Termite Resistant Properties of Sisal Fiberboards

Abstract

: A study was carried out to test sisal (Agave sisalana Perrine) fiberboards properties as building materials against Asian subterranean termite, Coptotermes gestroi (Wasmann). Evaluation was in the laboratory according to the JWPA Standard-TW-S.1-1992. To improve mechanical properties of fiberboards made from sisal fibers, the boards were overlaid by rubber veneer, betung bamboo matting or formica. Result showed that the formica-overlaid sisal fiberboards performed better than other overlaid fiberboards against C. gestroi.1. Introduction

Sisal fiberboards bonded by urea formaldehyde (UF), melamine urea formaldehyde (MUF) or phenol formaldehyde (PF) adhesives could meet the requirements of mechanical properties designated in JIS A5908-1994, whereas the physical properties of the boards were not satisfactory, especially thickness swelling properties [1]. The necessity to improve this unsuitability as building materials gave us some ideas of which sisal fibers prepared by a ring flaker were bonded with isocyanate adhesive, followed by overlaying by various materials on both the upper and lower faces of the boards [2]. Sisal fibers processed by a ring flaker significantly improved thickness swelling properties of sisal fiberboards, and the overlaying resulted in better mechanical properties.

Following these improvements, determination of board durability against termites was necessary. The tropical climate is suitable for survival of termites and this has become a threat to human dwellings in urban environments due to their ability to attack wooden building materials.

Subterranean termites are among the most widely distributed wood-attacking insects in Indonesia. Not only in Indonesia, Coptotermes gestroi Wasmann is the most destructive species in Thailand, attacking not only buildings and other timber constructions, but also any other cellulosic materials and furniture [3]. Genus Coptotermes is most destructive to wooden structures because they can damage wood in a short period [4]. Since Coptotermes do not always build their nest in contact with soil, but in infested timbers where occasional water supply such as rain water droplets from a leaky roof is available for termites [5], Coptotermes gestroi (Wasmann) is considered as a serious pest in Southeast Asia, causing damage to 63%–90% structures and buildings in Malaysia, Thailand and Singapore. Doors, window frames and parquet floors were infested with termites [6].

This study, therefore, reports the resistance of sisal fiberboards against common Asian subterranean termites, C. gestroi determined by the standardized laboratory method.

2. Materials and Methods

Two types of sisal fiberboards were prepared for the study: one was bare sisal fiberboards, namely, with no overlayings and the other with overlayings.

2.1. Bare Sisal Fiberboards

Sisal fibers were formed into boards by bonding with 8%, 10%, and 12% of isocyanate resin based on an oven-dried weight of sisal fibers. Sisal fibers and isocyanate were blended by a drum mixer and hand-formed before hot-pressed at 0.8 N/mm2 and 140 °C for 10 minutes. Target density of 1 cm-thick boards was 0.6 g/cm3.

2.2. Overlaid Sisal Fiberboards

The sisal fiberboards prepared by the above-mentioned manner were overlayed by rubber wood veneer, betung bamboo matting or formica. The amount of isocyanate was 10% based on an oven-dried weight of sisal fibers. Bonding of sisal fibers was done by 75% of the total isocyanate and the remaining was for bonding overlaying materials on both face and back faces. A single-stage board-hot-pressing was conducted at 0.8 N/mm2 and 140 °C for 10 minutes.

2.3. Termite-Resistance Test

Forced-feeding termite test was conducted with prepared fiberboards according to the Japan Wood Preserving Association (JWPA) standard No. 12-1992 (renamed as JWPA Standard-TW-S.1-1992) [7], provided that three replications were tested using Coptotermes gestroi. An individual test specimen of sisal fiberboard (20 × 20 × 10 mm) was placed at the center of the plaster bottom of a cylindrical test container (80 mm in diameter, 60 mm in height) with 150 workers and 15 soldiers of C. gestroi. The assembled containers were put on dampened cotton pads to supply water to the specimens and kept at 28 °C and 80% relative humidity. Termite mortality was determined regularly for 3 weeks (21 days). The percent mass loss of each test specimen was calculated from the difference in the oven-dried weights before and after the termite test. Data in percentage were subjected to Mean, Standard error and analysis of variance (ANOVA). Means were separated with Tukey's HSD.

3. Results and Discussion

3.1. Mass Loss

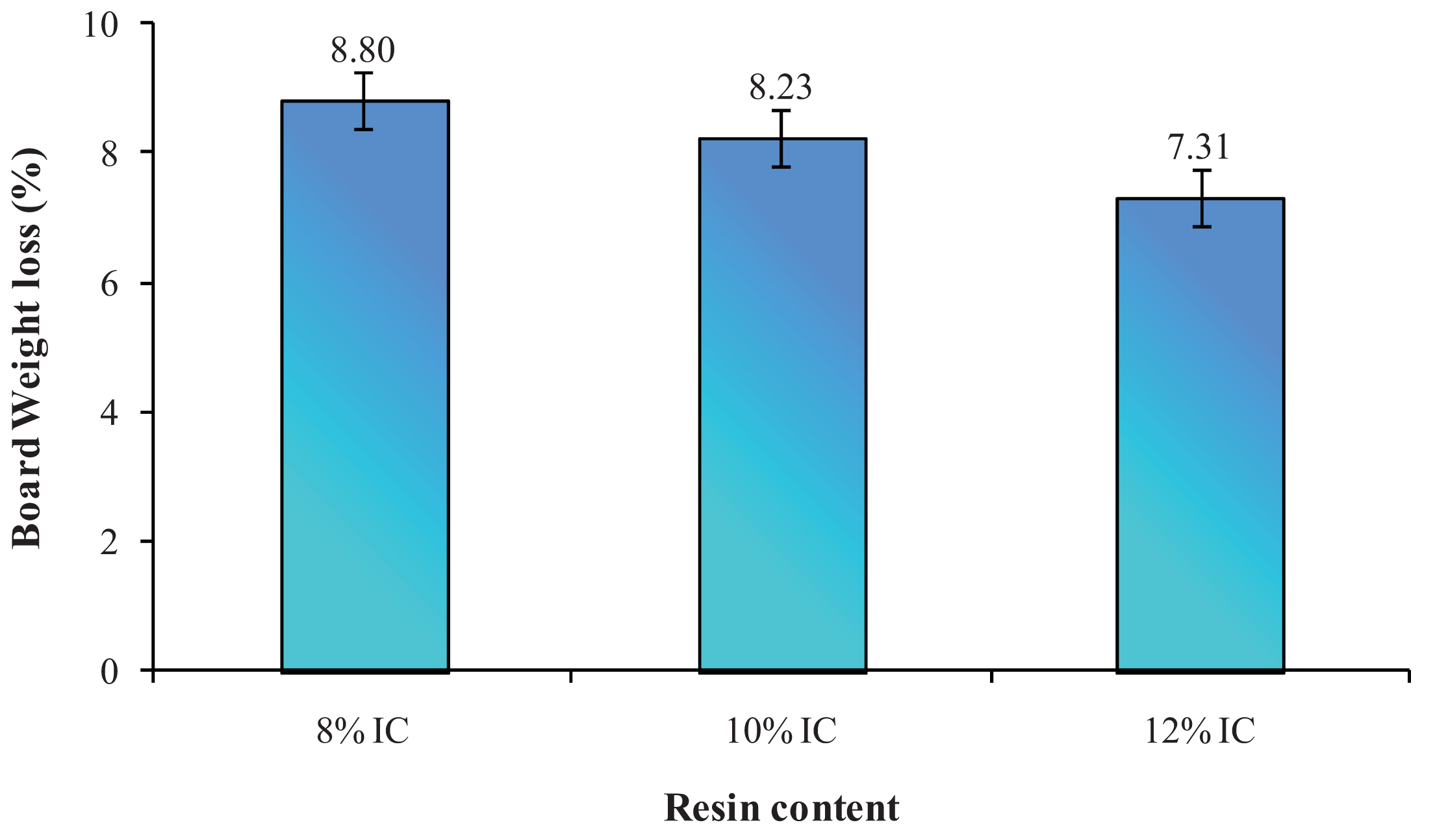

All samples had similar densities, showed no difference at 95% confidence level and the board mass loss was not affected. Sisal fiberboard resin contents affected the mean mass losses of bare sisal fiberboards as shown in Figure 1. Although there was no significant difference in sisal fiberboards mass losses between 10% and 12% isocyanate resin contents, 8% resin content sisal fiberboards showed different mass losses. Mean mass losses were 8.80%, 8.23% and 7.31% at 8%, 10% and 12% resin contents, respectively. The higher resin contents showed less attack by termites, possibly due to the reluctance in feeding activity of termites. One of the advantages of using isocyanate as an adhesive was to improve the durability of wood against deterioration. Visual observation showed that termites first attacked the core part of boards by making entry holes into the fiberboards. This behavior is a manisfestation of termite's characteristics that is cryptobiotic; termites tend to hide themselves and avoid the light [8]. Hardness gradients induced by manufacturing process might account for this phenomenon. Surface-layers were solidified during the hot-compression, impacting higher density than the core portion of the board.

A similar attack pattern was seen for overlaid-boards. It has been commonly known that termites attack the wood to get nutrition, i.e. cellulose. The amount of cellulose in sisal fibers ranges between 67%–78% [9], while betung bamboo contains approximately 52.9% [10]. In addition, the hardness of bamboo surface due to silica content, obstruct termite attack. Therefore, termites attack the core layer first, and then attack overlaying material of betung bamboo matting.

Among overlaid sisal fiberboards, the mass loss of bamboo-matting overlaid-sisal fiberboard was (243.33 mg in average) higher than rubber-veneer-overlaid sisal fiberboards or formica-overlaid sisal fiberboards (Figure 2). Bamboo is susceptible to microorganisms and insects and whole bamboo in the dry state can be attacked by Dinoderus sp. borers and drywood termites [10], due to high content of starch and cellulose. The mass loss of sisal fiberboards overlaid by rubber veneer was high, recording 200 mg on average, as a result of rubber susceptibility to biodegrading agents and low durability as categorized in class V [11].

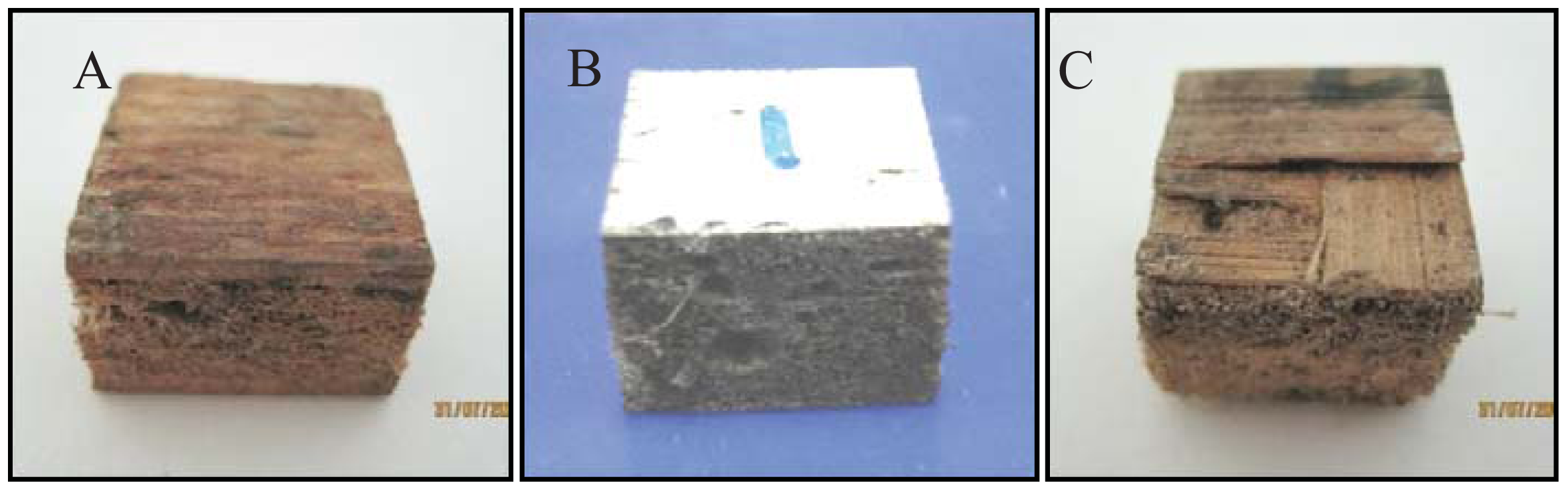

The type of overlaying materials did not affect sisal fiberboard weight loss and showed no significant difference at 95% confidence level. Visual observation showed that termite attacked the core parts of the board as a manisfestation of cryptobiotic characteristic. The termite attack on the formica-overlaid sisal fiberboards was lower than on rubber veneer or bamboo matting overlaid sisal fiberboards, although the amount of sisal fibers in formica-overlaid sisal fiberboard was higher than in sisal fiberboard with rubber veneer or bamboo matting overlaying. The density of formica (1.17 g/cm3) was higher than rubber veneer and betung bamboo matting, 0.57 g/cm3 and 0.53 g/cm3, respectively. Formica surface was impregnated with melamine, producing a hard surface. Therefore, termite did not attack formica but attacked only the core parts of the board. While in contrast, rubber veneer and bamboo matting are susceptible to termite attack. Sisal fiberboards with rubber veneer and bamboo overlaying weight loss were higher because termites attack the overlaying materials and also sisal fiber at the core part of the boards. Figure 3 shows termite attack on sisal fiberboards with various overlaying.

3.2. Termite Mortality

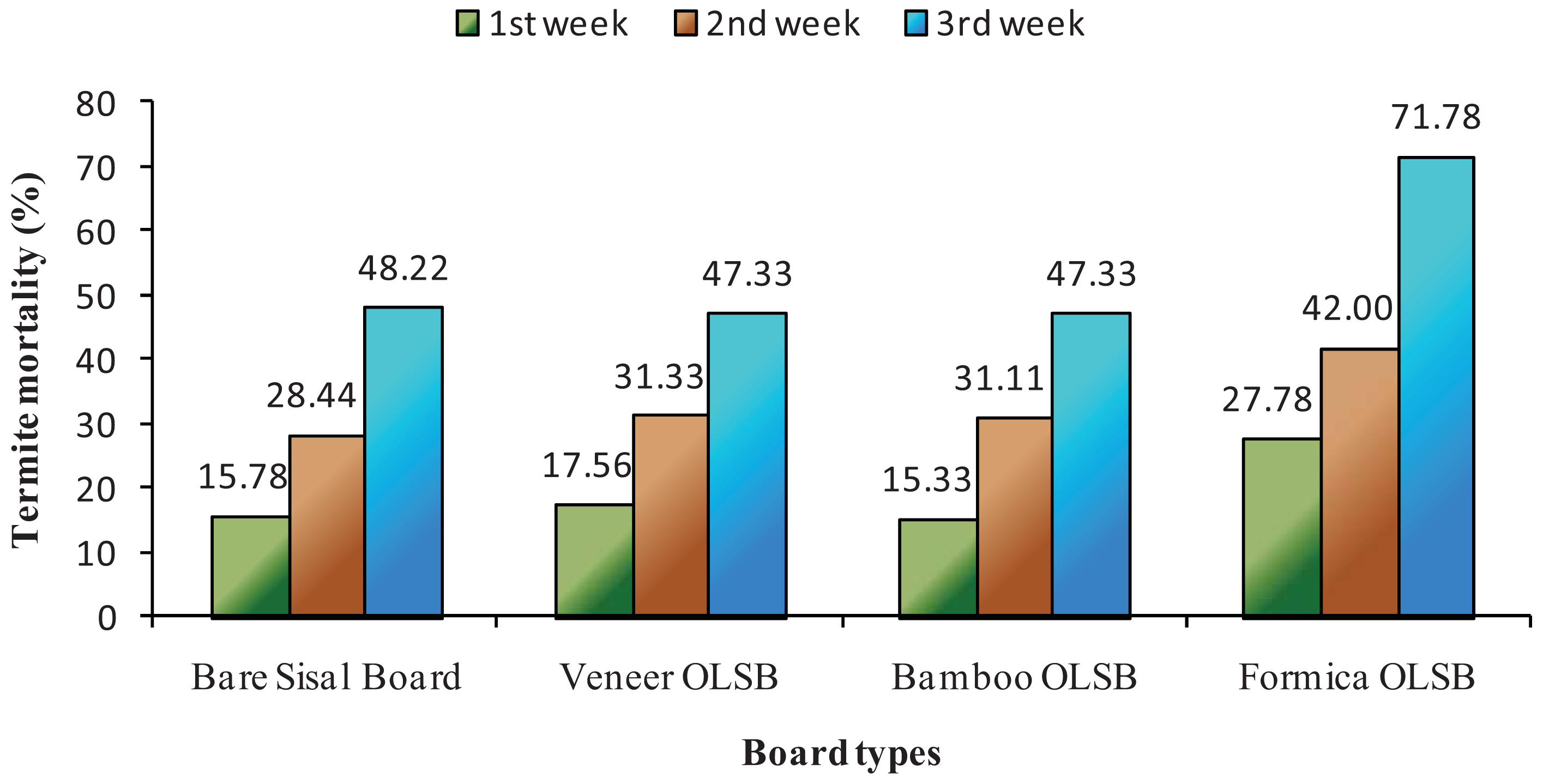

Figures 4 and 5 show the weekly termite mortality on bare and overlaid sisal fiberboards, respectively. Sisal fiberboard resin contents did not significantly affect termite mortality (Figure 4). However, the type of overlaying materials showed significant termite mortality, different at 95% confidence level. Formica-overlaid sisal fiberboards showed the highest mortality and proved significantly different from rubber-veneer-overlaid sisal fiberboards or bamboo matting overlaid sisal fiberboard (Figure 5).

Since formica consisted of several layers of kraft paper impregnated with resin protected with hard surface of melamine after curing by heat, its solidified hardness may have played a part in repelling termites. With limited food source which could not supply termite colonies with sufficient nutrition for survival, termites often feed on their non-productive colony members [13].

4. Conclusions

The sisal fiberboards bonded at higher isocyanate contents were less attacked by Coptotermes gestoi. Termites attacked the core parts of the board as a manifestation of cryptobiotic characteristics. The type of overlaying materials did not affect sisal fiberboard weight loss due to termite attack, although formica-overlaid sisal fiberboards which has a relatively hard surface, over-performed compared to rubber veneer or bamboo matting overlaid sisal fiberboards. These facts appear to suggest that utilization of hard surface materials and modified sisal fiber would improve sisal fiberboard durability against termite attack.

References

- Syamani, F.A.; Massijaya, M.Y.; Subiyanto, B. Physical and Mechanical Properties of Sisal (Agave sisalana Perr.) Composite Board. Presented at the 11th National Seminar of Indonesian Wood Researcher Association XI, Palangkaraya, Indonesia, 8 August 2008.

- Syamani, F.A.; Subyakto; Subiyanto, B.; Massijaya, M.Y. The Effects of Sisal Fiber Dimension after Processed in Ring Flaker on Sisal Composite Board Properties. Presented at the 12th National Seminar of Indonesian Wood Researcher Association, Bandung, Indonesia, 23 July 2009.

- Sornnuwat, Y.; Vongkaluang, C.; Yoshimura, T.; Tsunoda, K.; Takahashi, M. Wood Consumption and Survival of the Subterranean Termite, Coptotermes gestroi Wasmann using the Japanese Standardized Testing Method and the Modified Wood Block Test in Bottlel. Available online: http://repository.kulib.kyoto-u.ac.jp/dspace/bitstream/2433/53238/1/KJ00000017954.pdf (accessed on 20 September 2011).

- Tambunan, B.; Nandika, D. Wood Deterioritation by Biological Factors; IPB Press: Bogor, Indonesia, 1989. (in Indonesian) [Google Scholar]

- Tarumingkeng, R.C. Termite Biology and Behavior, Revised ed.; Center Study of Biological Sciences, Bogor University of Agriculture: Bogor, Indonesia, 2001. (in Indonesian) [Google Scholar]

- Gurbel, S.S.O. Laboratory Evaluations of Some Termiticides Againts Subterranean Termite Coptotermes gestroi (Wasmann) (Isoptera: Rhinotermitidae). M.S. Thesis, Universiti Sains Malaysia, Penang, Malaysia, 2008. [Google Scholar]

- JWPA Standard-TW-S.1-1992. Laboratory test method for evaluation the effectiveness of termiticides for pressure treatments and performance requirements of the treated materials; Japan Wood Preserving Association: Tokyo, Japan, 1992. [Google Scholar]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Mishra, M.; Hinrichsen, G. A review on pineapple leaf fibers, sisal fibers and their composites. Macromol. Mater. Eng. 2004, 289, 955–974. [Google Scholar]

- Krisdianto; Sumarni, G.; dan Ismanto, A.; Bamboo Research Overview. Compilation of Bamboo and Rattan Research Overview; Center of Forest Product Research, Research and Development Board of Forestry and Plantation: Bogor, Indonesia, 2000. (in Indonesian). Available online : http://www.dephut.go.id/files/SARI%20HASIL%20PENELITIAN%20BAMBU.pdf (accessed on 20 September 2011).

- Martawijaya, A. Rubber Wood Durability and Preservation; Research Report No. 1; LPHH: Bogor, Indonesia, 1972. (in Indonesian) [Google Scholar]

- Prasetiyo, K.W.; Yusuf, S. Protection Againt Termite and Termite Extermination; AgroMedia Pustaka: Jakarta, Indonesia, 2005. (in Indonesian) [Google Scholar]

- Syamani, F.A. Quality Improvement of Sisal Composite Board by Mechanical Treatment. M.S. Thesis, Bogor University of Agriculture, Bogor, Indonesia, 2009. (in Indonesian). [Google Scholar]

- Rismayadi, Y. Arinana. In New Way of Termite Extermination and Enviromental Friendly; PT. Gramedia: Jakarta, Indonesia, 2007. (in Indonesian) [Google Scholar]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Syamani, F.A.; Subiyanto, B.; Massijaya, M.Y. Termite Resistant Properties of Sisal Fiberboards. Insects 2011, 2, 462-468. https://doi.org/10.3390/insects2040462

Syamani FA, Subiyanto B, Massijaya MY. Termite Resistant Properties of Sisal Fiberboards. Insects. 2011; 2(4):462-468. https://doi.org/10.3390/insects2040462

Chicago/Turabian StyleSyamani, Firda Aulya, Bambang Subiyanto, and Muhamad Yusram Massijaya. 2011. "Termite Resistant Properties of Sisal Fiberboards" Insects 2, no. 4: 462-468. https://doi.org/10.3390/insects2040462

APA StyleSyamani, F. A., Subiyanto, B., & Massijaya, M. Y. (2011). Termite Resistant Properties of Sisal Fiberboards. Insects, 2(4), 462-468. https://doi.org/10.3390/insects2040462