.5 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wei, C.; Deng, Z.; Li, C.; Fan, G.; Li, M.; Huang, H. Recovery of Vanadium from H2SO4-HF Acidic Leaching Solution of Black Shale by Solvent Extraction and Precipitation. Metals 2016, 6, 63. https://doi.org/10.3390/met6030063

Li X, Wei C, Deng Z, Li C, Fan G, Li M, Huang H. Recovery of Vanadium from H2SO4-HF Acidic Leaching Solution of Black Shale by Solvent Extraction and Precipitation. Metals. 2016; 6(3):63. https://doi.org/10.3390/met6030063

Chicago/Turabian StyleLi, Xingbin, Chang Wei, Zhigan Deng, Cunxiong Li, Gang Fan, Minting Li, and Hui Huang. 2016. "Recovery of Vanadium from H2SO4-HF Acidic Leaching Solution of Black Shale by Solvent Extraction and Precipitation" Metals 6, no. 3: 63. https://doi.org/10.3390/met6030063

APA StyleLi, X., Wei, C., Deng, Z., Li, C., Fan, G., Li, M., & Huang, H. (2016). Recovery of Vanadium from H2SO4-HF Acidic Leaching Solution of Black Shale by Solvent Extraction and Precipitation. Metals, 6(3), 63. https://doi.org/10.3390/met6030063