In situ Investigation of Titanium Powder Microwave Sintering by Synchrotron Radiation Computed Tomography

Abstract

:1. Introduction

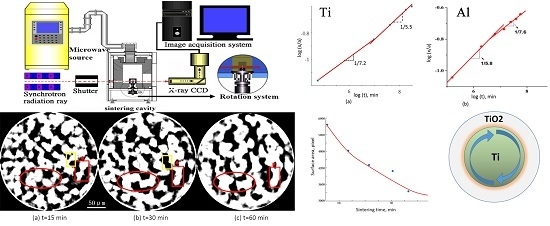

2. Experimental Section

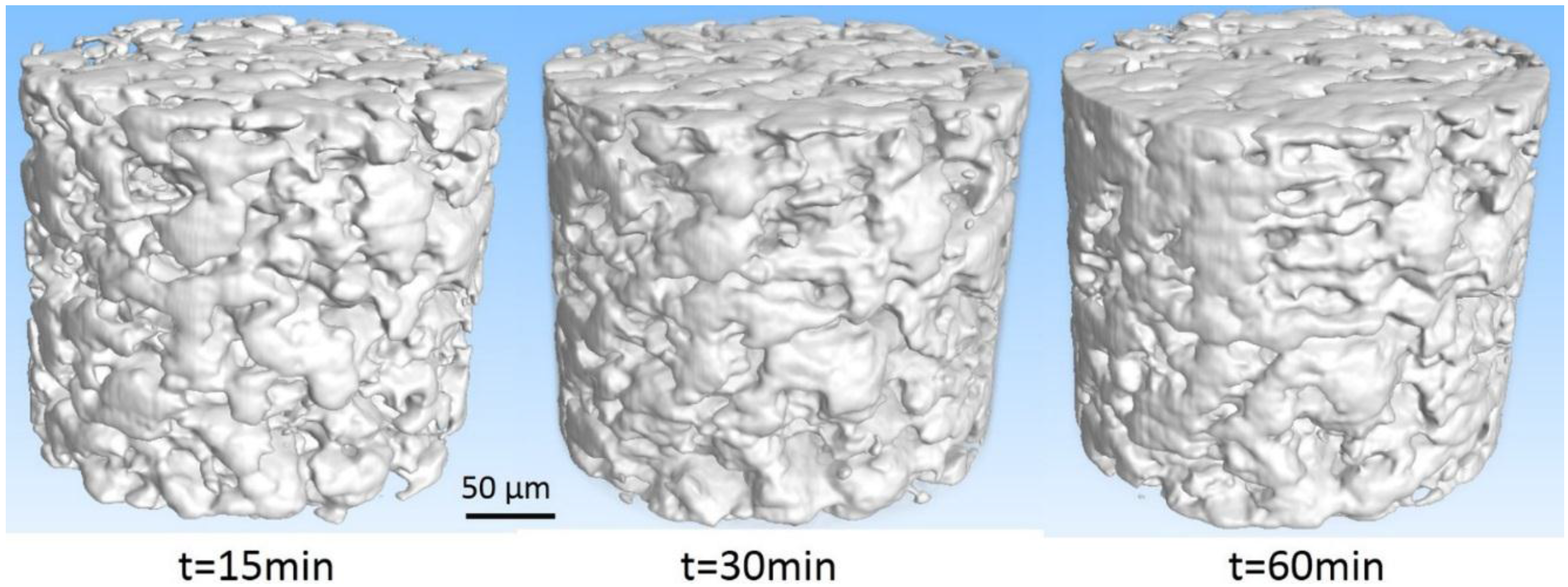

3. Results

- (1)

- The particles in the red rectangle grow more spherically and smoothly within a short time as the corners and burrs on the surface disappear. A similar process can also be observed in the circle. This phenomenon may be attributed to the loss of eddy current on the particle surface; as a result, mass diffusion is accelerated. Furthermore, non-thermal effects, such as interfacial polarization between grain surface and pores, and micro-focusing effects at the corner and burrs likely contribute to particle smoothing and rounding processes. Therefore, the proposed process was much faster than conventional sintering.

- (2)

- The two large particles in the red circle shown in Figure 3b come in contact with each other when the sintering neck is formed. However, the two particles are isolated from each other instead of sintering together (Figure 3c) as a consequence of the tensile and pressure from other particles. The particles in the yellow rectangle also exhibit similar behaviors. This phenomenon may have been caused by the micro-focusing effect. During microwave distribution, local microwave fields are disproportionately strong in certain regions because of the focusing influences of the microstructure, such as sintering neck, particle boundaries, and rough surfaces. Thus, non-uniform energy deposition occurs and temperature remarkably increases. The connecting region of two particles may be melted by the local high temperature attributed to the micro-focusing effect and then be broken by the tensile and pressure from other particles.

- (3)

- Several small particles in the red circle shown in Figure 3a quickly grow together into two large particles within 15 min. This phenomenon may have been caused by the acceleration of mass diffusion as a result of the micro-focusing effect at the sintering neck regions.

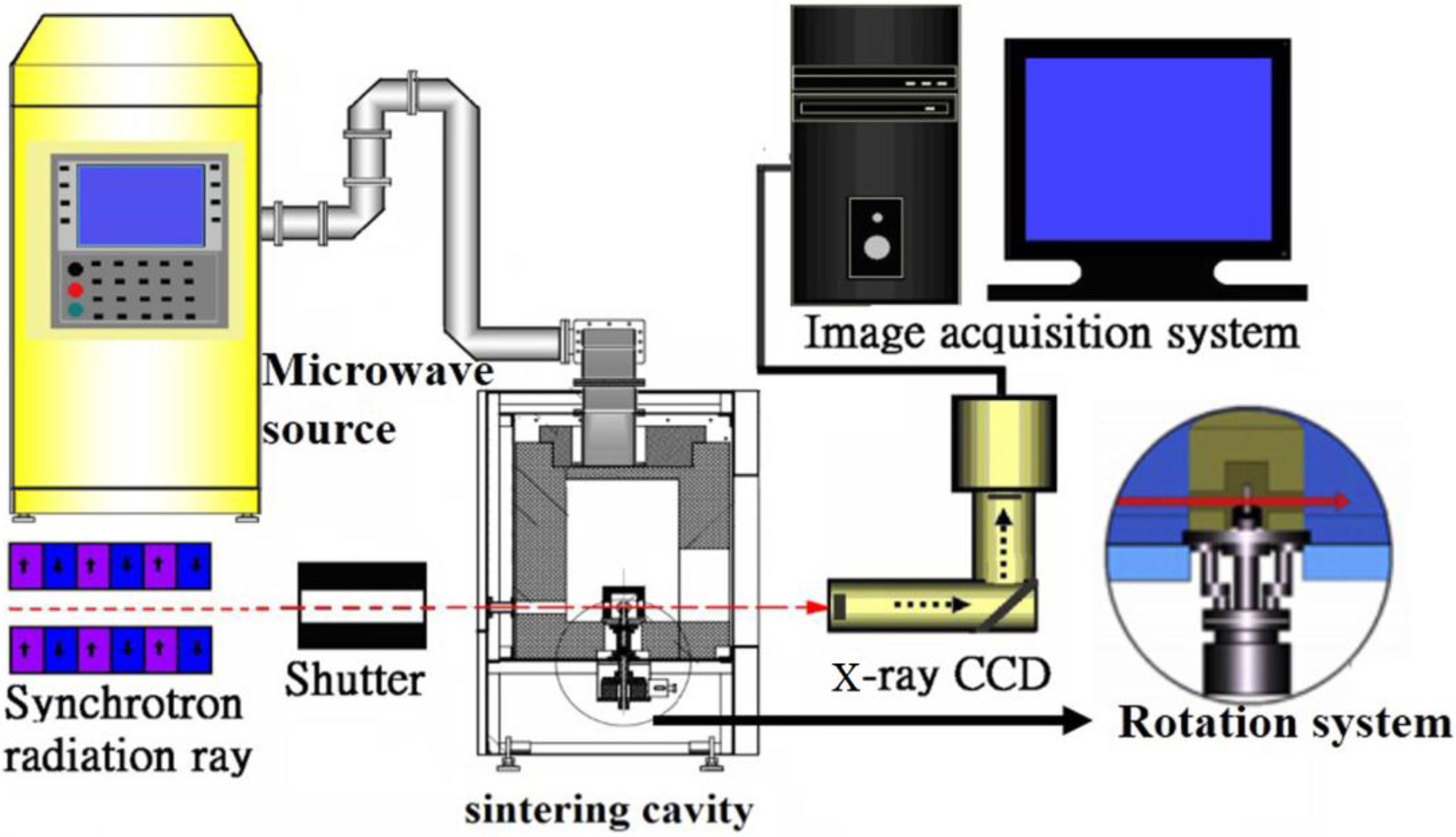

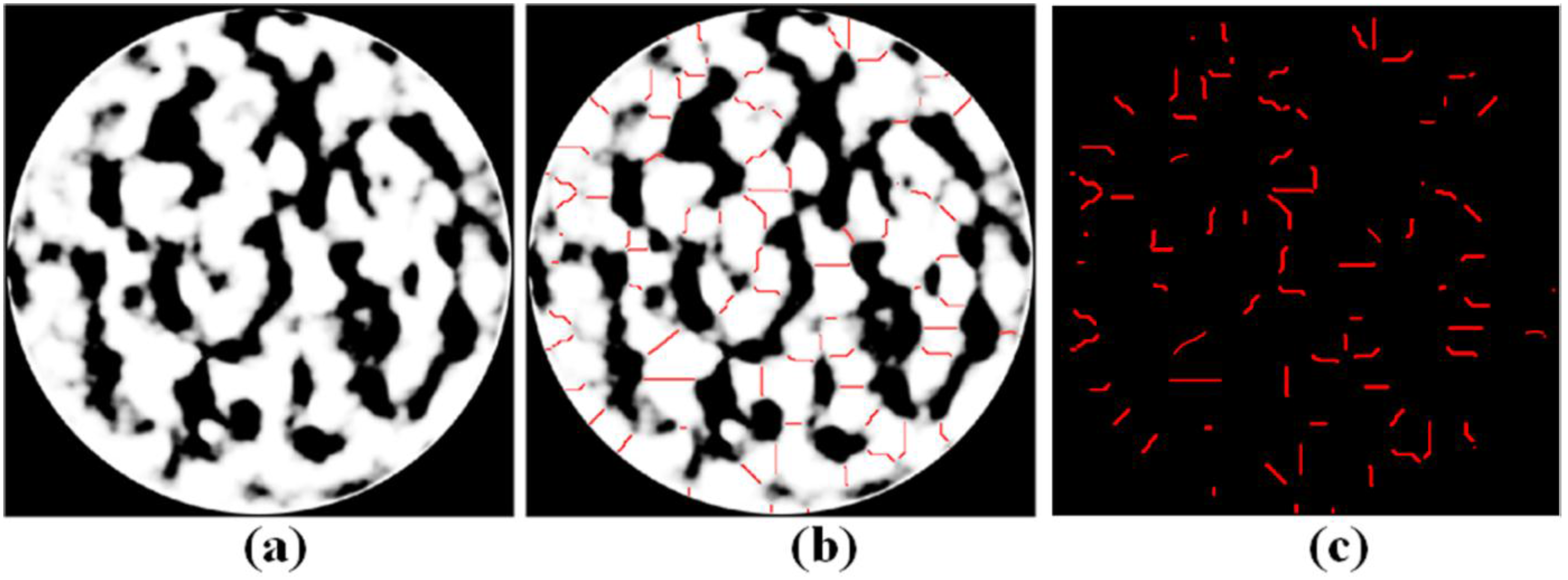

4. Discussion

- (1)

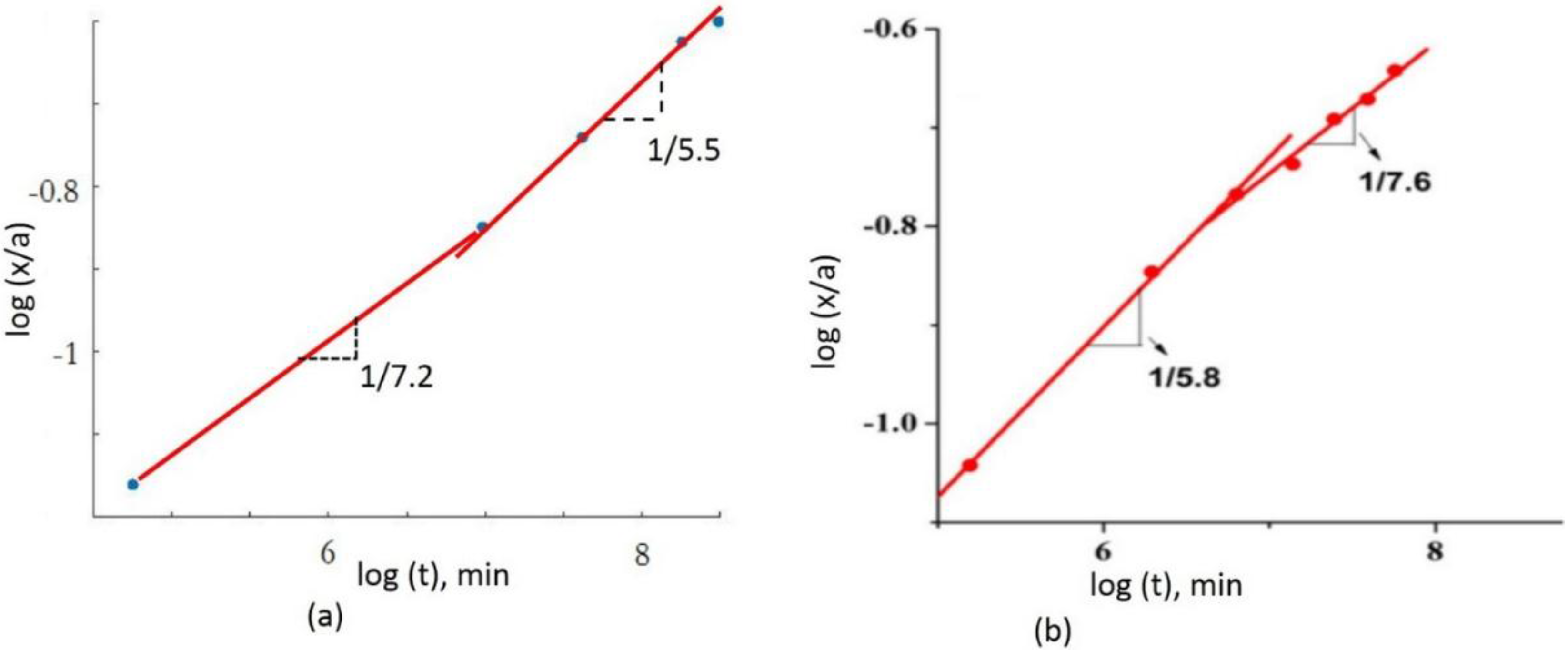

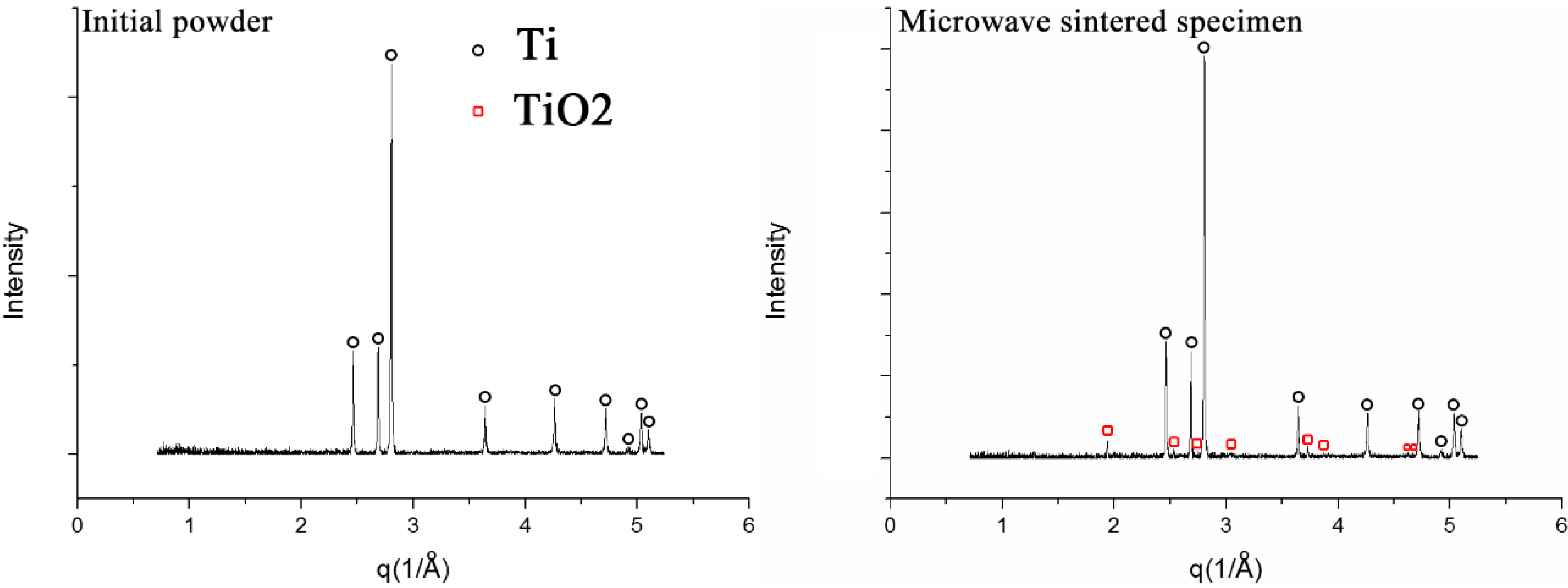

- Oxidation may occur to a certain extent because of the constraints in experimental conditions, such as open furnace chamber and slow protective atmosphere flow rate, although sintering proceeded in an argon-protected atmosphere. Titanium dioxide formed and covered the grains as sintering proceeded because of the slow protective gas flow rate. The X-ray diffraction patterns of the powder before and after microwave sintering are represented in Figure 7. Oxide was not detected in the initial powder before sintering. By contrast, the diffraction peaks of titanium dioxide appeared, and this finding indicated the formation of oxide after microwave sintering was completed. The dominant microwave heating mechanism of the pure metal powder was eddy current loss. When titanium dioxide covered the metal particles (Figure 8 showing the thickness of titanium dioxide as a representation, not the actual thickness), the inner metal was heated by the eddy current and the outer titanium dioxide was heated by dipolar polarization loss. Therefore, the total power loss of metal oxides may be higher than that of pure metal particles; as a result, the sintering neck of titanium grew rapidly from the intermediate period. In addition, the sintering neck growth of aluminum decelerated in the present work because of the poor microwave-absorbing property of alumina.

- (2)

- When titanium dioxide was formed, polarization charges accumulated at the interface of metal and oxide because of the heterogeneity between titanium and titanium dioxide. Therefore, the interfacial polarization effect cannot be ignored as another important heating mechanism. The heating effect caused by interfacial polarization probably accelerated the sintering neck growth. For the microwave sintering of aluminum, the difference between the interface of aluminum-alumina and titanium-titanium dioxide resulted in different strengths of interfacial polarization. Therefore, the sintering neck growth of aluminum decelerated in the present work.

- (3)

- Local plasma-activated sintering [18] promoted the sintering neck growth. The local electromagnetic field may be strong in some regions of the sintering neck, pores, and burrs of the rough surface because of the focusing influence of the microstructure; thus, the protective atmosphere of argon was ionized at the local regions. Evaporation-condensation mechanisms may be the local dominant diffusion mechanism because of plasma-generated ultra-high temperature; this mechanism likely accelerates the sintering neck growth and densification. Moreover, the atomic radius of most air components is smaller than that of argon; as such, the ionization energy of air is higher than that of argon and the ionization of air becomes more difficult than that of argon. Therefore, the microwave sintering of aluminum was not accelerated.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Roy, R.; Agrawal, D.; Cheng, J.; Gedevanishvili, S. Full sintering of powdered-metal bodies in a microwave field. Nature 1999, 399, 668–670. [Google Scholar]

- Janney, M.A.; Kimrey, H.D.; Allen, W.R.; Kiggans, J.O. Enhanced diffusion in sapphire during microwave heating. J. Mater. Sci. 1997, 32, 1347–1355. [Google Scholar] [CrossRef]

- Saitou, K. Microwave sintering of iron, cobalt, nickel, copper and stainless steel powders. Scr. Mater. 2006, 54, 875–879. [Google Scholar] [CrossRef]

- Chhillar, P.; Agrawal, D.; Adair, J.H. Sintering of molybdenum metal powder using microwave energy. Powder Metall. 2008, 51, 182–187. [Google Scholar] [CrossRef]

- Ma, J.; Diehl, J.F.; Johnson, E.J.; Martin, K.R.; Miskovsky, N.M.; Smith, C.T.; Weisel, G.J.; Weiss, B.L.; Zimmerman, D.T. Systematic study of microwave absorption, heating, and microstructure evolution of porous copper powder metal compacts. J. Appl. Phys. 2007. [Google Scholar] [CrossRef]

- Ahn, J.H.; Lee, J.N.; Kim, Y.C.; Ahn, B.T. Microwave-induced low-temperature crystallization of amorphous Si thin films. Curr. Appl. Phys. 2002, 2, 135–139. [Google Scholar] [CrossRef]

- Birnboim, A.; Calame, J.P.; Carmel, Y. Microfocusing and polarization effects in spherical neck ceramic microstructures during microwave processing. J. Appl. Phys. 1999, 85, 478–482. [Google Scholar] [CrossRef]

- Chen, G.; Liss, K.D.; Cao, P. An in situ Study of NiTi Powder Sintering Using Neutron Diffraction. Metals 2015, 5, 530–546. [Google Scholar] [CrossRef]

- Grupp, R.; Nöthe, M.; Kieback, B.; Banhart, J. Cooperative material transport during the early stage of sintering. Nat. Commun. 2011. [Google Scholar] [CrossRef] [PubMed]

- Bale, H.A.; Haboub, A.; MacDowell, A.A.; Nasiatka, J.R.; Parkinson, D.Y.; Cox, B.N.; Marshall, D.B.; Ritchie, R.O. Real-time quantitative imaging of failure events in materials under load at temperatures above 1600 °C. Nat. Mater. 2013, 12, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Li, Y.; Hu, X.; Niu, Y.; Zhao, J.; Zhang, Z. In situ investigation of metal’s microwave sintering. Mater. Lett. 2012, 67, 162–164. [Google Scholar]

- Li, Y.C.; Xu, F.; Hu, X.F.; Kang, D.; Xiao, T.Q.; Wu, X.P. In situ investigation on the mixed-interaction mechanisms in the metal-ceramic system’s microwave sintering. Acta Mater. 2014, 66, 293–301. [Google Scholar]

- Kuczynski, G.C. Self-diffusion in sintering of metallic particles. AIME Trans. 1949, 185, 169–178. [Google Scholar]

- Gonzalez, R.C.; Woods, R.E.; Eddins, S.L. Digital Image Processing Using Matlab; Publishing House of Electronics Industry: Beijing, China, 2005; pp. 315–317. [Google Scholar]

- Cheng, J.; Roy, R.; Agrawal, D. Experimental proof of major role of magnetic field losses in microwave heating of metal and metallic composites. J. Mater. Sci. Lett. 2001, 20, 1561–1563. [Google Scholar] [CrossRef]

- Huang, Y. Electromagnetic Field and Microwave Technology, 1st ed.; Posts & Telecom Press: Beijing, China, 2007; pp. 77–101. [Google Scholar]

- Feng, C. Electromagnetic Field, 2nd ed.; Higher Education Press: Beijing, China, 1983; pp. 322–362. [Google Scholar]

- Tracy, M.; Groza, J.R.; Yamazaki, K.; Sudarshan, T.S. Preliminary studies on the densification of fine tungsten powders by plasma activated sintering (PAS) process. In Proceedings of the 2nd International Conference on Tungsten and Refractory Metals, McLean, VA, USA, 17–19 October 1994; pp. 291–297.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Xu, F.; Hu, X.; Li, Y.; Liu, W.; Dong, B. In situ Investigation of Titanium Powder Microwave Sintering by Synchrotron Radiation Computed Tomography. Metals 2016, 6, 9. https://doi.org/10.3390/met6010009

Xiao Y, Xu F, Hu X, Li Y, Liu W, Dong B. In situ Investigation of Titanium Powder Microwave Sintering by Synchrotron Radiation Computed Tomography. Metals. 2016; 6(1):9. https://doi.org/10.3390/met6010009

Chicago/Turabian StyleXiao, Yu, Feng Xu, Xiaofang Hu, Yongcun Li, Wenchao Liu, and Bo Dong. 2016. "In situ Investigation of Titanium Powder Microwave Sintering by Synchrotron Radiation Computed Tomography" Metals 6, no. 1: 9. https://doi.org/10.3390/met6010009