Modeling of TiAl Alloy Grating by Investment Casting

Abstract

:1. Introduction

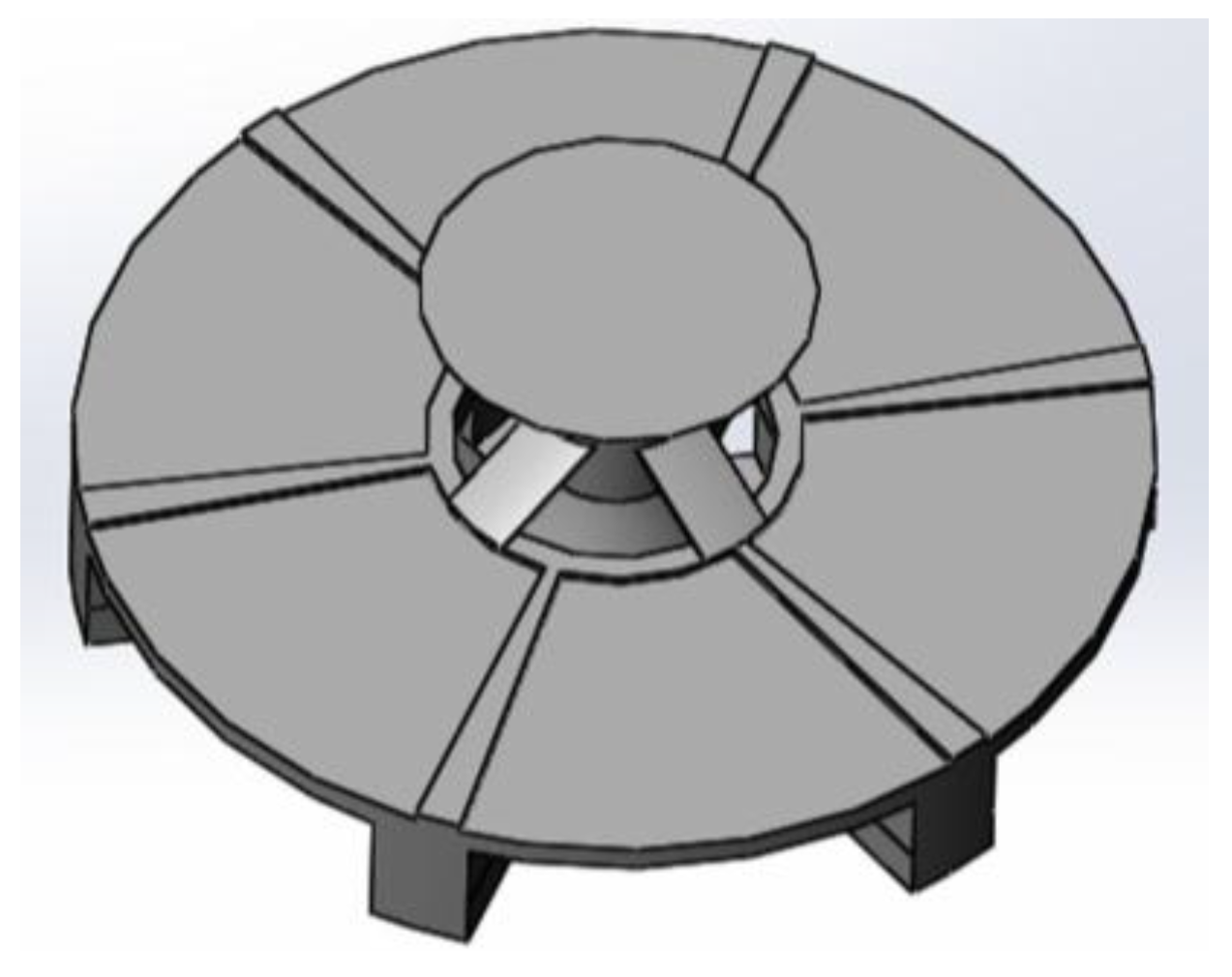

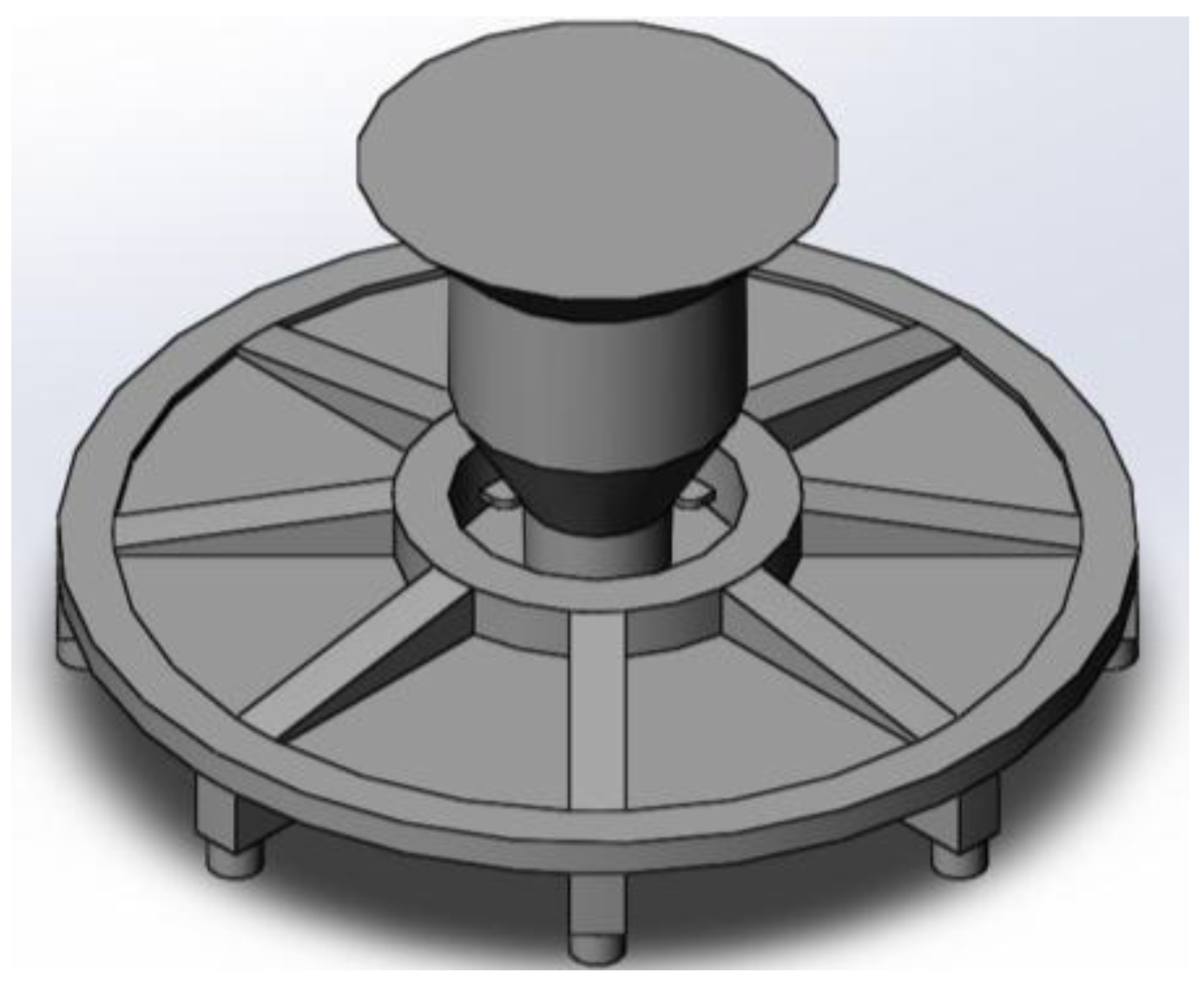

2. Experimental Section

2.1. Numerical Simulation

| Temperature/ (°C) | Density/ (kg·m−3) | Specific Heat/ (J·kg−1·K−1) | Thermal Conductivity/ (W·m−1·K−1) | Thermal Diffusion/ (m2·s−1) |

|---|---|---|---|---|

| 25 | 3857 | 598 | 13.2 | - |

| 200 | - | 630 | 16.7 | - |

| 400 | - | 667 | 20.2 | - |

| 600 | - | 703 | 23.1 | - |

| 700 | - | 799 | 25.4 | 8.4 |

| 800 | - | 769.3 | 26.8 | 8.8 |

| 900 | - | 900.1 | 28. | 8.1 |

| 1000 | - | 975.9 | 27.9 | 7.7 |

| 1100 | - | 995.6 | 26.5 | 7.2 |

| 1200 | - | 1140.4 | 27.3 | 6.7 |

| 1600 | 3788 | 786 | 31 | - |

| 1800 | 3612 | 794 | 37 | - |

| Thermophysical Properties | TiAl Alloy | Mold (ZrO2) |

|---|---|---|

| Density/(kg·m−3) | 3788 | 3970 |

| Specific heat/(J·kg−1·K−1) | 598 | 777 |

| Thermal conductivity/(W·m−1·K−1) | 13.2 | 39 |

| Liquidus temperature/(°C) | 1554 | 2323 |

| Solidus temperature/(°C) | 1478 | - |

| Latent heat/(J·kg−1·K−1) | 435 | - |

| Environment temperature/(°C) | 25 | 25 |

2.2. Production of Castings

2.3. Characterization of Microstructure and Mechanical Property

3. Results and Discussion

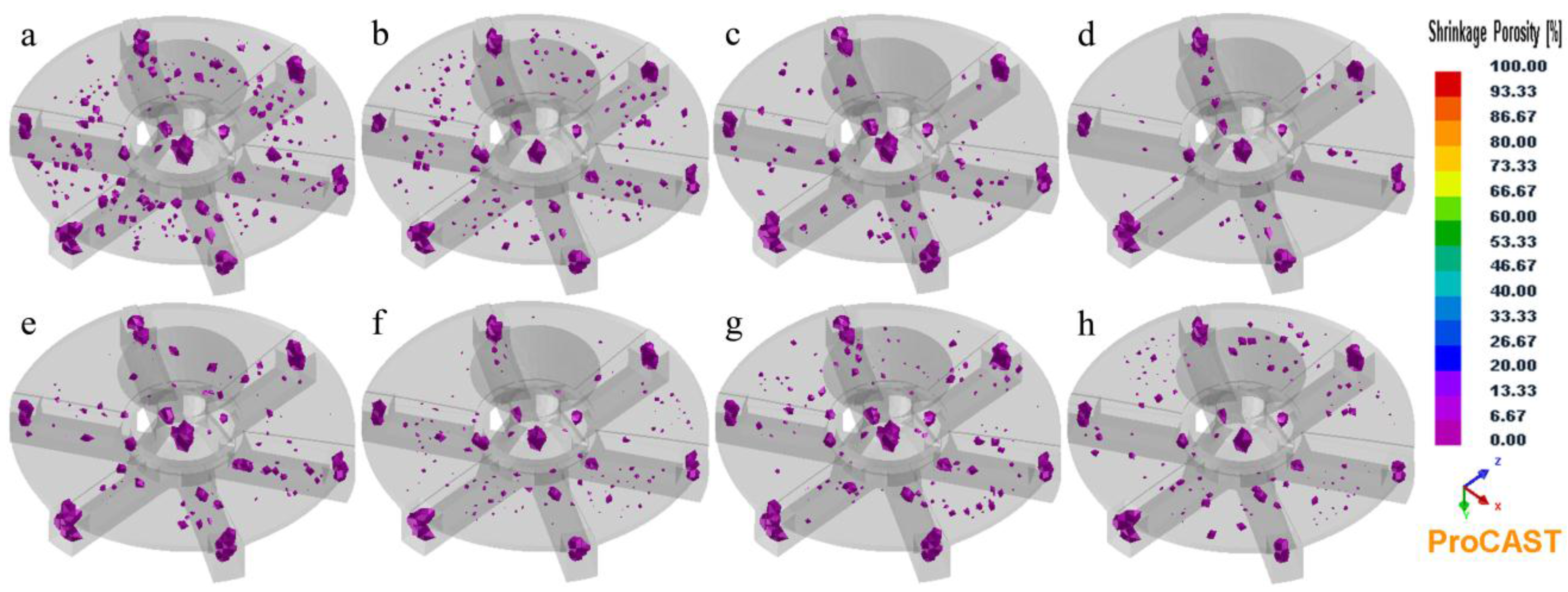

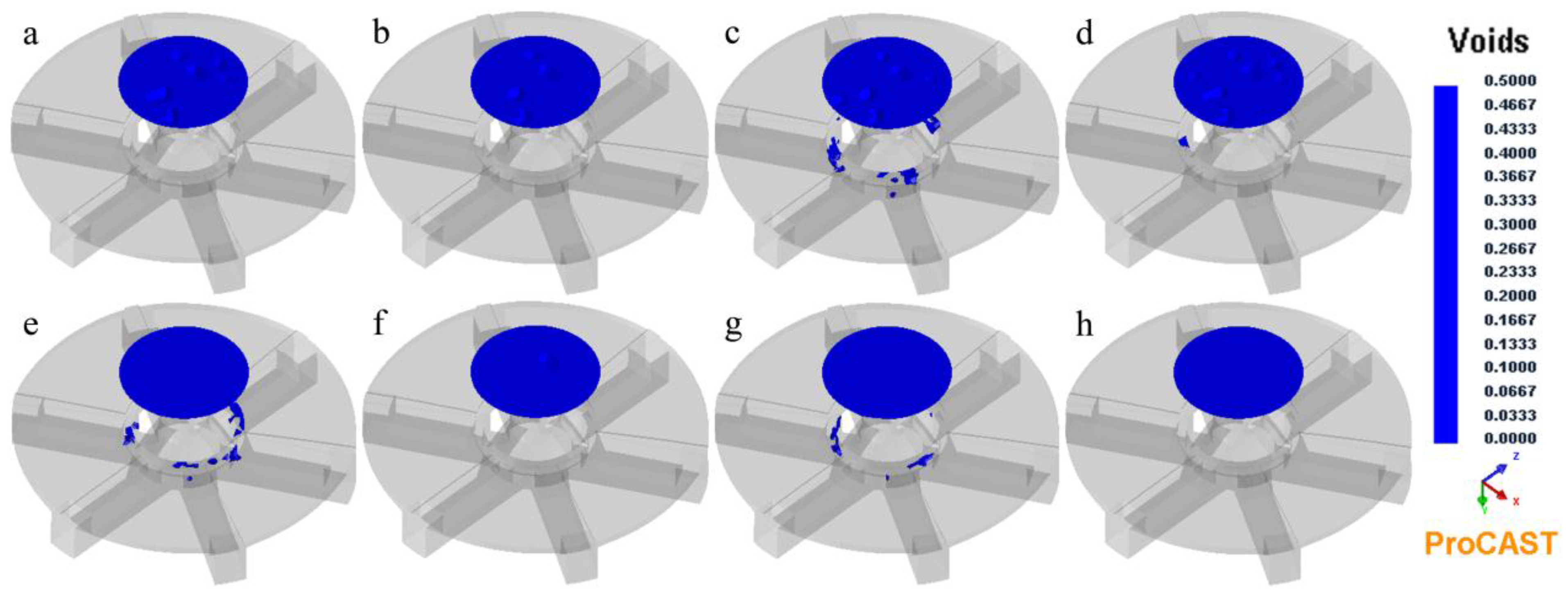

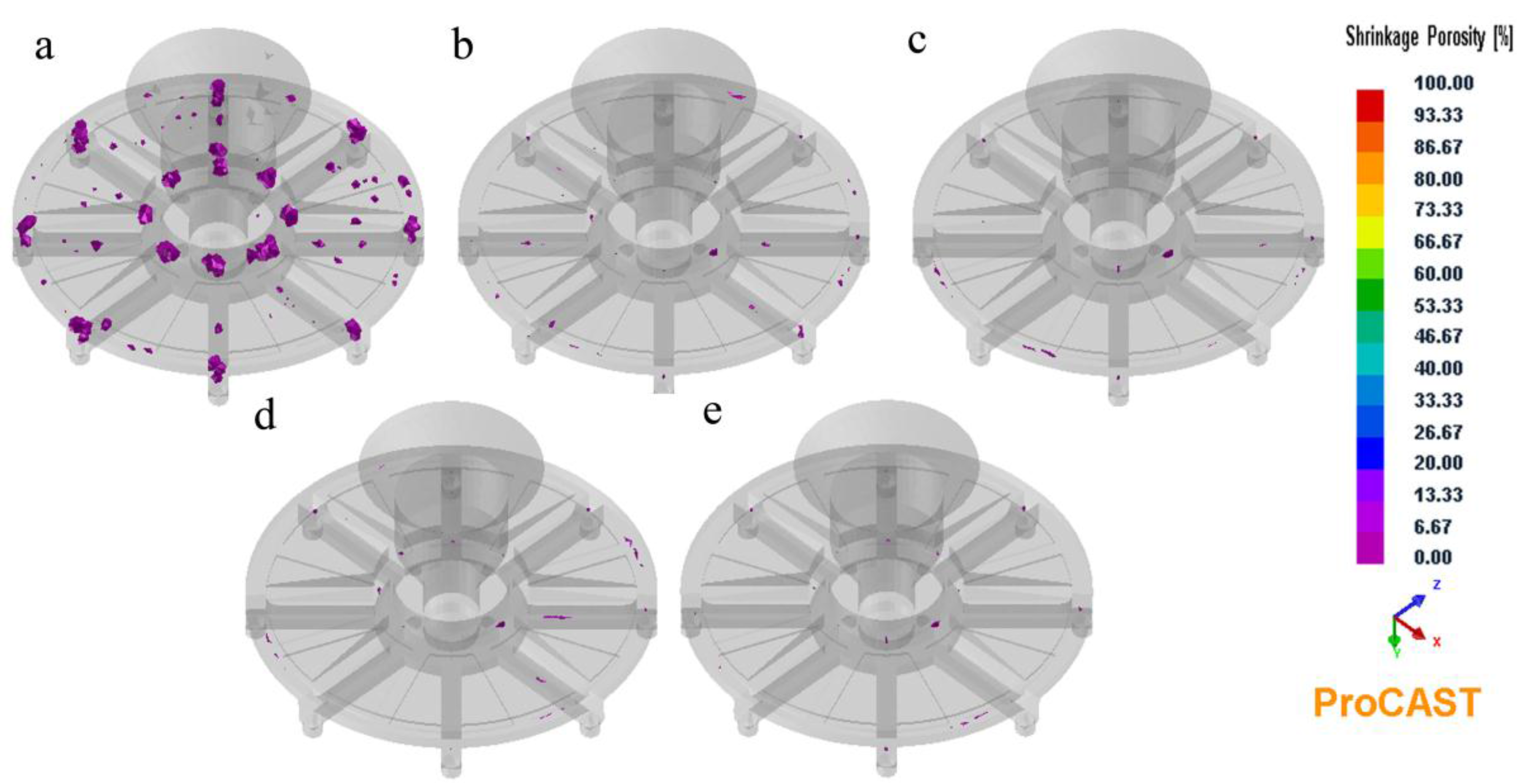

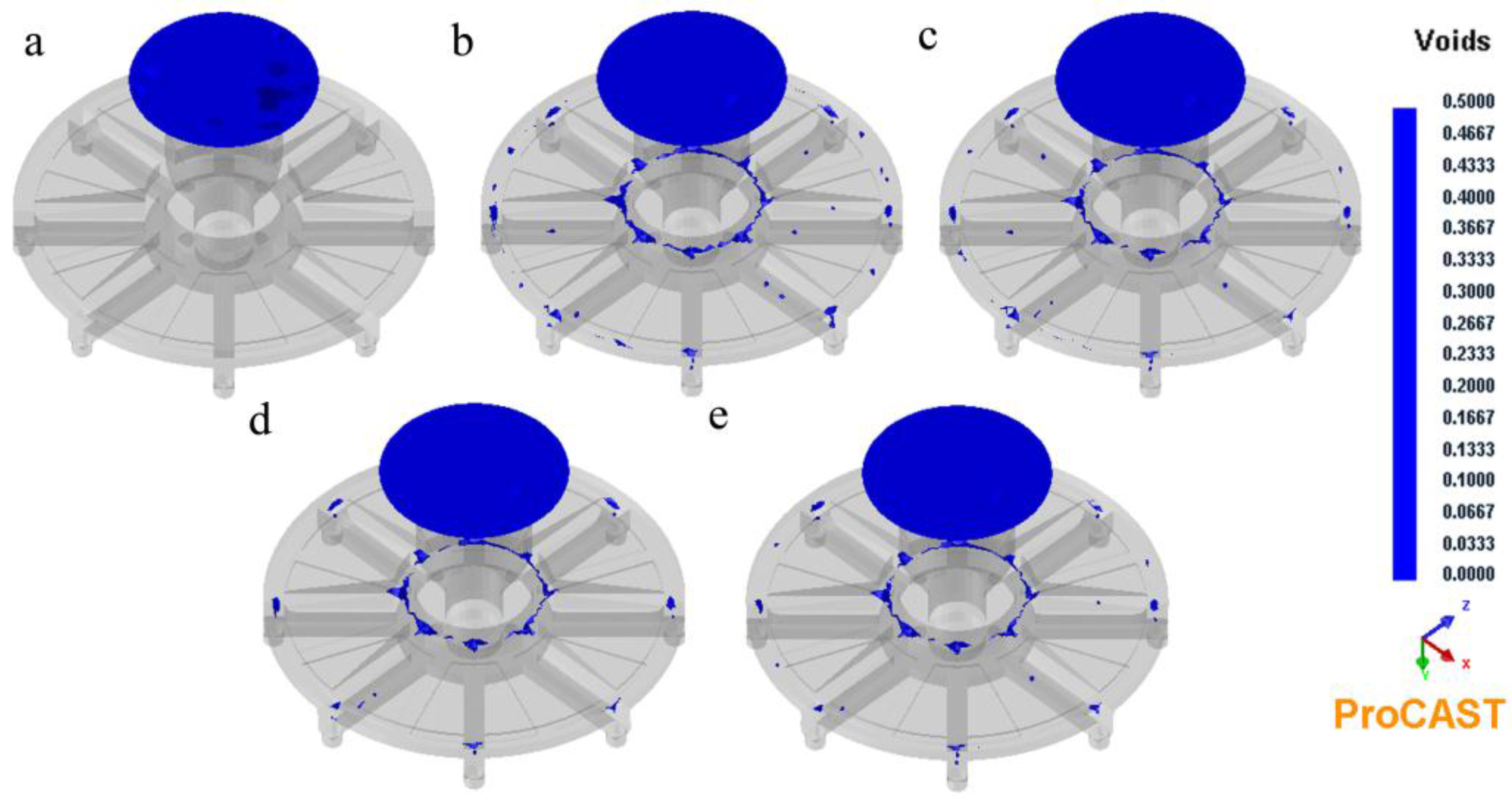

3.1. Numerical Simulation for Test Casting

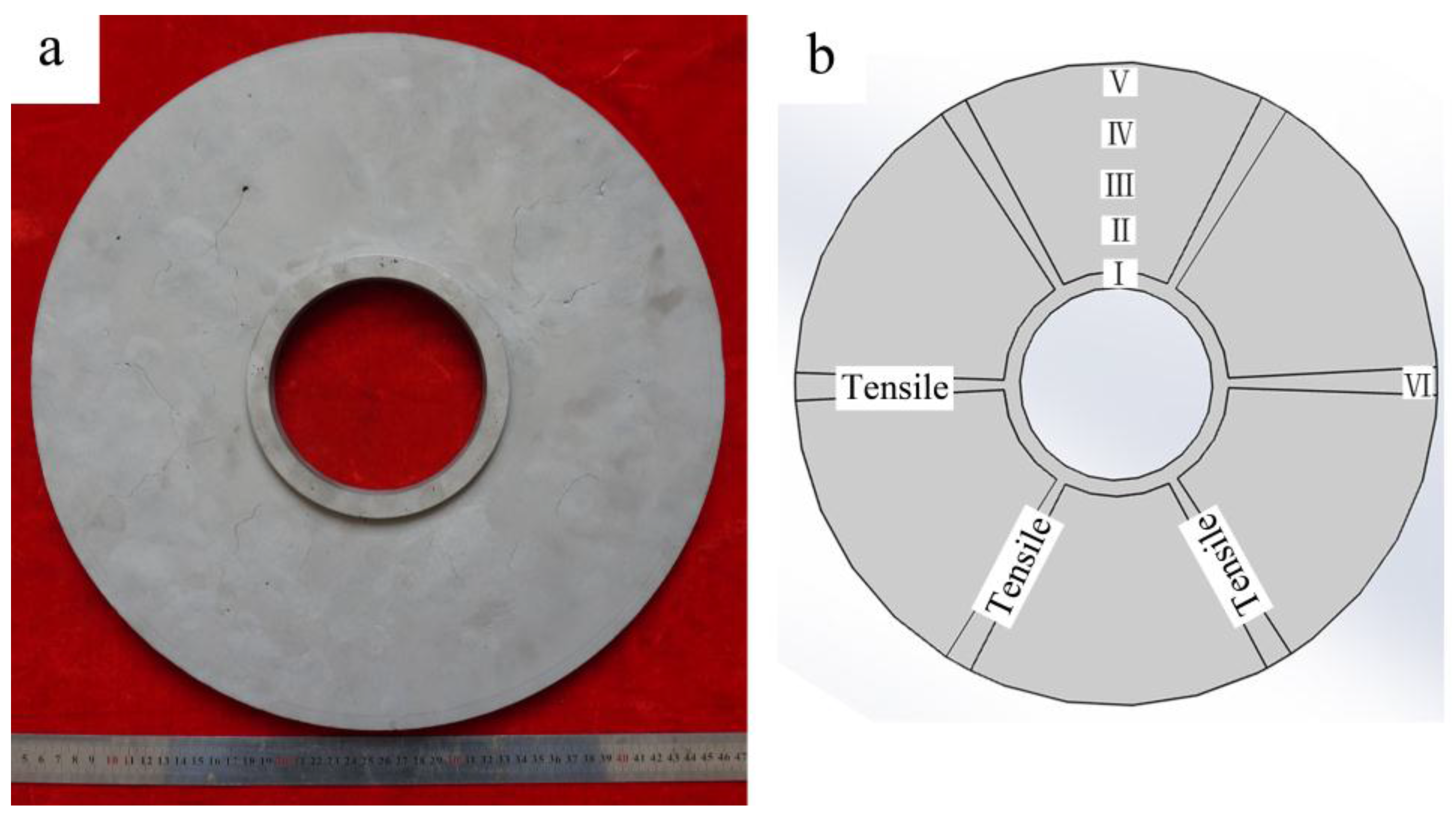

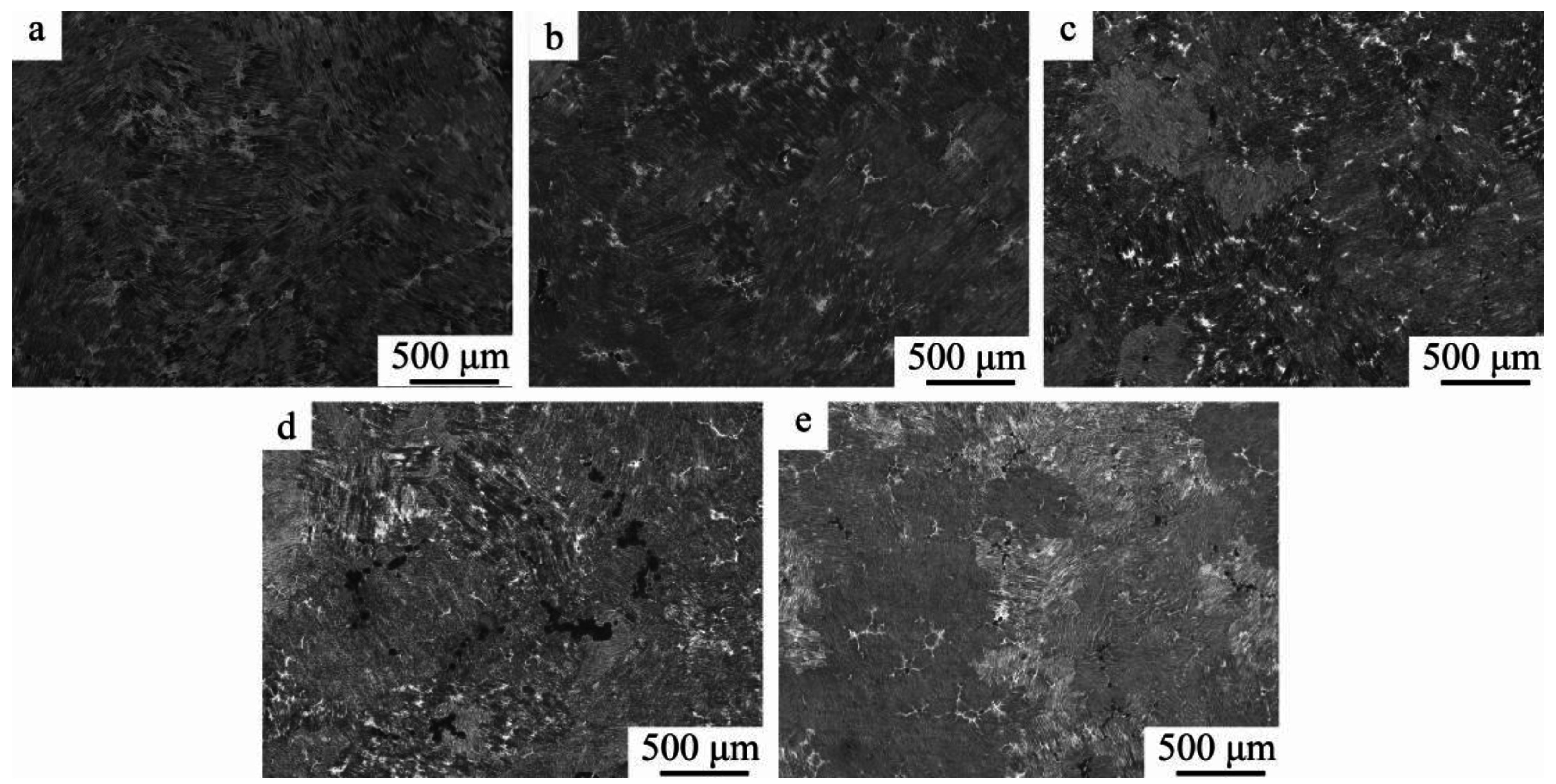

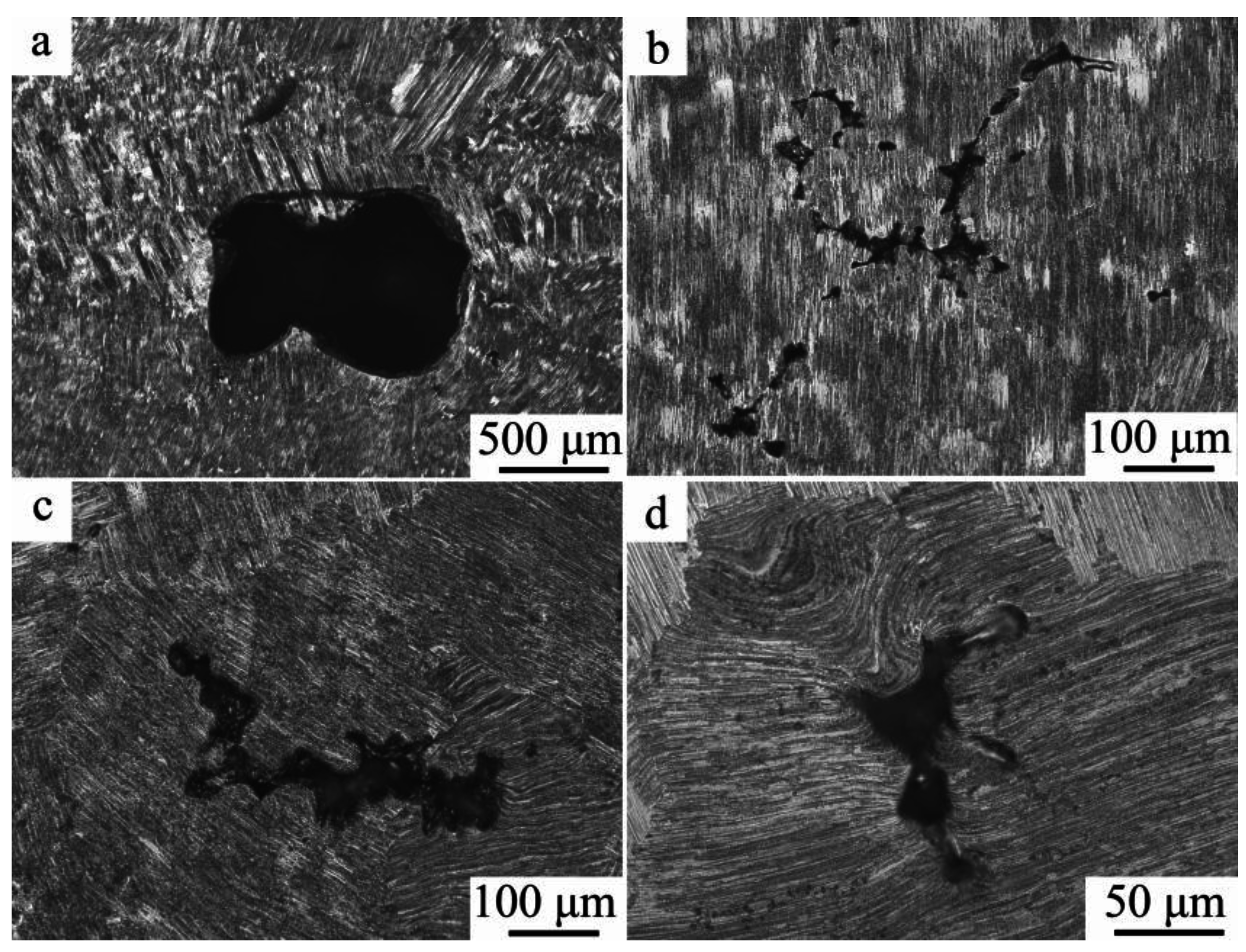

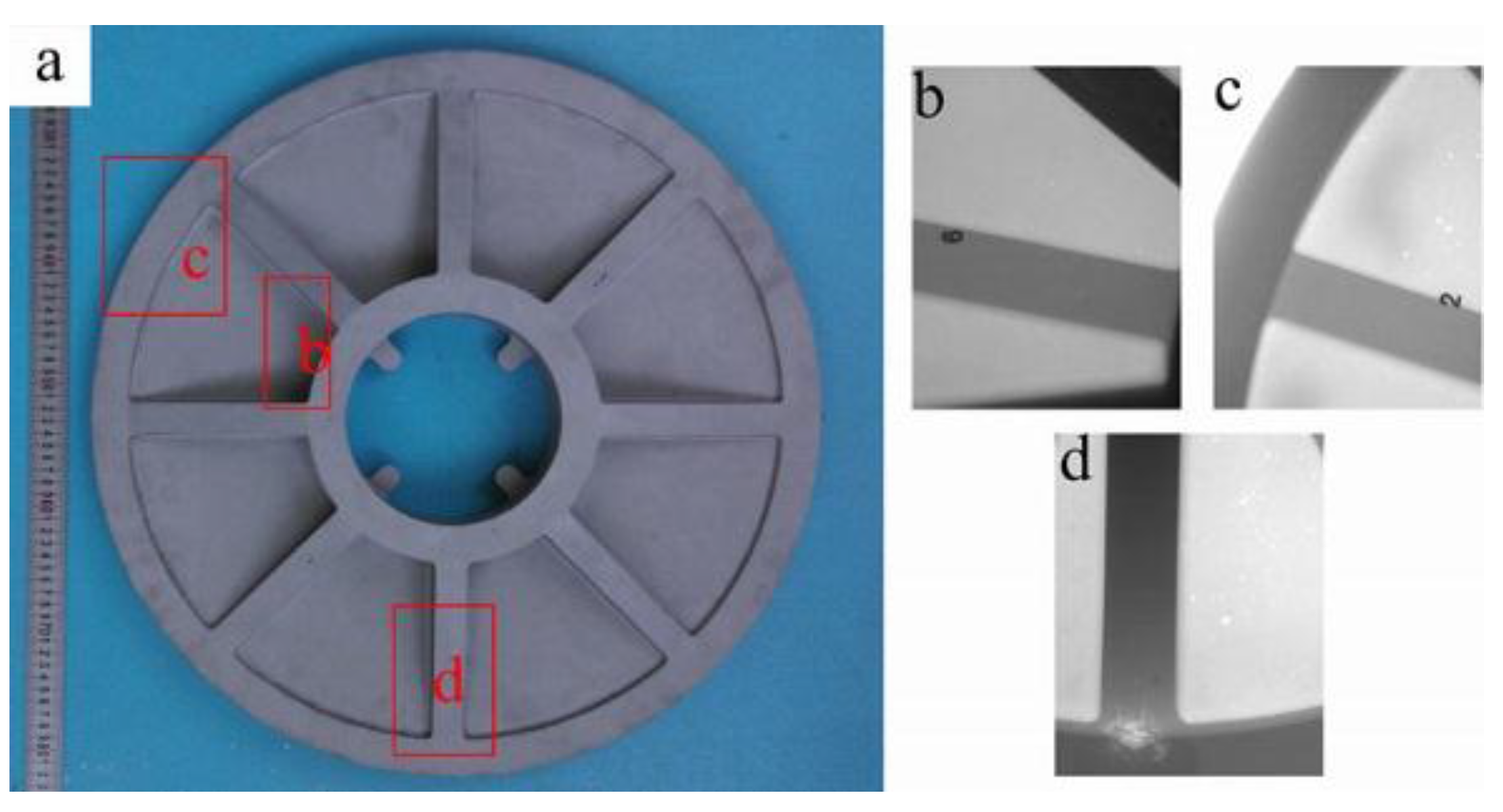

3.2. The Quality of Test Casting

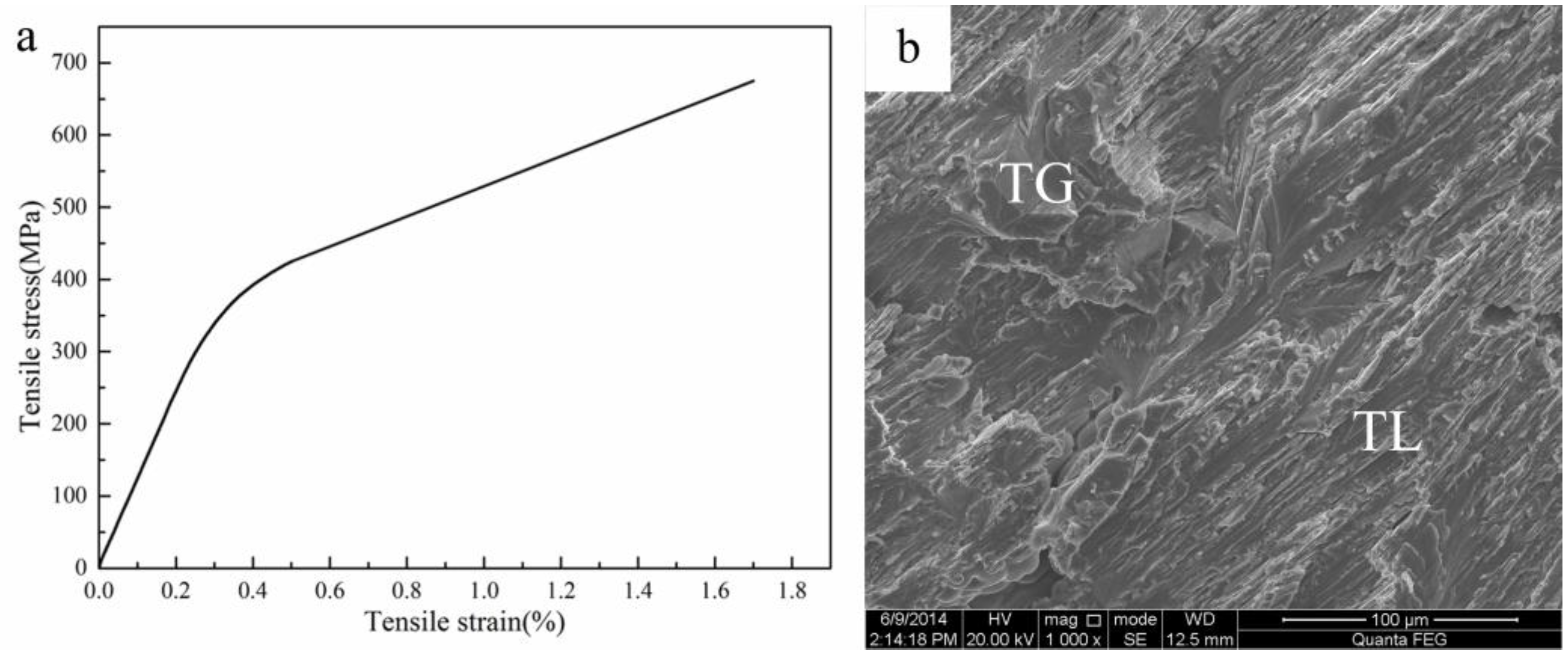

3.3. Mechanical Property for Test Casting

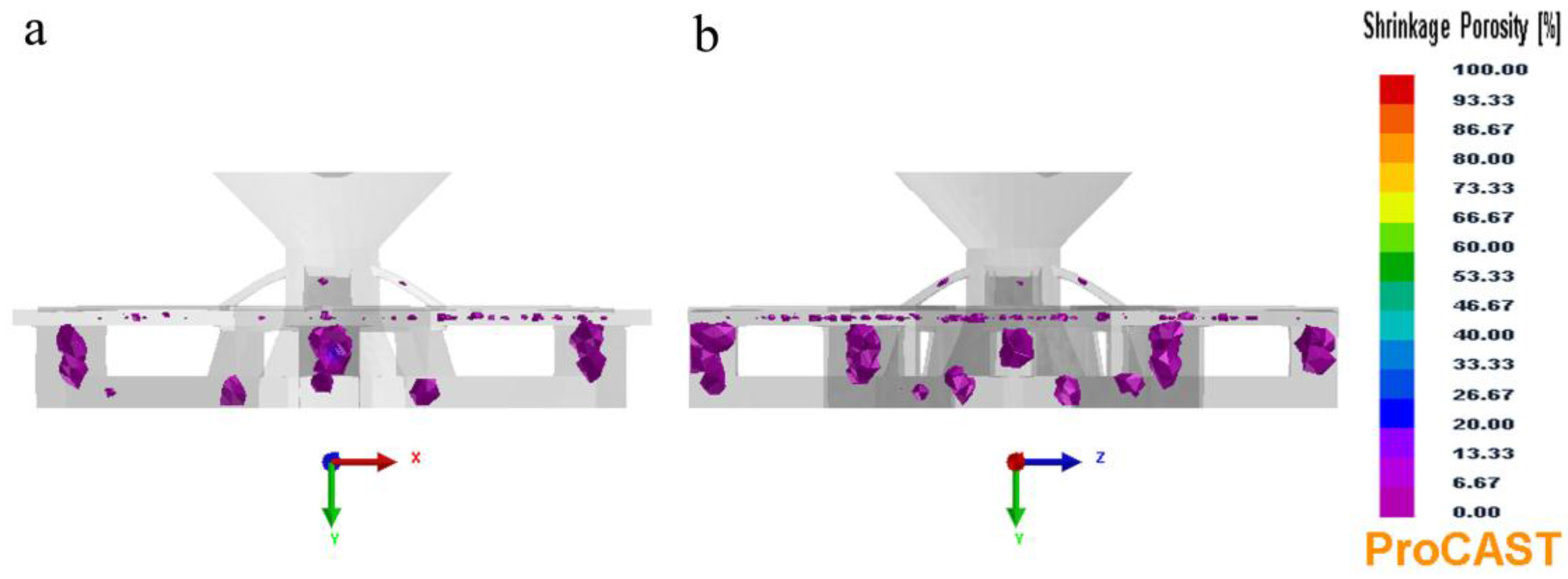

3.4. Numerical Simulation for Full-Size Casting

4. Conclusions

- (1)

- Gratings with diameters of 400 and 580 mm were successfully produced.

- (2)

- The casting parameters for the test casting were a pouring temperature of 1700 °C, a mold preheated temperature of 800 °C, and a rotation speed of 400 rpm.

- (3)

- The optimal casting parameters for full-size casting were a pouring temperature of 1700 °C, a mold preheated temperature of 600 °C, and a rotation speed of 200 rpm.

- (4)

- The specimens showed a typical fully lamellar microstructure, which exhibits finely segregated γ-grains. TiAl as-cast specimens exhibited a moderate mechanical property. At room temperature, the tensile strength and elongation were about 675 MPa and 1.7%, respectively.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, Y.W. Gamma-titanium aluminides: Their status and future. J. Miner. 1995, 47, 39–41. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Inui, H.; Ito, K. High-temperature structural intermetallics. Acta Mater. 2000, 48, 307–322. [Google Scholar] [CrossRef]

- Varin, R.A.; Gao, Q. The effect of chromium on the microstructure and micromechanical properties of TiAl-base alloys. Mater. Manuf. Process. 1996, 11, 381–410. [Google Scholar] [CrossRef]

- Kuang, J.P.; Harding, R.A.; Campbell, J. Microstructures and properties of investment castings of γ-titanium aluminide. Mater. Sci. Eng. A 2002, 329, 31–37. [Google Scholar] [CrossRef]

- Gomes, F.; Barbosa, J.; Ribeiro, C.S. Induction melting of γ-TiAl in CaO crucibles. Intermetallics 2008, 16, 1292–1297. [Google Scholar] [CrossRef]

- Tsukihashi, F.; Tawara, E.; Hatta, T. Thermodynamics of calcium and oxygen in molten titanium and titanium-aluminum alloy. Metall. Mater. Trans. B 1996, 27, 967–972. [Google Scholar] [CrossRef]

- Barbosa, J.; Ribeiro, C.S.; Monteiro, A.C. Influence of superheating on casting of γ-TiAl. Intermetallics 2007, 15, 945–955. [Google Scholar] [CrossRef]

- Kuang, J.P.; Harding, R.A.; Campbell, J. Investigation into refractories as crucible and mould materials for melting and casting γ-TiAl alloys. Mater. Sci. Technol. 2000, 16, 1007–1016. [Google Scholar] [CrossRef]

- Jia, Q.; Cui, Y.Y.; Yang, R. Intensified interfacial reactions between γ-titanium aluminide and CaO stabilised ZrO2. Int. J. Cast Met. Res. 2004, 17, 23–27. [Google Scholar] [CrossRef]

- Nowak, R.; Lanata, T.; Sobczak, N.; Ricci, E.; Giuranno, D.; Novakovic, R.; Holland-Moritz, D.; Egry, I. Surface tension of γ-TiAl-based alloys. J. Mater. Sci. 2010, 45, 1993–2001. [Google Scholar] [CrossRef]

- Cui, R.J.; Gao, M.; Zhang, H.; Gong, S.K. Interactions between TiAl alloys and yttria refractory material in casting process. J. Mater. Process. Technol. 2010, 210, 1190–1196. [Google Scholar]

- Teodoro, O.; Barbosa, J.; Naia, M.D.; Moutinho, A.M.C. Effect of low level contamination on TiAl alloys studied by SIMS. Appl. Surf. Sci. 2004, 231, 854–858. [Google Scholar] [CrossRef] [Green Version]

- Sung, S.Y.; Kim, Y.J. Modeling of titanium aluminides turbo-charger casting. Intermetallics 2007, 15, 468–474. [Google Scholar] [CrossRef]

- Fu, P.X.; Kang, X.H.; Ma, Y.C.; Liu, K.; Li, D.Z.; Li, Y.Y. Centrifugal casting of TiAl exhaust valves. Intermetallics 2008, 16, 130–138. [Google Scholar] [CrossRef]

- Yang, R.; Cui, Y.Y.; Dong, L.M.; Jia, Q. Alloy development and shell mould casting of γ-TiAl. J. Mater. Process. Technol. 2003, 135, 179–188. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Y.; Xiao, S.; Tian, J.; Xu, L.; Chen, Y. Modeling of TiAl Alloy Grating by Investment Casting. Metals 2015, 5, 2328-2339. https://doi.org/10.3390/met5042328

Jia Y, Xiao S, Tian J, Xu L, Chen Y. Modeling of TiAl Alloy Grating by Investment Casting. Metals. 2015; 5(4):2328-2339. https://doi.org/10.3390/met5042328

Chicago/Turabian StyleJia, Yi, Shulong Xiao, Jing Tian, Lijuan Xu, and Yuyong Chen. 2015. "Modeling of TiAl Alloy Grating by Investment Casting" Metals 5, no. 4: 2328-2339. https://doi.org/10.3390/met5042328