In Situ High-Energy X-ray Diffraction during Hot-Forming of a Multiphase TiAl Alloy

Abstract

:1. Introduction

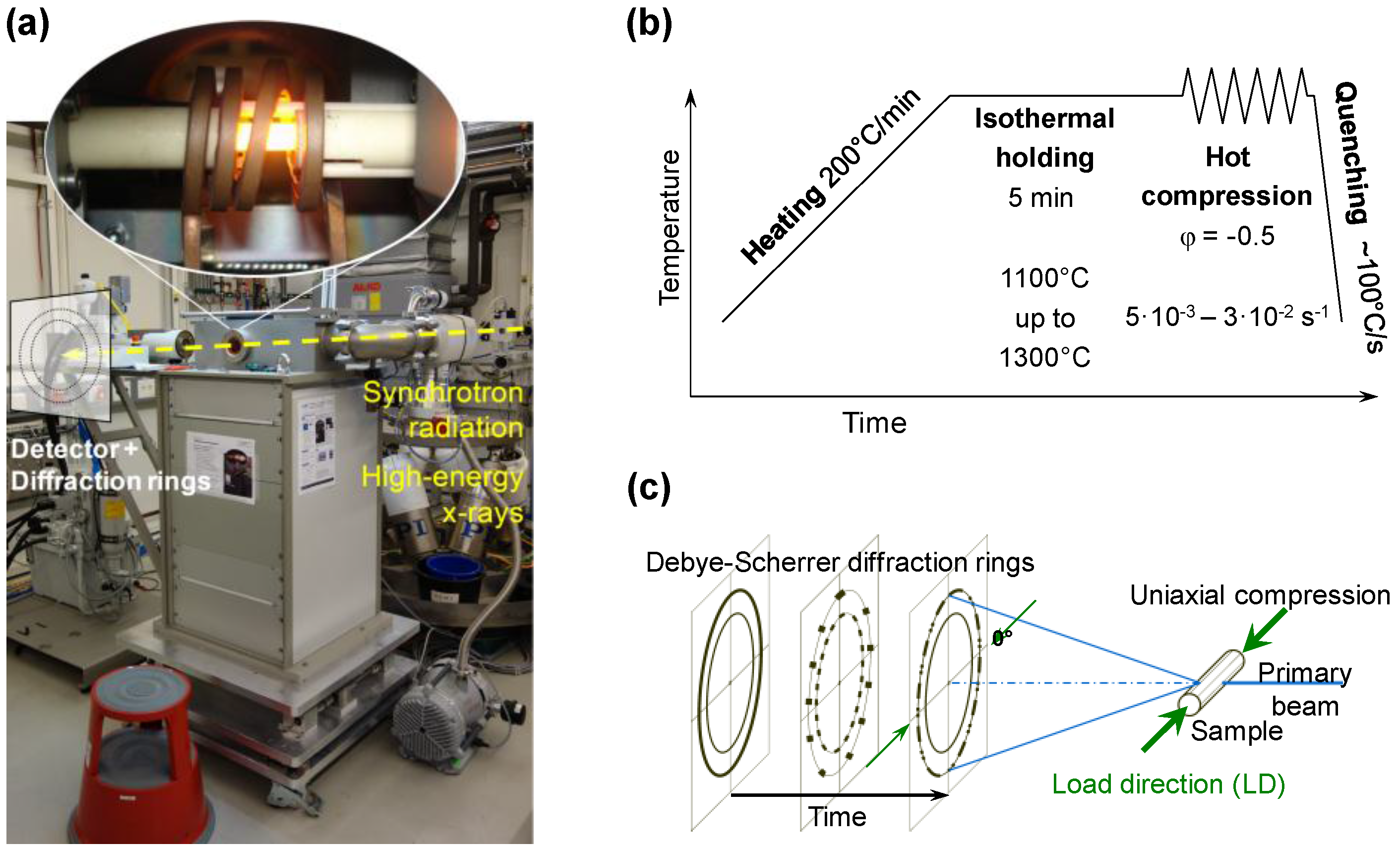

2. Experimental Section

3. Results and Discussion

3.1. Development of Phase Constitution with Temperature for Ti-42Al-8.5Nb

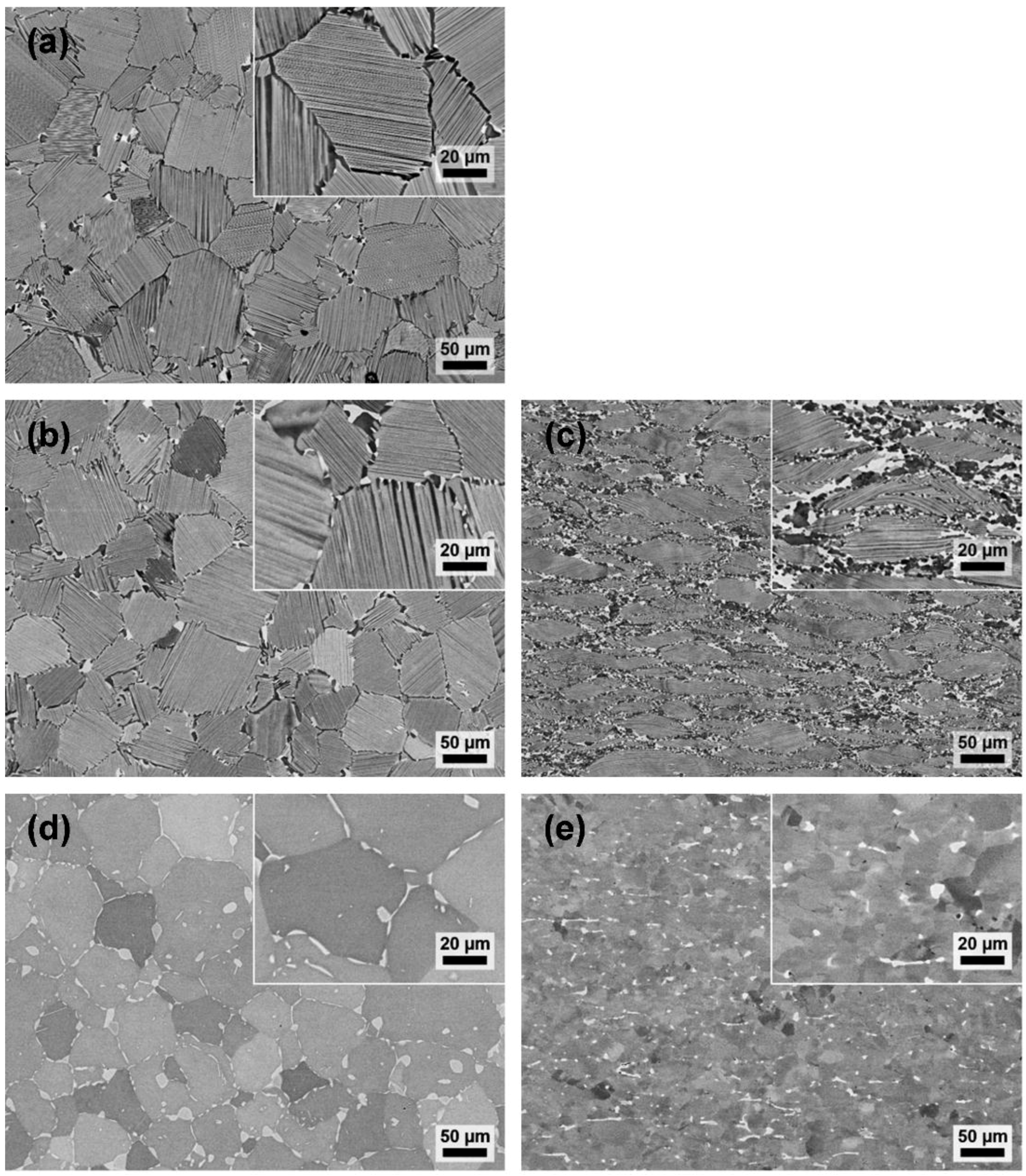

3.2. Microstructures before and after Deformation

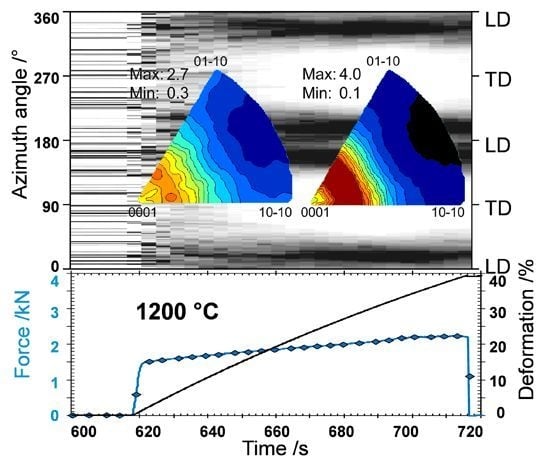

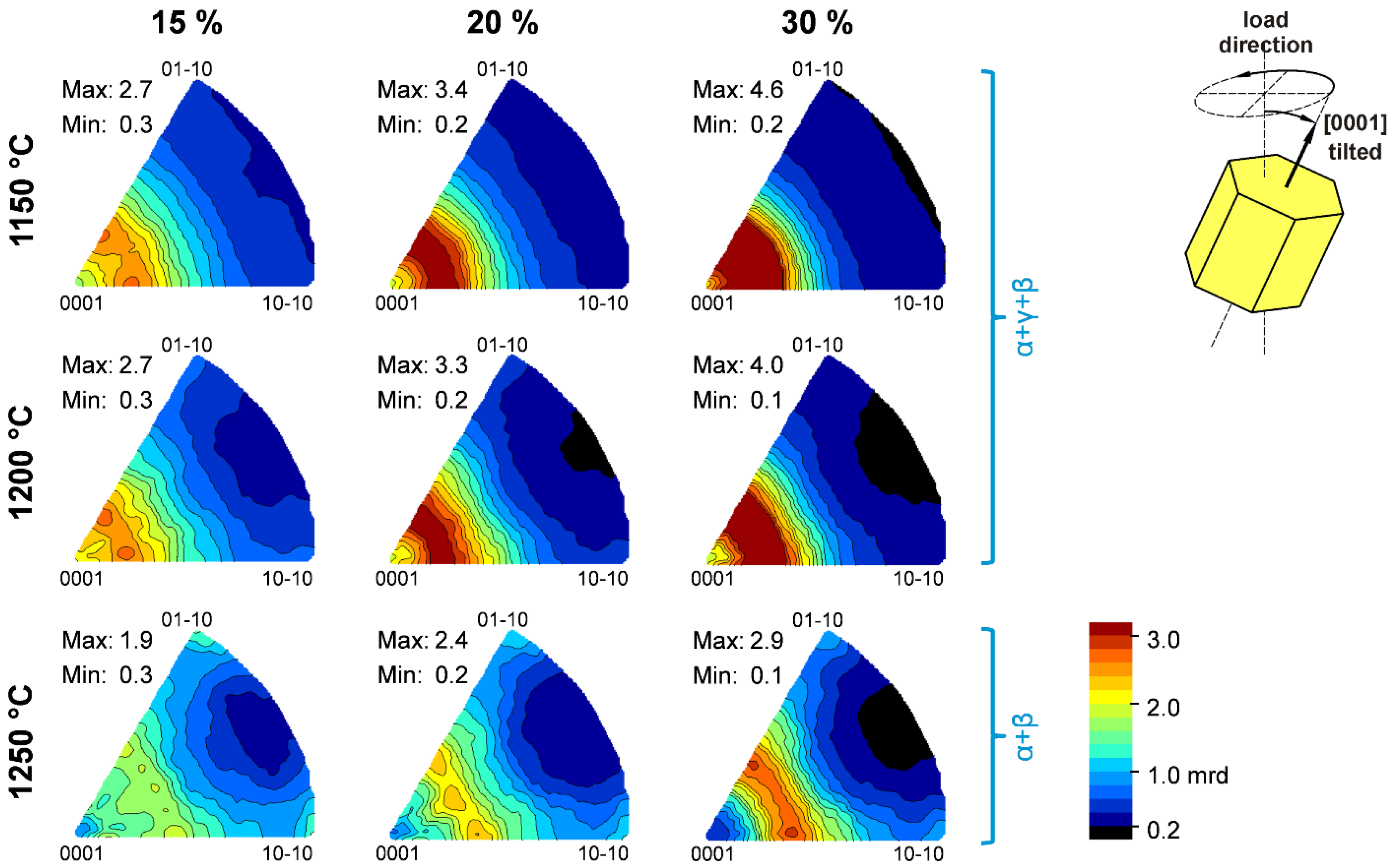

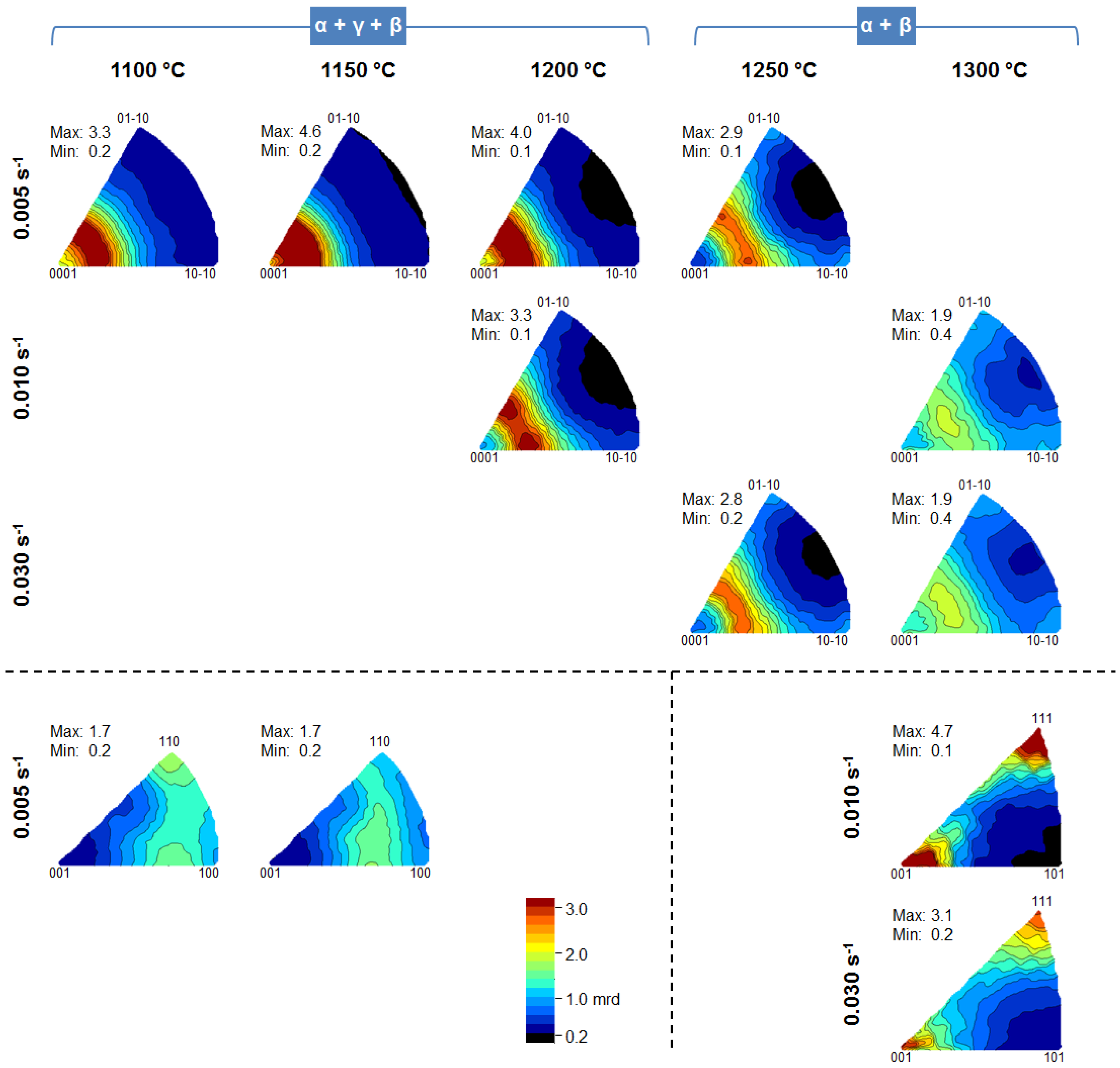

3.3. Texture Formation

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Bewlay, B.P.; Weimer, M.; Kelly, T.; Suzuki, A.; Subramanian, P.R. The Science, Technology, and Implementation of TiAl Alloys in Commercial Aircraft Engines. MRS Proc. 2013, 1516, 49–58. [Google Scholar] [CrossRef]

- Bolz, S.; Oehring, M.; Lindemann, J.; Pyczak, F.; Paul, J.; Stark, A.; Lippmann, T.; Schrüfer, S.; Roth-Fagaraseanu, D.; Schreyer, A.; et al. Microstructure and mechanical properties of a forged β-solidifying γ TiAl alloy in different heat treatment conditions. Intermetallics 2015, 58, 71–83. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Lindemann, J.; Stark, A.; Mayer, S. Hot-working behavior of an advanced intermetallic multi-phase γ-TiAl based alloy. Adv. Mater. Sci. Eng. A 2014, 614, 297–310. [Google Scholar] [CrossRef]

- Cheng, L.; Xue, X.; Tang, B.; Kou, H.; Li, J. Flow characteristics and constitutive modeling for elevated temperature deformation of a high Nb containing TiAl alloy. Intermetallics 2014, 49, 23–28. [Google Scholar] [CrossRef]

- Liang, X.-P.; Liu, Y.; Li, H.-Z.; Zhou, C.-X.; Xu, G.-F. Constitutive relationship for high temperature deformation of powder metallurgy Ti-47Al-2Cr-2Nb-0.2W alloy. Mater. Des. 2012, 37, 40–47. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Stark, A.; Bartels, A.; Clemens, H.; Kremmer, S.; Schimansky, F.-P.; Gerling, R. Microstructure and Texture Formation During Near Conventional Forging of an Intermetallic Ti-45Al-5Nb Alloy. Adv. Eng. Mater. 2009, 11, 976–981. [Google Scholar]

- Stark, A.; Schimansky, F.-P.; Clemens, H. Texture Formation during Hot-Deformation of High-Nb Containing γ-TiAl Based Alloys. Solid State Phenom. 2010, 160, 301–306. [Google Scholar] [CrossRef]

- Fukutomi, H.; Hartig, C.; Mecking, H. Change of Microstructure in a TiAl Intermetallic Compound during High Temperature Deformation. Z. Met. 1990, 81, 272–277. [Google Scholar]

- Hartig, C.; Fukotomi, H.; Mecking, H.; Aoki, K. Texture and Microstructure of Ti-49 at. % Al after Dynamic Recrystallization and Annealing. ISIJ Int. 1993, 33, 313–320. [Google Scholar] [CrossRef] [Green Version]

- Mecking, H.; Hartig, C.; Kocks, U.F. Deformation modes in γ-TiAl as derived from the single crystal yield surface. Acta Mater. 1996, 44, 1309–1321. [Google Scholar] [CrossRef]

- Bartels, A.; Schillinger, W.; Grassl, G.; Clemens, H. Texture formation in γ-TiAl sheets. In Gamma Titanium Aluminides 2003; Kim, Y.-W., Clemens, H., Rosenberger, A.H., Eds.; TMS: Warrendale, PA, USA, 2003; pp. 275–286. [Google Scholar]

- Schillinger, W.; Bartels, A.; Gerling, R.; Schimansky, F.-P.; Clemens, H. Texture evolution of the γ- and the α/α2-phase during hot rolling of γ-TiAl based alloys. Intermetallics 2006, 14, 336–347. [Google Scholar] [CrossRef]

- Stark, A.; Bartels, A.; Gerling, R.; Schimansky, F.-P.; Clemens, H. Microstructure and Texture Formation during Hot Rolling of Niobium-Rich Gamma TiAl Alloys with Different Carbon Contents. Adv. Eng. Mater. 2006, 8, 1101–1108. [Google Scholar] [CrossRef]

- Liss, K.-D.; Bartels, A.; Schreyer, A.; Clemens, H. High-Energy X-rays: A tool for Advanced Bulk Investigations in Materials Science and Physics. Textures Microstruct. 2003, 35, 219–252. [Google Scholar] [CrossRef]

- Staron, P.; Fischer, T.; Lippmann, T.; Stark, A.; Daneshpour, S.; Schnubel, D.; Uhlmann, E.; Gerstenberger, R.; Camin, B.; Reimers, W.; et al. In situ experiments with synchrotron high-energy X-rays. Adv. Eng. Mater. 2011, 13, 658–663. [Google Scholar] [CrossRef]

- Reimers, W.; Pycalla, A.R.; Schreyer, A.; Clemens, H. (Eds.) Neutrons and Synchrotron Radiation in Engineering Materials Science; Wiley-VCH: Weinheim, Germany, 2008.

- Liss, K.-D.; Bartels, A.; Clemens, H.; Bystrzanowski, S.; Stark, A.; Buslaps, T.; Schimansky, F.-P.; Gerling, R.; Scheu, C.; Schreyer, A. Recrystallization and phase transitions in a γ-TiAl-based alloy as observed by ex situ and in situ high-energy X-ray diffraction. Acta Mater. 2006, 54, 3721–3735. [Google Scholar] [CrossRef]

- Liss, K.-D.; Yan, K. Thermo-mechanical processing in a synchrotron beam. Mater. Sci. Eng. A 2010, 528, 11–27. [Google Scholar] [CrossRef]

- Gerling, R.; Clemens, H.; Schimansky, F.-P. Powder metallurgical processing of intermetallic Gamma Titanium Aluminides. Adv. Eng. Mater. 2004, 6, 23–38. [Google Scholar] [CrossRef]

- Schell, N.; King, A.; Beckmann, F.; Fischer, T.; Müller, M.; Schreyer, A. The High Energy Materials Science Beamline (HEMS) at PETRA III. Mater. Sci. Forum 2014, 772, 57–61. [Google Scholar] [CrossRef]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Häusermann, D. Two-dimensional detector software: From real detector to idealised image or two-theta scan. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- Lutterotti, L.; Bortolotti, M.; Ischia, G.; Lonardelli, I.; Wenk, H.-R. Rietveld texture analysis from diffraction images. Z. Krist. 2007, 26, 125–130. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Bondar, A.A.; Hecht, U.; Velikanova, T.Y. The Al-B-Nb-Ti system: IV. Experimental study and thermodynamic re-evaluation of the binary Al-Nb and ternary Al-Nb-Ti systems. J. Alloys Compd. 2009, 472, 133–161. [Google Scholar] [CrossRef]

- Stark, A.; Oehring, M.; Pyczak, F.; Schreyer, A. In situ observation of various phase transformation paths in Nb-rich TiAl alloys during quenching with different rates. Adv. Eng. Mater. 2011, 13, 700–704. [Google Scholar] [CrossRef]

- Rackel, M.; Stark, A.; Gabrisch, H.; Schimansky, F.-P.; Schell, N.; Schreyer, A.; Pyczak, F. In situ synchrotron radiation measurements of orthorhombic phase formation in an advanced TiAl alloy with modulated microstructure. MRS Proc. 2015. [Google Scholar] [CrossRef]

- Yan, K.; Liss, K.-D.; Garbe, U.; Daniels, J.; Kirstein, O.; Li, H.; Dippenaar, R. From single grains to texture. Adv. Eng. Mater. 2009, 11, 771–773. [Google Scholar] [CrossRef]

- Liss, K.-D.; Schmoelzer, T.; Yan, K.; Reid, M.; Peel, M.; Dippenaar, R.; Clemens, H. In situ study of dynamic recrystallization and hot deformation behavior of a multiphase titanium aluminide alloy. J. Appl. Phys. 2009. [Google Scholar] [CrossRef]

- Garces, G.; Morris, D.G.; Muñoz-Morris, M.A.; Perez, P.; Tolnai, D.; Mendis, C.L.; Stark, A.; Lim, H.K.; Kim, S.; Schell, N.; et al. Plasticity analysis by synchrotron radiation in a MgY2Zn1 alloy with bimodal grain structure and containing LPSO phase. Acta Mater. 2015, 94, 78–86. [Google Scholar] [CrossRef]

- Wassermann, G.; Grewen, J. Texturen Metallischer Werkstoffe; Springer: Berlin, Germany, 1962. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stark, A.; Rackel, M.; Tchouaha Tankoua, A.; Oehring, M.; Schell, N.; Lottermoser, L.; Schreyer, A.; Pyczak, F. In Situ High-Energy X-ray Diffraction during Hot-Forming of a Multiphase TiAl Alloy. Metals 2015, 5, 2252-2265. https://doi.org/10.3390/met5042252

Stark A, Rackel M, Tchouaha Tankoua A, Oehring M, Schell N, Lottermoser L, Schreyer A, Pyczak F. In Situ High-Energy X-ray Diffraction during Hot-Forming of a Multiphase TiAl Alloy. Metals. 2015; 5(4):2252-2265. https://doi.org/10.3390/met5042252

Chicago/Turabian StyleStark, Andreas, Marcus Rackel, Aristide Tchouaha Tankoua, Michael Oehring, Norbert Schell, Lars Lottermoser, Andreas Schreyer, and Florian Pyczak. 2015. "In Situ High-Energy X-ray Diffraction during Hot-Forming of a Multiphase TiAl Alloy" Metals 5, no. 4: 2252-2265. https://doi.org/10.3390/met5042252

APA StyleStark, A., Rackel, M., Tchouaha Tankoua, A., Oehring, M., Schell, N., Lottermoser, L., Schreyer, A., & Pyczak, F. (2015). In Situ High-Energy X-ray Diffraction during Hot-Forming of a Multiphase TiAl Alloy. Metals, 5(4), 2252-2265. https://doi.org/10.3390/met5042252