Forge-Hardened TiZr Null-Matrix Alloy for Neutron Scattering under Extreme Conditions

Abstract

:1. Introduction

2. Experimental Methods

| Composition wt. % | |||||||

|---|---|---|---|---|---|---|---|

| Zr | C | Al | B | O | N | Fe | Ti * |

| 47.1 | 0.008 | 0.01 | <0.01 | 0.053 | 0.004 | 0.03 | 52.8 |

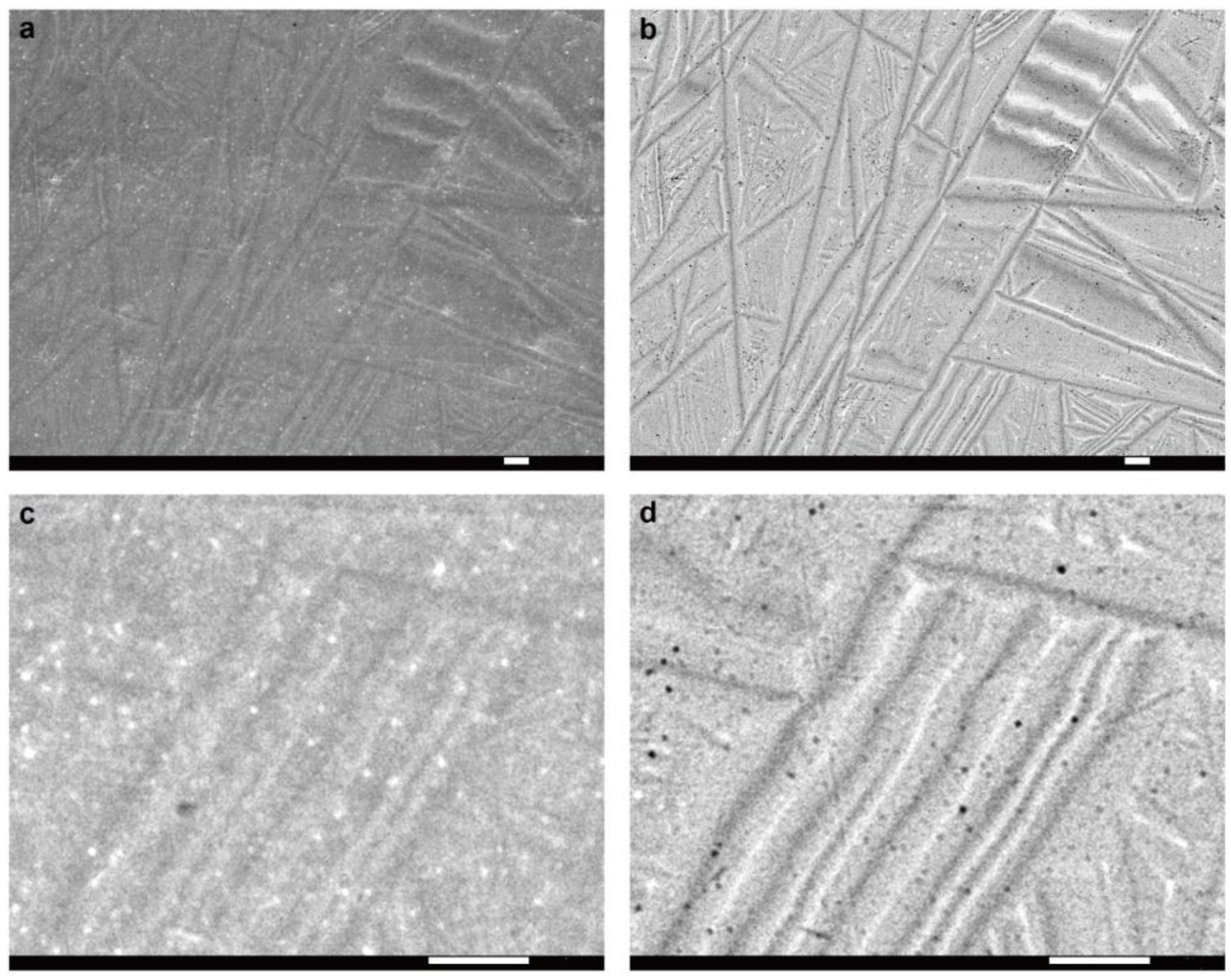

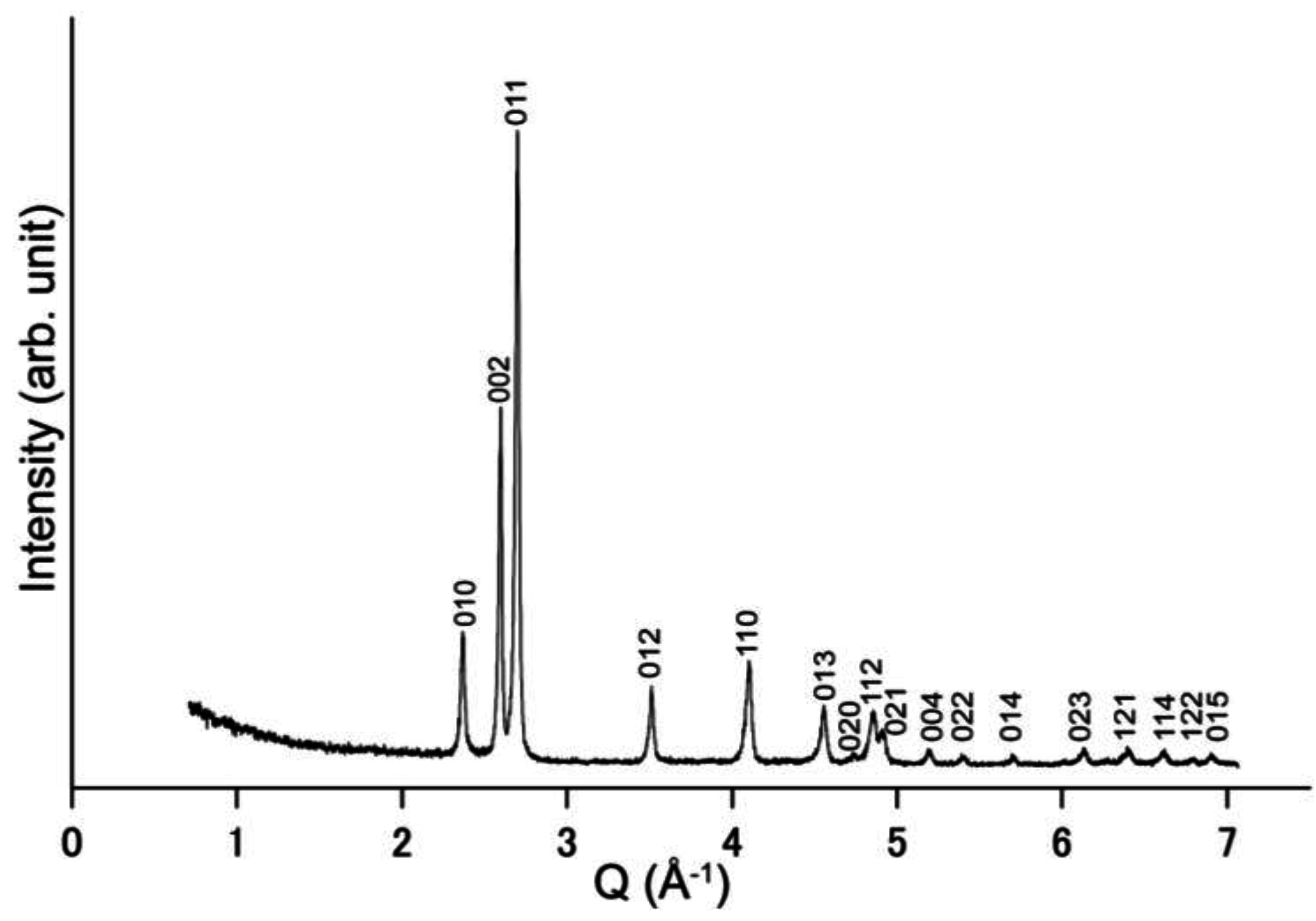

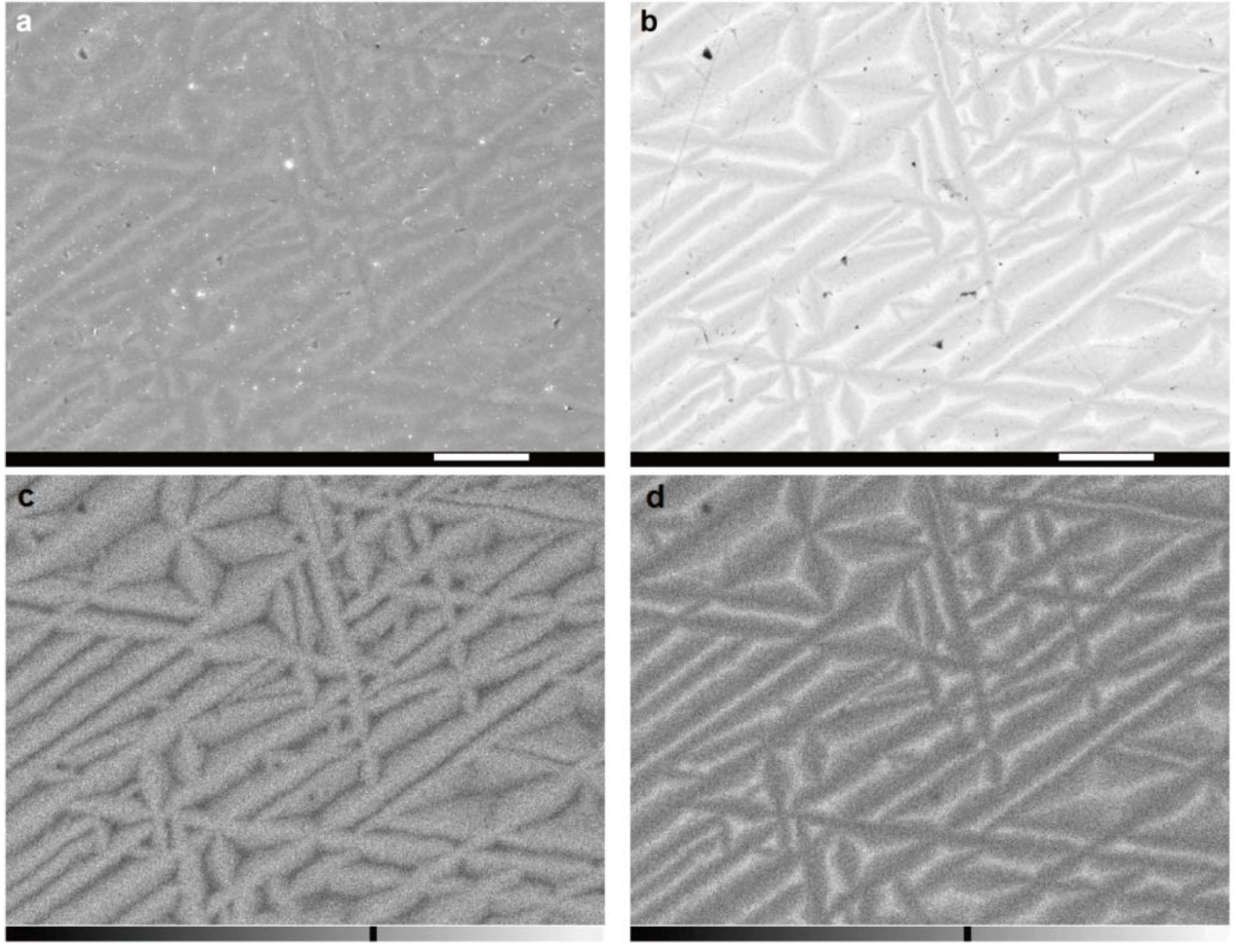

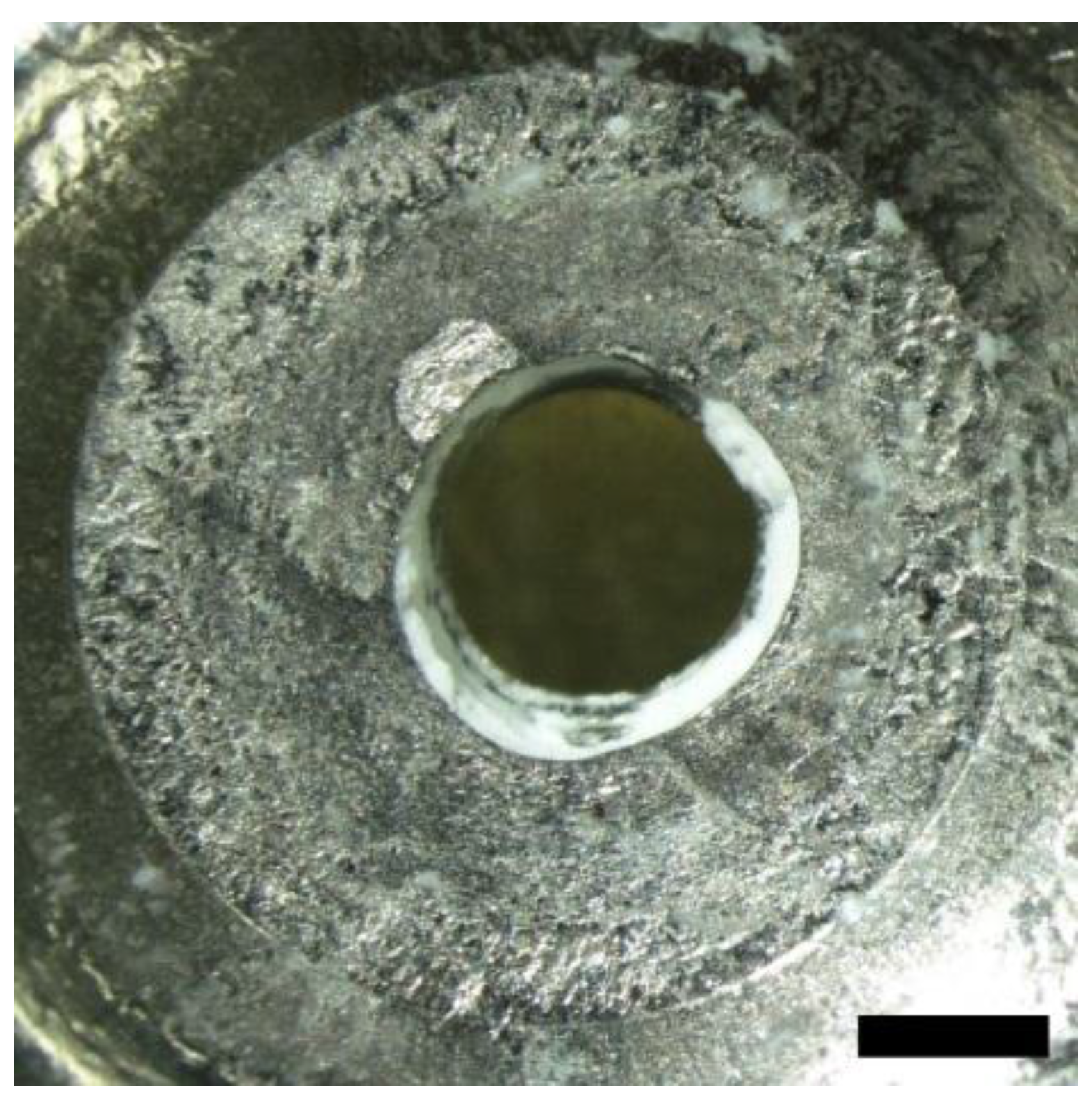

3. Results and Discussion

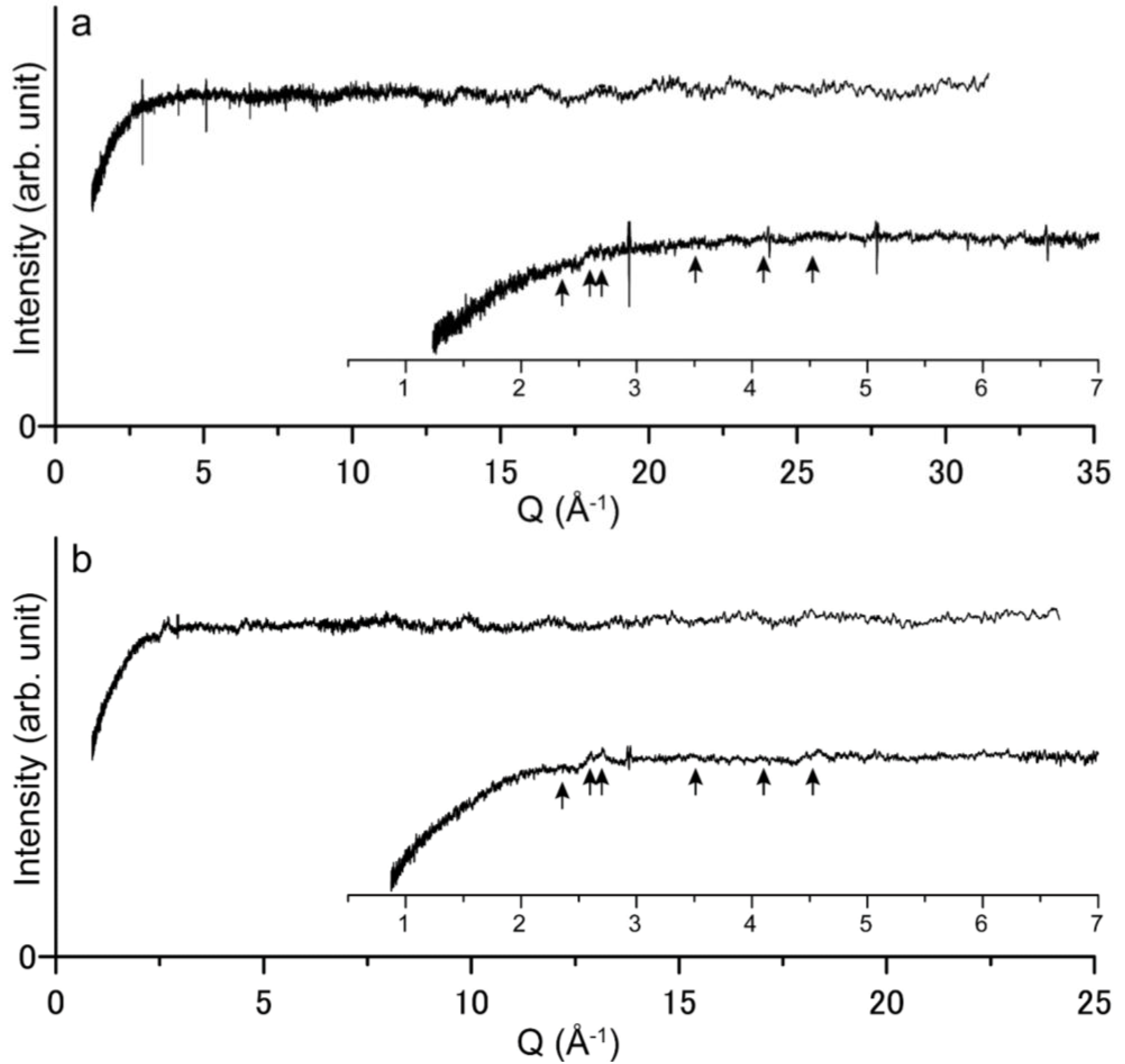

4. Application of the f-TiZr Alloy

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Klotz, S. Techniques in High Pressure Neutron Scattering; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Smith, J.H.; Vance, E.R.; Wheeler, D.A. A null-matrix alloy for neutron diffraction. J. Phys. E Sci. Instrum. 1968, 1, 945–947. [Google Scholar] [CrossRef]

- Sidhu, S.S.; Heaton, L.; Zauberis, D.D.; Campos, F.P. Neutron diffraction study of titanium-zirconium system. J. Appl. Phys. 1956, 27, 1040–1042. [Google Scholar] [CrossRef]

- Besson, J.M.; Nelmes, R.J.; Hamel, G.; Loveday, J.S.; Weill, G.; Hull, S. Neutron powder diffraction above 10 GPa. Phys. B Condens. Matter 1992, 180–181, 907–910. [Google Scholar] [CrossRef]

- Klotz, S.; Besson, J.M.; Hamel, G.; Nelmes, R.J.; Loveday, J.S.; Marshall, W.G.; Wilson, R.M. Neutron powder diffraction at pressures beyond 25 GPa. Appl. Phys. Lett. 1995, 66, 1735–1737. [Google Scholar] [CrossRef]

- Xu, J.; Ding, Y.; Jacobsen, S.D.; Mao, H.K.; Hemley, R.J.; Zhang, J.; Qian, J.; Pantea, C.; Vogel, S.C.; Williams, D.J.; et al. Powder neutron diffraction of wustite (Fe0.93O) to 12 GPa using large moissanite anvils. High Press. Res. 2004, 24, 247–253. [Google Scholar] [CrossRef]

- Williams, D.N.; Wood, R.A.; Jaffee, R.I.; Ogden, H.R. The effects of zirconium in titanium-base alloys. J. Less Common Met. 1964, 6, 219–225. [Google Scholar] [CrossRef]

- Zeidler, A.; Guthrie, M.; Salmon, P.S. Pressure-dependent structure of the null-scattering alloy Ti0.676Zr0.324. High Press. Res. 2005, 35, 239–246. [Google Scholar] [CrossRef] [Green Version]

- Imgram, A.G.; Williams, D.N.; Ogden, H.R. Tensile properties of binary titanium-zirconium and titanium-hafnium alloys. J. Less Common Met. 1962, 4, 217–225. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2005, 51, 427–556. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Blacktop, J.; Crangle, J.; Argent, B.B. The α → β transformation in the Ti–Zr system and the influence of additions of up to 50 at. % Hf. J. Less Common Met. 1985, 109, 375–380. [Google Scholar] [CrossRef]

- Ishigaki, T.; Hoshikawa, A.; Yonemura, M.; Morishima, T.; Kamiyama, T.; Oishi, R.; Aizawa, K.; Sakuma, T.; Tomota, Y.; Arai, M.; et al. IBARAKI materials design diffractometer (iMATERIA)—Versatile neutron diffractometer at J-PARC. Nucl. Instrum. Meth. A 2009, 600, 189–191. [Google Scholar] [CrossRef]

- Hall, E.O. Yield Point Phenomena in Metals and Alloys; Plenum Press: New York, NY, USA, 1970; p. 316. [Google Scholar]

- Herebtsov, S.; Lojkowski, W.; Mazurb, A.; Salishcheva, G. Structure and properties of hydrostatically extruded commercially pure titanium. Mater. Sci. Eng. A 2010, 527, 5596–5603. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Galeev, R.M.; Malysheva, S.P.; Zherebtsov, S.V.; Mironov, S.Y.; Valiakhmetov, O.R.; Ivanisenko, E.I. Formation of submicrocrystalline structure in titanium and titanium alloys and their mechanical properties. Met. Sci. Heat Treat. 2006, 48, 63–69. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Alexandrov, I.V. Paradox of strength and ductility in metals processed by severe plastic deformation. J. Mater. Res. 2002, 17, 5–8. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Tanaka, Y.; Matsuoka, K.; Kinoshita, K.; Miyamoto, Y.; Murata, H. Effect of forging ratio and grain size on tensile and fatigue strength of pure titanium forgings. J. Soc. Mater. Sci. Jpn. 2005, 54, 66–72. [Google Scholar] [CrossRef]

- Kobayashi, E.; Matsumoto, S.; Doi, H.; Yoneyama, T.; Hamanaka, H. Mechanical properties of the binary titanium-zirconium alloys and their potential for biomedical materials. J. Biomed. Mater. Res. 1995, 29, 943–950. [Google Scholar] [CrossRef] [PubMed]

- Dobromyslov, A.V.; Taluts, N.I. Structure investigation of quenched and tempered alloys of the Zr–Ti system. Phys. Met. Metallogr. 1987, 63, 114–120. [Google Scholar]

- Okuchi, T.; Sasaki, S.; Ohno, Y.; Abe, J.; Arima, H.; Osakabe, T.; Hattori, T.; Sano-Furukawa, A.; Komatsu, K.; Kagi, H.; et al. Neutron powder diffraction of small-volume samples at high pressure using compact opposed-anvil cells and focused beam. J. Phys. Conf. Ser. 2012. [Google Scholar] [CrossRef]

- Okuchi, T.; Yoshida, M.; Ohno, Y.; Tomioka, N.; Purevjav, N.; Osakabe, T.; Harjo, S.; Abe, J.; Aizawa, K.; Sasaki, S. Pulsed neutron powder diffraction at high pressure by a capacity-increased sapphire anvil cell. High Press. Res. 2013, 33, 777–786. [Google Scholar] [CrossRef]

- Okuchi, T.; Tomioka, N.; Purevjav, N.; Abe, J.; Harujo, S.; Gong, W. Structure refinement of sub-cubic-mm volume sample at high pressures by pulsed neutron powder diffraction: Application to brucite in an opposed anvil cell. High Press. Res. 2014, 34, 273–280. [Google Scholar] [CrossRef]

- Purevjav, N.; Okuchi, T.; Tomioka, N.; Abe, J.; Harjo, S. Hydrogen site analysis of hydrous ringwoodite in mantle transition zone by pulsed neutron diffraction. Geophys. Res. Lett. 2014, 41, 6718–6724. [Google Scholar] [CrossRef]

- Tomioka, N.; Okuchi, T.; Purevjav, N.; Abe, J.; Harjo, S. Hydrogen sites in the dense hydrous magnesian silicate phase E: A pulsed-neutron powder diffraction study. Phys. Chem. Miner. in press.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okuchi, T.; Hoshikawa, A.; Ishigaki, T. Forge-Hardened TiZr Null-Matrix Alloy for Neutron Scattering under Extreme Conditions. Metals 2015, 5, 2340-2350. https://doi.org/10.3390/met5042340

Okuchi T, Hoshikawa A, Ishigaki T. Forge-Hardened TiZr Null-Matrix Alloy for Neutron Scattering under Extreme Conditions. Metals. 2015; 5(4):2340-2350. https://doi.org/10.3390/met5042340

Chicago/Turabian StyleOkuchi, Takuo, Akinori Hoshikawa, and Toru Ishigaki. 2015. "Forge-Hardened TiZr Null-Matrix Alloy for Neutron Scattering under Extreme Conditions" Metals 5, no. 4: 2340-2350. https://doi.org/10.3390/met5042340