Investigation on Hot Deformation Behavior and Hot Processing Map of BSTMUF601 Super-Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

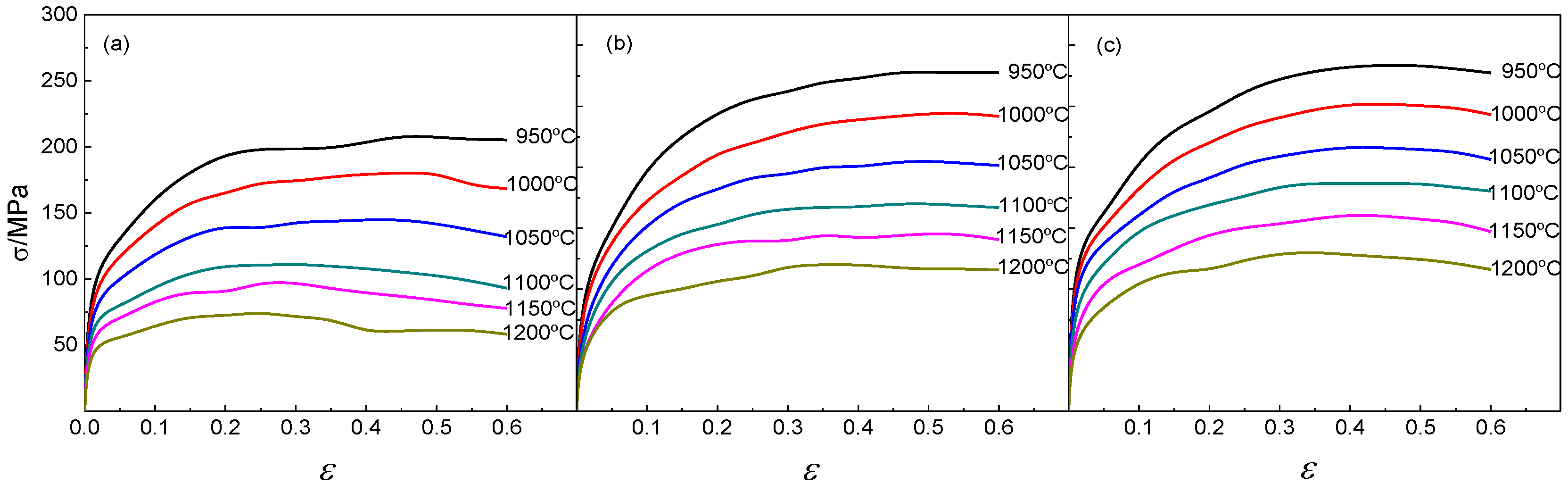

3.1. Flow Stress-Strain Curves

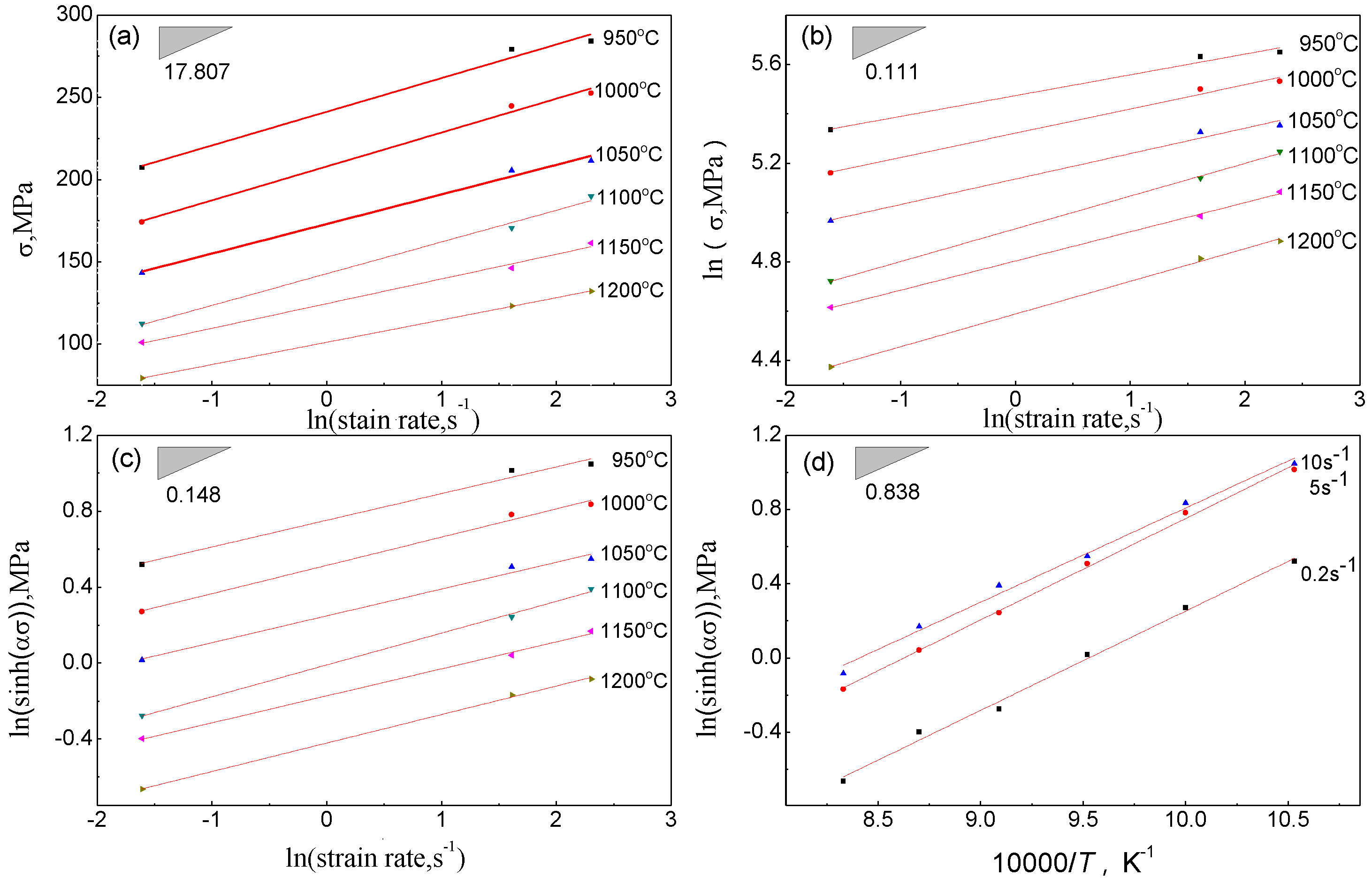

3.2. Constitutive Model of Peak Stress

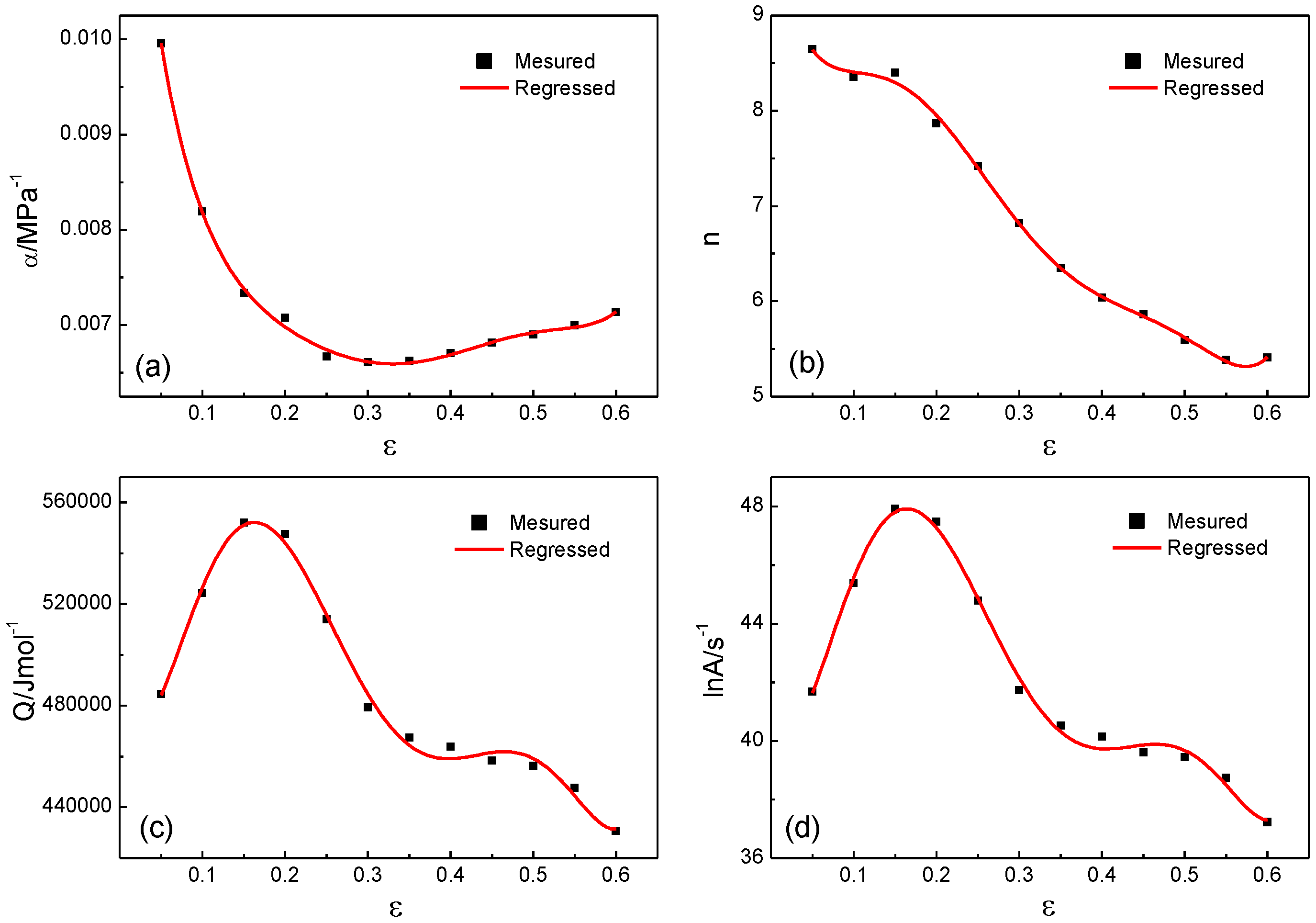

3.3. Unified Constitutive Model

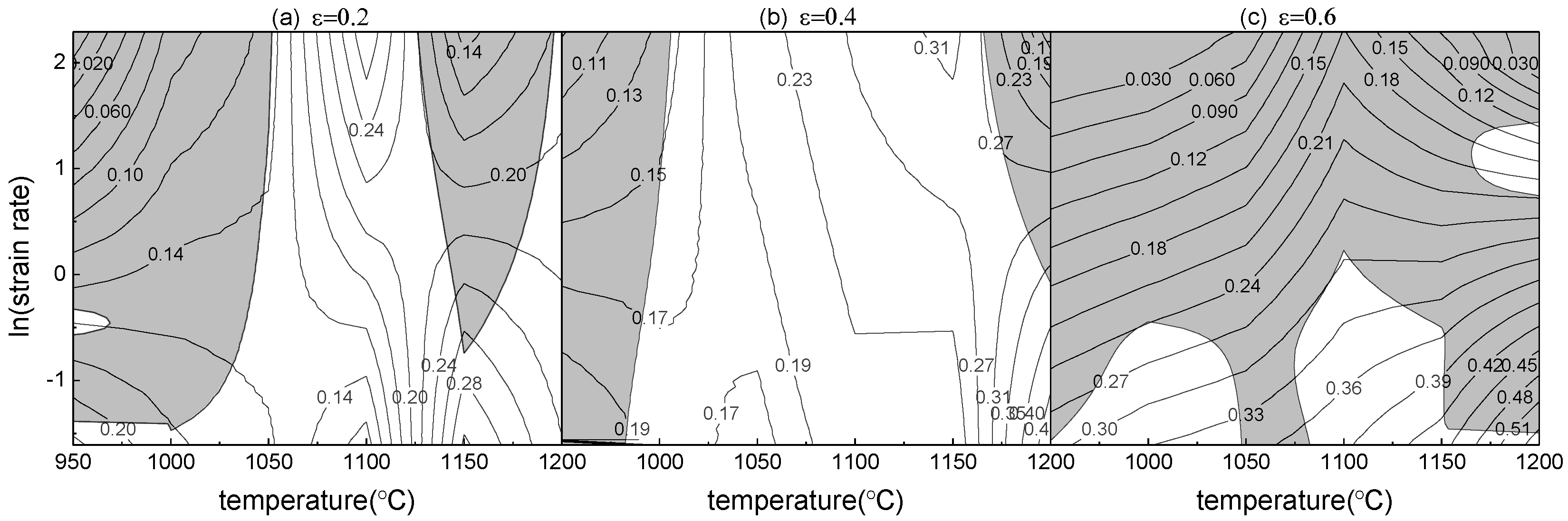

4. Hot Processing Map

4.1. Approach Processing Map

4.2. Processing Map of BSTMUF601 Super-Alloy

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ye, N.W.; Lv, X.B.; Sun, C.Y. Research and application about muffle material for bright annealing of grand stainless strip. Heavy Mach. 2013, 3, 37–41. [Google Scholar]

- Sun, C.Y.; Shi, B.; Wu, C.B.; Ye, N.W.; Ma, T.J.; Xu, W.L.; Yang, J. High temperature creep deformation mechanism of BSTMUF601 super-alloy. Acta Metall. Sin. 2015, 51, 349–356. [Google Scholar]

- Sun, C.Y.; Chen, G.C.; Wu, C.B.; Xu, W.L.; Ma, T.J.; Yang, J. High temperature oxidation behavior of typical Nickel-based super-alloys. Corros. Sci. Prot. Technol. 2014, 26, 345–349. [Google Scholar]

- Pan, Q.L.; Li, B.; Wang, Y.; Zhang, Y.W.; Yin, Z.M. Characterization of hot deformation behavior of Ni-base super-alloy Rene’41 using processing map. Mater. Sci. Eng. A 2013, 585, 371–378. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Shen, W.; Li, M.F.; Gu, S.D. Characterization of hot deformation behavior of hastelloy C-276 using constitutive equation and processing map. J. Mater. Eng. Perform. 2015, 24, 149–157. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Q.D.; Ye, B.; Guo, W. Hot deformation and processing maps of as-extruded Mg–9.8Gd–2.7Y–0.4Zr Mg alloy. Mater. Sci. Eng. A 2013, 576, 101–107. [Google Scholar] [CrossRef]

- Li, H.Z.; Wang, H.J.; Liang, X.P.; Liu, H.T.; Liu, Y.; Zhang, X.M. Hot deformation and processing map of 2519A aluminum alloy. Mater. Sci. Eng. A 2011, 528, 1548–1552. [Google Scholar] [CrossRef]

- Sun, C.Y.; Liu, G.; Zhang, Q.D.; Li, R.; Wang, L. Determination of hot deformation behavior and processing maps of IN 028 alloy using isothermal hot compression test. Mater. Sci. Eng. A 2014, 595, 92–98. [Google Scholar] [CrossRef]

- Guo, H.Z.; Zhang, W.; Zhao, Z.L.; Yao, Z.K. The super plastic tensile deformation behavior and structure evolution of new type titanium alloy-TC21. Rare Metal Mater. Eng. 2005, 34, 1935–1939. [Google Scholar]

- Taylor, A.S.; Hodgson, P.D. Dynamic behavior of 304 stainless steel during high deformation. Mater. Sci. Eng. A 2011, 528, 3310–3320. [Google Scholar] [CrossRef]

- Zhang, W.F.; Li, X.L.; Sha, W.; Wang, W.; Shan, Y.Y. Hot deformation characteristics of a nitride strengthened martensitic heat resistant steel. Mater. Sci. Eng. A 2014, 590, 199–208. [Google Scholar] [CrossRef]

- Sellars, C.M.; Tegart, W.J.M. Hot workability. Int. Mater. Rev. 1971, 17, 1–24. [Google Scholar] [CrossRef]

- Sun, C.Y.; Luan, J.D.; Liu, G.; Li, R.; Zhang, Q.D. Predicted constitutive modeling of hot deformation for AZ31 magnesium alloy. Acta Metall. Sin. 2012, 48, 853–860. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Cabrera, J.M.; Prado, J.M.; Najafizadeh, A. Hot deformation behavior of a medium carbon microalloyed steel. Mater. Sci. Eng. A 2011, 528, 3876–3882. [Google Scholar] [CrossRef]

- Sun, C.Y.; Liu, J.R.; Li, R.; Zhang, Q.D. Constitutive modeling for elevate temperature flow behavior of Incoloy 800H superalloy. Acta Metall. Sin. 2011, 47, 191–196. [Google Scholar]

- Sun, C.Y.; Liu, J.R.; Li, R.; Zhang, Q.D. Effect of process parameters on the exit temperature of IN690 alloy tubes during hot extrusion. J. Univ. Sci. Technol. B 2010, 32, 1483–1488. [Google Scholar]

- Zeng, W.D.; Zhou, Y.G.; Zhou, J.; Yu, H.Q. Recent development of processing map theory. Rare Metal Mater. Eng. 2006, 35, 673–677. [Google Scholar]

- Wang, L.; Liu, F.; Cheng, J.J.; Zuo, Q.; Chen, C.F. Hot deformation characteristics and processing map analysis for Nickel-based corrosion resistant alloy. J. Alloy. Compd. 2015, 623, 69–78. [Google Scholar] [CrossRef]

- Kong, Y.P.; Chang, Q.P.; Li, Q.; Xie, L.X.; Zhu, S.G. Hot deformation characteristics and processing map of nickel-based C276 superalloy. J. Alloy. Compd. 2015, 622, 738–744. [Google Scholar] [CrossRef]

- Robi, P.S.; Dixit, U.S. Application of neural networks in generating processing map for hot working. J. Mater. Process. Technol. 2003, 142, 289–294. [Google Scholar] [CrossRef]

- Li, M.Q.; Li, X.L.; Li, L.; Xu, G.X. Deformation behavior and processing map of high temperature deformation of TA15 alloy. Rare Metal Mater. Eng. 2006, 35, 1354–1358. [Google Scholar]

- Prasad, Y.V.R.K. Processing maps: A status report. J. Mater. Eng. Perform. 2003, 12, 638–645. [Google Scholar] [CrossRef]

| C | Si | Mn | S | P | Cr | Fe | Ni |

|---|---|---|---|---|---|---|---|

| 0.013 | 0.02 | 0.21 | 0.002 | 0.005 | 29.19 | 9.49 | balance |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, C.; Zuo, X.; Xiang, Y.; Yang, J. Investigation on Hot Deformation Behavior and Hot Processing Map of BSTMUF601 Super-Alloy. Metals 2016, 6, 70. https://doi.org/10.3390/met6030070

Sun C, Zuo X, Xiang Y, Yang J. Investigation on Hot Deformation Behavior and Hot Processing Map of BSTMUF601 Super-Alloy. Metals. 2016; 6(3):70. https://doi.org/10.3390/met6030070

Chicago/Turabian StyleSun, Chaoyang, Xun Zuo, Yu Xiang, and Jing Yang. 2016. "Investigation on Hot Deformation Behavior and Hot Processing Map of BSTMUF601 Super-Alloy" Metals 6, no. 3: 70. https://doi.org/10.3390/met6030070

APA StyleSun, C., Zuo, X., Xiang, Y., & Yang, J. (2016). Investigation on Hot Deformation Behavior and Hot Processing Map of BSTMUF601 Super-Alloy. Metals, 6(3), 70. https://doi.org/10.3390/met6030070